It makes my heart happy

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An ILM R2 Story

- Thread starter Duncanator

- Start date

Adam Savage likes to refer to his R2 as a "happiness machine".

It just makes you feel good looking at it

It just makes you feel good looking at it

DBoz

Sr Member

Adam Savage likes to refer to his R2 as a "happiness machine".

It just makes you feel good looking at it

That’s my standard response when people ask what he does. “He makes people smile.”

Another pic of my droid turning blue! That's the stern of the original Black Pearl behind him.

In the paper bucket in front of R2, you can see some of the aluminum parts that have waiting almost 20 years to be installed.

In the paper bucket in front of R2, you can see some of the aluminum parts that have waiting almost 20 years to be installed.

Last edited:

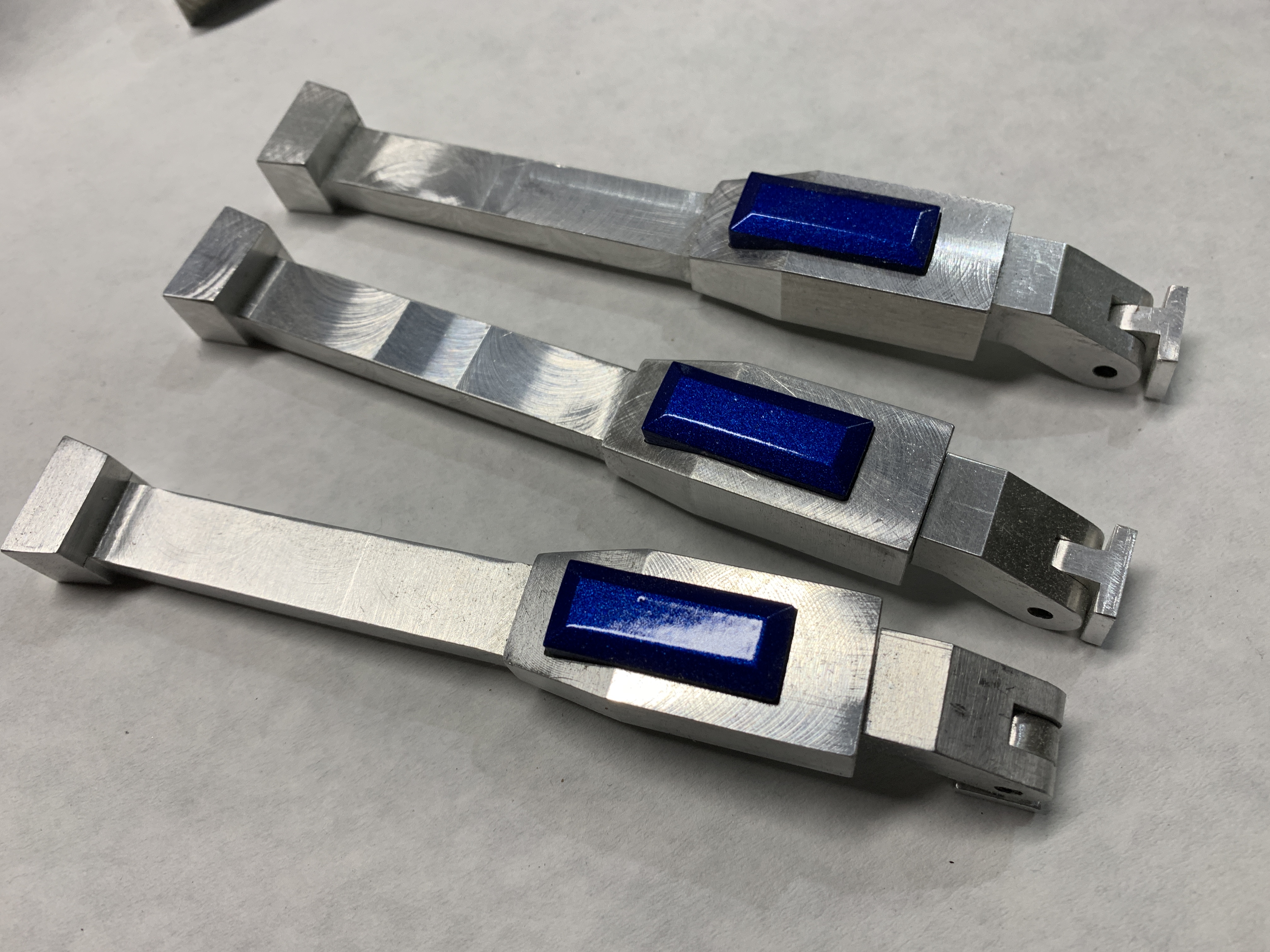

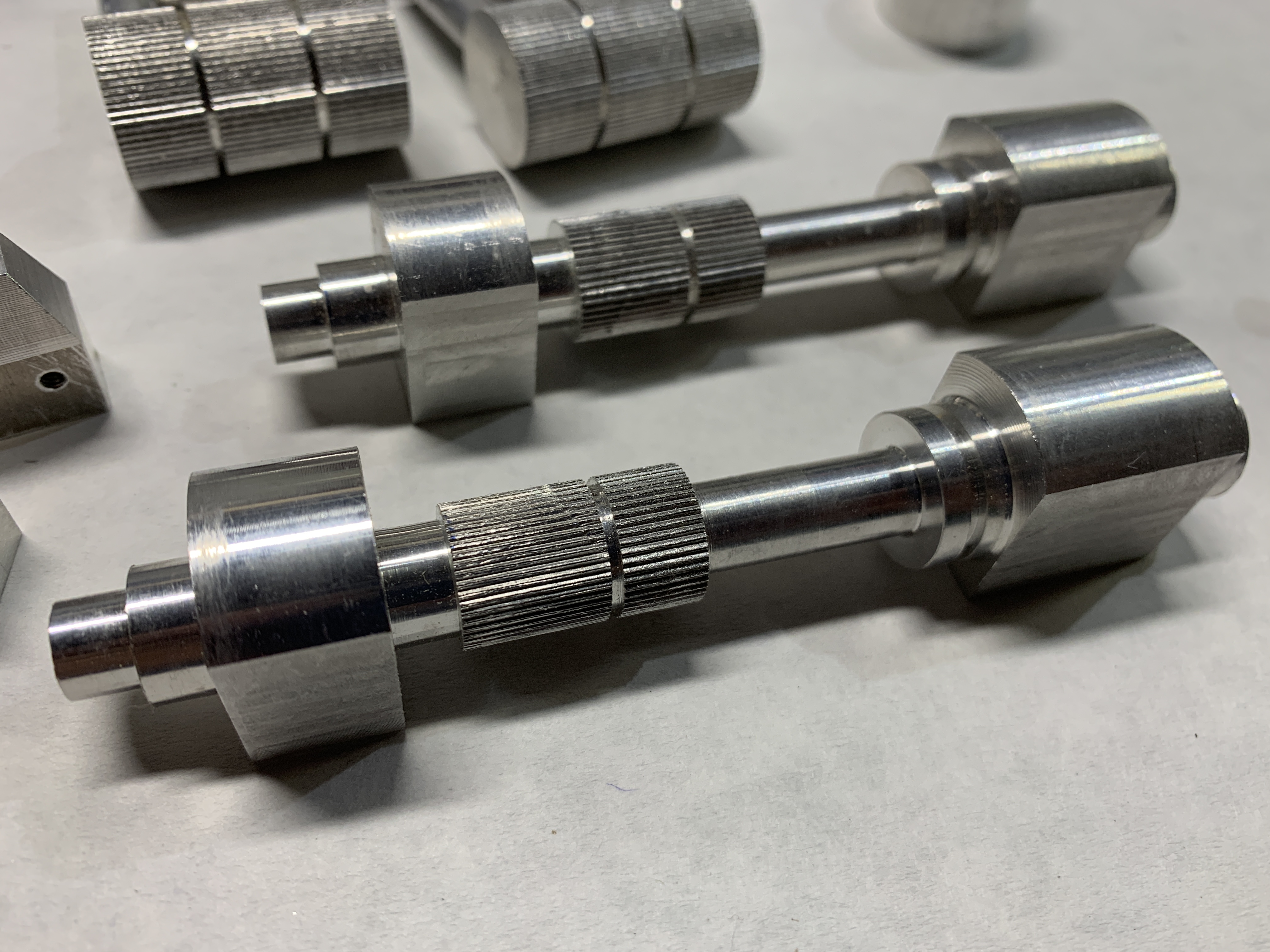

Even though my droid has a fiberglass body, I wanted as many of his shiny bits to be made of real aluminum. So back when I started these shenanigans 2 decades ago; and I still had access to the original parts, I machined all the metal parts for my R2.

Some of them were fairly straight-forward to mill or turn, but some presented more of a challenge.

.....Aaaaaaaand close-ups!!!!

Some of them were fairly straight-forward to mill or turn, but some presented more of a challenge.

.....Aaaaaaaand close-ups!!!!

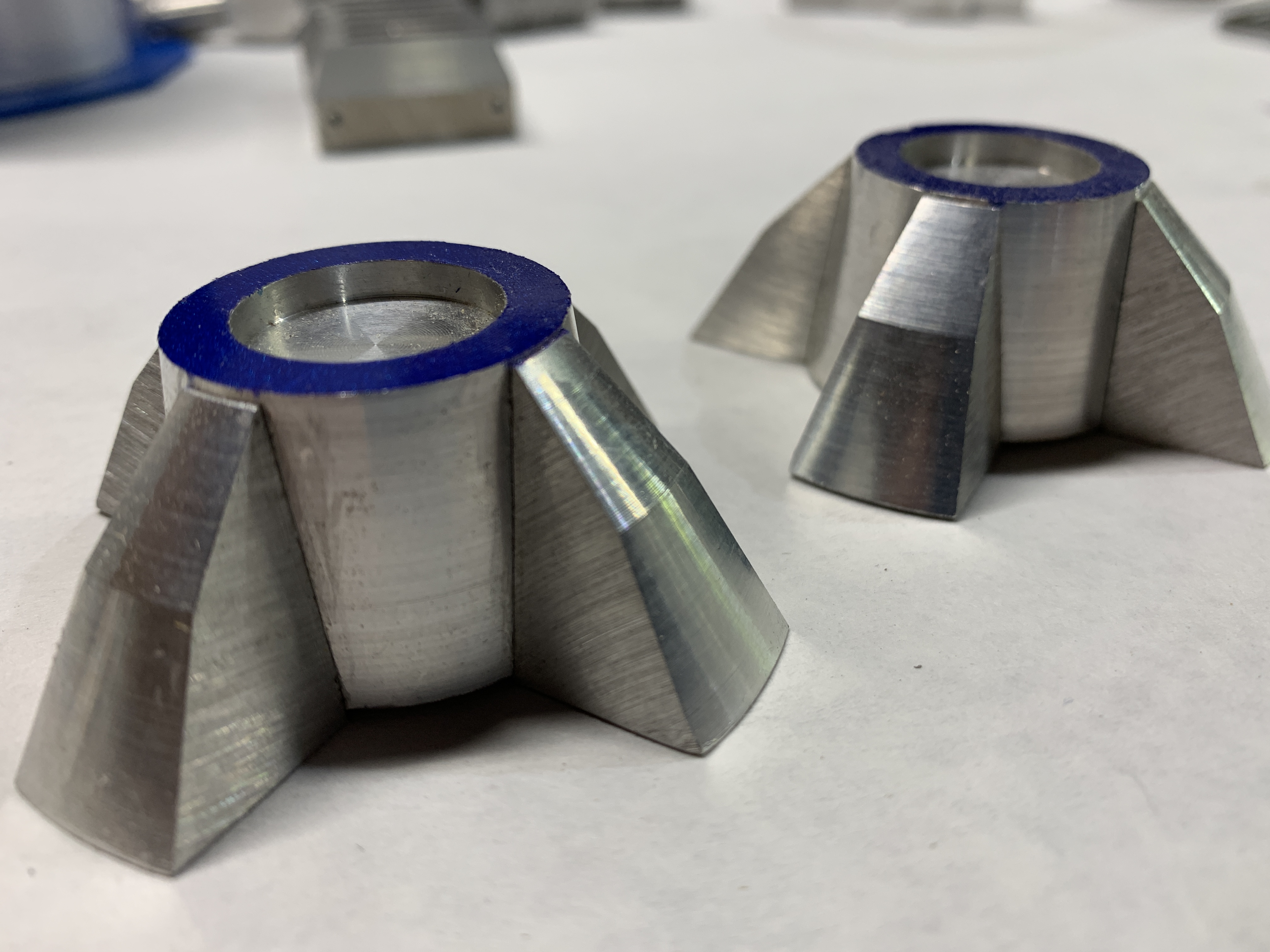

Now some of the metal bits were a tad more tricky to machine....

These charge port internals needed to have two nested, tapered turnings lathed, and then the outer parts milled down to create the four wings.

Oh! The angles! Lordy help me!

Making square corners in the coin slot's slot had me scratching my head.

Drill lots of holes and file?

Mill with a long, tiny, fragile cutter and file?

I couldn't figure it out until I asked one of my machinist friends in the shop how to do it.

He didn't miss a beat when he told me to mill a channel that is half the depth of the slot in a plate. Then cut the plate in half, and screw the two plate halves face-to-face to create a perfect square cornered slot. After that, I just cut the plate into shorter sections, and milled the angles.

I'm very happy with the way they came out!

These charge port internals needed to have two nested, tapered turnings lathed, and then the outer parts milled down to create the four wings.

Oh! The angles! Lordy help me!

Making square corners in the coin slot's slot had me scratching my head.

Drill lots of holes and file?

Mill with a long, tiny, fragile cutter and file?

I couldn't figure it out until I asked one of my machinist friends in the shop how to do it.

He didn't miss a beat when he told me to mill a channel that is half the depth of the slot in a plate. Then cut the plate in half, and screw the two plate halves face-to-face to create a perfect square cornered slot. After that, I just cut the plate into shorter sections, and milled the angles.

I'm very happy with the way they came out!

This is exactly why I've never attempted to build one yet (oh and money...). I would never be happy unless I had as many metal parts as possible, all the electronics, opening compartments, etc. Very cool!

MattWinchell

Sr Member

Gorgeous

Thank you all for the encouragement!

This is a great thread with a better story behind it.

I doubt I’ll ever build an R2 unit, but I’m still enjoying the stories here.

Carry on!

ID10T, I love your username! It made me laugh out loud!

Great update Duncanator

Love the way you opted for real alu pieces for your R2 unit. Nothing beats the look of real metal.

Real metal is the way to go if one has the tools. It takes about the same amount of work to make them out of plastic or wood.

But admittedly, not everyone has machine tools available.

Making these logic surrounds REALLY kicked my butt.

First I had to mill long strips with all the angles on them, then cut and mitre them to fit together. Getting all the angles to line up properly was trickier than it should have been.

And then getting the proper curved bevel on the longer surround stretched my machining skills in a whole new direction. I spent so much time setting up the cut, it was crazy!

And then I decided to weld them together rather than use screws.

ahem..

My TIG welding skills were brand new when I did these; and as often happens when a new skill is acquired, you look at every project as a chance to use it - even when it might be wiser to use a different technique. The thrill of joining two pieces of METAL into one piece with welding is intoxicating the first time you do it! It feels like magic after years of screws and glues. The lure of fusing metal with fire was more than I could resist!

So it took a few tries (and failures), but eventually I had some finished parts that I was happy with.

Duncanator!! Im right there with ya. My R2 has been sitting waiting for motors for longer than I care to admit. Looking good and keep pressing!!!

That being said...

Making these logic surrounds REALLY kicked my butt.

View attachment 1426739

First I had to mill long strips with all the angles on them, then cut and mitre them to fit together. Getting all the angles to line up properly was trickier than it should have been.

And then getting the proper curved bevel on the longer surround stretched my machining skills in a whole new direction. I spent so much time setting up the cut, it was crazy!

And then I decided to weld them together rather than use screws.

ahem..

My TIG welding skills were brand new when I did these; and as often happens when a new skill is acquired, you look at every project as a chance to use it - even when it might be wiser to use a different technique. The thrill of joining two pieces of METAL into one piece with welding is intoxicating the first time you do it! It feels like magic after years of screws and glues. The lure of fusing metal with fire was more than I could resist!

So it took a few tries (and failures), but eventually I had some finished parts that I was happy with.

View attachment 1426746

You making them yourself is damn impressive sir!!

I was fortunate to have the brain-trust in the modelshop.You making them yourself is damn impressive sir!!

If there was something I didn't know how to do, there was always someone who knew how, or could at least give me advice.

Wolfsburg

Master Member

An astromech is def something I want to build someday (I've bought a dome and a few other associated parts years ago) but it intimidates the hell out of me, especially the electronics and such, which I know zilch about. I figured I may go for a static "statue" and work myself up to something that can actually move, with lights and such.

Similar threads

- Replies

- 10

- Views

- 1,996

- Replies

- 40

- Views

- 2,561

- Replies

- 16

- Views

- 3,848