Next I did my first coat of Dark Steel paint on Han! So I did my primer coat, and I sanded it down. And in the primer coat I really thought it was sanded smooth enough to get the look I wanted...boy was I wrong! This Dark Steel shows every little mistake and problem and magnifies it and punches you in the gut with it! Oof! Soo many issues. I had kind of a melt down after seeing this.

Talked with a few smart people on my facebook group and they calmed me down and trained me. I think I moved from a Padawan to Knight that day! hehe

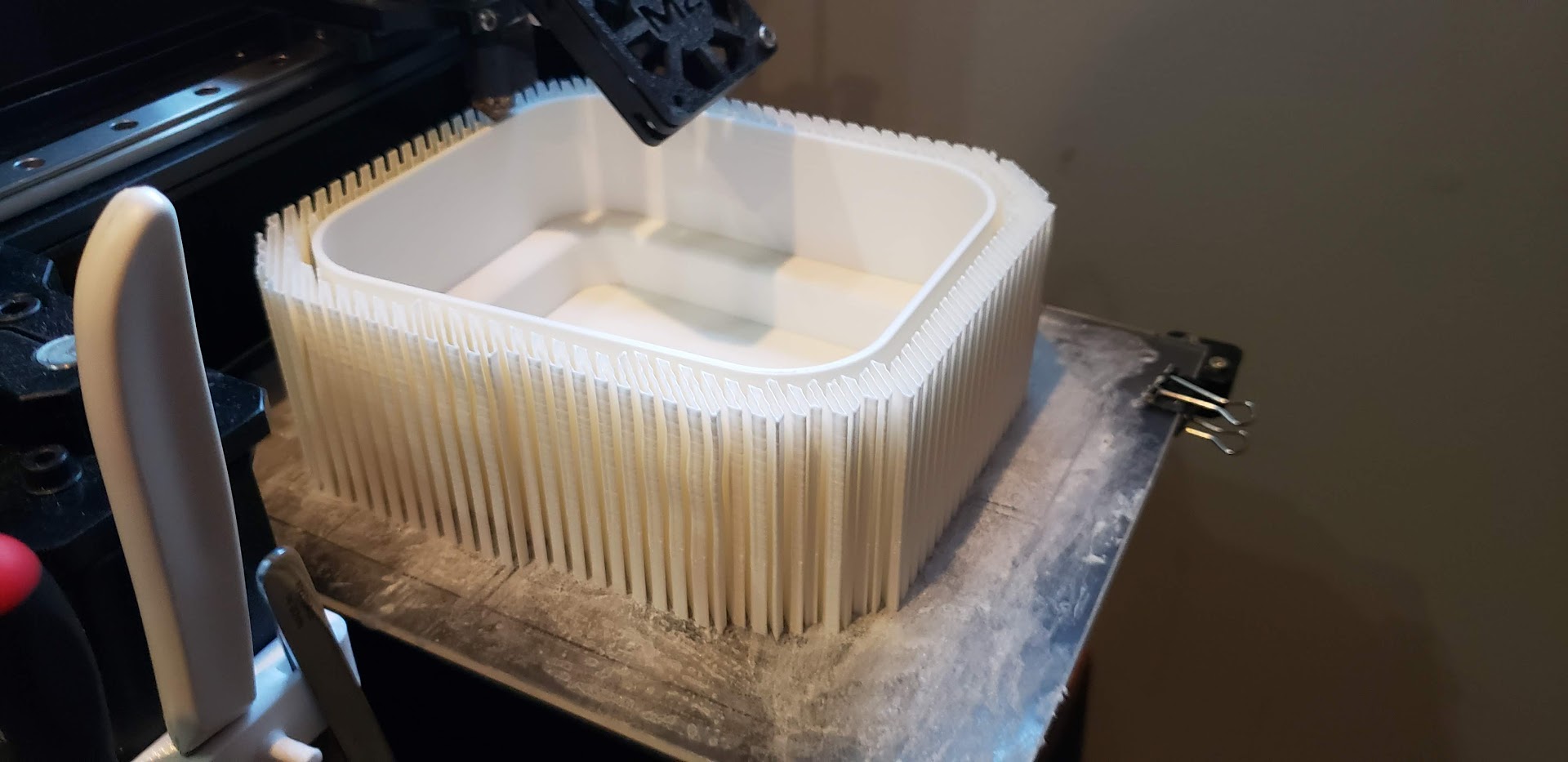

So here is what it looked like after just the first coat of Dark Steel. You can see all of those fuzzy looking areas. The recessed areas.

Up close they just look grainy and fuzzy. The original didn't look like this. It's got a much smoother overall look to it.

So I tried a little acetone on a paper towel. That didn't work the way I had hoped. Someone at Home Depot suggested this Laquer house primer which I didn't even try. Just returned it. Instead what worked was just a lot of elbow grease mixed with 320 grit sandpaper and #1 and #0000 steel wool! I went over the whole things sanding out the grainy bits and leaving a little of it where it seemed to make sense using the 320 and working down to #0000. And it was HUMID AS HELL while I did this. Made for a pretty miserable day. I will not be doing that again any time soon! Funny note...when you show people at Home Depot pictures like the one above asking these types of questions, you get some funny looks! HAHAHA

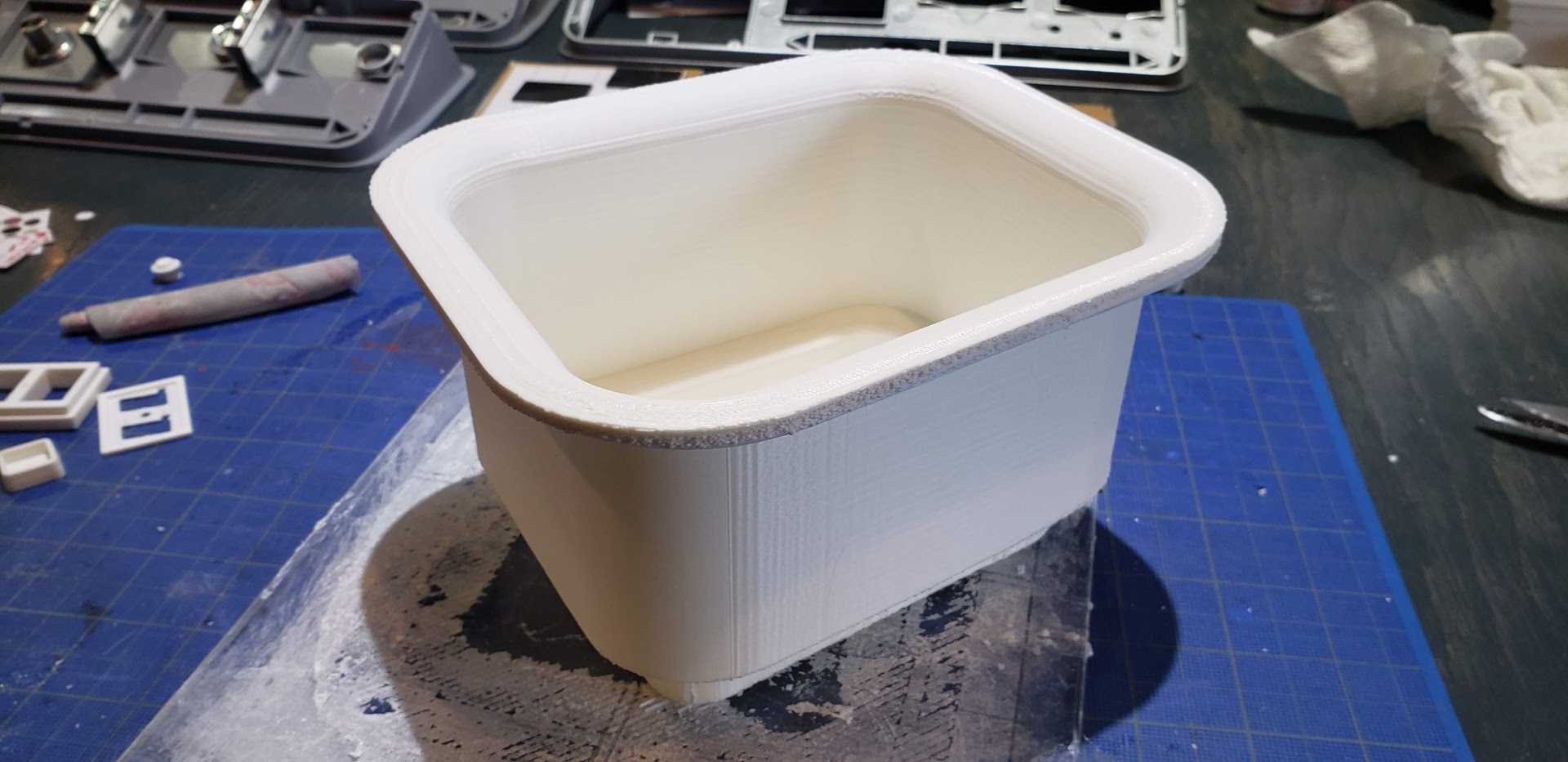

But once done, you can see it looks ALOT better! It's not perfectly smooth, but another coat of paint will help that a bit more and it should look pretty good!

Next step was to tackle the smooth sides and edges of the face. You can see in this pic very clearly the scuffing that just didn't get covered with the filler primer and sanding in that phase. And unfortunately a lot of the problems when viewed up close are little recessed pockets, not raised bumps. So you cant just easily sand them off.

So I masked off the cast because I was very happy with where I got it and didn't want to mess it up. Then I did 2 more coats of filler primer over top of what was already there. Then a coat of primer sealer which is supposed to help the overcoat from seeping through the primer. Then another coat of filler primer and SAND!!! And I did A LOT OF SANDING! I basically in some places had to sand off most of the coats I just put on to get it smooth enough to get rid of the pockets and holes.

But after it was all done, it was totally worth it!! This thing is super smooth and looks really good!

As you can see in this pic, its not perfect, but the scuffs and scratches left just kinda look like normal wear.

So I then pulled off the tape to reveal the final product!! And DAMN does he look nice!!!

I am super happy with the look. Dark Steel is the perfect paint for this Carbonite look too! It reacts with the light in the space your in the same way as it did in the movies. Soo cool!

He is ready to be finished!! Weathering here we come!!