You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NASA ACES suit disconnects

- Thread starter antarusfree

- Start date

-

- Tags

- aces disconnects nasa replica suit

Thank youPro-Job for sure

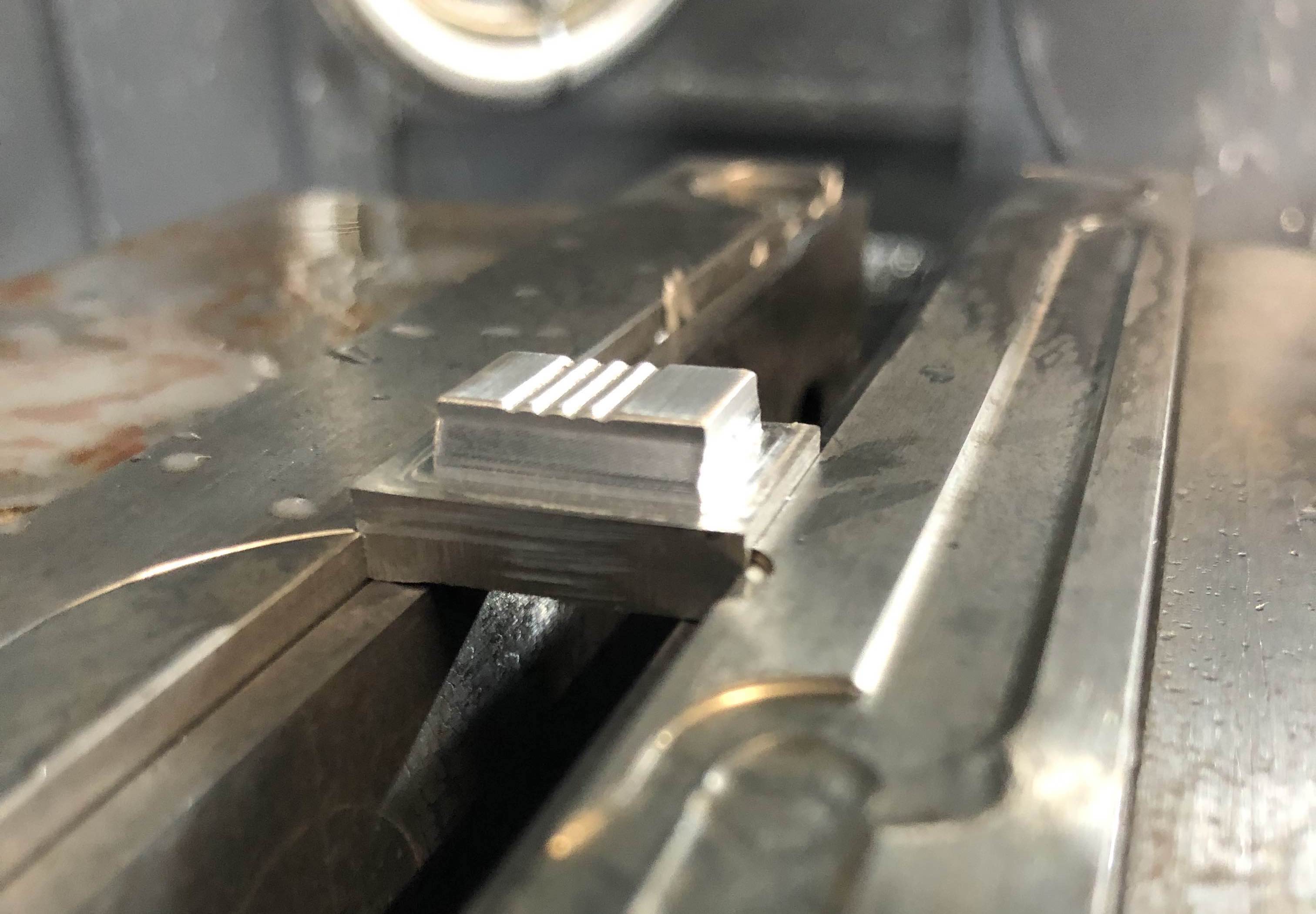

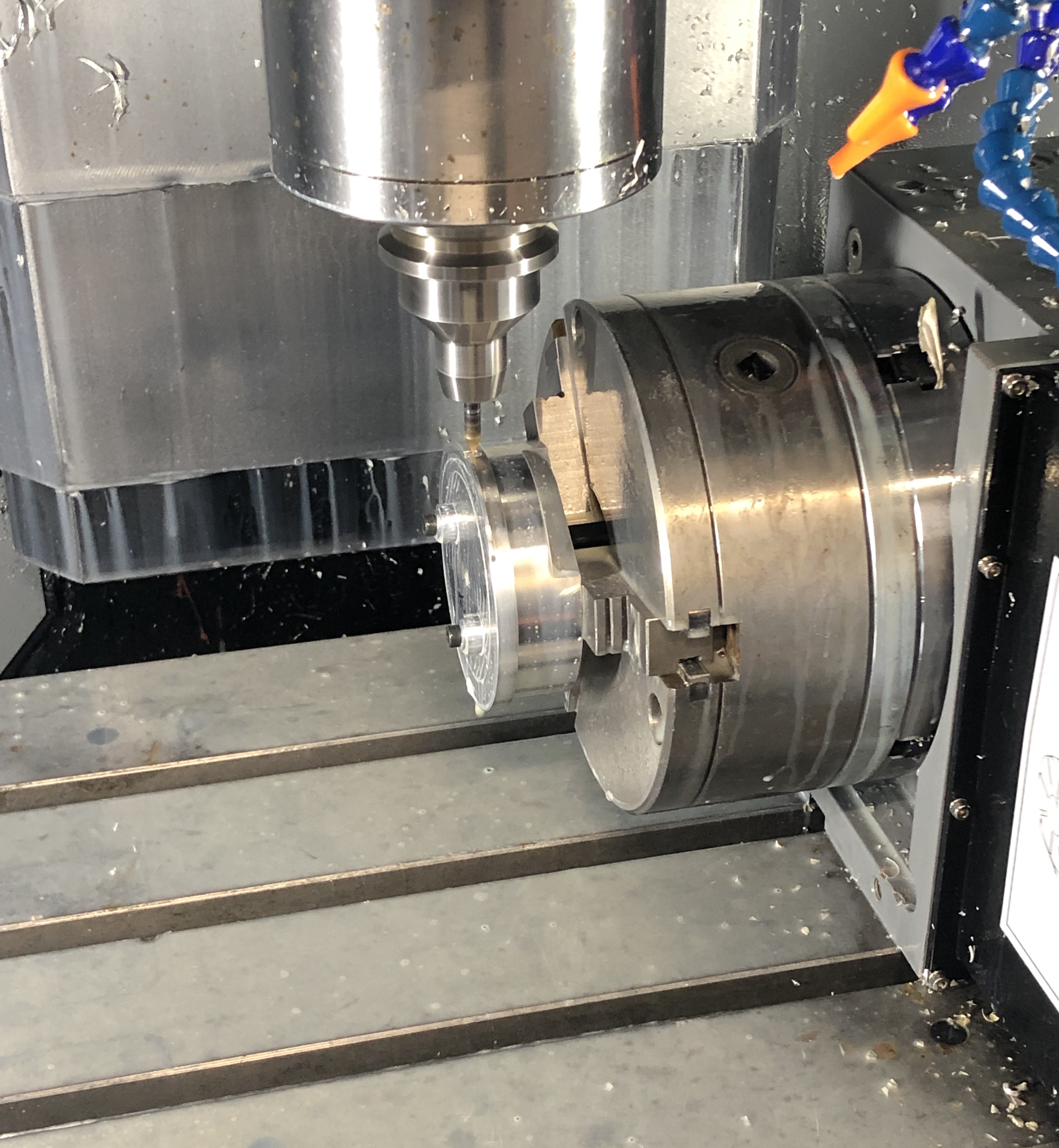

Started on the locking tabs, not finished yet just the first machining operation for now, tab at the top and holes next. To ensure that it fits in the dovetail on the locking ring. Getting the tolerances correct was a little tricky.

The machining itself isn't too difficult, but holding the part securely require a bit of work.

The machining itself isn't too difficult, but holding the part securely require a bit of work.

Thank youMarvelous work...sometimes machinists will use ice if the piece is too small to clamp/secure.

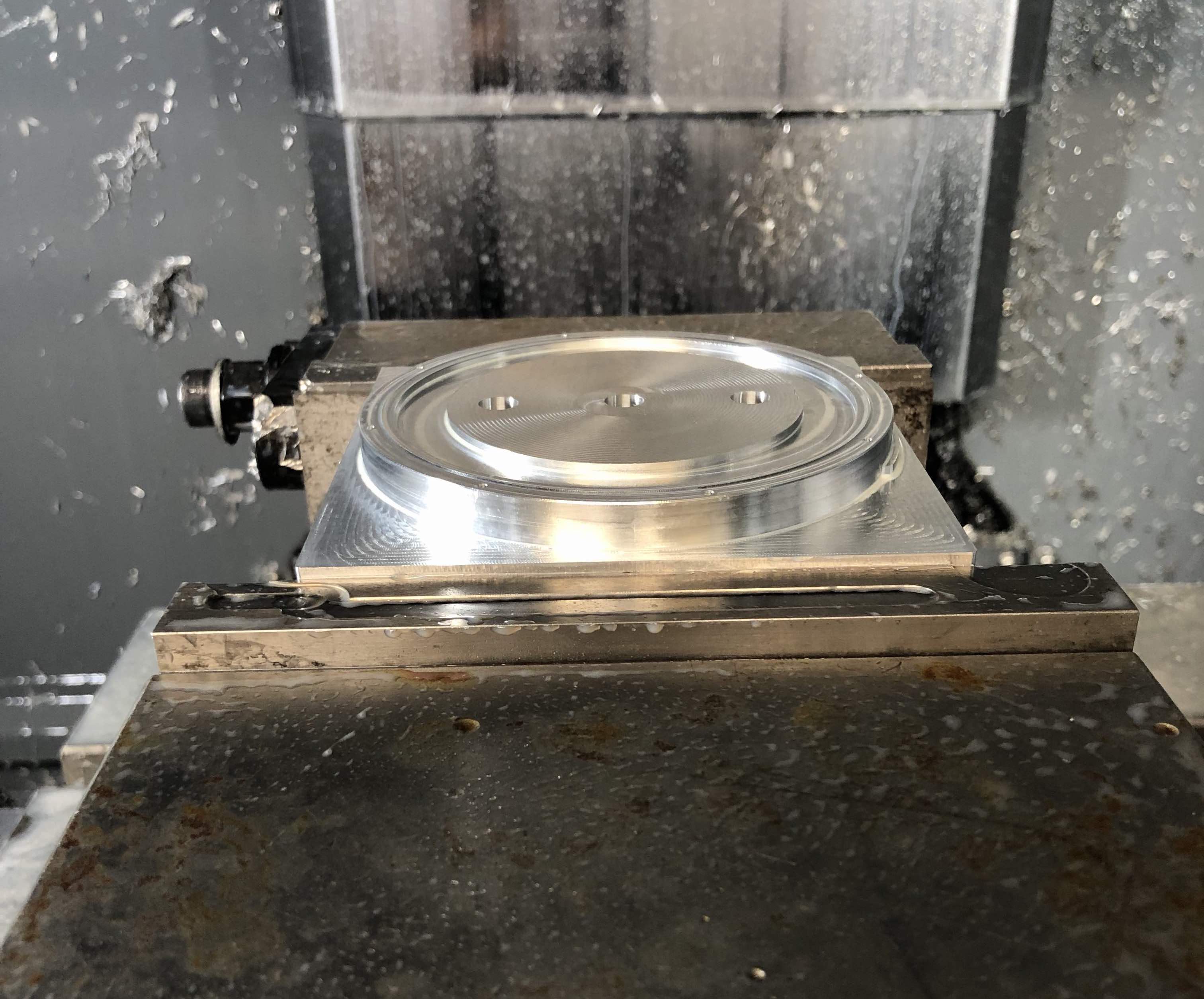

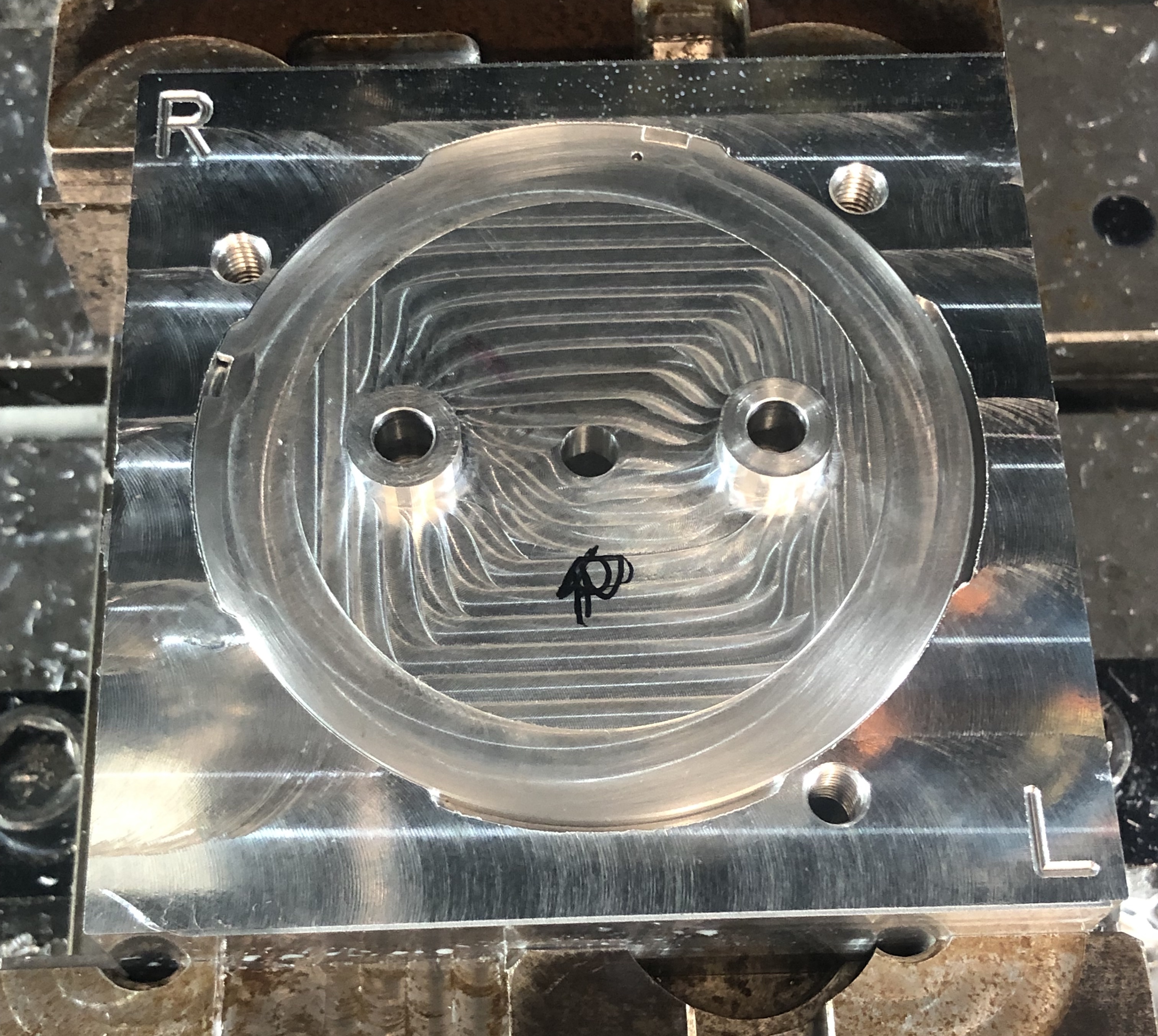

Started on the cuff rings the last major component, first 2 ops completed, 2 to go. Including the most complicated one with all the internal slots. Next these parts go back on the fixture, this time on a rotary axis to complete the radial feature - the 2 cutouts for the tabs and the yellow markings. I have made both left and righthand version, didn't take picture of both its exactly the same process just mirrored.

After OP10

After OP20

And the part off the fixture.

After OP10

After OP20

And the part off the fixture.

Thank youThree things about that project:

1: Sharp

2: Sharp

3: Sharp

antarusfree

Well-Known Member

Amazing work Alex, as always

After a little break on this project, due to being busy with real work. I have managed to make some more progress

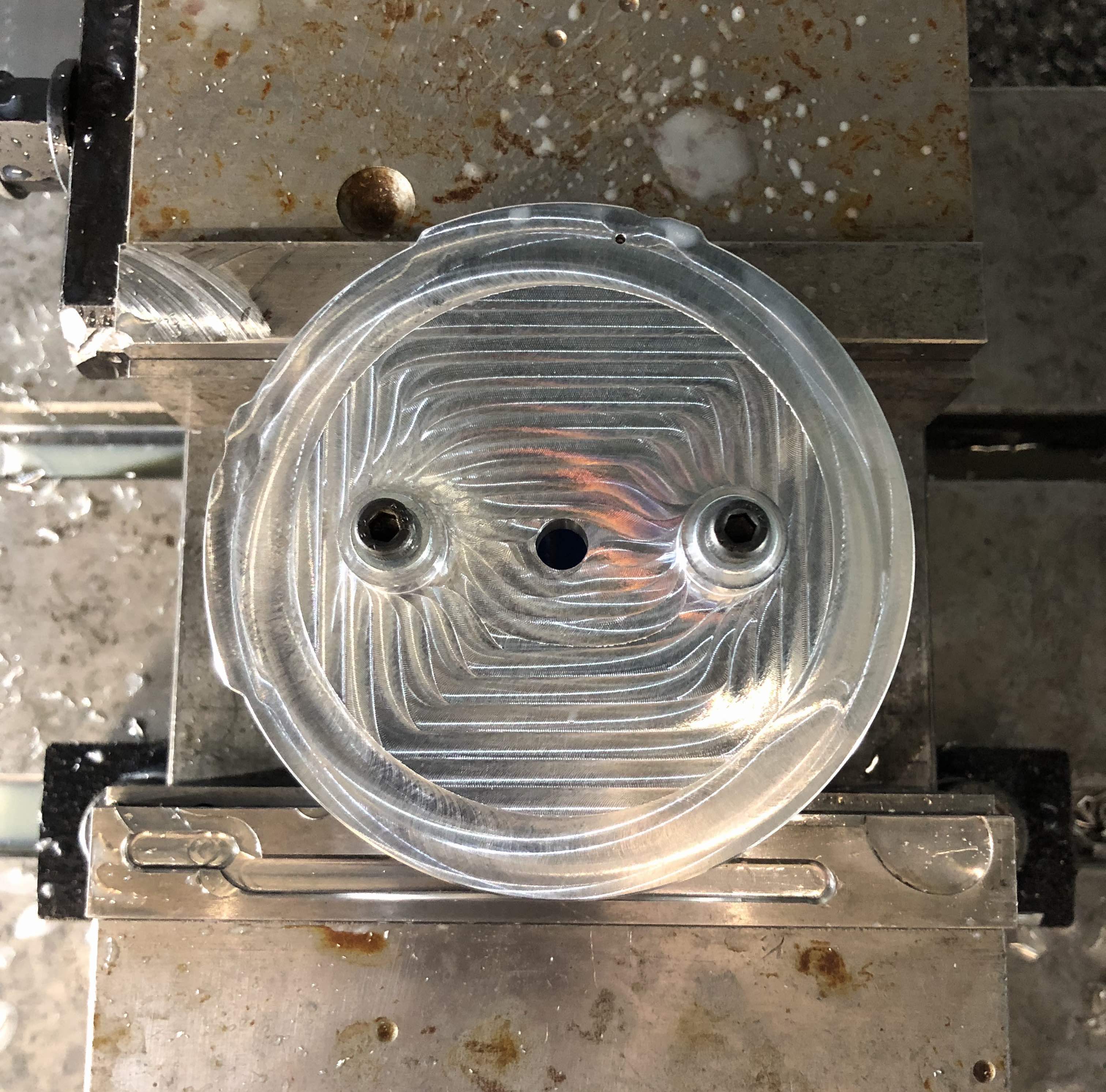

Finished the radial features on the cuff rings and the fixture to complete the internal features.

I should be working on the internal feature the last major machining op on the ring. Probably the most complicated some very complicated features in there. Then getting pretty close to finishing the machining on this. On to anodising etc.

What are others thought on the colour of these? To me there quite a bit of variation on the reference photos. Maybe difference between training and flight versions?

Finished the radial features on the cuff rings and the fixture to complete the internal features.

I should be working on the internal feature the last major machining op on the ring. Probably the most complicated some very complicated features in there. Then getting pretty close to finishing the machining on this. On to anodising etc.

What are others thought on the colour of these? To me there quite a bit of variation on the reference photos. Maybe difference between training and flight versions?

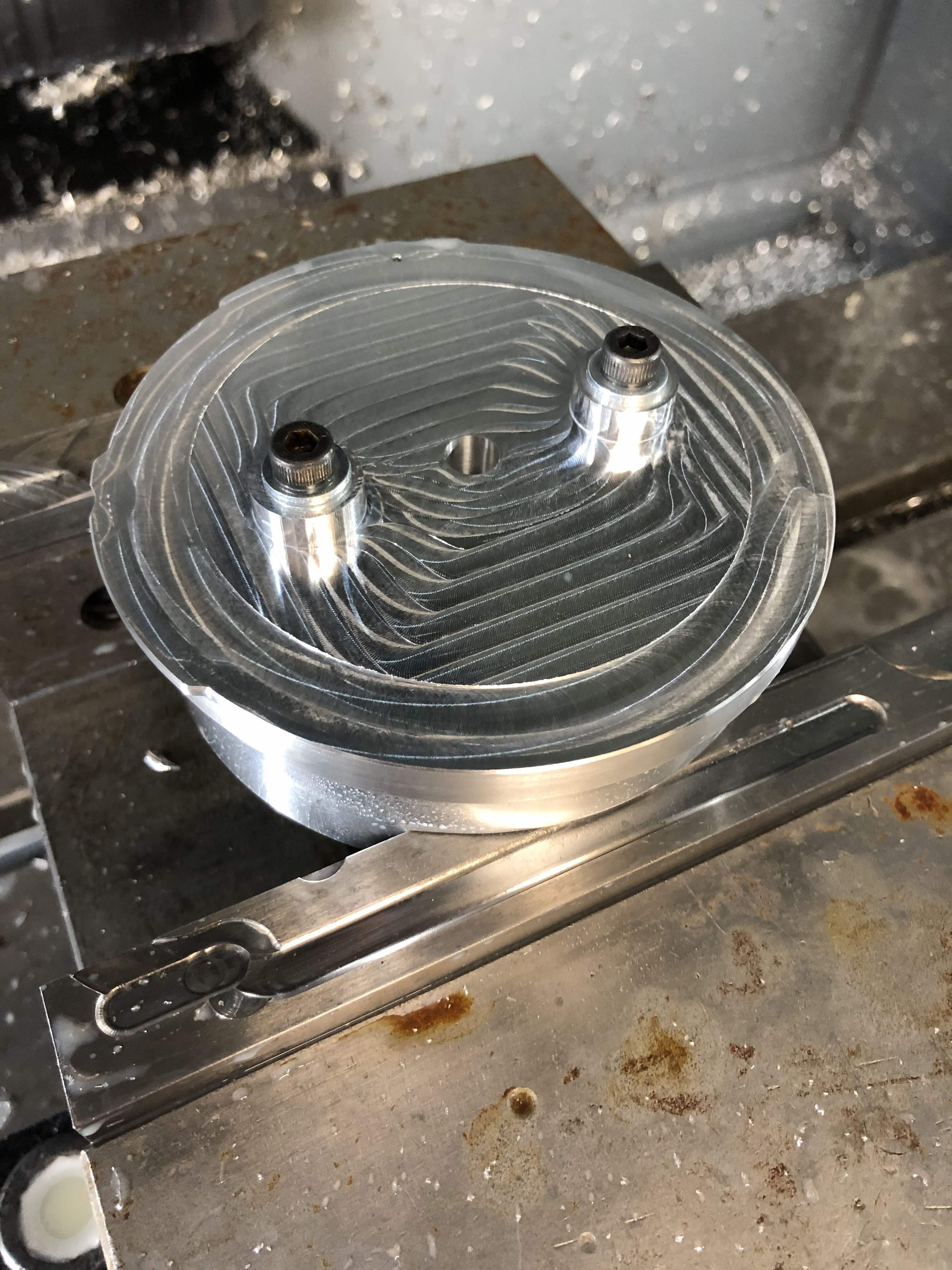

I have now finished machine the right hand cuff ring, the internal feature are now machined. the locking mechanism, minus the tabs now works. Getting pretty close to completing the first set. I was concerned that it would be really tricky to get the system to work correctly. I programmed the machine to CAD data, assuming I would have to make some offsets and adjustments, this is very normal. Somewhat to my surprise it worked first time without any adjusts being required. All credit for must go to antarusfree for his great work on the CAD data.

Here it is the in unlocked position, followed by the locked position. I try and get a video to show it working, it's nice and smooth and a snug fit when locked. I don't think the O ring will be required, however I plan to keep it as an option in case I just got lucky with this part a others may not fit as well.

Here it is the in unlocked position, followed by the locked position. I try and get a video to show it working, it's nice and smooth and a snug fit when locked. I don't think the O ring will be required, however I plan to keep it as an option in case I just got lucky with this part a others may not fit as well.

antarusfree

Well-Known Member

Thank you Alex for your kind words. Absolutely amazing work from your side.

It's always great to see my models turn to the real objects.

I'm glad that the models don't have any major issues.

Can't wait for you next progress

It's always great to see my models turn to the real objects.

I'm glad that the models don't have any major issues.

Can't wait for you next progress

Thanks, not too much more work to finish the first set.Thank you Alex for your kind words. Absolutely amazing work from your side.

It's always great to see my models turn to the real objects.

I'm glad that the models don't have any major issues.

Can't wait for you next progress

I made progress on several more locking tabs these now need the tab machining on one end and the hole for the pin in the back, as you can see the clearance machining these is very small.

antarusfree

Well-Known Member

Great job Alex

I am still working on this project, I've had a somewhat disputed summer with one thing and another, should be back to it soon.

Similar threads

- Replies

- 5

- Views

- 6,690

- Replies

- 25

- Views

- 4,779

- Replies

- 117

- Views

- 26,062

- Replies

- 1

- Views

- 1,240