I've always had issue with my cast V2's emitters. One of its key features (now) are the dents around the emitter face and that was a detail I just couldn't fully replicate on my cast replicas without minor and major cracks forming (or chipping off completely). I always thought it was just the quality of my casting aluminium, and the extruded aluminium before it, and that whatever the stuff the real hilts were made from surely had to be made of tougher stuff. Well, it is and it isn't cast aluminium. Tonight proved my assertions (and worries) correct: The V2's emitter is likely not made of a cast alloy.

This is the 4145 cast emitter that I managed to dent with my custom die. Looks good...

...Until you turn it over. Hairline fractures and cracks running the perimeter of where the bends are. This is not something that the real prop in its current state has. It is, however, something that all my previous attempts at replicating this detail has resulted. The cast alloys used to make the hilts are not strong enough endure the damage in an area as thin as the emitter plate. Therefore, for it to be as dinged but remain intact as it is currently on the real prop, the emitter at least must not be made of a cast alloy. This is not a conclusion reached just from denting this one piece in my die, this is something that's happened from dropping on the ground, this has happened despite annealing; this has happened across the spectrum of casting alloys I have used in each iteration of casts I've made. It just cannot be. If it is able to crack then it is then able to break off completely.

Finally, after all my trials, it is definitive here that the emitter cannot be a cast piece if it is able to sustain such damage while remaining wholly intact. This then implies that the emitter on the V2 was a replacement. For what reason, who can say? It's likely that it's something as mundane as what I've encountered making these more than something mechanical or planned out. The emitter plate is just easy to breaking or not filling in properly.

That asks another question: so, what else can it be? Steel? Maybe, but there's no sign of rust. A harder, rare-earth metal? Unlikely, this is something that has to be in a studio workshop, after all. Could it be a tougher pot metal, like zamack? Possible, but just for the emitter? No, the XRF results shows that the cast are made from 4145/A, and while brazing and light welding work may have been in the studio by builders and the like, the amount of hilts made for the production (at the very least 4), and the amount of work and resources needed to make them, implies these were contracted to an outside source that already had the labor and supply ready. (I currently believe it was outsourced to the same place that cast the E-11 Bapty/Tunisia stunt parts and the Artoo arms).

That leaves only one candidate, something readily available on-hand in a studio workshop to grab and work on should anything get damaged on the casts, particularly the emitter...

Yes, everyone's done it by now except me, but I needed to be absolutely sure at this point: good ol' stock aluminium! It's proven to be able to take the damage without crumbling to pieces by way of every V2 replica made by other makers. It's something that would've been available and meets every criteria needed that the V2 needs to meet.

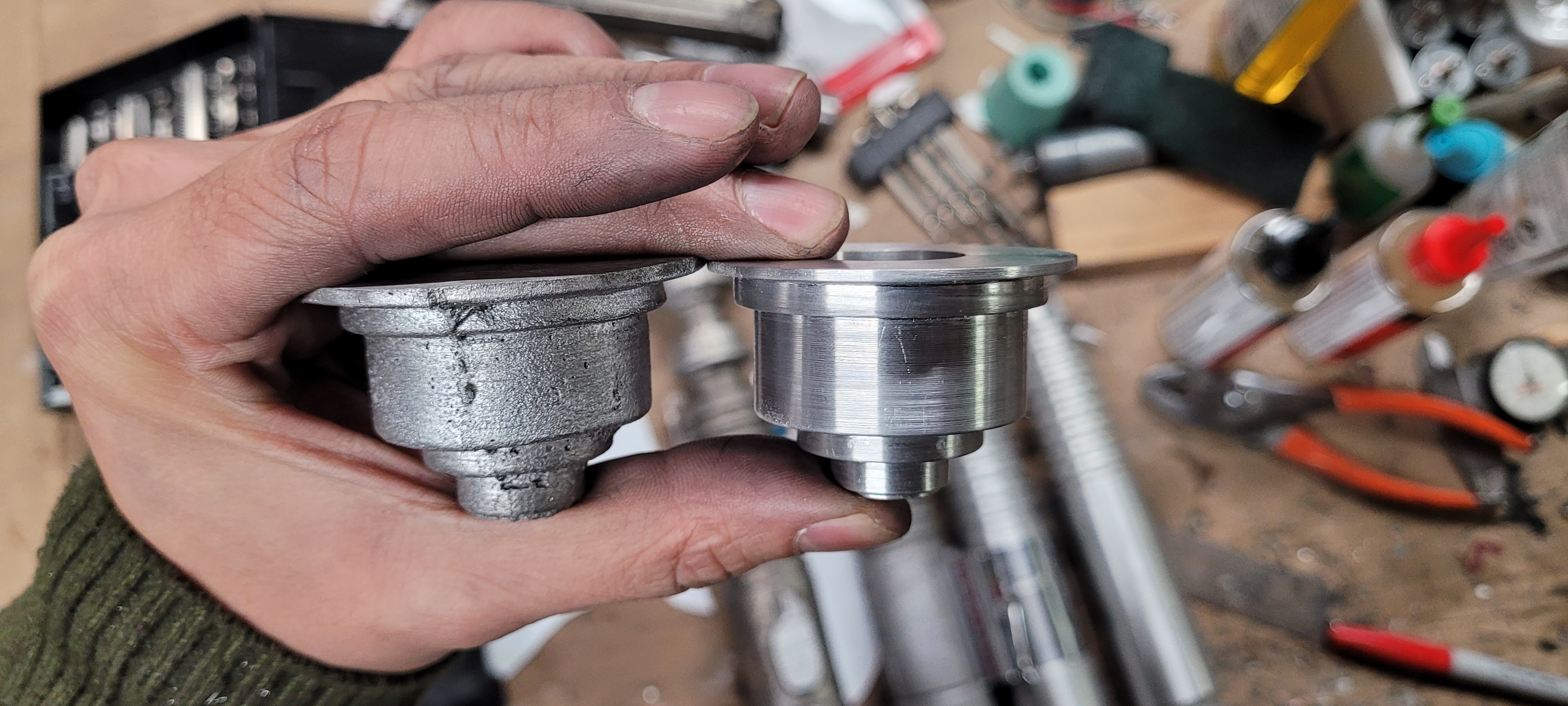

Measurements and scale of the replacement emitter? I just grabbed them from the other cast! The final machined emitter looks a bit different than the cast one because it doesn't have the rounded edges that the cast piece does, despite me taking measurements directly from it to make the replacement.

Because I'm doing a V2, I have to have the smaller emitter plate, despite it being machined from stock with the adequate girth to leave a larger emitter plate like the original cast. Why would the replacement emitter be smaller? Who knows? Maybe it was the size of stock they had to work with. Anyone's guess is as good as another's on that topic.

With that figured, from here on, it's back to the basic machining practices I've developed for boring out the internals. My next update on this will probably be finishing and assembling the V2 hilt, and getting to work on the V3.

This is the 4145 cast emitter that I managed to dent with my custom die. Looks good...

...Until you turn it over. Hairline fractures and cracks running the perimeter of where the bends are. This is not something that the real prop in its current state has. It is, however, something that all my previous attempts at replicating this detail has resulted. The cast alloys used to make the hilts are not strong enough endure the damage in an area as thin as the emitter plate. Therefore, for it to be as dinged but remain intact as it is currently on the real prop, the emitter at least must not be made of a cast alloy. This is not a conclusion reached just from denting this one piece in my die, this is something that's happened from dropping on the ground, this has happened despite annealing; this has happened across the spectrum of casting alloys I have used in each iteration of casts I've made. It just cannot be. If it is able to crack then it is then able to break off completely.

Finally, after all my trials, it is definitive here that the emitter cannot be a cast piece if it is able to sustain such damage while remaining wholly intact. This then implies that the emitter on the V2 was a replacement. For what reason, who can say? It's likely that it's something as mundane as what I've encountered making these more than something mechanical or planned out. The emitter plate is just easy to breaking or not filling in properly.

That asks another question: so, what else can it be? Steel? Maybe, but there's no sign of rust. A harder, rare-earth metal? Unlikely, this is something that has to be in a studio workshop, after all. Could it be a tougher pot metal, like zamack? Possible, but just for the emitter? No, the XRF results shows that the cast are made from 4145/A, and while brazing and light welding work may have been in the studio by builders and the like, the amount of hilts made for the production (at the very least 4), and the amount of work and resources needed to make them, implies these were contracted to an outside source that already had the labor and supply ready. (I currently believe it was outsourced to the same place that cast the E-11 Bapty/Tunisia stunt parts and the Artoo arms).

That leaves only one candidate, something readily available on-hand in a studio workshop to grab and work on should anything get damaged on the casts, particularly the emitter...

Yes, everyone's done it by now except me, but I needed to be absolutely sure at this point: good ol' stock aluminium! It's proven to be able to take the damage without crumbling to pieces by way of every V2 replica made by other makers. It's something that would've been available and meets every criteria needed that the V2 needs to meet.

Measurements and scale of the replacement emitter? I just grabbed them from the other cast! The final machined emitter looks a bit different than the cast one because it doesn't have the rounded edges that the cast piece does, despite me taking measurements directly from it to make the replacement.

Because I'm doing a V2, I have to have the smaller emitter plate, despite it being machined from stock with the adequate girth to leave a larger emitter plate like the original cast. Why would the replacement emitter be smaller? Who knows? Maybe it was the size of stock they had to work with. Anyone's guess is as good as another's on that topic.

With that figured, from here on, it's back to the basic machining practices I've developed for boring out the internals. My next update on this will probably be finishing and assembling the V2 hilt, and getting to work on the V3.