You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Elstree Studio documentary with discarded Graflex.

- Thread starter Skelatorious

- Start date

Sorry I didn't make my 70's welding ref clear. I was just pointing out that mig/tig was not readily available then & that stick welding (aka MMA) would not have been delicate enough (as you pointed out) but gas welding was a mainstay for this gauge of material. I didn't mean that I thought this joint is a weld.

It's Not welded it's Brased (aka 'brazed'). Brass soldered, melted brass not lead. You need oxy-acetylene, oxy-propane or oxy-MAP gas equipment to be able to get enough heat to melt the brasing rod (red heat). Flux (& goggles) is also needed.

Oxy-Acetylene is what I was referring to when I said that the deformation could've come from heating the flash for "welding" that washer to it.

I've taken time off from working in movies to take welding courses, and the first thing we learned was OAW (Oxy-Acetylene Welding). So that's what I pictured in my head, someone with a welding torch, perhaps not knowing the flash is plated brass, using too much heat to try to weld that washer in place.

Oxy-Acetylene is what I was referring to when I said that the deformation could've come from heating the flash for "welding" that washer to it.

I've taken time off from working in movies to take welding courses, and the first thing we learned was OAW (Oxy-Acetylene Welding). So that's what I pictured in my head, someone with a welding torch, perhaps not knowing the flash is plated brass, using too much heat to try to weld that washer in place.

That's what I thought as well. The first time I worked on a cracked some 20 odd years ago, I thought I was working with stainless steel

Mouse Vader

Sr Member

From my experience of brazing all sorts of types of metal in varying thicknesses & on this scale this joint was made by some who knows how to braze, it's neatly done & not overheated - you do have to get both parts to be joined to a good red heat.

1st time I saw this hilt (in the video) I too thought, that's heat damage. The deformation is definitely mechanical, & deliberate.

1st time I saw this hilt (in the video) I too thought, that's heat damage. The deformation is definitely mechanical, & deliberate.

AnubisGuard

Master Member

Y'all know how I feel about Roger Christian. Totally untrustworthy. I don't think I could believe anything that comes out of his mouth regarding these props, not anymore.

I don’t believe a single thing Christian says anymore.

I just learned that production designer Roger Christian is the same Roger Christian who directed Battlefield Earth.

I feel like this explains some things, although which things exactly are up for debate...

AnubisGuard

Master Member

I know, right? I was re-reading Roger Ebert's excellent review when he name-dropped the director. I thought there was no way, so I ran off to Wikipedia to check, and sure enough!

Having any connection to that train wreck seriously damages your movie street cred as it is. To have been in charge of it and made those decisions...man.

Having any connection to that train wreck seriously damages your movie street cred as it is. To have been in charge of it and made those decisions...man.

CHalcyon82

New Member

In his defense, you can blame that film more on Travolta and Scientology than anything. They were the real puppet masters.

Shingouki28

Sr Member

Wouldn't we all keep that sorta thing quiet?I didn’t know Christian did that film

AnubisGuard

Master Member

Wouldn't we all keep that sorta thing quiet?

"I'm beloved for my contributions to Star Wars and Alien. I'll make it big as a science fiction film director!"

[one box office bomb later]

"I'm beloved for my contributions to Star Wars and Alien. Maybe those rubes will buy some fakes."

JunkSabers1138

Sr Member

I just learned that production designer Roger Christian is the same Roger Christian who directed Battlefield Earth.

I feel like this explains some things, although which things exactly are up for debate...

Oh?

Hi all,

I finally had some time to do my perspective matching and reverse engineering tricks with the Elstree saber information.

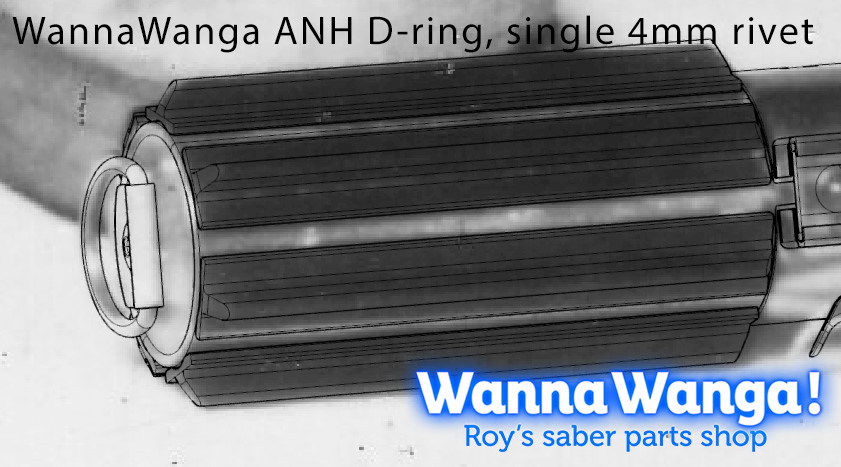

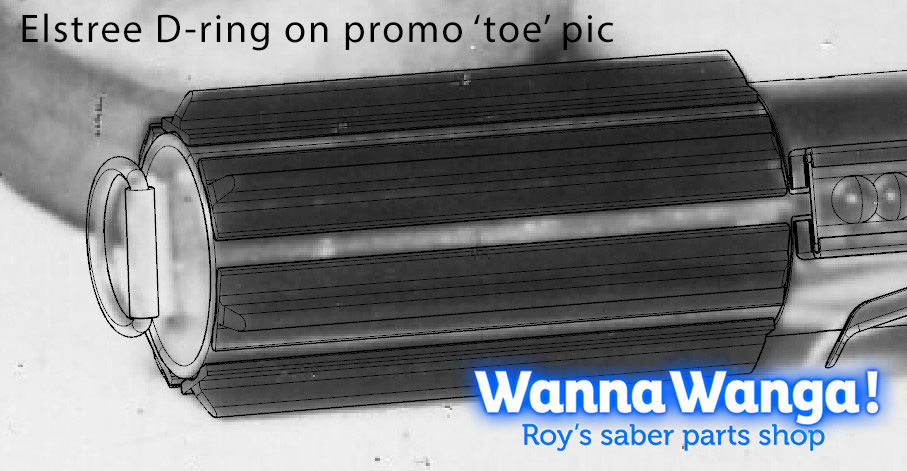

First, I checked my current ANH D-ring and clip on the old promo pictures. They still seem to be matching nicely!

Then I created the Elstree saber D-ring in CAD. I found out that it's the EXACT SAME SIZE RING as on the hero prop.

So my current D-ring matches perfectly (I mean the ring itself).

The rivet heads are 6.0mm diameter (the same as my 3mm rivets).

Then I tried to match this Elstree D-ring and bracket combo on the promo pics. As predicted: no match.

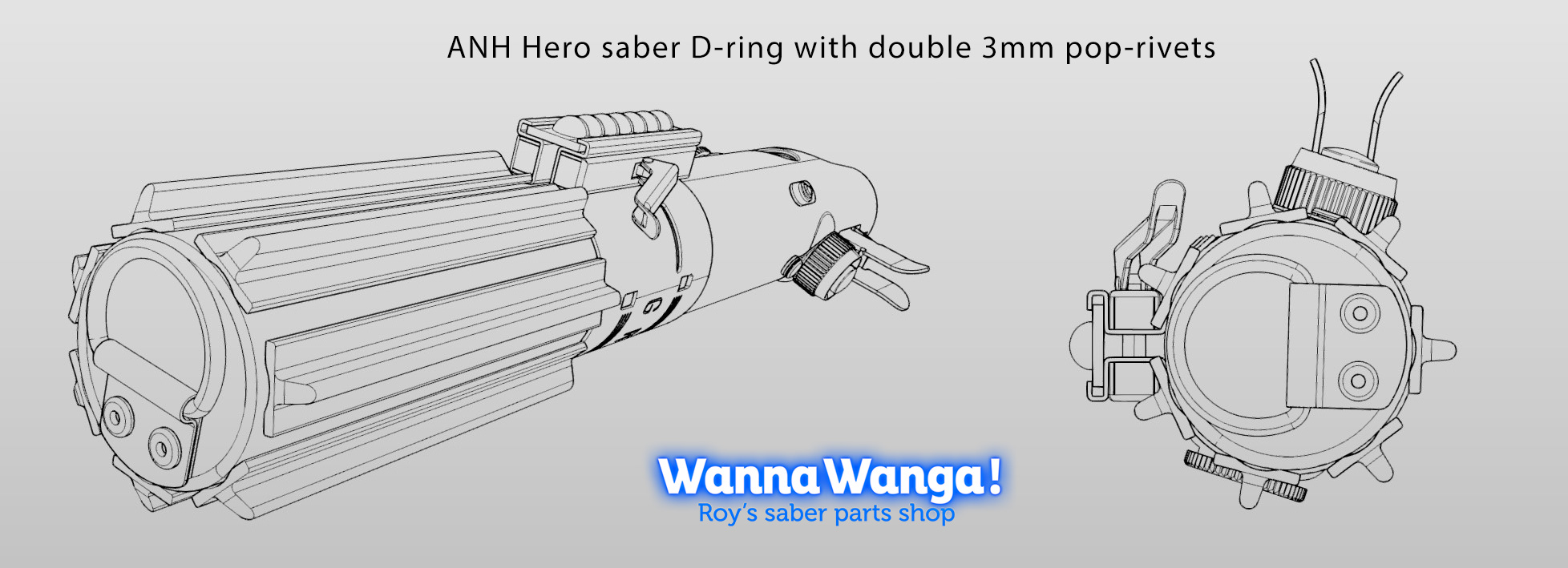

Then I tried a mix between the two brackets: a longer bracket with two 3mm pop-rivets.

So, my conclusions are:

What do you guys think?

Cheers,

Roy

I finally had some time to do my perspective matching and reverse engineering tricks with the Elstree saber information.

First, I checked my current ANH D-ring and clip on the old promo pictures. They still seem to be matching nicely!

Then I created the Elstree saber D-ring in CAD. I found out that it's the EXACT SAME SIZE RING as on the hero prop.

So my current D-ring matches perfectly (I mean the ring itself).

The rivet heads are 6.0mm diameter (the same as my 3mm rivets).

Then I tried to match this Elstree D-ring and bracket combo on the promo pics. As predicted: no match.

Then I tried a mix between the two brackets: a longer bracket with two 3mm pop-rivets.

So, my conclusions are:

- the hero belt-hanger had a longer bracket than the Elstree saber (we knew that already!)

- my D-ring size is spot on!

- my current bracket (or clip) is very close, but could be little shorter (the ring is inside the Graflex diameter)

- a double rivet assembly is very probable. The toe-pic MIGHT show the gloss of two rivet heads. With the Elstree as a reference I think it's VERY likely.

What do you guys think?

Cheers,

Roy

Last edited:

AnubisGuard

Master Member

I am now thinking of changing my ANH clips to a double rivet version. And in aluminium.

Yes to double rivets, no to aluminum. Or at least I'd prefer a non-aluminum option, if possible. Raw aluminum just seems a little tacky.

Yes !!!id be in for a new d ring bracket.

Is there a possibility that the d ring bracket is just attached nor toward the center instead of being longer?

Similar threads

- Replies

- 5

- Views

- 1,613

- Replies

- 77

- Views

- 7,327

- Replies

- 25

- Views

- 4,615

- Replies

- 12

- Views

- 5,064

- Replies

- 210

- Views

- 23,510