No I didn't do anything new yet but I do have some great news. check out this post I made.... it basically all relates to this threat too.

http://www.therpf.com/f9/doctor-who-time-agents-vortex-manipulator-spoiler-89715/index6.html#post1369116

so basically, when i finish updating you'll just order thsi in stainless steel from shapeways, and sand it. I've gotten good results with sanding the stainless steel, and i've seen other people get a near mirror finish.

i'm going to make the holes in the part where the watchband attaches because I am now confident in the steel, and it will make the hole.

i need to get aronud to making the lip, and I think we should add the holes in the side of the case for buttons.

for those of you who are too lazy to click:

hey sorry for neglecting you guys! i've been so busy with my inception totems and stuff. they sold like crazy and its been a hassle to deal with that, and my gf and all the normal work stuff and normal life stuff.

i have some sweet news though. I recently ordered a bunch of my little designs as rings and earings and necklace pendants and things like that, all made from stainless steel. I've learned a lot, and everything i've learned is GREAT news.

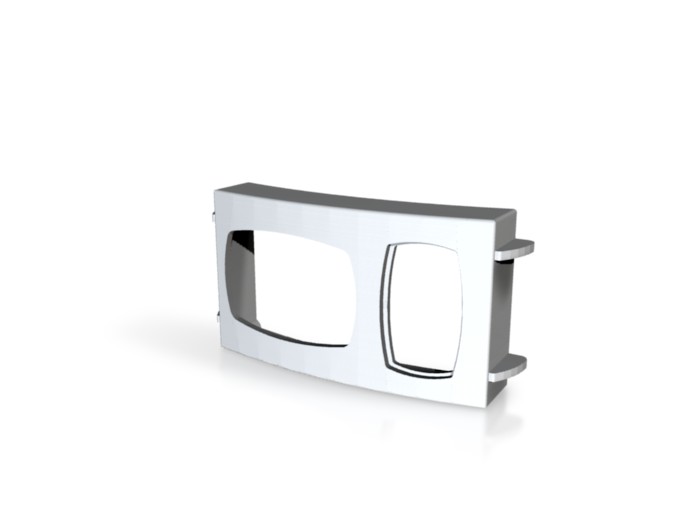

for starters, here is a picture:

in there you see 3 rings:

mobius strip split ring

egyptian eye of horus ring

howard street bridge ring

also you'll see a set of my star of david swoop earings, a twisted pendant, and a go stone with AGA 1D 'engraved'

I want to draw your attention to the go stone and the howard street bridge, and I want to make 3 points.

First, sandability. Looking at the stone, you can see its shinier. I sanded it for a couple minutes with 320 and then 1000, real quick, not a lot of time, and i got great results. pic is from my cellphone but literally i can see my reflection and recognize myself.

second point is the detail on the howard street bridge. i dunno if you can see it in the pic but the beams and top arch are actual I beams and you can make out the i-beam on the arched part of the bridge. you cant see it on the bars cuz they are facing to the left and right. its a clear line taht you can see in this pic on the right arch. i see it on both in real life but th epicture cant grab that i think

Point three is also looking at the bridge. those bars are SO thin.... 0.4mm wide. the I part of the I beam that sticks out is 0.13mm, so like less than two hairs thick.

the strength is this third point. i can make the part thinner and still strong. this brings down the amt of material used so the price will be lower.

sandability, detail, strength.

so i guess sorry for whoever has already ordered, but i'll be revising and making it better, cheaper faster stronger sexier whatever

send me messages if i forget or am slacking off... i guess i respond to $ and to nagging most in life =)

after these results, and the poor results i've been getting with the aluminum sandasting stuff, i'm going to scrap trying to sand cast this in aluminum and only focus on the stainless steel method."