Great parts, thanks Vince!

-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Done / Completed Greedo Blaster DT-12 Machined Aluminum Parts

- Thread starter Corellianexports

- Start date

I'm glad you like them.Great parts, thanks Vince!

I have updated the waiting lists.

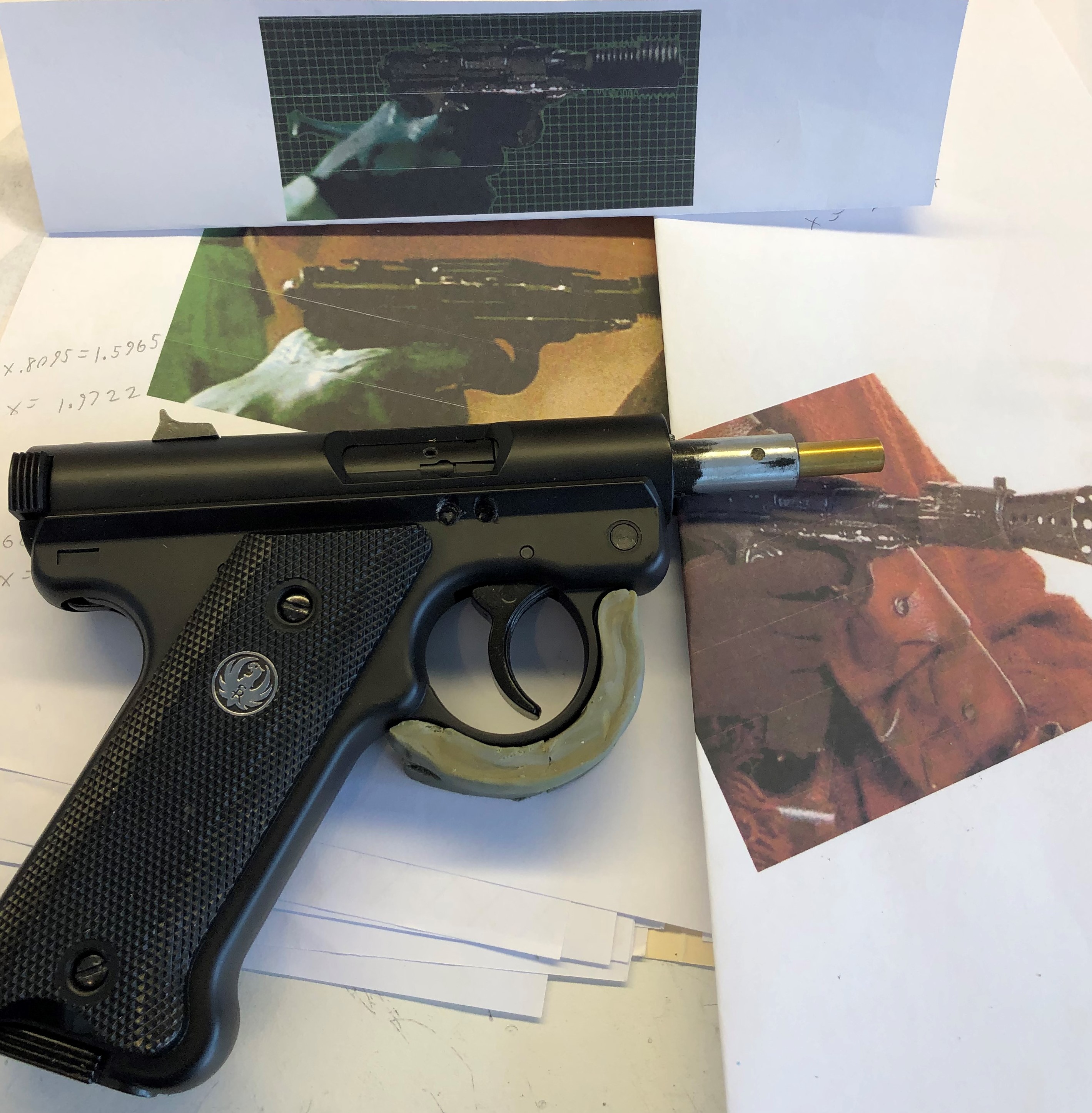

I'm taking measurements on the thickness of the trigger guard and I'm hoping to get some feedback before I start ordering material.

After scaling up one of the reference photos, I'm coming up with a fairly thick trigger guard:

I thought that maybe it looked thicker at an angle, but it's actually the same size when measured at an angle. Any thoughts or does this look correct?

Also, my first thought is to use some thick aluminum tubing to create an exact radius to make a part similar to the clay example above. If I do this, the aluminum will need to be blended in with the existing trigger guard. JB Weld would probably do it.

An alternate method would be to machine a straight piece of aluminum that would either fit the trigger guard with a small seam or completely cover the trigger guard, then bent to a radius. Now if I bend the part, it won't be an exact radius because I don't have a large rolling machine.

What would be the preference?

After scaling up one of the reference photos, I'm coming up with a fairly thick trigger guard:

I thought that maybe it looked thicker at an angle, but it's actually the same size when measured at an angle. Any thoughts or does this look correct?

Also, my first thought is to use some thick aluminum tubing to create an exact radius to make a part similar to the clay example above. If I do this, the aluminum will need to be blended in with the existing trigger guard. JB Weld would probably do it.

An alternate method would be to machine a straight piece of aluminum that would either fit the trigger guard with a small seam or completely cover the trigger guard, then bent to a radius. Now if I bend the part, it won't be an exact radius because I don't have a large rolling machine.

What would be the preference?

Mara Jade's Father

Master Member

How about a single machined piece that is made to slip over the existing guard. The existing guard would set in a recessed track of this add-on piece. This way there would be no seam from the side, it would only be seen from looking down And at the ends at the top and bottom. Someone could easily fill the seams if they wanted. The thickness would only be a milli or two wider the the actual trigger guard. Just enough for part to overlap.

Last edited:

View attachment 1324504

How about a single machined piece that is made to slip over the existing guard. The existing guard would set in a recessed track of this add-on piece. This way there would be no seam from the side, it would only be seen from looking down And at the ends at the top and bottom. Someone could easily fill the seams if they wanted. The thickness would only be a milli or two wider the the actual trigger guard. Just enough for part to overlap.

I was originally thinking that making a part that would slip over the existing guard would make the area too wide, but it may be possible to machine an indentation very close to the edge within some round stock aluminum. It's a real challenge machining an inner groove like that. A lot like taking a donut and turning it into a tire.

Something I've never attempted to do before, but it's possible. Thanks for the feedback, Frank.

Very, very similar. Check it out:how close are real Rugers and the airsoft profiles of the trigger guard?

Mara Jade's Father

Master Member

I was originally thinking that making a part that would slip over the existing guard would make the area too wide,

I think that because we don’t get really good images or the thickness from the front, you can cheat with a couple extra millimeters. Let’s face it, if you are building a replica and keeping the trigger and the original trigger guard, then you are really making this an idealized replica. The real prop lacked a trigger like the DH-17 in A New Hope. Also, I’m willing to bet that on the real prop, when they made the trigger guard, it was a total replacement. I think it was totally removed from a cast of a Rugers and moved outward in order to give more space for the Greedo costumed finger.

That's a good point. My first thought when I saw it was that the trigger was thickened with clay and then molded so the resin copy would be more sturdy. I hadn't considered the costumed glove. Thanks again for all the feedback.

As for machining the part, I did some research on aluminum tubing and I have a couple of ideas for two different machined prototypes (possibly a budget version and a high end version), so we'll see how they turn out. The good news is that this is a relatively small part, so it shouldn't be too difficult to machined.

As for machining the part, I did some research on aluminum tubing and I have a couple of ideas for two different machined prototypes (possibly a budget version and a high end version), so we'll see how they turn out. The good news is that this is a relatively small part, so it shouldn't be too difficult to machined.

Last edited:

Mara Jade's Father

Master Member

My only concerns about using a tubing is that you cannot create ends that flair out to follow the natural shape of the trigger guard.

If you are trying to avoid a machined item, it seems like sculpting a piece that would fit the existing trigger guard and then used the sculpted piece to make a mold or create a 3D model for 3D printing. That seems like it would be much more of a budget piece.

If you are trying to avoid a machined item, it seems like sculpting a piece that would fit the existing trigger guard and then used the sculpted piece to make a mold or create a 3D model for 3D printing. That seems like it would be much more of a budget piece.

That's my concern as well and it is staring to look as if a tube may not work at all. Machining the part from a solid piece of aluminum

or bending the aluminum are two possibilities.

If I were to mold the part in resin, we'd only be looking at a part that would run about $5 to $10 each.

or bending the aluminum are two possibilities.

If I were to mold the part in resin, we'd only be looking at a part that would run about $5 to $10 each.

Clutch

Master Member

I think it was totally removed from a cast of a Rugers and moved outward in order to give more space for the Greedo costumed finger.

The rebel blaster castings and the stormtrooper pistol shared the same fattened trigger guard so I don't think it was just for Greedo's finger.

Mara Jade's Father

Master Member

The rebel blaster castings and the stormtrooper pistol shared the same fattened trigger guard so I don't think it was just for Greedo's finger.

I honestly think the main reason for the thick rebuilt guards on both those props os because they made they either had problem and/or concerns about the thinner guards casting well. I believe these weapons were made by first casting the real weapon, then taking that cast and removing, modifying, and adding parts, to then cast it to create a master mold, and then the resulting casts from that mold had final greeblies added for the final on-screen prop.

My real point was that I think the guard of the original weapon was removed from a cast of a Ruger and that there is no reason to assume that the prop makers felt obligated to follow the shape, size, and even location of the original guard.

I think if two molds were made, that might explain why the final props appear to be warped, broken, etc. Interesting stuff.

So here's some progress photos of the first prototype trigger guard so far:

The fit is close to perfect, which surprises me since the barrel and bolts are all metric. I used basic inches to measure the trigger guard.

I'm keeping my fingers crossed that the piece bends fairly easily. The next step is to machine a rod to be used for bending the part around.

So here's some progress photos of the first prototype trigger guard so far:

The fit is close to perfect, which surprises me since the barrel and bolts are all metric. I used basic inches to measure the trigger guard.

I'm keeping my fingers crossed that the piece bends fairly easily. The next step is to machine a rod to be used for bending the part around.

I tried bending the part, but unfortunately it's going to take a sledge hammer and possible an large anvil to bend it,

so I'm going to scratch prototype 1 off the list and move on to prototype 2:

Machining a finished part out of a single piece of aluminum.

so I'm going to scratch prototype 1 off the list and move on to prototype 2:

Machining a finished part out of a single piece of aluminum.

I've made the necessary adjustments, along with a very slight curl near the top, but looking at the reference photos, it doesn't look like it's enough. I've marked the area in black:

It's a tough call looking at the screen cap. Looking at the Jawa photo it does appear to be deeper, cutting into the width of the radius.

Here's a high resolution scan from the Chronicles book:

I'm going to take the rest of the night off and take a fresh look at it tomorrow, but I'm thinking that the curl needs to be a bit deeper.

It's a tough call looking at the screen cap. Looking at the Jawa photo it does appear to be deeper, cutting into the width of the radius.

Here's a high resolution scan from the Chronicles book:

I'm going to take the rest of the night off and take a fresh look at it tomorrow, but I'm thinking that the curl needs to be a bit deeper.

Mara Jade's Father

Master Member

I think with the black area removed, you will have it. I know I’d be happy with it.

Similar threads

Done / Completed

TEMPLE DART from Raiders, Chachapoya / Hovitos

- Replies

- 88

- Views

- 7,759

Limited Run

Mynock Cave Dagobah Oxygen Tank

- Replies

- 64

- Views

- 6,064

- Replies

- 53

- Views

- 7,827

Done / Completed

Obi-Wan Kenobi Episode 1 TPM Resin Cast Stunt Lightsaber

- Replies

- 107

- Views

- 16,511

Done / Completed

NERF SCOUT TROOPER BLASTER Conversion Kit by Astyanax & AnubisGuard

- Replies

- 15

- Views

- 2,407