Oh, yeah, it absolutely spins now.. No question. I think v312 is talking about pre ROTJ, when it was used as the motorised stunt on ANH. It's not obvious why the emitter would have been separated as it isn't strictly necessary for the mechanism to to have worked.Well, in the video with Mark Hamill, Brandon shows off that it spins, independently of the body. About 38 seconds in:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DaveP's Luke RotJ V2 Research/Development Thread 2021

- Thread starter DaveP

- Start date

Yes, as I assume originally they wanted to have this rather long blade spin around its axis, not to wiggle and the tip to "draw circles" in the air. And for that you'd like to have the rod secured with 2 bearings to the body to make as stable axis as possible. So separating the emitter works against that in theory. But there could be many reasons that they ended up with separate pieces after they made the casts.Oh, yeah, it absolutely spins now.. No question. I think v312 is talking about pre ROTJ, when it was used as the motorised stunt on ANH. It's not obvious why the emitter would have been separated as it isn't strictly necessary for the mechanism to to have worked.

Poopapapalps found it extremely difficult and dangerous to drill through the entire thing.

Brandon has said that the emitter had an extra section that fits into the body/neck

the two emitter thing was from me about the V3 not the V2. Cool argument though, the V3 emitter is not cleaned up and the body is, add not being able to match the fat set screw, and it may be that they pieced the V3 together from mismatched casts.

but the V2 has been cleaned up and machined so much that it’s smaller, crazy huh?

I still think the nipple has two diameters that are the same length. If the nipple were half height, then today without the bearing it would sink down into the emitter and not poke out

great work Dave, seriously

Brandon has said that the emitter had an extra section that fits into the body/neck

the two emitter thing was from me about the V3 not the V2. Cool argument though, the V3 emitter is not cleaned up and the body is, add not being able to match the fat set screw, and it may be that they pieced the V3 together from mismatched casts.

but the V2 has been cleaned up and machined so much that it’s smaller, crazy huh?

I still think the nipple has two diameters that are the same length. If the nipple were half height, then today without the bearing it would sink down into the emitter and not poke out

great work Dave, seriously

...Switches are usually rectangular and the switch we see on the prop sticks straight out... meaning it toggled left and right (so the side profile would look straight) and probably not up down.

That means the switch casing was up against a curved wall, and would probably need a thinner wall to get the threads up and out of the saber!

Thanks Tom! Not a small comment at all. That's a really good point! I did think it might be that way around, but for a different reason. I figured that there might not be room to have it length ways due to it being so close to the pommel.

I don't know if this is necessarily true for all of them. The toggle switch I have has its box laying horizontally and the toggle moves up and down. It is true about the space in the booster, though. I can't turn it the other way, there's just not enough space for the pommel to fit if I did.

For practicality, I used wires with male and female connectors to plug the power, rig, and switch together after seating them all in place. The motor and drive-shaft assembly goes in first, then the switch and you've got to have enough room to even screw the thing in place; connect them all together without bundling the wires up and getting the pommel to fit with it all. It's a lot for something with not a lot of space.

Poopapapalps found it extremely difficult and dangerous to drill through the entire thing.

I do preclude that I'm working on a small bench lathe and doing this by myself. The fact that I've found reason for why the emitter comes separate and why there's a stump on these casts where the pommel should be doesn't necessarily mean the original crew working on these couldn't have done it any other way. We'll just never know.

In my experience though, because of the cast lilting ~2-3 degrees from the face of the emitter to the bottom of the pommel, it spinning in the lathe creates a notable wobble. This wreaks havoc on my bearings in my steady-rest when I work on the V3's. Drilling straight through it like that creates chatter in the drill bit, which can lead to an uneven or crooked bore, if the thing doesn't kick free from it's place.

Brandon has said that the emitter had an extra section that fits into the body/neck

IIRC he says it "sleeves into the hilt" and that the design looks intentional. I think we've just all embellished it over time, though I'm really fond of the idea that this protrusion also makes the break in the neck rather than it being an insert jetting from the neck break.

LOM

Well-Known Member

The updated model is looking great! Nice work!

Did you find an era-appropriate model train motor?!? I've spent so many hours looking as well... Lots of the vintage ones that I've come across are square or rectangular in shape, not a lot of round ones like that! There's a Märklin that I found that matched the specs very closely but it was rectangular and unfortunately began being produced about 5 years after filming, and another one that was close, but had a terribly low RPM.

Regarding emitters - the joint as Mr. Aligner quoted (from the same post I linked on page 2):

Did you find an era-appropriate model train motor?!? I've spent so many hours looking as well... Lots of the vintage ones that I've come across are square or rectangular in shape, not a lot of round ones like that! There's a Märklin that I found that matched the specs very closely but it was rectangular and unfortunately began being produced about 5 years after filming, and another one that was close, but had a terribly low RPM.

Regarding emitters - the joint as Mr. Aligner quoted (from the same post I linked on page 2):

Assuming the joint on the real hilt is similar to the one constructed by PPP and the Starkiller kits(?), could they have just put glue around the joint? That would stop the spinning, and it could easily have come undone later with all the abuse from stunt work.I don't think the emitter was ever cut or anything like that. The emitter neck fits cleanly into the neck of the hilt itself -- they are made to fit together. This feels very intentional.

The updated model is looking great! Nice work!

Did you find an era-appropriate model train motor?!? I've spent so many hours looking as well... Lots of the vintage ones that I've come across are square or rectangular in shape, not a lot of round ones like that! There's a Märklin that I found that matched the specs very closely but it was rectangular and unfortunately began being produced about 5 years after filming, and another one that was close, but had a terribly low RPM.

I ran into the same while looking. The ones I settled on were around at the time but were mostly used in model boats and cars (and maybe non-Marklin trains, who knows?).

Regarding emitters - the joint as Mr. Aligner quoted (from the same post I linked on page 2):

Assuming the joint on the real hilt is similar to the one constructed by PPP and the Starkiller kits(?), could they have just put glue around the joint? That would stop the spinning, and it could easily have come undone later with all the abuse from stunt work.

Possible. Literally any method could've been used.

Hi Guys.

My understanding of the motors now, is that the current Märklin E126050, which was manufactured long after 1977 is a replacement part for the Bühler 62201. This was made by Bühler "for" Märklin/LGB.

I haven't been able to find a date for this motor, but Bühler have been making motors since 1955, so there's a good chance that this is similar to the one that Jon was talking about.

Finding a diagram with measurements proved impossible, but I did find a photo of the E126050 (which should be the same dimensions being it's replacement), with scale reference:

It matches Jon's description perfectly!

I managed to find a page where someone has scanned practically EVERY Märklin catalogue since 1930, and it seams that this kind of motor wasn't sold separately by them until more recently: Märklin Catalogues

The standardisation of motor sizes began around the beginning of the 1970s and those sizes have pretty much persisted up until the present day. It seems that the motors for model railways have adopted the same/similar specs as other small motors:

*Note the jump from 27/28mm-36mm

That's kind of where I am with regards to the motor anyway.

My understanding of the motors now, is that the current Märklin E126050, which was manufactured long after 1977 is a replacement part for the Bühler 62201. This was made by Bühler "for" Märklin/LGB.

I haven't been able to find a date for this motor, but Bühler have been making motors since 1955, so there's a good chance that this is similar to the one that Jon was talking about.

Finding a diagram with measurements proved impossible, but I did find a photo of the E126050 (which should be the same dimensions being it's replacement), with scale reference:

It matches Jon's description perfectly!

I managed to find a page where someone has scanned practically EVERY Märklin catalogue since 1930, and it seams that this kind of motor wasn't sold separately by them until more recently: Märklin Catalogues

The standardisation of motor sizes began around the beginning of the 1970s and those sizes have pretty much persisted up until the present day. It seems that the motors for model railways have adopted the same/similar specs as other small motors:

*Note the jump from 27/28mm-36mm

That's kind of where I am with regards to the motor anyway.

With regard to the emitter being a separate piece....

It's damn near impossible to catch a glimpse of it spinning. It's being prevented from spinning in almost every shot by Sir Alec Guinness. The blade doesn't appear to be spinning in every shot either. So there are shots like the one at the end of the fight, where he isn't holding it steady, but the blade appears not to be spinning either.

I have managed to find some evidence that the emitter spins though. There are some quite distinct markings on the emitter face, and whilst it does seem to be held in place by Guinness, it appears to be at different orientations between shots:

Assuming that he held the prop with the control box facing the same way (which can be assumed I guess, both for reasons of comfort and because of the wires coming out of the pommel), this looks to me as though the emitter is at two different orientations.

Of course, the marks could have changed between shots!

For me though, it's the way he's holding it. Knowing that it does definitely spin today, and that it would need to have been prevented from doing so if it were the case back then, and that he does appear to be holding it exactly how you'd expect him to... It suggests to me that the general construction hasn't changed.

It's damn near impossible to catch a glimpse of it spinning. It's being prevented from spinning in almost every shot by Sir Alec Guinness. The blade doesn't appear to be spinning in every shot either. So there are shots like the one at the end of the fight, where he isn't holding it steady, but the blade appears not to be spinning either.

I have managed to find some evidence that the emitter spins though. There are some quite distinct markings on the emitter face, and whilst it does seem to be held in place by Guinness, it appears to be at different orientations between shots:

Assuming that he held the prop with the control box facing the same way (which can be assumed I guess, both for reasons of comfort and because of the wires coming out of the pommel), this looks to me as though the emitter is at two different orientations.

Of course, the marks could have changed between shots!

For me though, it's the way he's holding it. Knowing that it does definitely spin today, and that it would need to have been prevented from doing so if it were the case back then, and that he does appear to be holding it exactly how you'd expect him to... It suggests to me that the general construction hasn't changed.

Just one last little note on the break between the neck and the emitter....

Sorry, I didn't have time to cover everything in one post.

Currently my model has just a simple break at the neck, but this isn't set in stone by any stretch. I'm just yet to see or read anything conclusive to direct me one way or the other on this. I'm very much open to changing this in light of anything I've missed.

From what I gathered, when Brandon was discussing additional metal "sleeves", he was talking about the resin R2/Sail barge hilt that fires out of the top of R2's head?

Sorry, I didn't have time to cover everything in one post.

Currently my model has just a simple break at the neck, but this isn't set in stone by any stretch. I'm just yet to see or read anything conclusive to direct me one way or the other on this. I'm very much open to changing this in light of anything I've missed.

From what I gathered, when Brandon was discussing additional metal "sleeves", he was talking about the resin R2/Sail barge hilt that fires out of the top of R2's head?

Sleeved meaning there's a metal tube inserted in them that mated perfectly with the launch tube on the air cannon rig. The rig is present at the archives as well.

Brandon

This that LOM posted:

"I don't think the emitter was ever cut or anything like that. The emitter neck fits cleanly into the neck of the hilt itself -- they are made to fit together. This feels very intentional."

is about the V2 though. So "the emitter fits into the neck of the hilt" I understand as " there is a step on the emitter".

The way PPP makes his emitters (although I can't know if Brandon meant exactly this) really check all the boxes for me

- emitter separate piece, that fits into the hilt,

- can spin, but still adds stability to the blade axis compared to a straight cut in the middle

- does not really look separate or cut in the middle like the V3 neck looks - matches what I see on the AHN pictures with Alec.

There are few frames at the end of the duel where Alec holds the saber on the wind vane and does not touch the emitter. You can catch the blade spinning but the paint chips on the emitter stay at the same places (just watched it yesterday as I got curious). So to me this should mean that the rod was not attached with a hard connection to the emitter, but maybe with a bearing like on Dave's diagram. But Brandon also says that the "nipple" is not a separate piece from the emitter as far as he can tells ...

"I don't think the emitter was ever cut or anything like that. The emitter neck fits cleanly into the neck of the hilt itself -- they are made to fit together. This feels very intentional."

is about the V2 though. So "the emitter fits into the neck of the hilt" I understand as " there is a step on the emitter".

The way PPP makes his emitters (although I can't know if Brandon meant exactly this) really check all the boxes for me

- emitter separate piece, that fits into the hilt,

- can spin, but still adds stability to the blade axis compared to a straight cut in the middle

- does not really look separate or cut in the middle like the V3 neck looks - matches what I see on the AHN pictures with Alec.

There are few frames at the end of the duel where Alec holds the saber on the wind vane and does not touch the emitter. You can catch the blade spinning but the paint chips on the emitter stay at the same places (just watched it yesterday as I got curious). So to me this should mean that the rod was not attached with a hard connection to the emitter, but maybe with a bearing like on Dave's diagram. But Brandon also says that the "nipple" is not a separate piece from the emitter as far as he can tells ...

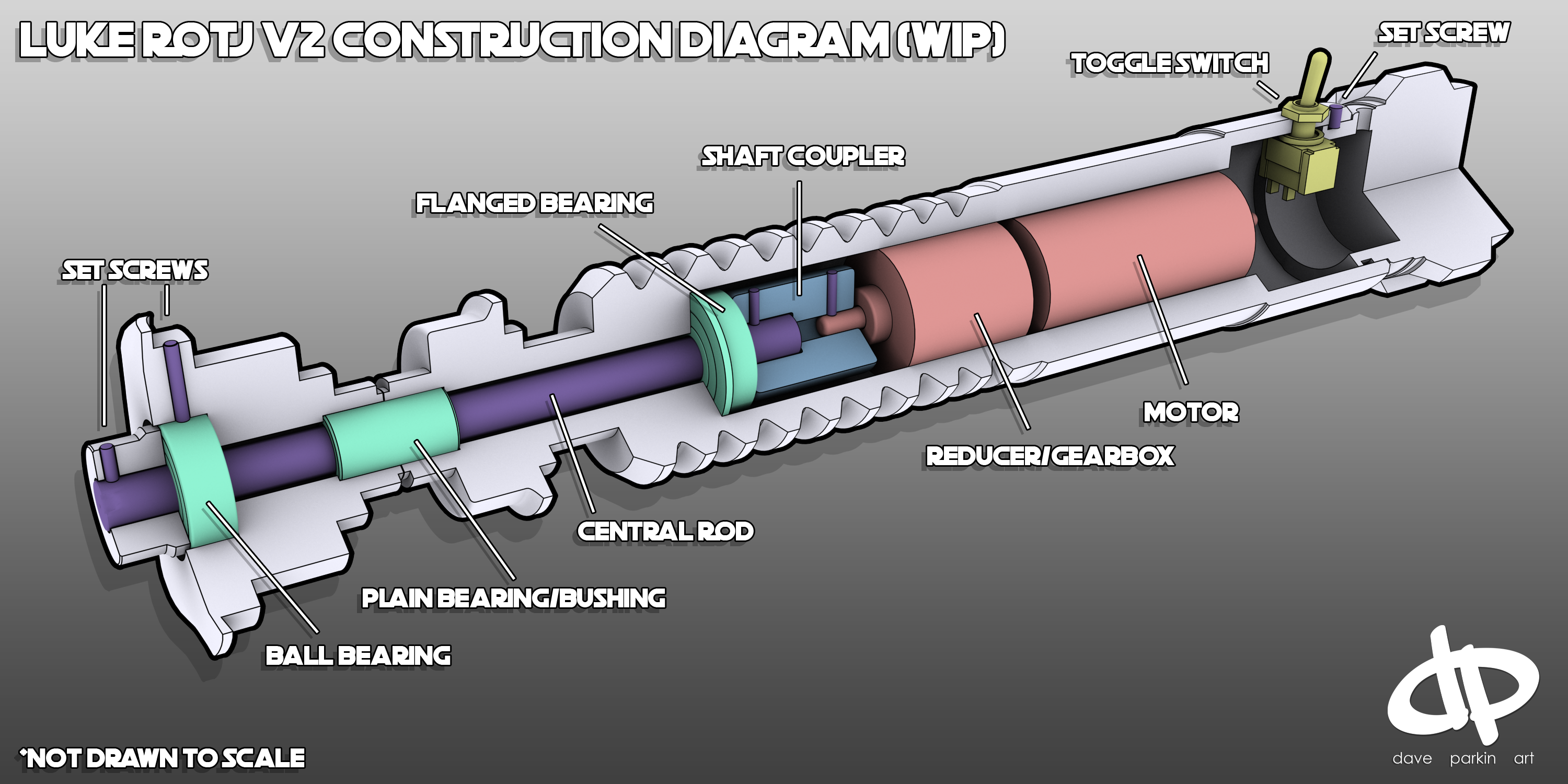

**Update**

Hi Everyone.

Exciting update, as there have been quite a few changes to the internals on the models! I was away last week on a camping trip, but I was busy having numerous discussions behind the scenes and researching various things from the "comfort" of my tent!

I've revised the models based on my findings, and I'm really happy with how things are looking...

The first and most obvious change is that the length of the motor chamber has increased dramatically. This is mostly down to me accounting for the length of the vintage motor, which was longer than more recent motors of the same/similar diameter.

I spent some time trying to track down the manufacturer of the gearbox and contacted a couple of UK based companies. Markel/Buhler don't appear to have manufactured their own gearboxes, so I figured the gearbox was probably supplied by a local (UK) engineering firm.

I was very excited to receive this reply from MFA COMO, who were manufacturing miniature gearboxes/reducers at the time of production:

After further conversation though, it turned out that the product in question was only ever sold as a single unit (including motor) and the gearbox would not have been sold separately.

I then contacted another UK based company who manufacture a similar standalone gearbox. The person I spoke to was very helpful, but they weren't able to give me any conclusive information due to restructuring within the company. Rotalink produce a gearbox that would have fit perfectly (being slightly smaller than the motor), but prior to 1986, Rotalink was called Sterling Instruments Limited, and there is VERY little information available regarding the products they offered.

It's "possible" that the planetary reducer gear that Rotalink make today was produced under their previous name, but due to a change in ownership in the early 2000's and then a change to digital record keeping, it's impossible to say for sure.

There is a New York based firm with the same name, who also manufactures gearboxes/reducers, but it seams that this is a coincidence and there is no connection other than them presumably associating themselves with the sterling engine.

So, whilst I was unable to find a conclusive manufacturer for the gearbox used in the original motorised stunt I think I've manged to get a good idea of the size it would likely have needed to be, based on the examples I've seen.

Accounting for the length of the motor (which is longer than more modern motors of the same diameter), along with the gearbox, the length of the mechanism chamber has been pushed further in to the grenade section of the hilt.

It also occurred to me that the step in the main bore wasn't necessary! I tried to find a bearing that matched the outside diameter of the motor as well as the inside diameter of the central rod, and I managed to find a flanged bearing that fit perfectly. It would have made no sense to add a step for the bearing when there was one available that fit the required measurements.

I've also added a bushing (plain bearing) to the neck section. At first I wasn't sure whether one would be needed, but having looked in to it further and having actually read up on Plain bearings and their uses, it now makes perfect sense! The purpose of a bearing is to reduce/eliminate friction between moving parts. A bearing at the neck would have prevented any friction between the rod and the body, as well as securing the emitter to the body section and keeping them both aligned. I looked in to various options, but finally settled on a straight bushing.

The quote from Brandon that LOM and v312 mentioned also got me thinking more on this:

This particular quote flew under my radar annoyingly, even after hunting down Brandon's messages on here. I think possibly because it was posted on a Vader thread.

I didn't want to add the bushing without looking for some visual evidence that it might be there. Luckily, I think I may have found some!

The last image here appears to show an exposed bushing. Having taken the image and done some comparative analysis in photoshop, the exposed neck section in this image is significantly thinner than the neck section of the hilt and emitter, and is thicker than the internal rod.

I've based my choice of bushing on the measurements taken from this image.

Another small update that you might notice is the the groove in the pommel for the set screw. I didn't want to add this feature without investigating for myself weather it would have been there. I thought that it was at least possible that there could have been a hole that the screw went in to rather than a groove. Having looked at all of the references, I have found that the pommel is NOT always oriented the same in relation to the body section, nor is the Glaflex clamp always at the same orientation, but this is to be expected I guess.

The fact that the pommel is orientated differently between references leads me to think that a groove might exist around the flange section of the pommel.

So, this is my latest cross section for the parts:

I really do feel, with each iteration, that we're getting closer to the truth of what the inside of this prop might have looked like!

As always, I welcome any comments/suggestions.

All the best and MTFBWY,

Dave

Hi Everyone.

Exciting update, as there have been quite a few changes to the internals on the models! I was away last week on a camping trip, but I was busy having numerous discussions behind the scenes and researching various things from the "comfort" of my tent!

I've revised the models based on my findings, and I'm really happy with how things are looking...

The first and most obvious change is that the length of the motor chamber has increased dramatically. This is mostly down to me accounting for the length of the vintage motor, which was longer than more recent motors of the same/similar diameter.

I spent some time trying to track down the manufacturer of the gearbox and contacted a couple of UK based companies. Markel/Buhler don't appear to have manufactured their own gearboxes, so I figured the gearbox was probably supplied by a local (UK) engineering firm.

I was very excited to receive this reply from MFA COMO, who were manufacturing miniature gearboxes/reducers at the time of production:

"We did produce the 918D series which is 25mm in dia and we certainly have supplied the Elstree studios with items over the years."

After further conversation though, it turned out that the product in question was only ever sold as a single unit (including motor) and the gearbox would not have been sold separately.

I then contacted another UK based company who manufacture a similar standalone gearbox. The person I spoke to was very helpful, but they weren't able to give me any conclusive information due to restructuring within the company. Rotalink produce a gearbox that would have fit perfectly (being slightly smaller than the motor), but prior to 1986, Rotalink was called Sterling Instruments Limited, and there is VERY little information available regarding the products they offered.

It's "possible" that the planetary reducer gear that Rotalink make today was produced under their previous name, but due to a change in ownership in the early 2000's and then a change to digital record keeping, it's impossible to say for sure.

There is a New York based firm with the same name, who also manufactures gearboxes/reducers, but it seams that this is a coincidence and there is no connection other than them presumably associating themselves with the sterling engine.

So, whilst I was unable to find a conclusive manufacturer for the gearbox used in the original motorised stunt I think I've manged to get a good idea of the size it would likely have needed to be, based on the examples I've seen.

Accounting for the length of the motor (which is longer than more modern motors of the same diameter), along with the gearbox, the length of the mechanism chamber has been pushed further in to the grenade section of the hilt.

It also occurred to me that the step in the main bore wasn't necessary! I tried to find a bearing that matched the outside diameter of the motor as well as the inside diameter of the central rod, and I managed to find a flanged bearing that fit perfectly. It would have made no sense to add a step for the bearing when there was one available that fit the required measurements.

I've also added a bushing (plain bearing) to the neck section. At first I wasn't sure whether one would be needed, but having looked in to it further and having actually read up on Plain bearings and their uses, it now makes perfect sense! The purpose of a bearing is to reduce/eliminate friction between moving parts. A bearing at the neck would have prevented any friction between the rod and the body, as well as securing the emitter to the body section and keeping them both aligned. I looked in to various options, but finally settled on a straight bushing.

The quote from Brandon that LOM and v312 mentioned also got me thinking more on this:

The emitter neck fits cleanly into the neck of the hilt itself

This particular quote flew under my radar annoyingly, even after hunting down Brandon's messages on here. I think possibly because it was posted on a Vader thread.

I didn't want to add the bushing without looking for some visual evidence that it might be there. Luckily, I think I may have found some!

The last image here appears to show an exposed bushing. Having taken the image and done some comparative analysis in photoshop, the exposed neck section in this image is significantly thinner than the neck section of the hilt and emitter, and is thicker than the internal rod.

I've based my choice of bushing on the measurements taken from this image.

Another small update that you might notice is the the groove in the pommel for the set screw. I didn't want to add this feature without investigating for myself weather it would have been there. I thought that it was at least possible that there could have been a hole that the screw went in to rather than a groove. Having looked at all of the references, I have found that the pommel is NOT always oriented the same in relation to the body section, nor is the Glaflex clamp always at the same orientation, but this is to be expected I guess.

The fact that the pommel is orientated differently between references leads me to think that a groove might exist around the flange section of the pommel.

So, this is my latest cross section for the parts:

I really do feel, with each iteration, that we're getting closer to the truth of what the inside of this prop might have looked like!

As always, I welcome any comments/suggestions.

All the best and MTFBWY,

Dave

Last edited:

Thanks Enrico!Waiting for your news, Dave MTFBWY always

Lots of progress this week! I've been busy drawing up the latest CAD drawings to send off for quotation (amongst other things). The models are still likely to change, but not enough to drastically alter the price. So should be able to post the interest thread soon (when I can give people an idea of the price)

I'm away on a short camping break this weekend though, so the next update is going to be the middle of next week

Lots of exciting things to announce

enrico

Well-Known Member

Thanks Dave!Thanks Enrico!

Lots of progress this week! I've been busy drawing up the latest CAD drawings to send off for quotation (amongst other things). The models are still likely to change, but not enough to drastically alter the price. So should be able to post the interest thread soon (when I can give people an idea of the price)

I'm away on a short camping break this weekend though, so the next update is going to be the middle of next week

Lots of exciting things to announce

Enjoy your free time!

All the best from Italy

That's awesome. Thank you. I'll be posting the interest thread soon, as soon as I get the quotes in for the parts.I'm interested in one!

Thank you.Thanks Dave!

Enjoy your free time!

All the best from Italy

Quick question! Not sure if this is gonna be the right thread, but it seemed kind of on topic here compared to some other threads. So if the shaft is 8mm on the Obi V2 stunt, what size Ball bearing would it use? Are bearings tolerances designed to fit over the same size shaft?

Hi there.Quick question! Not sure if this is gonna be the right thread, but it seemed kind of on topic here compared to some other threads. So if the shaft is 8mm on the Obi V2 stunt, what size Ball bearing would it use? Are bearings tolerances designed to fit over the same size shaft?

I removed any references to sizes, as there have been people coming on here and copying mine and others' work unfortunately. I will say that it's a fairly standard size of bearing though, and it fits with my 3D overlays and measurements. It also explains the small gap around the nipple.

The bearing in the body section is flanged and matches the outside diameter of the motor, and is the same internal diameter as the one in the emitter.

I'll be supplying any bearings that are needed with my kits when the run goes ahead of course.

Good to know Dave! Thanks!Hi there.

I removed any references to sizes, as there have been people coming on here and copying mine and others' work unfortunately. I will say that it's a fairly standard size of bearing though, and it fits with my 3D overlays and measurements. It also explains the small gap around the nipple.

The bearing in the body section is flanged and matches the outside diameter of the motor, and is the same internal diameter as the one in the emitter.

I'll be supplying any bearings that are needed with my kits when the run goes ahead of course.

**Update**

Hi everyone. I had a few days downtime last week, but I just wanted to give a quick update. I've spent the past couple of days finishing off the CAD drawings and getting them sent off for quotation.

I've now sent all of the drawings for the current parts, but they're still very much open to changes. I can use the prices that come back as a basis for the run going forward though and I'll get the official interest thread posted as soon as those come in.

I've sent the drawings for my vice jig too (for recreating the accurate dents in the emitter plate).

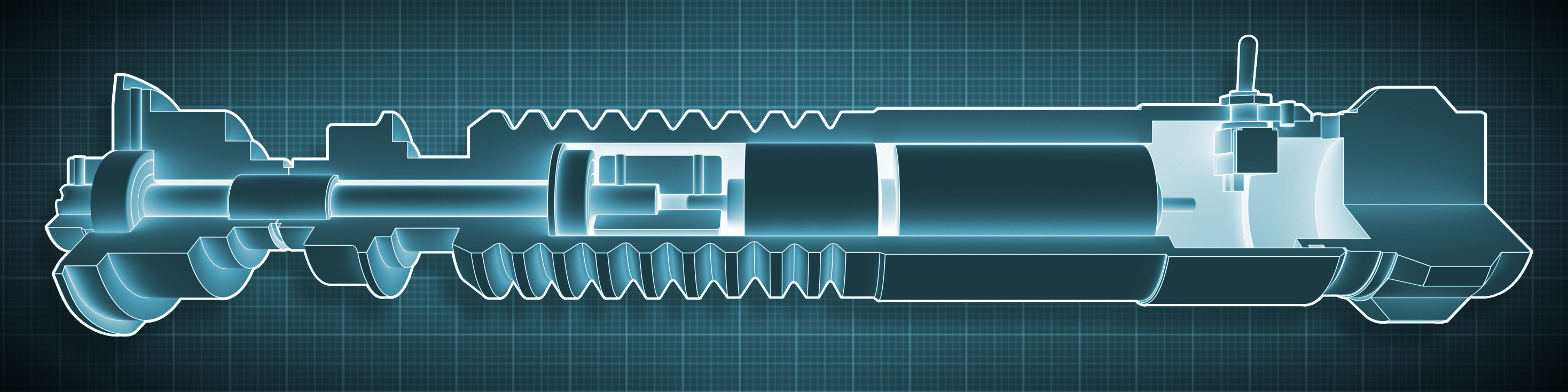

I'm just in the process of rendering some artwork to post with the run and to help explain some of the options that will be available as part of the kit. Here's a sneak peek:

Here's a shot of the current bent emitter:

As I'll be adding the dents myself, both the straight ANH version and the bent ROTJ versions will be available. The bent version will be slightly more expensive to cover the cost of the jig obviously.

I've also done a quick study of the damage on the Pommel. The standard Kit will come "as machined" but will include a self adhesive guide for adding the damage to the bottom of the pommel. Or, like the Emitter, a slightly more expensive pre-dented version will be available as an option.

As with everything else, these are still a work in progress, and are likely to change prior to the run going ahead.

My next job is to finish the stencils which should hopefully be done in time for the quotes coming in.

Thanks again for all of your comments and suggestions on this. Really looking forward to getting the ball rolling!

All the best and MTFBWY,

Dave

Hi everyone. I had a few days downtime last week, but I just wanted to give a quick update. I've spent the past couple of days finishing off the CAD drawings and getting them sent off for quotation.

I've now sent all of the drawings for the current parts, but they're still very much open to changes. I can use the prices that come back as a basis for the run going forward though and I'll get the official interest thread posted as soon as those come in.

I've sent the drawings for my vice jig too (for recreating the accurate dents in the emitter plate).

I'm just in the process of rendering some artwork to post with the run and to help explain some of the options that will be available as part of the kit. Here's a sneak peek:

Here's a shot of the current bent emitter:

As I'll be adding the dents myself, both the straight ANH version and the bent ROTJ versions will be available. The bent version will be slightly more expensive to cover the cost of the jig obviously.

I've also done a quick study of the damage on the Pommel. The standard Kit will come "as machined" but will include a self adhesive guide for adding the damage to the bottom of the pommel. Or, like the Emitter, a slightly more expensive pre-dented version will be available as an option.

As with everything else, these are still a work in progress, and are likely to change prior to the run going ahead.

My next job is to finish the stencils which should hopefully be done in time for the quotes coming in.

Thanks again for all of your comments and suggestions on this. Really looking forward to getting the ball rolling!

All the best and MTFBWY,

Dave

Similar threads

- Replies

- 9

- Views

- 1,154

- Replies

- 19

- Views

- 1,557

- Replies

- 22

- Views

- 4,983