You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ESB Bladed Stunt Graflex Lightsaber "The Core!"

- Thread starter thd9791

- Start date

Thanks!

Tonight I prepped the Graflex.

Okay, now that I accidentally italicized that sentence let me show you. I completely disassembled Romans Graflex socket (thank god those bunny ears are threaded) and put it back together with only the main socket screws and the plates/nut for the front slotted screw. I left out the bulb socket main spring and pin, so there’s room to drill and tap for a threaded blade.

The brass pins are long enough that they have to be put back in from the outside, after the socket is slid back into place.

So now I realize that I can’t copy the Vader saber. Why? Both red buttons are in place on the ESB saber, and the famous empty socket on the Vader saber where you can see the insert... it would get in the way, in this configuration it never had a button there, maybe that’s why the tire valve is stuck in.

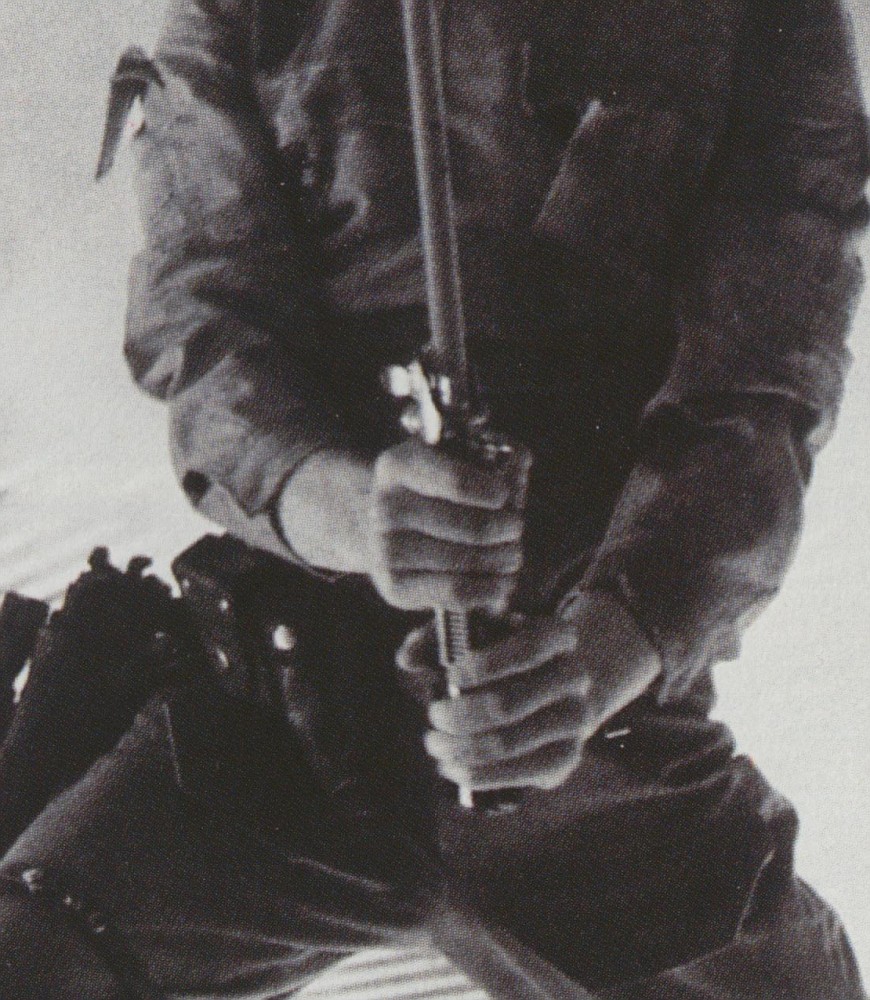

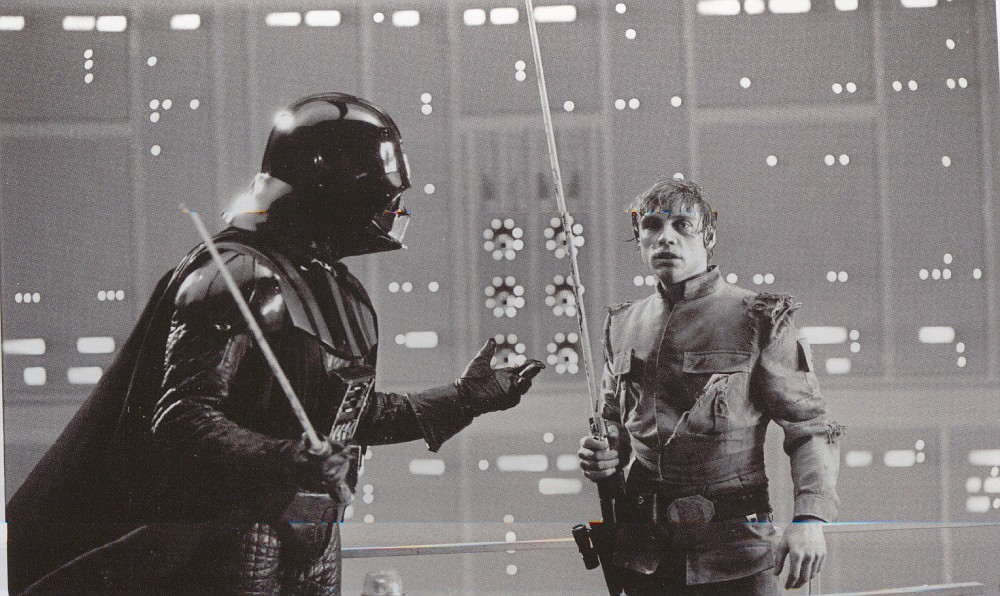

So it’s time to slide my core into place and mark where the screws are going to go. I first placed the one we see on Dagobah peeking out under Marks fingers under the beer tab. Then, diagonally, the ones on each side.

That bolt, if it is one in the second photo, is very high up. I decided to alter mine a bit based on all the photos there are.

Also, I decided to hide number 4 under the clamp

Tonight I prepped the Graflex.

Okay, now that I accidentally italicized that sentence let me show you. I completely disassembled Romans Graflex socket (thank god those bunny ears are threaded) and put it back together with only the main socket screws and the plates/nut for the front slotted screw. I left out the bulb socket main spring and pin, so there’s room to drill and tap for a threaded blade.

The brass pins are long enough that they have to be put back in from the outside, after the socket is slid back into place.

So now I realize that I can’t copy the Vader saber. Why? Both red buttons are in place on the ESB saber, and the famous empty socket on the Vader saber where you can see the insert... it would get in the way, in this configuration it never had a button there, maybe that’s why the tire valve is stuck in.

So it’s time to slide my core into place and mark where the screws are going to go. I first placed the one we see on Dagobah peeking out under Marks fingers under the beer tab. Then, diagonally, the ones on each side.

That bolt, if it is one in the second photo, is very high up. I decided to alter mine a bit based on all the photos there are.

Also, I decided to hide number 4 under the clamp

Thanks!

Tonight I prepped the Graflex.

Okay, now that I accidentally italicized that sentence let me show you. I completely disassembled Romans Graflex socket (thank god those bunny ears are threaded) and put it back together with only the main socket screws and the plates/nut for the front slotted screw. I left out the bulb socket main spring and pin, so there’s room to drill and tap for a threaded blade.

View attachment 977260

The brass pins are long enough that they have to be put back in from the outside, after the socket is slid back into place.

View attachment 977261

So now I realize that I can’t copy the Vader saber. Why? Both red buttons are in place on the ESB saber, and the famous empty socket on the Vader saber where you can see the insert... it would get in the way, in this configuration it never had a button there, maybe that’s why the tire valve is stuck in.

So it’s time to slide my core into place and mark where the screws are going to go. I first placed the one we see on Dagobah peeking out under Marks fingers under the beer tab. Then, diagonally, the ones on each side.

View attachment 977263 View attachment 977264 View attachment 977262

That bolt, if it is one in the second photo, is very high up. I decided to alter mine a bit based on all the photos there are.

Also, I decided to hide number 4 under the clamp

View attachment 977266 View attachment 977265

Freak’n perfect, thanks for posting this! Now I get your PM!!

I was also going to say how did you located the screws. I knew of the 1 black and white pic on dagobah, but didn’t know of the rest!!

Good freak’n eyes man!!

Yes - I'm trying to find a ski pole and when I do, I plan on doing a Vadermania and drilling and tapping an insert to plug the bottom?

Yup! So the ski pole would have a 3/8-16 bolt/rod coming out the bottom. Which will slide into the graflex bulb release section, the screw into the aluminum round stock, great idea!!

Even though Ski poles taper at the end - these replacement poles are not tapered.

"

Maša Leskošek <sales@tehnomat.si>

Mon, Jan 14, 3:03 AM (1 day ago)

to me, sales

Dear Mr. Delmonte,

thank you for your email.

Unfortunately we don't offer tapered alu tubes.

If you'd be interested in cylindricALU tubes (fi 14, 16 and 18 mm) the price is 13,50€/kg (without VAT).

The weight of cylindrical ALU tubes is:

- 14 mm x 0,8 mm - tube 3m long: 283g

- 16 mm x 0,7 mm - tube 3m long: 289g

- 18 mm x 0,7 mm - tube 3m long: 327g

In case of any additional questions please feel free to contact us.

Kind regards,

Maša

Maša Leskošek

Tehnomat, Kranj, d.o.o.

Jezerska cesta 55, SLO-4000 Kranj, Slovenia

---------------------------------------------------

E-mail: sales@tehnomat.si

Phone: +386 4 2351810

Fax: +386 4 2351811

---------------------------------------------------

http://www.tehnomat.si

http://www.ski-poles-accessories.com

On 12.01.2019 07:00, t.delmonte9@gmail.com wrote:

Na strani www.ski-poles-accessories.com je bil ustvarjen kontakt.

Ime in priimek: Tom Delmonte

Podjetje:

Naslov:

Pošta: Buffalo, NY USA

Telefon:

E-pošta: t.delmonte9@gmail.com

Komentar: Hi, I wanted to ask what the current prices are for 18mm Aluminum ski pole shafts? Pice for each, and if it changes for a bulk order? An image of a full tapered rod would be helpful too. Thank you! Tom Delmonte

"

Maša Leskošek <sales@tehnomat.si>

Mon, Jan 14, 3:03 AM (1 day ago)

to me, sales

Dear Mr. Delmonte,

thank you for your email.

Unfortunately we don't offer tapered alu tubes.

If you'd be interested in cylindricALU tubes (fi 14, 16 and 18 mm) the price is 13,50€/kg (without VAT).

The weight of cylindrical ALU tubes is:

- 14 mm x 0,8 mm - tube 3m long: 283g

- 16 mm x 0,7 mm - tube 3m long: 289g

- 18 mm x 0,7 mm - tube 3m long: 327g

In case of any additional questions please feel free to contact us.

Kind regards,

Maša

Maša Leskošek

Tehnomat, Kranj, d.o.o.

Jezerska cesta 55, SLO-4000 Kranj, Slovenia

---------------------------------------------------

E-mail: sales@tehnomat.si

Phone: +386 4 2351810

Fax: +386 4 2351811

---------------------------------------------------

http://www.tehnomat.si

http://www.ski-poles-accessories.com

On 12.01.2019 07:00, t.delmonte9@gmail.com wrote:

Na strani www.ski-poles-accessories.com je bil ustvarjen kontakt.

Ime in priimek: Tom Delmonte

Podjetje:

Naslov:

Pošta: Buffalo, NY USA

Telefon:

E-pošta: t.delmonte9@gmail.com

Komentar: Hi, I wanted to ask what the current prices are for 18mm Aluminum ski pole shafts? Pice for each, and if it changes for a bulk order? An image of a full tapered rod would be helpful too. Thank you! Tom Delmonte

The search continues

Oh, I haven't given up on ski poles. This means I get to cut up a used one

Ok, we all know Tom as a huge “stunt” guy. He’s helped me out a lot with all my stunt builds

Actually most of my stunt builds are just copied from Tom lol he never has a problem helping the community reach their goals.

Tom asked if I could drill and tap some holes in his ESB bladed stunt. So I told him to send it my way and I’ll bang it out

Before I go destroying someone else’s lightsaber I wanted to double check with Tom on everything he wanted me to do

I ran by him every step I was going to do. The I asked to hear what his plan was, and then we would compare each other’s steps and come up with a plan. Then he told me “I was going to do exactly what you said” the anxiety was lifted and work began!!

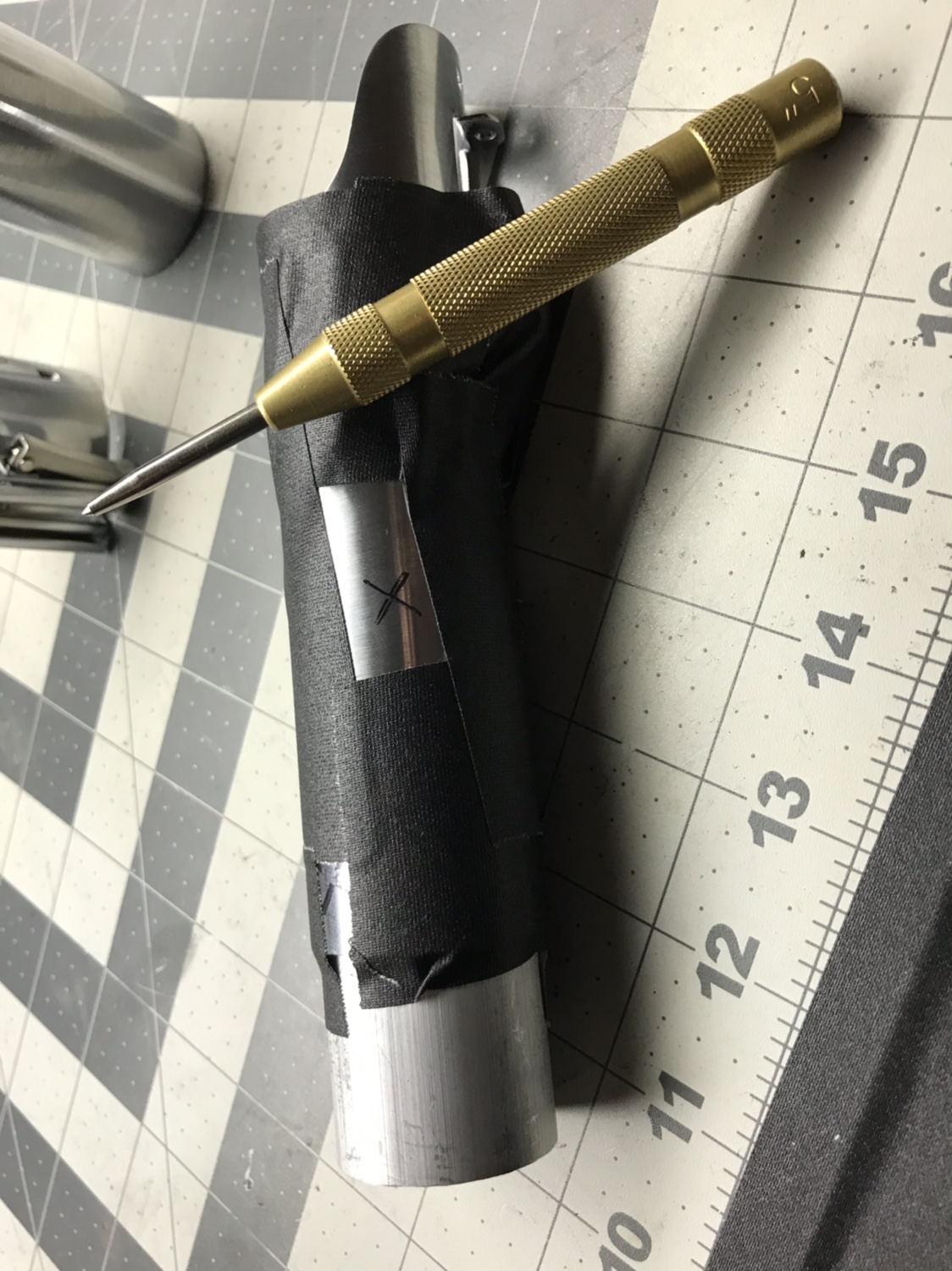

So first I gathered all his pieces. Tom actually marked every hole he wanted already with a X. And labeled with tape instructions on what size threads

He made this really easy, all I had to do was literally drill and tap holes

He also found some beautiful vintage screws!!

Next I wrapped the entire graflex in gaffers tape. This stuff works great for protecting things.

It also works great for covering up boosters SethS

SethS

I center punched where the X lands and off to the shed...

So before I begin drilling I want these straight, so I swapped out my end mill chuck for my drill chuck, and centering gauge

I drilled my pilot hole with a 1/8” drill bit. I drilled in 18mm deep

Next step was to drill the pilot whole with the actual 1/4-20 drill for the tap

After I tapped it i doubled checked to make sure the thread works, sure enough we are good!!

Now that the thread is tapped, I used my counter sink, this took me forever because I would plunge a little, write down my depth. Then test the screw, then repeat. Probably the scariest part of the job...and the first one was the most time consuming

I did this for all 4 holes he wanted, drill pilot, drill with the drill bit for the tap, then tap the hole.

One key thing to doing this was locking the “core” into orientation. I would complete each screw one at a time. So this way I don’t have to re center the saber. And the first screw locks everything into place so I don’t have to worry about orientation changing

Once I had all the holes, drilled, tapped. And counter sunk. I removed the core to clean all the threads

Because I was using cutting oil, the bottom of the screw holes would fill with chunks. And the vacuum wouldn’t pull them out. So I would blast the hole with wd-40 while using the vacuum. And they came out squeaky clean!

Next step Tom asked to drill a hole right down the bulb socket hole. Might I add I didn’t have to remove any of this stuff, Tom sent it ready to roll! And saved me a lot of time

So the saber is centered up, and I drilled down into the flash, hitting the aluminum core. I wanted to just make a mark because the drill bit ran out of stroke, now with the core marked I can remove the core and drill it with out the flash on it

The glass eye actually chucked plastic out of it when I was drilling, like the graflex was throwing up or something lol

The tap handle I brought home from the big shop was the wrong size.. I tapped this with a adjustable wrench. It worked out great

I ended up counter sinking the top.. only because I thought this would help “align” the bolt when he put it down the flash

Here’s a view from the other end

The holes I drilled in the side of the flash for the bolts, there was some burs so it really bit into the core and was really tough to get out. So I sanded the inside of the flash and removed the burs, the core slides in perfectly now

Here we are all back together

This was a fun little project. Can’t wait to see what ya do with it Tom! She’s leaving back to you in the morning! Keep us all updated!!

Actually most of my stunt builds are just copied from Tom lol he never has a problem helping the community reach their goals.

Tom asked if I could drill and tap some holes in his ESB bladed stunt. So I told him to send it my way and I’ll bang it out

Before I go destroying someone else’s lightsaber I wanted to double check with Tom on everything he wanted me to do

I ran by him every step I was going to do. The I asked to hear what his plan was, and then we would compare each other’s steps and come up with a plan. Then he told me “I was going to do exactly what you said” the anxiety was lifted and work began!!

So first I gathered all his pieces. Tom actually marked every hole he wanted already with a X. And labeled with tape instructions on what size threads

He made this really easy, all I had to do was literally drill and tap holes

He also found some beautiful vintage screws!!

Next I wrapped the entire graflex in gaffers tape. This stuff works great for protecting things.

It also works great for covering up boosters

I center punched where the X lands and off to the shed...

So before I begin drilling I want these straight, so I swapped out my end mill chuck for my drill chuck, and centering gauge

I drilled my pilot hole with a 1/8” drill bit. I drilled in 18mm deep

Next step was to drill the pilot whole with the actual 1/4-20 drill for the tap

After I tapped it i doubled checked to make sure the thread works, sure enough we are good!!

Now that the thread is tapped, I used my counter sink, this took me forever because I would plunge a little, write down my depth. Then test the screw, then repeat. Probably the scariest part of the job...and the first one was the most time consuming

I did this for all 4 holes he wanted, drill pilot, drill with the drill bit for the tap, then tap the hole.

One key thing to doing this was locking the “core” into orientation. I would complete each screw one at a time. So this way I don’t have to re center the saber. And the first screw locks everything into place so I don’t have to worry about orientation changing

Once I had all the holes, drilled, tapped. And counter sunk. I removed the core to clean all the threads

Because I was using cutting oil, the bottom of the screw holes would fill with chunks. And the vacuum wouldn’t pull them out. So I would blast the hole with wd-40 while using the vacuum. And they came out squeaky clean!

Next step Tom asked to drill a hole right down the bulb socket hole. Might I add I didn’t have to remove any of this stuff, Tom sent it ready to roll! And saved me a lot of time

So the saber is centered up, and I drilled down into the flash, hitting the aluminum core. I wanted to just make a mark because the drill bit ran out of stroke, now with the core marked I can remove the core and drill it with out the flash on it

The glass eye actually chucked plastic out of it when I was drilling, like the graflex was throwing up or something lol

The tap handle I brought home from the big shop was the wrong size.. I tapped this with a adjustable wrench. It worked out great

I ended up counter sinking the top.. only because I thought this would help “align” the bolt when he put it down the flash

Here’s a view from the other end

The holes I drilled in the side of the flash for the bolts, there was some burs so it really bit into the core and was really tough to get out. So I sanded the inside of the flash and removed the burs, the core slides in perfectly now

Here we are all back together

This was a fun little project. Can’t wait to see what ya do with it Tom! She’s leaving back to you in the morning! Keep us all updated!!

***** Danny, this is amazing to read though. The documentation alone rivals mugutu and his grenade repair thread!

I have to say, you saved my ass here. I have a hard time tapping straight, and my equipment isn't large enough to do this safely. Thank you so much! It was a good call chatting beforehand, but I wasn't worried when the guy who has my saber is rigging up V2's one after another

I bet this feels pretty solid, at least it will be a weapon if anyone robs me.

next step is decorating the 3 cell bottom (kobold replica clip, T track and screws)

and then developing a blade and adapter, with a threaded tang that you so kindly made!

"I don't care at this juncture. Tony? Will you do me a kindness? Don't slam the GODDAMN DOOR"

Will update soon

I have to say, you saved my ass here. I have a hard time tapping straight, and my equipment isn't large enough to do this safely. Thank you so much! It was a good call chatting beforehand, but I wasn't worried when the guy who has my saber is rigging up V2's one after another

I bet this feels pretty solid, at least it will be a weapon if anyone robs me.

next step is decorating the 3 cell bottom (kobold replica clip, T track and screws)

and then developing a blade and adapter, with a threaded tang that you so kindly made!

"I don't care at this juncture. Tony? Will you do me a kindness? Don't slam the GODDAMN DOOR"

Will update soon

No worries Tom. You help me out all the time. Glad I can return the favor

This thing is solid!! And heavy!! You now know what this means...

I need one for myself!! Lol

What do you plan on using for a blade? The ski pole?

It may take me a little while to do something but that’s because before I do it i run through my head ever possibly error.. this way I cover all my bases

It’s a trick my dad taught me on the job site

Before you drill or cut, think of every possible error.. make sure your not going to do it. And when all is clear, do it

Again, this sucker is heavy!!!

This thing is solid!! And heavy!! You now know what this means...

I need one for myself!! Lol

What do you plan on using for a blade? The ski pole?

It may take me a little while to do something but that’s because before I do it i run through my head ever possibly error.. this way I cover all my bases

It’s a trick my dad taught me on the job site

Before you drill or cut, think of every possible error.. make sure your not going to do it. And when all is clear, do it

Again, this sucker is heavy!!!

Are you thinking of drilling holes into the metal cylinder to make it lighter?

It’s already heading back to Tom

I personally like the weight, Anderson has even been on record stating how he design the hilts, and put weight in them to counter balance the blade

I think Tom is going to be very happy with it, and achieve his mission

That's not something that I've thought of...

We know from people like vadermania that the DV6 is a very heavy lightsaber, and the core/blade that was handled in that behind the scenes video with Roger Christian also looked to only have holes drilled for the bolts. The blade didn't even go all the way through, the bottom of the core was solid. For this reason, I think I may leave it alone.

We know from people like vadermania that the DV6 is a very heavy lightsaber, and the core/blade that was handled in that behind the scenes video with Roger Christian also looked to only have holes drilled for the bolts. The blade didn't even go all the way through, the bottom of the core was solid. For this reason, I think I may leave it alone.

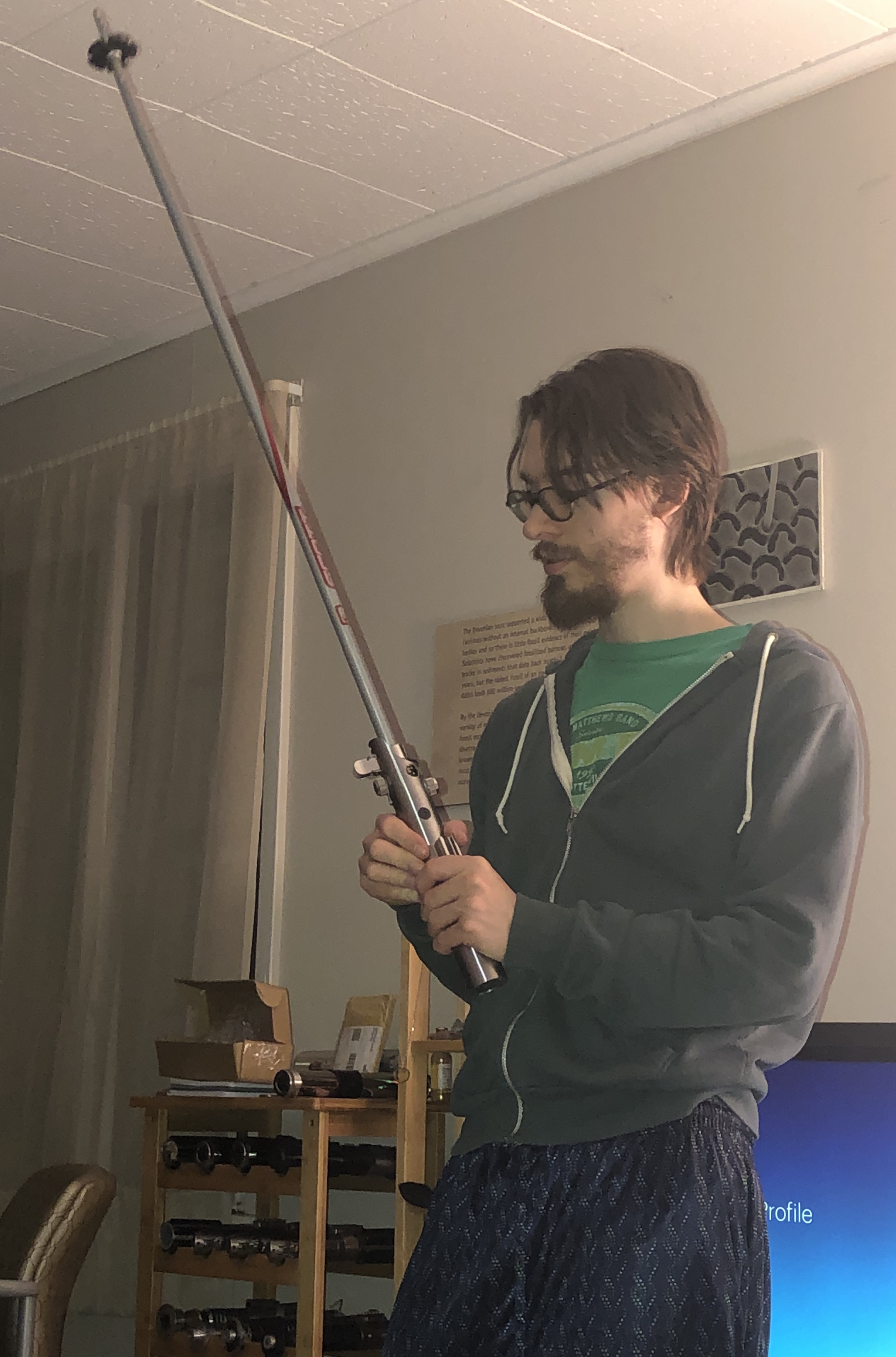

So, unfortunately like most projects, we were prone to human error. Somehow the countersink ended up deep below the surface, instead of starting at the Graflex wall. Thankfully the holes were a tad too small and that meant the bolts still pinched the Graflex to the core. I went ahead and countersunk the rim of the hole to give the bolts some more surface area to grip AND to get them flush with the surface, then I filled the “tunnel” straight bore section with apoxie sculpt, so I think we’re in good shape. I also burrowed the threaded rod deeper into the core. Here is a dry loose fit with the wrong size ski

pole

pole

Last edited:

This Ski pole is only 16mm wide at the base. From what I've seen in BTS shots, the blades almost fill the bunny ear ring, with some space to spare

I've been comparing the thickness of the blades to the square hole for the reflector dish, and to the profile of the Graflex top, or the buttons. the blades look like they're the same size or larger than the red buttons. These 16mm rods are about the diameter of the beveled area of the button. This is weird. I will say, the shape looks and feels right.

I've been comparing the thickness of the blades to the square hole for the reflector dish, and to the profile of the Graflex top, or the buttons. the blades look like they're the same size or larger than the red buttons. These 16mm rods are about the diameter of the beveled area of the button. This is weird. I will say, the shape looks and feels right.

Similar threads

- Replies

- 4

- Views

- 860

- Replies

- 4

- Views

- 1,203

- Replies

- 20

- Views

- 2,744

- Replies

- 3

- Views

- 1,851

- Replies

- 2

- Views

- 1,556