SentencedToBurn

Active Member

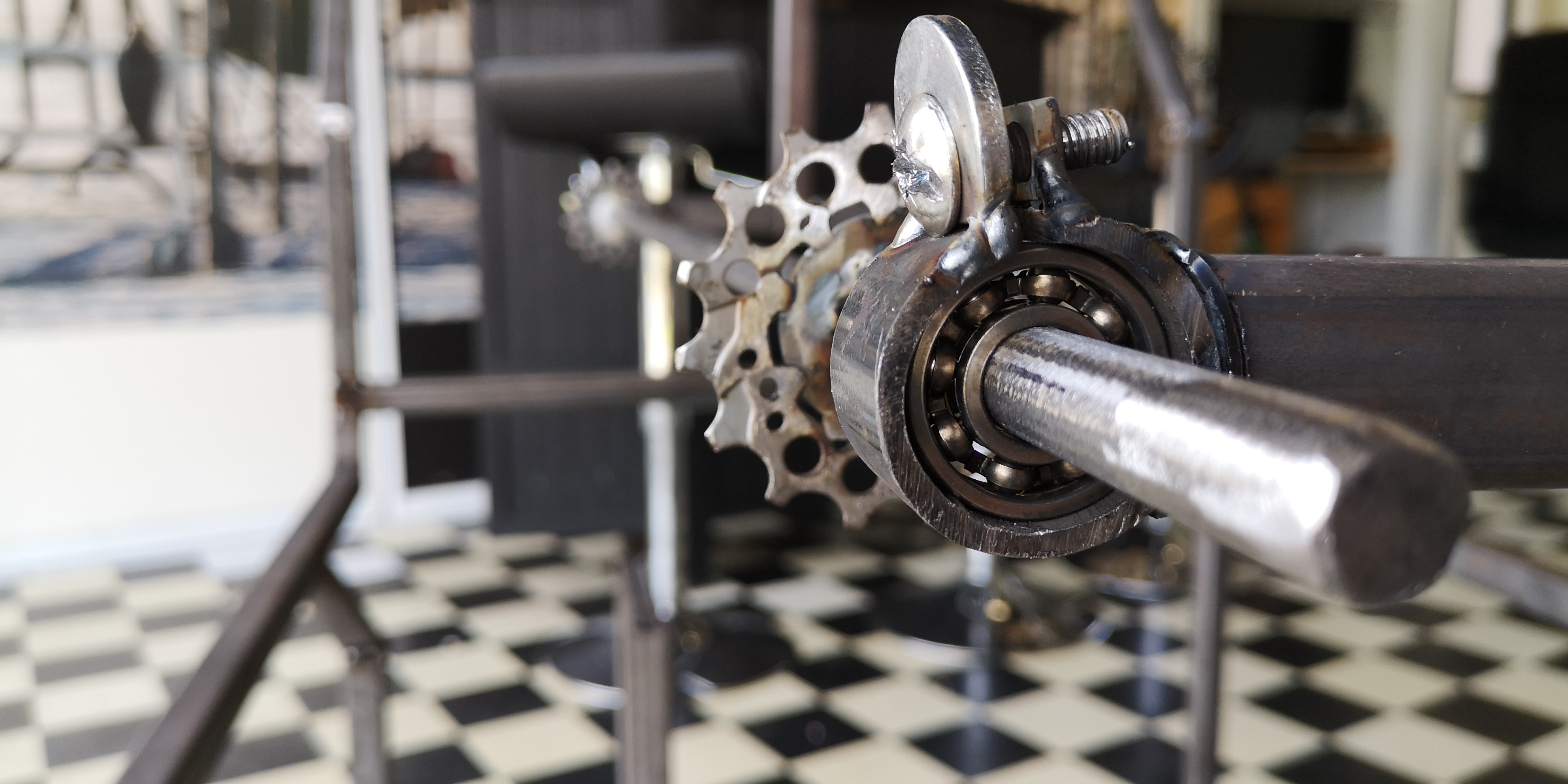

Decided to redo the bearing mounts. The original ones were a bit too flimsy, and tightening the bolt stopped them spinning so they need to be clamped from all sides to be held in properly.

Used a 3mm thick pipe with ID that was about 1mm less than the OD of the bearing, cut a slot in it and welded a square M6 nut and a filed down washer. Seems to be strong as, is adjustable so I can lock the bearing in there and it still spins through great.

Will be redoing all of the bearing mounts like this in the next couple of days. Takes a bit longer but it'll be worth it when I need to keep the chain tight and I can be confident nothing will pop out.

Used a 3mm thick pipe with ID that was about 1mm less than the OD of the bearing, cut a slot in it and welded a square M6 nut and a filed down washer. Seems to be strong as, is adjustable so I can lock the bearing in there and it still spins through great.

Will be redoing all of the bearing mounts like this in the next couple of days. Takes a bit longer but it'll be worth it when I need to keep the chain tight and I can be confident nothing will pop out.