The Merr-Sonn Power 5..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DL-44 FDM c96 & MGC replicas…

- Thread starter chubsANDdoggers

- Start date

Posted a thread showing off my FDM PS/RIA blaster. For anyone who’s interested you can follow this link here..

www.therpf.com

www.therpf.com

Pawn Star / Rock Island Auction Million Dollar Blaster replica..

All the controversy aside at the very least this was a great CAD learning experience. I actually designed this up over a year ago and made it in MJF (below) but I wanted to redue it to be printed on an FDM printer instead..For this blaster there is many great pics and videos to drawn from so...

Merr-Sonn Power 5 is now finished..

Greedo killer film and Chronicles..

Looks great! Though I don't know if the scope was bent during the time of filming, I always thought it happened afterwards.

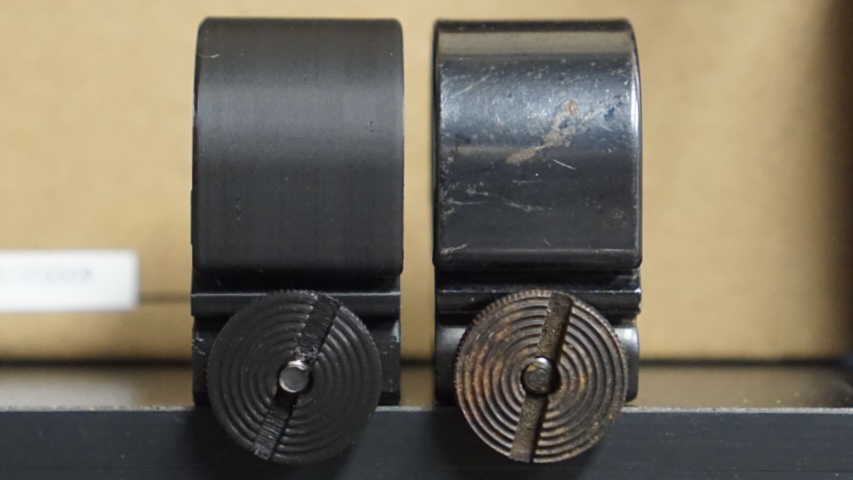

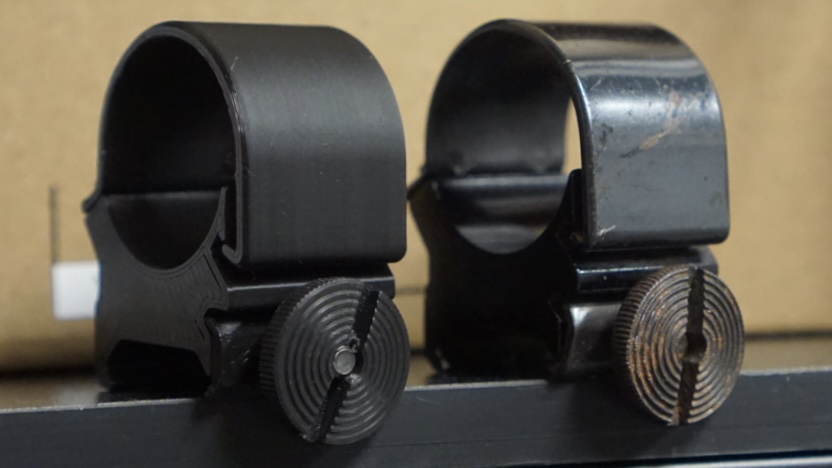

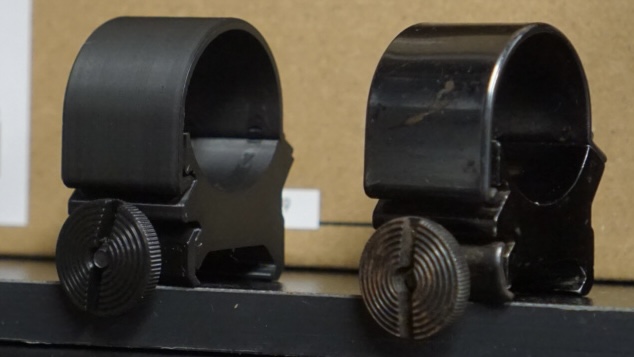

Maybe V but honestly not really sure how that could ever be truly confirmed or denied. The only time you ever see that scope and those specific weavers together is only on screen and that lasts.. hot second or two. It’s definitely the same scope cause of that dent on that wheel.

But was it actually straight when filming took place?? Maybe but I honestly don’t know. In this pic the light captured on the scope itself makes it look bent but it’s way too subjective..

It’s a movie so it depends on how the scene is lit, where the lights coming from. But because of that light and how it’s being reflected on film I’m pretty positive that those weavers are definitely the tall ones. Not the medium and definitely not the small ones (which I think most people already know).

I truly enjoy seeing your printing work the way you orientate the layering to come out so smooth

I truly enjoy seeing your printing work the way you orientate the layering to come out so smooth

Thanks for noticing that. Truly. Definitely spend a lot of time figuring all that out but it really is worth it in the end I believe.

You are very welcome and it definitely makes the parts not only look more finished and smoothThanks for noticing that. Truly. Definitely spend a lot of time figuring all that out but it really is worth it in the end I believe.

but it also looks like you are taking into account that some of the orientation is also for structural

integrity so that literally aligns with the way the parts are made and looks natural even when you

can see it so again bravo on that as well

The company I've used to do some of my printing does the same thing which is why they are

more expensive than most but its definitely worth the time as it shows in the final product.

Especially if printing transparent items.

Not exactly something you find typically coming out of shapeways

Using an authentic tall weaver I believe I got it pretty close..

Last edited:

You are very welcome and it definitely makes the parts not only look more finished and smooth

but it also looks like you are taking into account that some of the orientation is also for structural

integrity so that literally aligns with the way the parts are made and looks natural even when you

can see it so again bravo on that as well

The company I've used to do some of my printing does the same thing which is why they are

more expensive than most but its definitely worth the time as it shows in the final product.

Especially if printing transparent items.

Not exactly something you find typically coming out of shapeways

Ya the biggest thing that Ive learned is that if specific parts are going to use parts for strength then they need to be basically flat on the print bed. Printed that way they are actually really quite strong. Way stronger than I anticipated. Screws and such for example that I can’t find in the real world. But outside of all of that a big thanks has to go to Bambu Lab for making these printer so great and “easy” to use. I honestly still am amazed with what these FDM printers can accomplish.

Just look at the weaver above. The top part looks crazy smooth doesn’t!? That’s straight off the print bed. No post processing at all.

It certainly does and I'm guessing those didn't require and post finishing/sanding to look that good correct?

interesting info about printing screws as well, what model of Bambu Lab printer do you have?

I think I saw you mention it somewhere but don't remember where.

interesting info about printing screws as well, what model of Bambu Lab printer do you have?

I think I saw you mention it somewhere but don't remember where.

It certainly does and I'm guessing those didn't require and post finishing/sanding to look that good correct?

interesting info about printing screws as well, what model of Bambu Lab printer do you have?

I think I saw you mention it somewhere but don't remember where.

I have the P1S with the AMS. No real post process either other than cutting off supports I designed into files.

For the screws ya it works great. I posted this pic as well already but u can see (if u zoom in) how this screw is actually two parts glued together to accomplish the best strength possible. The threaded part was printed flat on the bed. The one on the left is with a .2 nozzle while right is .4. Second pic is it in use threaded into the bullbarrel..

Very nice that is certainly a smooth looking barrel there and good idea on the 2 piece screws

and thank you for the info on that printer

I originally saw your work on the obi-wan saber which is what caught my attention with the metallic looking filaments

www.therpf.com

www.therpf.com

and thank you for the info on that printer

I originally saw your work on the obi-wan saber which is what caught my attention with the metallic looking filaments

Obi Wan “Chronicles” Lightsaber FDM print

STL files for FDM printing available as well. Recently tried my hand at duplicating Kenobi’s lightsaber and eventually landed on the “Chronicles” version simply because I liked the way it looked the most. With the added screws and pins on Graflex it really makes it quite unique in its...

Last edited:

Here’s a video showing off my new FDM Merr-Sonn..

timothyk

New Member

It's a shame, chubsANDdoggers, I don't care for your work.(The display is a WIP)View attachment 1823702View attachment 1823703View attachment 1823704View attachment 1823705View attachment 1823706View attachment 1823707View attachment 1823708View attachment 1823709View attachment 1823710View attachment 1823711

Amazing display.

Similar threads

- Replies

- 119

- Views

- 6,256

- Replies

- 0

- Views

- 140

- Replies

- 4

- Views

- 238