You had me trying to get a hair off of my screen for longer than I’d like to admit.

-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interest DaveP’s Luke RotJ V2 / Obi Wan ANH Motorised Stunt Prop-Replica Run (Sign Up Closed)

- Thread starter DaveP

- Start date

**UPDATE**

Hi everyone. First off, the usual apology for radio silence... These updates always take me way longer than you might expect, so I’ve been trying to get through a good chunk of the work I have left to do before doing this one. I feel like it’s been a while though, and I do have quite a lot of news this week that needs to be discussed (as well as a few revelations)….

The amount of work involved in this run has been really quite astronomical, but I am making good progress and getting through it all as fast as I can, whilst ensuring that I maintain the high standards that you’ve come to expect.

Thank you so much to everyone for providing me with your numbers last week! It’s much appreciated and will save me messaging everyone individually when it comes time to ship your orders.

All orders that were not waiting on the arrival of additional parts, and that did not require damage commissions have been sent out, and have started to arrive with people.

All non-damaged kits that are still waiting on the arrival of additional parts have been prepped and assembled and are packaged ready to leave as soon as possible. Even these DIY kits have required a fair bit of work, and there have been a lot to get through. I’m really very happy with all of the parts, but they do always have some evidence of the machining process, and I make a point of removing any tool marks or scratches myself before sending out.

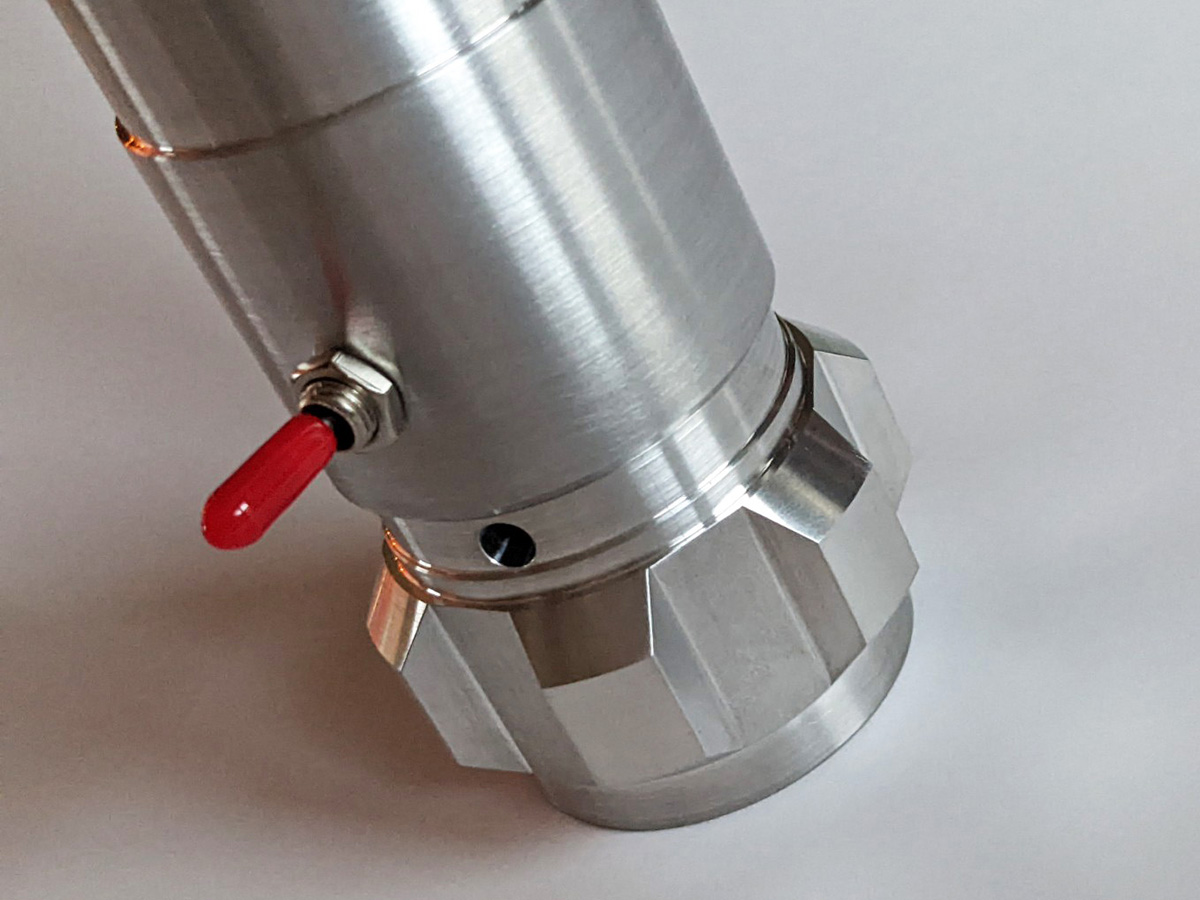

Where an order has included a motor kit, an additional grub screw has been added below the clamp.

This is to grip on to the motor and to prevent it from spinning free of it’s connections. I can’t say for certain, but I strongly suspect that this is present on the original prop.

It has come to my attention that, while the switches and the cone knobs are both 6mm, they actually have a different pitch on their threads (this is because the nuts on the switches are shallow, so require a shallow pitch on the threading). For this reason, I have de-threaded the hole on all motorised kits (All kits that come with a switch).

Interestingly, I don’t actually think that this makes the hilt inaccurate. Hear me out… The switch came first (not the cone knob), and there would have been no reason to thread that hole. I wonder… Does this suggest that the hole for the cone knob is in fact un-threaded? This would raise the question of whether or not the cone knob is held on using it’s original grub screw, or perhaps, it is screwed on to a short M6 bolt, pushed through the hole from the inside? A possibility.

This is only a theory, so I have only removed the threading from the motorised stunt kits. The ROTJ kits and the base kits purchased without motors have all been left with the threading intact. Simply for ease of attaching the cone knob. I do suspect that this hole should be unthreaded to be completely accurate though (An assumption on my part).

Pommel/Emitter damage commissions for DIY kits are VERY nearly finished. This has been a HUGE job as I hope you’ll understand and they have taken a few days to get through, but they are all very nearly done. It’s not so much the work that has dragged things out, but the shear quantity.

For the pommel damage, I used my vinyl damage guide (these are being sent out with stencil kits).

The emitters are relatively straight forward, but again, the numbers have meant that just getting them detached has taken a good few hours stood at the vice hack sawing! Once they’re removed, I then clean them up and ensure that the cut line is straight, before adding the dents to the emitter face.

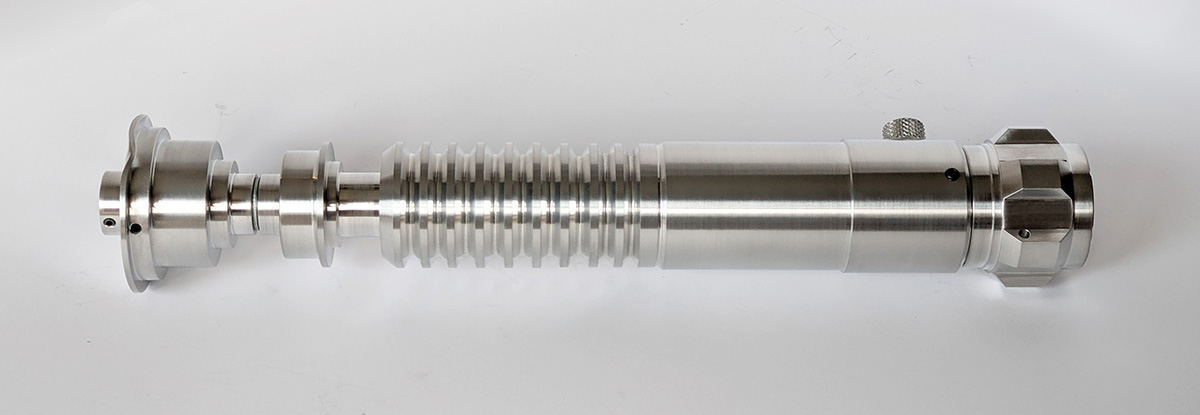

Here is a complete ROTJ kit (with additional Cone Knob) including pommel and emitter commission:

There have been a couple of revelations with the ROTJ kit too, which I’ll explain... Please note the washer at the neck. It’s my strong belief that the neck of the original prop was broken (rather than being cut) This is not something that I’m able to replicate due to the nature of the materials, so roughly 1mm is missing from the length of the neck section. Lost to the cutting process. I’ve replaced this with the washer, which will be hidden below the neck tape (supplied with the stencil kit).

I have also noticed something important that could well be another discovery relating to the original prop and it’s design. As you know, the point at which the emitter joins to the body is a straight cut/break. Whilst there is not enough room for a bushing, unless it was a VERY thin one, there IS a small gap between the rod and the inner wall of the hilt. This would have been necessary for the mechanism to work. Interestingly, this has meant that the emitter, once detached, not only spins, but it has a slight wobble too… Nothing too drastic, but of course, it does make sense. There is a definite clacking sound as Hamill inspects the original prop in PCQ, and it’s not necessarily just the D-Ring. It sounds a lot like the sound that comes from mine when fully assembled:

This got me considering the tape. Why would it have been necessary to prevent the emitter from spinning? Maybe preferable that it didn’t I guess, but it’s not *that* important in the grand scheme of things. Could the tape have been applied to keep it from wobbling/rattling too? Just a thought.

They shouldn’t be necessary once the tape has been applied, and they’re certainly not there on the actual prop, but I have ordered some extra thin nylon shoulder washers to replace the metal one that I’m using at the moment. This should solve both the above mentioned issues in one go (if they are issues?).

Blades:

Now for some bad news I'm afraid… To say that this has been weighing heavily on me would be an understatement! I have finally heard back from my carpenter this week, and it is bad news. He just can’t seem to get these blades made to a satisfactory standard. Not for lack of trying, or lack of ability. He’s widely regarded as one of the UK’s best wood turners! The problem, is that they’re just so thin that they warp whilst being worked on, and the result is that the finished product does not end up straight in relation to the bore:

This is obviously a problem! After several failed attempts, he’s decided that he’d rather not make them. This is fair enough I guess as he doesn’t want to put his name to something that isn’t perfect, but it puts me in a VERY difficult position. Some of you have paid for blades as part of your motorised stunt kits. I was expecting to have these in hand by now, and I appear to be back to square one!

Well, all is not lost! After frantically looking around for possible solutions, I believe I can still provide you all with blades within the same sort of budget (and in a relatively short amount of time). The only snag is that they won’t be tapered. I have sourced some Carbon Fibre rods that are the correct diameter and available immediately from within the UK.

I just need to check with everyone that this is acceptable before placing the order, as it’s a lot of money still, and if some people would prefer a refund on their blades instead, I need to establish the right quantity.

Something to consider is that some references do appear to show blades that have no taper, so it does appear that at least some of them were straight:

18mm is very thin to start with, so the addition of a tapper wouldn’t make too much of a difference really, and I believe that these alternatives will still look the part.

After speaking with my wood turning friend, I actually have my doubts that wood was ever used in the first place. He believes that the grain in the wood would have prevented them from drilling a perfectly centred hole.

Tapered carbon rods can be found, BUT, it would be impossible for me to get the internal bore in line with the centre without having a tapered internal plug made (Too expensive). These tapered rods are also TOO tapered, tapering to a near point. The straight ones are actually closer to my original design than the available tapered ones are! There is also the problem that these would be well outside of the budget, which was based originally on the quote I received to have them made in wood.

** So, please, if you have any objection to a non-tapered carbon blade, please do let me know, and I can arrange a refund for the blade part of your kit. If you’re happy for me to proceed, I’ll get the order in over the next couple of days, and should have them constructed/coated at some point next week.**

If it’s any consolation, I actually think these carbon ones will be superior and more mechanically stable than the wooden ones could ever have been, and like I said, I now have my doubts that wooden ones were ever used in the first place.

Boot Studs:

It’s not all bad news! I was lucky enough to get my hands on a second pair of Uniroyal boots! I was a couple of studs short somehow, so I had been on the lookout for another pair, but they’re rarely in Grade A condition like these:

So, I now have plenty of vintage studs available for those who need them. I’m afraid I can’t cancel orders of Wannawnaga studs at this stage I’m, as the order has been placed. I can sell them at a lower price of £15 to those who have already ordered one of Roy’s though. The usual price is £20.

The price is not to cover the cost of the boots (although this pair were considerably more expensive than the last pair). Anyone who has extracted these before will know that the price is to cover the time and effort of extracting them, as well as the time and energy taken to find them in the first place.

Please let me know if you would be interested in taking one of these. I'll be putting any remaining ones up on the Junkyard once the run is finished.

On the subject of boot studs, I did a test run on removing the zinc plating on ten of them (the ten for my first batch of commissions). Distilled vinegar works an absolute treat and they’re now safe to work on. I now have a load more in the process of being stripped too, and have removed the tabs from one, just to check how long it takes.

So... hopefully you can see that I’ve been incredibly busy in my absence over the past week or so. It does play on my mind me when it’s been a while since my last update, but I find that when I’m in the zone, it’s better to just crack on and get the work done!

I’m always available though, should you have any concerns or questions.

I know I probably sound like a stuck record but THANK YOU all for your patience and for placing your trust in me. It’s not something that I take lightly, and I’m working as hard as I can to get these out to everyone as quickly as I can. We should hopefully be in a very good position this time next week, and should the other parts arrive, there will be a lot of kits going out of the door.

Thanks for taking the time to read what I realise is a long update. I hope you understand that It’s better to get the occasional large update out, rather than many short ones.

Please let me know if you have any questions, and if you’ve messaged me recently, and I haven’t got around to replying yet, I’ll get on to replying to messages shortly, now that I’ve got the update posted.

Thanks everyone! All the best and MTFBWY,

Dave

Hi everyone. First off, the usual apology for radio silence... These updates always take me way longer than you might expect, so I’ve been trying to get through a good chunk of the work I have left to do before doing this one. I feel like it’s been a while though, and I do have quite a lot of news this week that needs to be discussed (as well as a few revelations)….

The amount of work involved in this run has been really quite astronomical, but I am making good progress and getting through it all as fast as I can, whilst ensuring that I maintain the high standards that you’ve come to expect.

Thank you so much to everyone for providing me with your numbers last week! It’s much appreciated and will save me messaging everyone individually when it comes time to ship your orders.

All orders that were not waiting on the arrival of additional parts, and that did not require damage commissions have been sent out, and have started to arrive with people.

All non-damaged kits that are still waiting on the arrival of additional parts have been prepped and assembled and are packaged ready to leave as soon as possible. Even these DIY kits have required a fair bit of work, and there have been a lot to get through. I’m really very happy with all of the parts, but they do always have some evidence of the machining process, and I make a point of removing any tool marks or scratches myself before sending out.

Where an order has included a motor kit, an additional grub screw has been added below the clamp.

This is to grip on to the motor and to prevent it from spinning free of it’s connections. I can’t say for certain, but I strongly suspect that this is present on the original prop.

It has come to my attention that, while the switches and the cone knobs are both 6mm, they actually have a different pitch on their threads (this is because the nuts on the switches are shallow, so require a shallow pitch on the threading). For this reason, I have de-threaded the hole on all motorised kits (All kits that come with a switch).

Interestingly, I don’t actually think that this makes the hilt inaccurate. Hear me out… The switch came first (not the cone knob), and there would have been no reason to thread that hole. I wonder… Does this suggest that the hole for the cone knob is in fact un-threaded? This would raise the question of whether or not the cone knob is held on using it’s original grub screw, or perhaps, it is screwed on to a short M6 bolt, pushed through the hole from the inside? A possibility.

This is only a theory, so I have only removed the threading from the motorised stunt kits. The ROTJ kits and the base kits purchased without motors have all been left with the threading intact. Simply for ease of attaching the cone knob. I do suspect that this hole should be unthreaded to be completely accurate though (An assumption on my part).

Pommel/Emitter damage commissions for DIY kits are VERY nearly finished. This has been a HUGE job as I hope you’ll understand and they have taken a few days to get through, but they are all very nearly done. It’s not so much the work that has dragged things out, but the shear quantity.

For the pommel damage, I used my vinyl damage guide (these are being sent out with stencil kits).

The emitters are relatively straight forward, but again, the numbers have meant that just getting them detached has taken a good few hours stood at the vice hack sawing! Once they’re removed, I then clean them up and ensure that the cut line is straight, before adding the dents to the emitter face.

Here is a complete ROTJ kit (with additional Cone Knob) including pommel and emitter commission:

There have been a couple of revelations with the ROTJ kit too, which I’ll explain... Please note the washer at the neck. It’s my strong belief that the neck of the original prop was broken (rather than being cut) This is not something that I’m able to replicate due to the nature of the materials, so roughly 1mm is missing from the length of the neck section. Lost to the cutting process. I’ve replaced this with the washer, which will be hidden below the neck tape (supplied with the stencil kit).

I have also noticed something important that could well be another discovery relating to the original prop and it’s design. As you know, the point at which the emitter joins to the body is a straight cut/break. Whilst there is not enough room for a bushing, unless it was a VERY thin one, there IS a small gap between the rod and the inner wall of the hilt. This would have been necessary for the mechanism to work. Interestingly, this has meant that the emitter, once detached, not only spins, but it has a slight wobble too… Nothing too drastic, but of course, it does make sense. There is a definite clacking sound as Hamill inspects the original prop in PCQ, and it’s not necessarily just the D-Ring. It sounds a lot like the sound that comes from mine when fully assembled:

This got me considering the tape. Why would it have been necessary to prevent the emitter from spinning? Maybe preferable that it didn’t I guess, but it’s not *that* important in the grand scheme of things. Could the tape have been applied to keep it from wobbling/rattling too? Just a thought.

They shouldn’t be necessary once the tape has been applied, and they’re certainly not there on the actual prop, but I have ordered some extra thin nylon shoulder washers to replace the metal one that I’m using at the moment. This should solve both the above mentioned issues in one go (if they are issues?).

Blades:

Now for some bad news I'm afraid… To say that this has been weighing heavily on me would be an understatement! I have finally heard back from my carpenter this week, and it is bad news. He just can’t seem to get these blades made to a satisfactory standard. Not for lack of trying, or lack of ability. He’s widely regarded as one of the UK’s best wood turners! The problem, is that they’re just so thin that they warp whilst being worked on, and the result is that the finished product does not end up straight in relation to the bore:

This is obviously a problem! After several failed attempts, he’s decided that he’d rather not make them. This is fair enough I guess as he doesn’t want to put his name to something that isn’t perfect, but it puts me in a VERY difficult position. Some of you have paid for blades as part of your motorised stunt kits. I was expecting to have these in hand by now, and I appear to be back to square one!

Well, all is not lost! After frantically looking around for possible solutions, I believe I can still provide you all with blades within the same sort of budget (and in a relatively short amount of time). The only snag is that they won’t be tapered. I have sourced some Carbon Fibre rods that are the correct diameter and available immediately from within the UK.

I just need to check with everyone that this is acceptable before placing the order, as it’s a lot of money still, and if some people would prefer a refund on their blades instead, I need to establish the right quantity.

Something to consider is that some references do appear to show blades that have no taper, so it does appear that at least some of them were straight:

18mm is very thin to start with, so the addition of a tapper wouldn’t make too much of a difference really, and I believe that these alternatives will still look the part.

After speaking with my wood turning friend, I actually have my doubts that wood was ever used in the first place. He believes that the grain in the wood would have prevented them from drilling a perfectly centred hole.

Tapered carbon rods can be found, BUT, it would be impossible for me to get the internal bore in line with the centre without having a tapered internal plug made (Too expensive). These tapered rods are also TOO tapered, tapering to a near point. The straight ones are actually closer to my original design than the available tapered ones are! There is also the problem that these would be well outside of the budget, which was based originally on the quote I received to have them made in wood.

** So, please, if you have any objection to a non-tapered carbon blade, please do let me know, and I can arrange a refund for the blade part of your kit. If you’re happy for me to proceed, I’ll get the order in over the next couple of days, and should have them constructed/coated at some point next week.**

If it’s any consolation, I actually think these carbon ones will be superior and more mechanically stable than the wooden ones could ever have been, and like I said, I now have my doubts that wooden ones were ever used in the first place.

Boot Studs:

It’s not all bad news! I was lucky enough to get my hands on a second pair of Uniroyal boots! I was a couple of studs short somehow, so I had been on the lookout for another pair, but they’re rarely in Grade A condition like these:

So, I now have plenty of vintage studs available for those who need them. I’m afraid I can’t cancel orders of Wannawnaga studs at this stage I’m, as the order has been placed. I can sell them at a lower price of £15 to those who have already ordered one of Roy’s though. The usual price is £20.

The price is not to cover the cost of the boots (although this pair were considerably more expensive than the last pair). Anyone who has extracted these before will know that the price is to cover the time and effort of extracting them, as well as the time and energy taken to find them in the first place.

Please let me know if you would be interested in taking one of these. I'll be putting any remaining ones up on the Junkyard once the run is finished.

On the subject of boot studs, I did a test run on removing the zinc plating on ten of them (the ten for my first batch of commissions). Distilled vinegar works an absolute treat and they’re now safe to work on. I now have a load more in the process of being stripped too, and have removed the tabs from one, just to check how long it takes.

So... hopefully you can see that I’ve been incredibly busy in my absence over the past week or so. It does play on my mind me when it’s been a while since my last update, but I find that when I’m in the zone, it’s better to just crack on and get the work done!

I’m always available though, should you have any concerns or questions.

I know I probably sound like a stuck record but THANK YOU all for your patience and for placing your trust in me. It’s not something that I take lightly, and I’m working as hard as I can to get these out to everyone as quickly as I can. We should hopefully be in a very good position this time next week, and should the other parts arrive, there will be a lot of kits going out of the door.

Thanks for taking the time to read what I realise is a long update. I hope you understand that It’s better to get the occasional large update out, rather than many short ones.

Please let me know if you have any questions, and if you’ve messaged me recently, and I haven’t got around to replying yet, I’ll get on to replying to messages shortly, now that I’ve got the update posted.

Thanks everyone! All the best and MTFBWY,

Dave

Kermit3001

New Member

Unbelievable work, Dave. So happy to be a part of this run. Can not wait to get my hands on my two! Very very excited to do the painting and weathering work on them.

I’ve just received a V2 from Dave for a client. When I tell you this is a masterpiece….I have held/weathered almost every V2 kit to date, and this one feels like no other, but absolutely perfect. The weight, and slightly slimmer diameter, fits Mark’s description perfectly from the pop culture quest video. There’s a ton on this piece that lines up better measurement wise to the real prop as it is seen in references. This is an example of supreme accuracy, in every way. Dave i’m very very pleased to own one of these for myself. Thank for everything you’ve committed to this project!!

-Ariston

-Ariston

Wells

Well-Known Member

I can just see them filming the Luke and Leia scene in the Ewok village, total serious.... and then the v2 starts squeaking and rattling!

I like the theory about the cone using a nut to hold it. Why would they take the time to tap it when you can just bang on a nut really quickly and problem solved.

Lovely work as ever. Excited to see it in person.

I like the theory about the cone using a nut to hold it. Why would they take the time to tap it when you can just bang on a nut really quickly and problem solved.

Lovely work as ever. Excited to see it in person.

Last edited:

**UPDATE**

Hi everyone. Just a quick update on the blade situation... I believe I've found a suitable carbon rod now (with taper!), thanks to some very helpful suggestions from vadermania. Thank you!

So, everything is back on track. In budget and sourced in the UK (so should have them in hand fairly quickly). I'm going to go ahead and get them ordered!

Please speak now if you have any objections to the blade being carbon rather than wood. As I've said, I now have my doubts that they were ever made from wood in the first place.

Thanks again for your patience everyone. Things are getting back on track!

As soon as I get one of these made up, I'll get one installed and post a demo!

Cheers,

Dave

Hi everyone. Just a quick update on the blade situation... I believe I've found a suitable carbon rod now (with taper!), thanks to some very helpful suggestions from vadermania. Thank you!

So, everything is back on track. In budget and sourced in the UK (so should have them in hand fairly quickly). I'm going to go ahead and get them ordered!

Please speak now if you have any objections to the blade being carbon rather than wood. As I've said, I now have my doubts that they were ever made from wood in the first place.

Thanks again for your patience everyone. Things are getting back on track!

As soon as I get one of these made up, I'll get one installed and post a demo!

Cheers,

Dave

**Update**

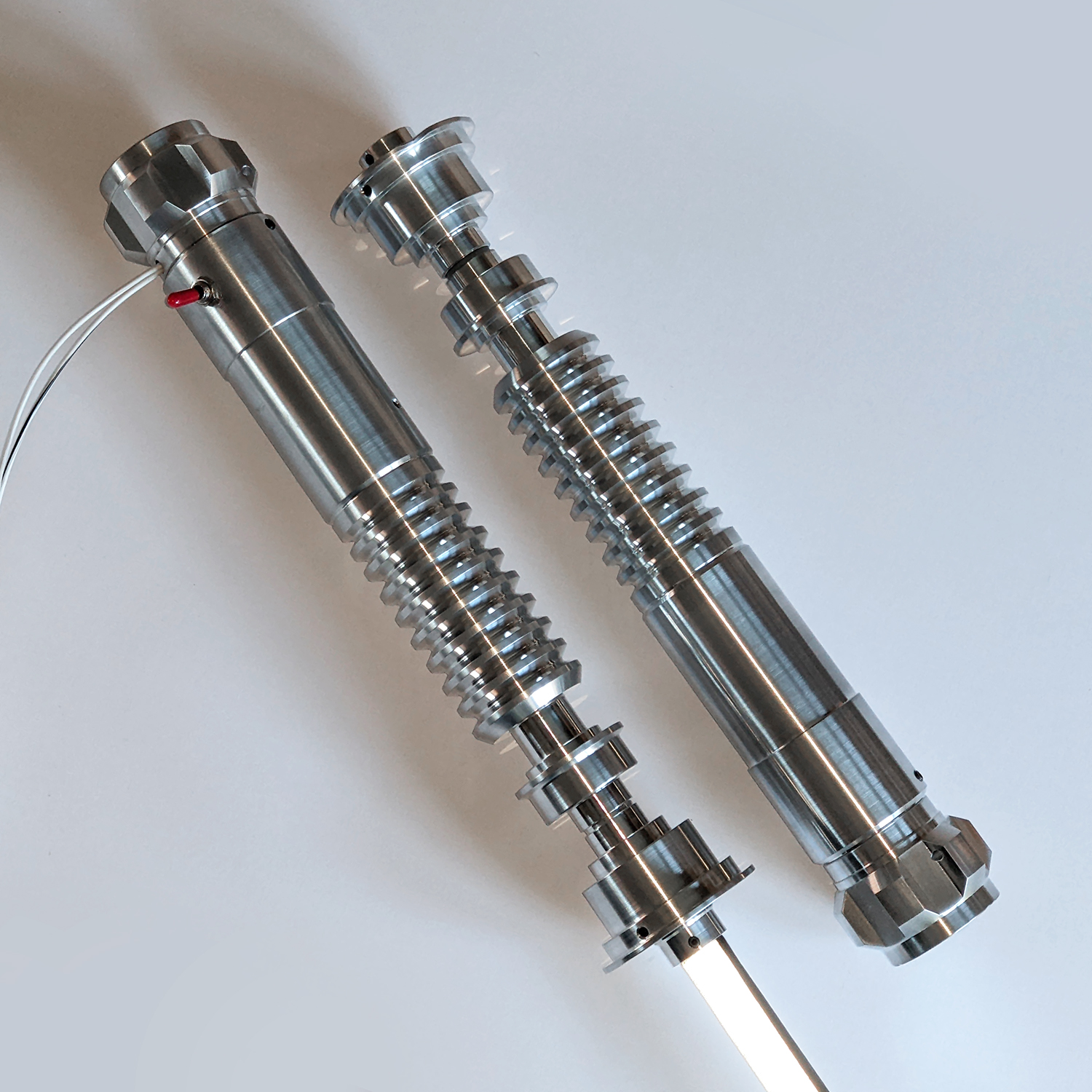

Hey everyone. just a quick update to show off the blades. They turned out great. Really VERY happy with them. I got one of the Obi stunts wired up this morning to check that everything works ok, and it's sooo smooth compared with the first attempt that I made from wood. The vibration is completely gone.

Here's a shot of it on the floor using the flash. The reflective tape works really well.

And a shot of the Obi Stunt next to a finished V2 kit (with pommel/emittter Damage):

I now have the vast majority of DIY kits made up and wrapped, ready to ship out. This includes those with Pommel/Emitter damage! As soon as the remaining parts come in, I'll begin getting these shipped out to people.

I've just heard from Roy this evening. The levers are finished and should be on their way to him very soon (if not already). So, as soon as they land here, I'll begin getting any outstanding DIY kits out to people.

The levers are finished and should be on their way to him very soon (if not already). So, as soon as they land here, I'll begin getting any outstanding DIY kits out to people.

I'm going to make a start on requesting second payments soon for all remaining DIY kits, so that I can just get on with shipping them out as soon as possible. Hope that's ok with everyone. Really excited to see everyone's builds over the holidays.

I will be making a start on my first batch of full commissions next week too, so I'll look forward to sharing my progress on those too.

Thanks again everyone!

All the best,

Dave

Hey everyone. just a quick update to show off the blades. They turned out great. Really VERY happy with them. I got one of the Obi stunts wired up this morning to check that everything works ok, and it's sooo smooth compared with the first attempt that I made from wood. The vibration is completely gone.

Here's a shot of it on the floor using the flash. The reflective tape works really well.

And a shot of the Obi Stunt next to a finished V2 kit (with pommel/emittter Damage):

I now have the vast majority of DIY kits made up and wrapped, ready to ship out. This includes those with Pommel/Emitter damage! As soon as the remaining parts come in, I'll begin getting these shipped out to people.

I've just heard from Roy this evening.

I'm going to make a start on requesting second payments soon for all remaining DIY kits, so that I can just get on with shipping them out as soon as possible. Hope that's ok with everyone. Really excited to see everyone's builds over the holidays.

I will be making a start on my first batch of full commissions next week too, so I'll look forward to sharing my progress on those too.

Thanks again everyone!

All the best,

Dave

That looks stunning mate!

Marv

Sr Member

Looking forward to that to see what colours and techniques you use especially on the anh saberI will be making a start on my first batch of full commissions next week too, so I'll look forward to sharing my progress on those too.

Looking good Dave! That motorized stunt looks extremely stable! Very nice!

I somehow missed your Friday update.

Dave, I can’t tell you how excited I am to receive these hilts. Thanks again for all the effort you have put into this. The obi stunt will be hanging on the wall next to my TV very soon. Can’t wait!

Merry Christmas! Hope you will be taking a break over the holidays. You deserve it!

Dave, I can’t tell you how excited I am to receive these hilts. Thanks again for all the effort you have put into this. The obi stunt will be hanging on the wall next to my TV very soon. Can’t wait!

Merry Christmas! Hope you will be taking a break over the holidays. You deserve it!

**Merry Christmas**

Hi everyone. I just wanted to grab a moment to wish you all a very merry Christmas, and all the best for the new year!

It's been a CRAZY few weeks and still a hell of a lot of work to get through. Hope you don't mind me downing tools for a few days though, to recharge and enjoy the festivities.

A lot of orders have gone out already, and many more are boxed up and ready to go out as soon as they're complete. Looking forward to getting these out to everyone as soon as possible in the new year.

I'll be posting an update the first week of January to show progress on the first batch of commissions. Nothing much to show right now, but I've made a start on prepping the parts for treating/stenciling.

Hope you'll understand that I need to draw a line under this year now.

looking forward to picking things up as soon as possible, refreshed and re- energised

Thanks again to everyone for taking part in the run. I really couldn't do these without people placing their trust in me, and it's very much appreciated! Hope you all have a great time over the holidays!

Merry Christmas and MTFBWY!

All the best,

Dave

Hi everyone. I just wanted to grab a moment to wish you all a very merry Christmas, and all the best for the new year!

It's been a CRAZY few weeks and still a hell of a lot of work to get through. Hope you don't mind me downing tools for a few days though, to recharge and enjoy the festivities.

A lot of orders have gone out already, and many more are boxed up and ready to go out as soon as they're complete. Looking forward to getting these out to everyone as soon as possible in the new year.

I'll be posting an update the first week of January to show progress on the first batch of commissions. Nothing much to show right now, but I've made a start on prepping the parts for treating/stenciling.

Hope you'll understand that I need to draw a line under this year now.

looking forward to picking things up as soon as possible, refreshed and re- energised

Thanks again to everyone for taking part in the run. I really couldn't do these without people placing their trust in me, and it's very much appreciated! Hope you all have a great time over the holidays!

Merry Christmas and MTFBWY!

All the best,

Dave

Martin Sabers

Active Member

Merry christmas Dave. Well deserved break ;-)

Mr Mold Maker

Master Member

Dave, I received the saber today and it is a masterpiece! Thank you so much for your hard work. It is very appreciated. Wishing you a happy new year. Whatever you decide to do next, I am on board.

Thank you, Dave!!! This hilt is amazing

Excited to get it painted/finished

Excited to get it painted/finished

Similar threads

- Replies

- 23

- Views

- 2,302

- Replies

- 2

- Views

- 1,562

- Replies

- 10

- Views

- 2,023

- Replies

- 302

- Views

- 37,759