Awesome, thank you! I'll message you about shipping when they're closer to finished. Right now I'm just focused on keeping things rolling down the line so I can deliver as quickly as possibleAdd me... I'll pay right now.

Deposit sent. If you'll let me know the total with shipping I can pay in full. Thanks!

-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Limited Run Dredd Lawgiver 2012 Full Electronics and Action

- Thread starter Props3D

- Start date

Looks like I'm reprinting all the front and rear sights, but I think it's well worth it:

I'll measure progress in frames completed:

The stronger engineering PLAs are a real PITA to remove support material from and sand so I'm just going slow and steady. If I ever have a fail or sub-standard I may do a short vid hammering a nail in with one to show just how good this new PLA is...or if they all work out I may just print a hammer for fun, we'll see. Though these are mostly only frames in the pic, I'm printing them in complete sets. Laying out that many parts would have been a little crazy.

I'm working in sets of two, I may mail them out in sets of 2 or sets of 4, but no more than 4 complete before mailing for sure. With BeakZ and Spidey74 doing their parts, this should fly once the initial work is done.

Status:

2 - Sanded, fitted, tapped. Ready for first primer coat and then second detail sand

2 - Support material removed, in sanding

3 - Printed and ready for support material to be removed

more printing as we speak...

I'll measure progress in frames completed:

The stronger engineering PLAs are a real PITA to remove support material from and sand so I'm just going slow and steady. If I ever have a fail or sub-standard I may do a short vid hammering a nail in with one to show just how good this new PLA is...or if they all work out I may just print a hammer for fun, we'll see. Though these are mostly only frames in the pic, I'm printing them in complete sets. Laying out that many parts would have been a little crazy.

I'm working in sets of two, I may mail them out in sets of 2 or sets of 4, but no more than 4 complete before mailing for sure. With BeakZ and Spidey74 doing their parts, this should fly once the initial work is done.

Status:

2 - Sanded, fitted, tapped. Ready for first primer coat and then second detail sand

2 - Support material removed, in sanding

3 - Printed and ready for support material to be removed

more printing as we speak...

I’m new to this site but saw your post on FB Dredd group.I’d like to snag that last spot.

Added you to the list! Spot just opened a few hours ago, still sorting the early reserved list and the person moved to 'electronics only'.

There were 3 held from the build thread and I didn't expect them all to come through, I messaged everyone and there's now one open space. I don't think I'll do more of these after, it's really fun to do an initial run like this to celebrate the end of a long road but it's not something I plan on doing very often, there's a lot more cool models to design!I'm interested in one if you make more.

It's yours!if i can have the open one please let me know and i will send the deposit today.

Primus Palus

New Member

Any ability to change the LCD screen in the future so it says our name vs "Dredd" after the ID check?

Also would be amazing if each one had a unique serial number on the side plate.

Also would be amazing if each one had a unique serial number on the side plate.

I'm making everyone custom brass plates on the grip, will send DM about the text after all deposits are confirmed. It's custom engraving so I'd like to do it all in one go, it's a lot of work. I think it's a far more personal option and it really stands out.Any ability to change the LCD screen in the future so it says our name vs "Dredd" after the ID check?

Also would be amazing if each one had a unique serial number on the side plate.

I can customize the boot text for you, no probelm. There will be directions on how to do it in the video but I'll be happy to do it for you while I'm uploading the code, same goes for anyone else. Just know it's easy to swap later

Primus Palus ....uuurrrgggghhhh and you twisted my rubber arm.

The plates already already done, but if you want a custom serial I can remake it for you. DM me the number, same goes for everyone on the run. BUT I'll put a cap date of Aug 10th for custom serials, firm. I need to mail BeakZ and Spidey74 the resin parts by that date so they're not held up either. My big concern is scope creep delaying the run, I don't want to drag things out of respect for everyone here. But in this case I've been powering on it every day and I'm ahead of schedule, so let's do it!

This also leaves me with lots of extra resin parts, since I reprinted the front and rear sights as well as all the plates. So I might as well do more of the laser sights and anyone ordering the 'electronics only' option can have a full set of resin pieces included, I'll update the description.

The plates already already done, but if you want a custom serial I can remake it for you. DM me the number, same goes for everyone on the run. BUT I'll put a cap date of Aug 10th for custom serials, firm. I need to mail BeakZ and Spidey74 the resin parts by that date so they're not held up either. My big concern is scope creep delaying the run, I don't want to drag things out of respect for everyone here. But in this case I've been powering on it every day and I'm ahead of schedule, so let's do it!

This also leaves me with lots of extra resin parts, since I reprinted the front and rear sights as well as all the plates. So I might as well do more of the laser sights and anyone ordering the 'electronics only' option can have a full set of resin pieces included, I'll update the description.

Last edited:

Sent the deposit.Added you to the list! Spot just opened a few hours ago, still sorting the early reserved list and the person moved to 'electronics only'.

Electronics are almost all kitted and ready for solder, going to try and get at least 2 kits done tomorrow to pair with the 2 going into the paint process, it's a crazy amount of soldering but if it goes well I'll try and get 2 more done, still want to work in sets of 4 if possible:

One thing that's never been explicitly stated is the battery, there's a lot of regs in shipping these but after checking there shouldn't be an issue to most places, esp in North America. Just know if there is an issue to your address we can handle that on a case by case basis, esp if you're in the EU somewhere.

Oh, and no resin sights yet, they're all printed but I figured I'd go a bit more legit than usual on my airbrushing. I usually mix Tamiya paint: 45% paint, 30% Windex, 20% distilled water, 5% glycerin. But in this case I thought I would slap myself on the wrist and order the proper Tamiya thinner, which will take another day or two to arrive

Edit: Reminder, if you ordered and want a custom serial # let me know in the next 2 days! DMs sent but just in case you missed it! I'll be reaching out to you about the brass inlay in a few days, just finishing upgrading the Z axis on my CNC, adding a lead screw and a new mounting plate to eliminate wobble while engraving something so small.

One thing that's never been explicitly stated is the battery, there's a lot of regs in shipping these but after checking there shouldn't be an issue to most places, esp in North America. Just know if there is an issue to your address we can handle that on a case by case basis, esp if you're in the EU somewhere.

Oh, and no resin sights yet, they're all printed but I figured I'd go a bit more legit than usual on my airbrushing. I usually mix Tamiya paint: 45% paint, 30% Windex, 20% distilled water, 5% glycerin. But in this case I thought I would slap myself on the wrist and order the proper Tamiya thinner, which will take another day or two to arrive

Edit: Reminder, if you ordered and want a custom serial # let me know in the next 2 days! DMs sent but just in case you missed it! I'll be reaching out to you about the brass inlay in a few days, just finishing upgrading the Z axis on my CNC, adding a lead screw and a new mounting plate to eliminate wobble while engraving something so small.

Attachments

Last edited:

Amazing work! I’m late to the show, but would love to get on the waiting list if anyone drops or if more slots open, thanks!

My kids say my videos are too long and slow, thought I would practice today while etching the metal thank you cards for the lawgivers. It's also the first part of upgrading my CNC for cutting the brass inserts. The Z axis is still on belt drive, I just retrammed it and tested with these, which worked out really well! Almost makes me not want to take it apart over the weekend, but the box of upgrade parts is just too tempting to leave any longer..

Volume warning:

Knightmare This one is for you (Sorta, I remade it after. I scratched the paint marker wiping the aluminum dust off in an outtake)

And on this note the run is now feature locked and set at 16, super happy to be doing this run to celebrate finishing by far the most feature rich and technical model I've ever designed, but there's no way I'm doing this for a living, phew! Hand made is very different than factory made. Feels like the Flintstones meet the Jetsons where a 3D printer makes the parts then I spend days hand sanding and carving it to shape!

Colored filament to film the YouTube videos came, going to wait until I have 8 printed for the run before switching over so it doesn't hold things up. The natural filament does not show up on camera until the primer goes on. Going to print 2 of those and they'll end up as mine, unless anyone wants one of the ones used in the videos instead, in which case let me know and they're yours. I would recommend against it as the natural stuff has better properties, but if you want 'screen used' then who am I to argue

Volume warning:

Knightmare This one is for you (Sorta, I remade it after. I scratched the paint marker wiping the aluminum dust off in an outtake)

And on this note the run is now feature locked and set at 16, super happy to be doing this run to celebrate finishing by far the most feature rich and technical model I've ever designed, but there's no way I'm doing this for a living, phew! Hand made is very different than factory made. Feels like the Flintstones meet the Jetsons where a 3D printer makes the parts then I spend days hand sanding and carving it to shape!

Colored filament to film the YouTube videos came, going to wait until I have 8 printed for the run before switching over so it doesn't hold things up. The natural filament does not show up on camera until the primer goes on. Going to print 2 of those and they'll end up as mine, unless anyone wants one of the ones used in the videos instead, in which case let me know and they're yours. I would recommend against it as the natural stuff has better properties, but if you want 'screen used' then who am I to argue

Last edited:

Number 1? Yesssssss!My kids say my videos are too long and slow, thought I would practice today while etching the metal thank you cards for the lawgivers. It's also the first part of upgrading my CNC for cutting the brass inserts. The Z axis is still on belt drive, I just retrammed it and tested with these, which worked out really well! Almost makes me not want to take it apart over the weekend, but the box of upgrade parts is just too tempting to leave any longer..

Volume warning:

CNC Etching Aluminum Cards

Knightmare This one is for you (Sorta, I remade it after. I scratched the paint marker wiping the aluminum dust off in an outtake)

Question: In the past when I've shipped props, I've created custom packaging by CNC cutting clamshell inserts out of styrofoam. As awesome as this works, I'm looking for something more environmentally friendly. I'm rolling around CNC cutting cardstock to sort of an origami inset/box all in one, but even sketching this out makes my brain hurt. I've never seen it done so it does appeal from a nerdy perspective.

I don't just want to shove it in a box with crumpled newspaper, I have standards, but does anyone know of any good, environmentally friendly, and non-cranium imploding, options?

I don't just want to shove it in a box with crumpled newspaper, I have standards, but does anyone know of any good, environmentally friendly, and non-cranium imploding, options?

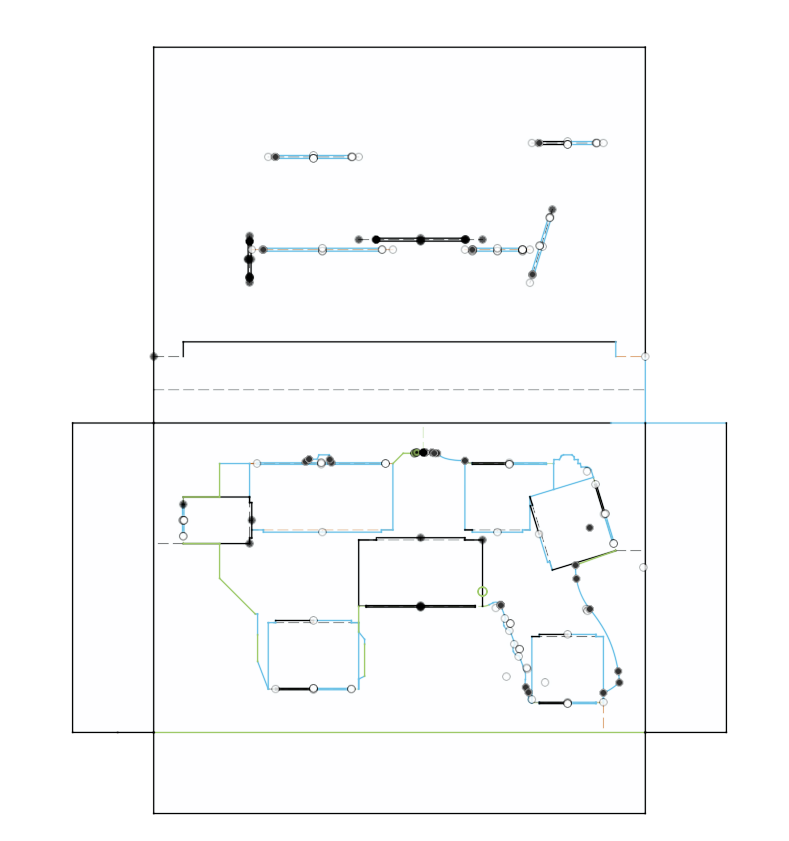

After an hour of noodling, and I'm still VERY open to ideas, I think I have an answer. I can buy unbleached cardstock and my CNC drag knife to cut a pattern like this (lots missing from this insert still):

This will create a foldable insert design that locks together, securing the lawgiver, and suspends 1 1CM at the bottom for a small foam insert. Then I can do the same for a box and add another 1cm insert on top. Secure box, looks great, minimal material, thoughts?

edit: to head off the 'it won't fit together' comments in advance, I know, I just gave myself 1hr to solve the problem, doesn't have to be perfect as long as the idea is captured

This will create a foldable insert design that locks together, securing the lawgiver, and suspends 1 1CM at the bottom for a small foam insert. Then I can do the same for a box and add another 1cm insert on top. Secure box, looks great, minimal material, thoughts?

edit: to head off the 'it won't fit together' comments in advance, I know, I just gave myself 1hr to solve the problem, doesn't have to be perfect as long as the idea is captured

Similar threads

- Replies

- 53

- Views

- 7,676

Limited Run

AEP-9 "Laser Pistol" (Fallout)

- Replies

- 15

- Views

- 1,770

- Replies

- 10

- Views

- 2,047