SentencedToBurn

Active Member

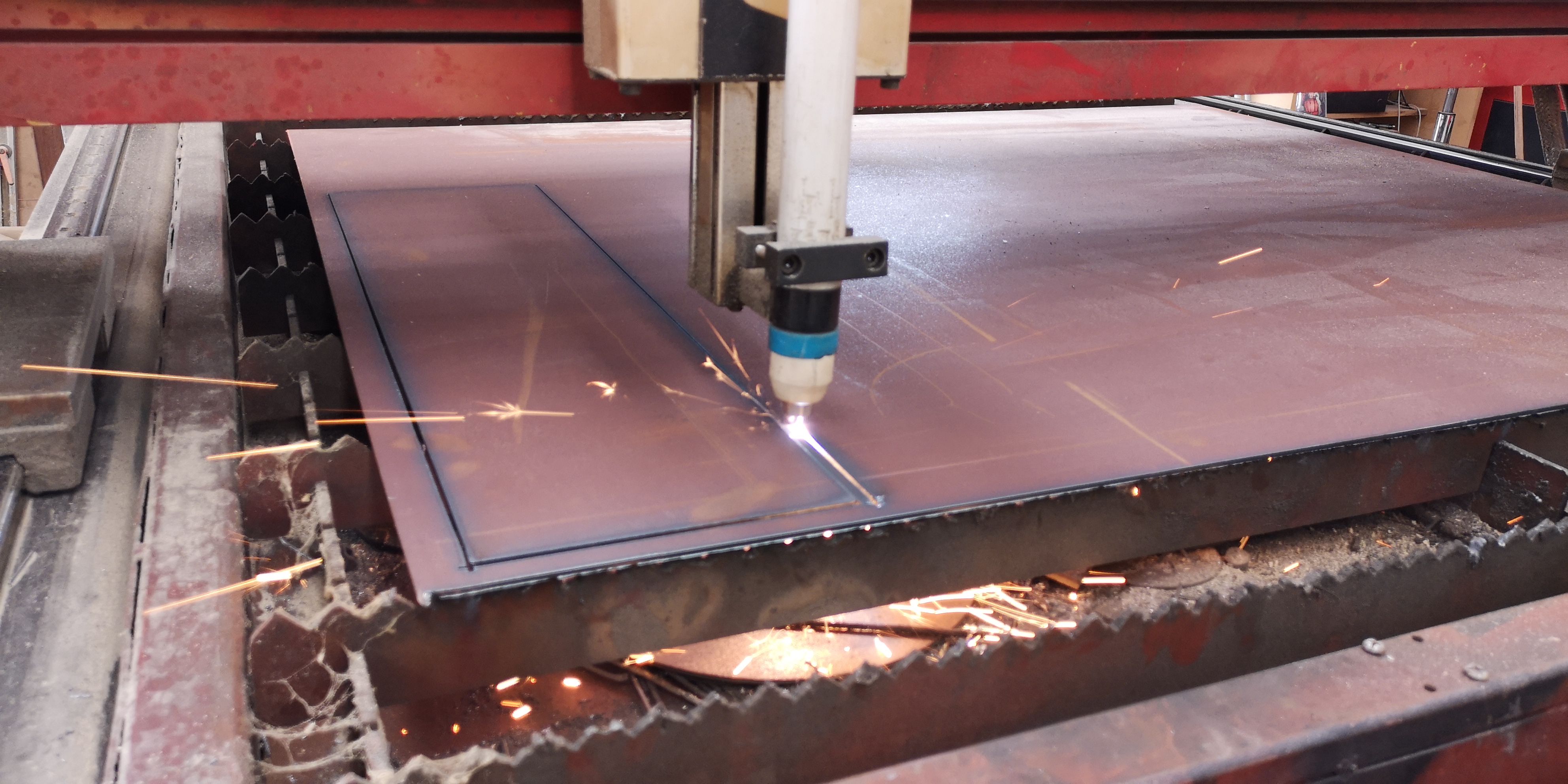

Started on the shelves today. I stopped off at my mate's workshop and got the plates cut out of a 2.5mm sheet. The plates are 670x177mm and ended up weighing at 2.3kgs each so even 10 of these definitely gonna put some load on the machine. we'll see how it takes them.

We only had a limited amount of time with the laser cutter so just did rectangles, and I'll be cleaning them up and chopping them up at home.

I got the first 5 cleaned up and cut the corners to size this morning:

The next step is to work out how to keep one side insulated. I have a pretty good idea on how to do that, while also utilising a couple of bolts/rivets that are shown ingame:

We only had a limited amount of time with the laser cutter so just did rectangles, and I'll be cleaning them up and chopping them up at home.

I got the first 5 cleaned up and cut the corners to size this morning:

The next step is to work out how to keep one side insulated. I have a pretty good idea on how to do that, while also utilising a couple of bolts/rivets that are shown ingame: