You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anakin Starkiller V2 + V3 Builders kit Tutorial

- Thread starter Halliwax

- Start date

Wow great sabers here...I still have a not built V2 kit here and the older stencils from troopertrent.Are his new stencilversions also for the V2 kit?

I´m not so the saberexpert but I also wanna build my kit in the next time.

You can order his newest stencil kits here

www.etsy.com/shop/TrooperTrent

The starkiller stencil kit works on the FX starkiller and the Builders Kit Startkiller

I don’t believe Trents older stencils fit the newer V2’s

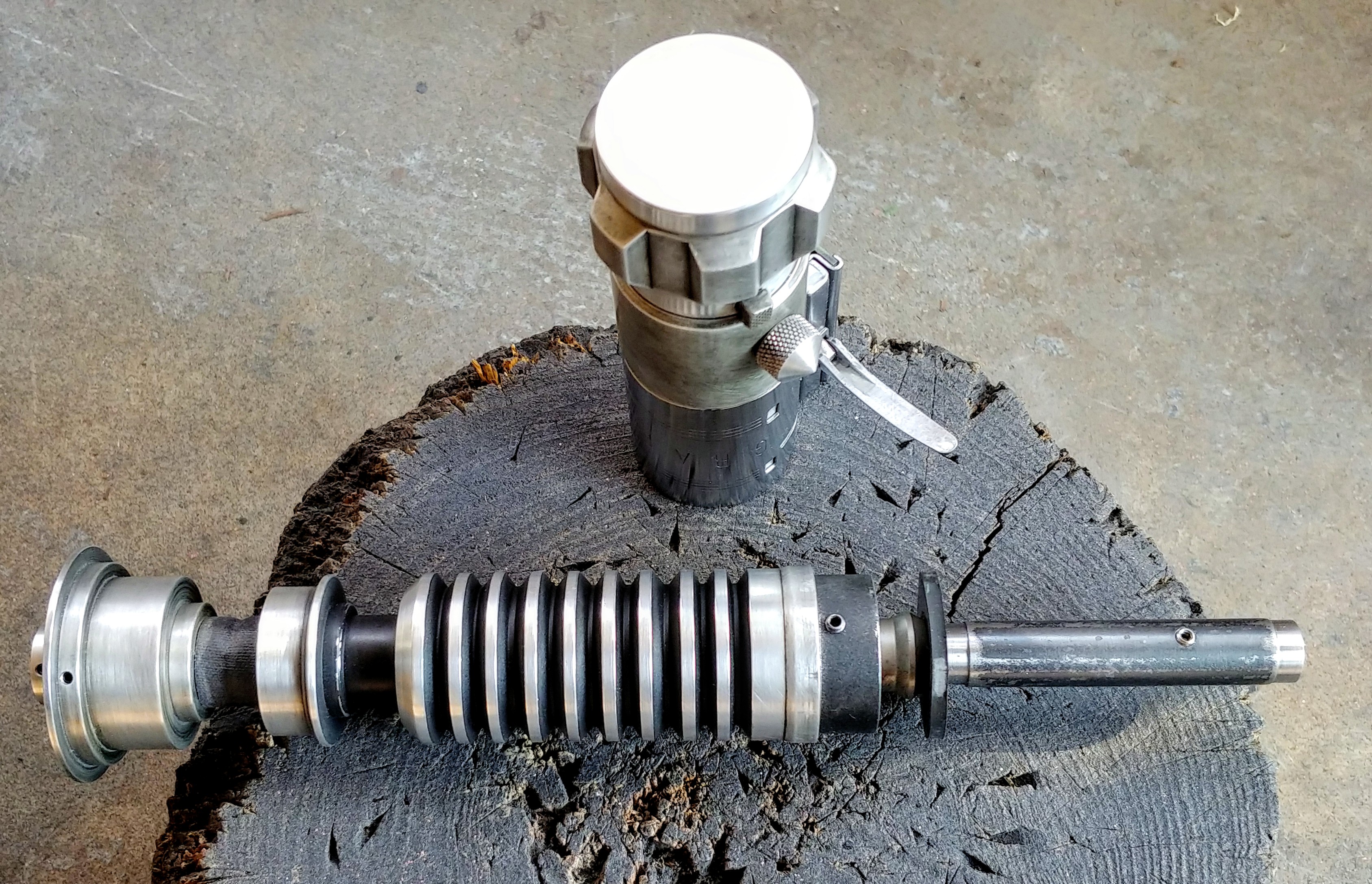

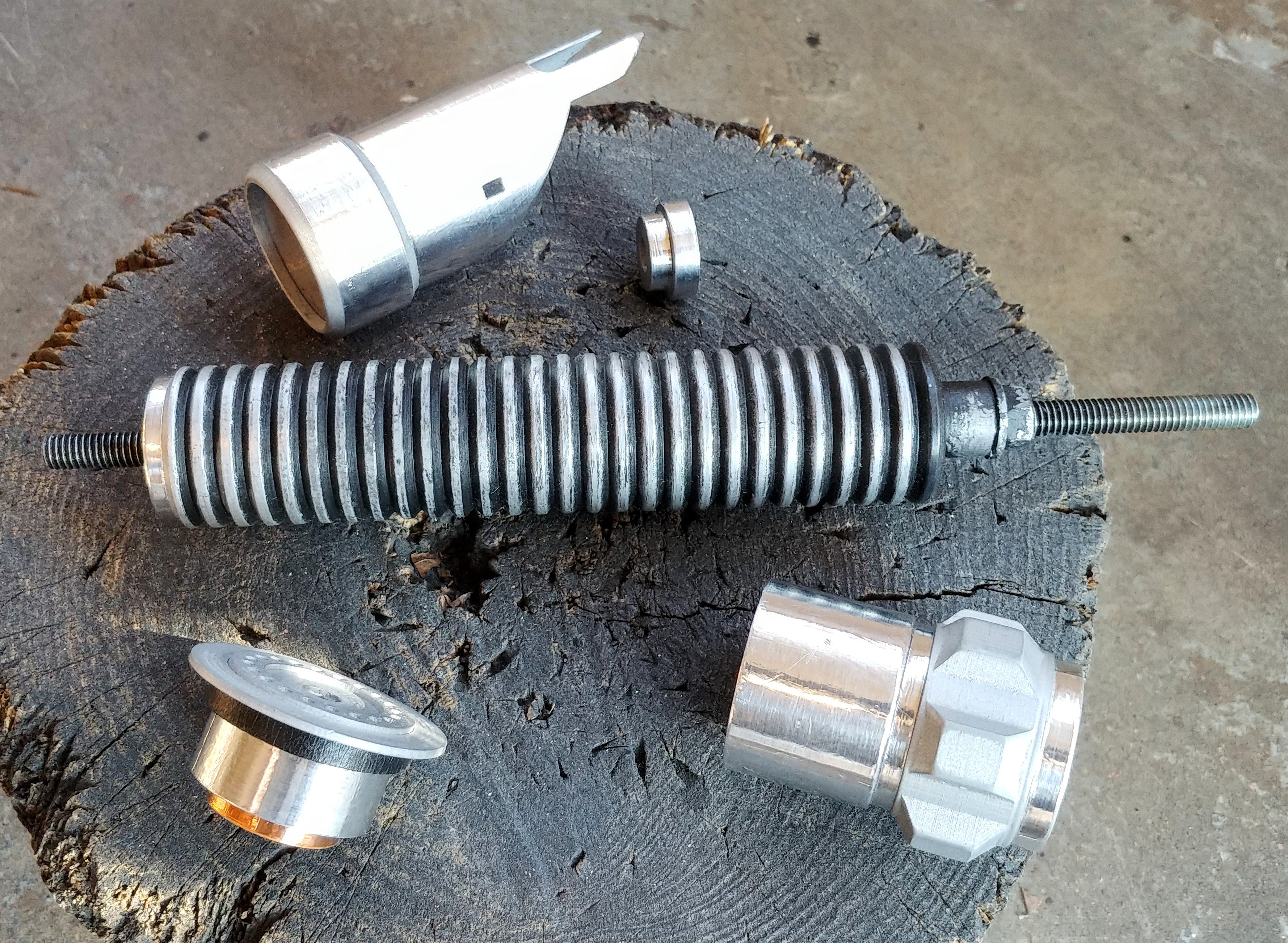

Here's a couple "picture-takin'-stump" pics of where I'm at with the builder's kit.

I think the only other thing I've done is stamp that circle.

I've got it rigged up with random heavy things with "close enough" to 5/16" thru-holes, then I drilled out a length of steel rod on the lathe (haven't drilled a long hole through steel round bar in years, probably not since the last machine shop I worked at like twelve years ago, so THAT was fun), and drilled and tapped it for a set screw, to lock all the weights in. There's a couple rubber washers in there to keep the rattling to a minimum.

This was the rig I used to stamp the circle in the pommel. Ball Pein (or Peen) or machinists' hammers are MUCH better for beating metal than claw hammers, but I suppose not as great as blacksmith hammers. Still, give me a ball pein over a claw any day!! And some soft jaws are a must! I just make them from angle aluminum (I've thankfully got bumloads of scrap), nothing fancy. And don't forget a little wood on the underside to protect the pommel!

Oh, and here's an Obi-Wan Apprentice hilt I've been working on. Modeled it in Tinkercad, just playing around with it a little. I've printed a slightly different grip core with the rings spread out a bit more, but haven't got any pics yet. Haven't even cleaned it up on the lathe, yet. Anyway, I miss Stormpath, he did some great work. I based this model on pics I could find around the net of his, and a crappy pic of the book cover. It's A REALLY quick and dirty paint/finishing job, nothing final! Like I say, just playing around, I like to get a better idea of how a thing will look by doing "preliminary" (crap-fast) painting and finishing.

I think the only other thing I've done is stamp that circle.

I've got it rigged up with random heavy things with "close enough" to 5/16" thru-holes, then I drilled out a length of steel rod on the lathe (haven't drilled a long hole through steel round bar in years, probably not since the last machine shop I worked at like twelve years ago, so THAT was fun), and drilled and tapped it for a set screw, to lock all the weights in. There's a couple rubber washers in there to keep the rattling to a minimum.

This was the rig I used to stamp the circle in the pommel. Ball Pein (or Peen) or machinists' hammers are MUCH better for beating metal than claw hammers, but I suppose not as great as blacksmith hammers. Still, give me a ball pein over a claw any day!! And some soft jaws are a must! I just make them from angle aluminum (I've thankfully got bumloads of scrap), nothing fancy. And don't forget a little wood on the underside to protect the pommel!

Oh, and here's an Obi-Wan Apprentice hilt I've been working on. Modeled it in Tinkercad, just playing around with it a little. I've printed a slightly different grip core with the rings spread out a bit more, but haven't got any pics yet. Haven't even cleaned it up on the lathe, yet. Anyway, I miss Stormpath, he did some great work. I based this model on pics I could find around the net of his, and a crappy pic of the book cover. It's A REALLY quick and dirty paint/finishing job, nothing final! Like I say, just playing around, I like to get a better idea of how a thing will look by doing "preliminary" (crap-fast) painting and finishing.

Last edited:

Thanks buddy!

Yeah, the checkering on the chunk is just rotated 45 degrees. I actually offered to do that for anyone who wanted it, but nobody requested it.

I did one up for myself to see how it'd look, and I like it!

And yeah, the steel is just for weight. There are a few other heavy parts further up that you can't see. It's about as heavy as the unibody, now. Like as if it were solid aluminum.

Yeah, the checkering on the chunk is just rotated 45 degrees. I actually offered to do that for anyone who wanted it, but nobody requested it.

I did one up for myself to see how it'd look, and I like it!

And yeah, the steel is just for weight. There are a few other heavy parts further up that you can't see. It's about as heavy as the unibody, now. Like as if it were solid aluminum.

jorged123

Well-Known Member

I think it's still a mystery, but perhaps the KR part might be the closest, if there's no checkering. I think Halliwax has almost all the V2 parts and chunks available as well as an opinion on the matter.

I ordered a threaded one from Dann for my V2. I think it had vertical/horizontal checkering with black patina in the grooves/outside.

I ordered a threaded one from Dann for my V2. I think it had vertical/horizontal checkering with black patina in the grooves/outside.

Well yeah, just chop it with an angle grinder or Dremel cutoff wheel (or a hacksaw), then bring it to the belt sander and rotate the end of the threads at an angle all the way around to dress it back up! Takes about a minute, unless you don't have a belt sander.

It's funny, I assumed this was common knowledge, but I guess it's just something that machinists do. I mean, it's so second nature, I don't even think about it. I shorten screws and bolts and such ALL the time! I don't know if I could live in a world where you MUST have the exact length screw/bolt for every possible situation!

I just shortened a couple grub screws on my V3 last night because I was adding a rod and weights to it, as well.

Or do you mean making the threading a smaller size? Like instead of 1/4-20, maybe 6-32 or something like that?

If that's the case, I'd need a four jaw chuck, or a jig to hold the square portion, in order to turn the threads down and run a die over them.

My little Sherline doesn't cut threads, which is annoying as all hell. You have to buy the threading stuff separate. I always figured I'd upgrade to a larger lathe before that!

It's funny, I assumed this was common knowledge, but I guess it's just something that machinists do. I mean, it's so second nature, I don't even think about it. I shorten screws and bolts and such ALL the time! I don't know if I could live in a world where you MUST have the exact length screw/bolt for every possible situation!

I just shortened a couple grub screws on my V3 last night because I was adding a rod and weights to it, as well.

Or do you mean making the threading a smaller size? Like instead of 1/4-20, maybe 6-32 or something like that?

If that's the case, I'd need a four jaw chuck, or a jig to hold the square portion, in order to turn the threads down and run a die over them.

My little Sherline doesn't cut threads, which is annoying as all hell. You have to buy the threading stuff separate. I always figured I'd upgrade to a larger lathe before that!

Last edited:

jorged123

Well-Known Member

I bet that's the idea since his tutorials used metric size drills. I think the hole he spec'd was smaller than 1/4"-20 at 4.2 mm. 1/4" is about 6.35mm.Or do you mean making the threading a smaller size? Like instead of 1/4-20, maybe 6-32 or something like that?

Have you got a 4 jaw chuck?

No, I would rig it up in my drill chuck and put that in my lathe

Similar threads

Done / Completed

V3 Emitter Limited Run Thread for V2/V3 Builder’s Kit

- Replies

- 180

- Views

- 16,939

- Replies

- 39

- Views

- 12,009

- Replies

- 94

- Views

- 17,148

- Replies

- 210

- Views

- 30,154