You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Correcting the Lunar Models 41" Excelsior

- Thread starter Vidar 710

- Start date

Vidar 710

Well-Known Member

The Superstructure is pretty much finished except for the two fins, and the impulse engine exhaust ports.

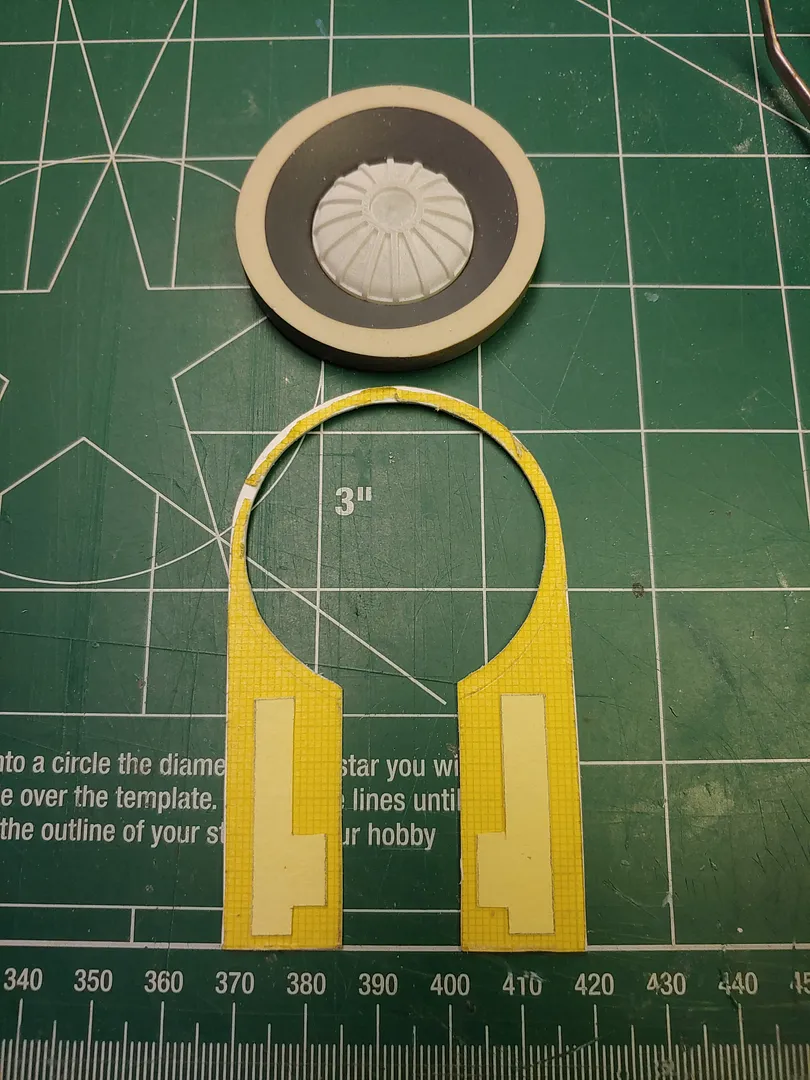

Here, I used Tamiya's 1mm x 1mm grid tape to fasion the raised and recessed details around the Impulse Crystal assembly.

A paper template is used to make the raised plating under the bridge and the spine that extends aft behine it in 2.5mm thick sheet styrene.

Cutting way the styrene from the part.

All the raised plating details in place on the Superstructure's Buck.

More to come, maybe on the Warp Nacelle pylons finally.

Tracy

Here, I used Tamiya's 1mm x 1mm grid tape to fasion the raised and recessed details around the Impulse Crystal assembly.

A paper template is used to make the raised plating under the bridge and the spine that extends aft behine it in 2.5mm thick sheet styrene.

Cutting way the styrene from the part.

All the raised plating details in place on the Superstructure's Buck.

More to come, maybe on the Warp Nacelle pylons finally.

Tracy

If I've said it before, I will say it again: At what point does it stop being the Lunar kit? Has all of it been redone at this point?

I loved my Lunar Excelsior until now. Now it just looks wrong.

Cough,...kit, cough,...kit!!!!!!!!!!!!

I think such a talented individual must share his talent with the world, and make a bunch of money in the process.

No moderators we are not discussing run. Just me dreams.

Last edited:

Vidar 710

Well-Known Member

I took a break from modeling due to friends n family issues. I’ve been getting back into it slowly with smaller projects. Work on the secondary hull’s cargo bay have had some forward progress, and the Warp Nacelle pylons have been planned out in my head. Hope to pull her down off the shelf soon.

Tracy

Tracy

Starbase101

Sr Member

Sub'd and love the work you're putting into this kit. It will be very inspiring when I get around to building my LM kit (someday).

Vidar 710

Well-Known Member

So, The Lunar Models saucer has another issue. The outer edge (with the window ports) is leaning at too much of an angle. It needs to be more to the vertical. Some preliminary work in progress correcting it.

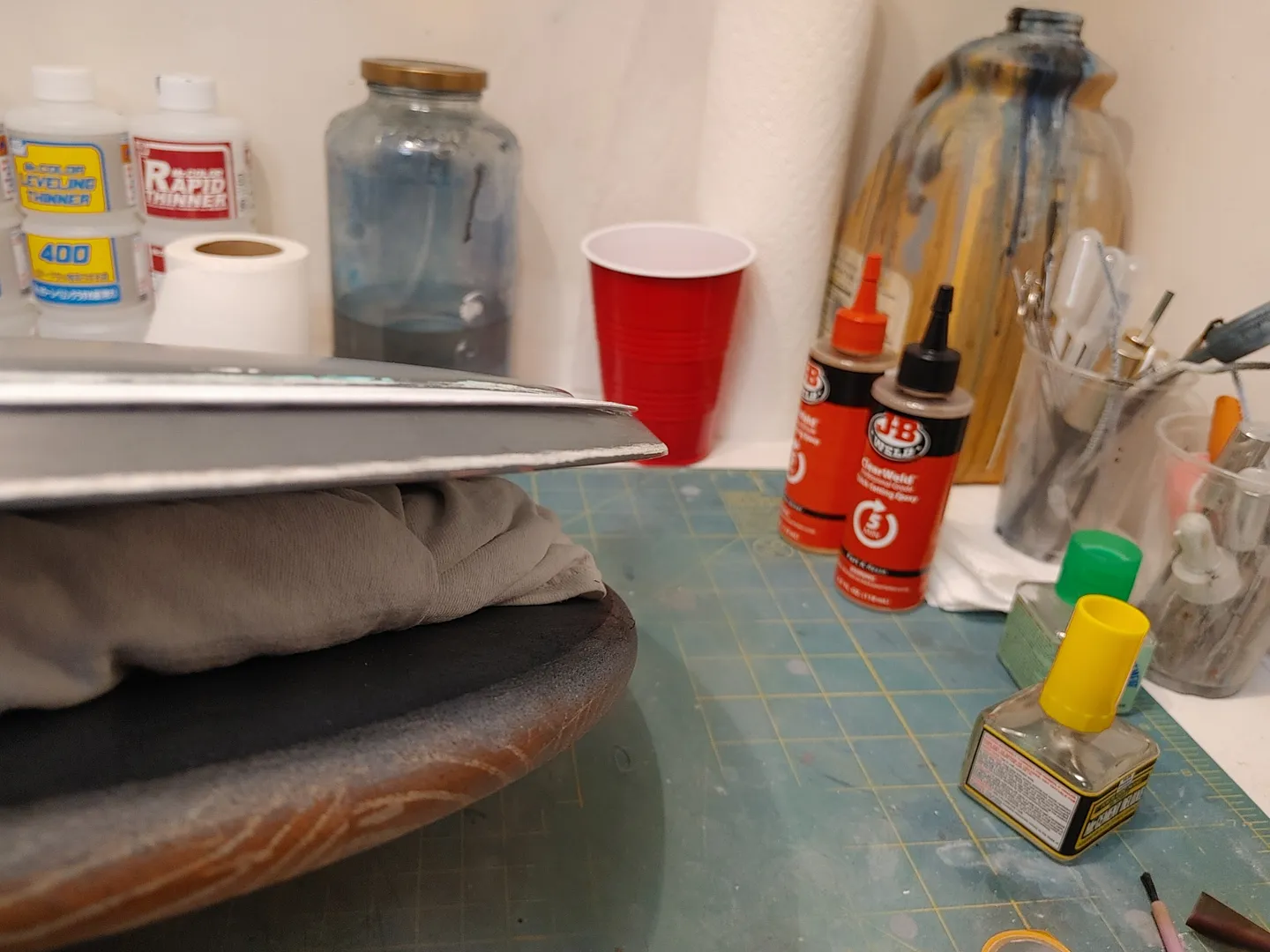

Here you can see the difference in the angles.

The saucer's edge is sanded and stripped down so a new ring section can be cemented into place.

The new ring to correct the profile is cemented into place.

Then filled in at the inner radius at the base of the dome.

Side view of the new angle before the filler is applied.

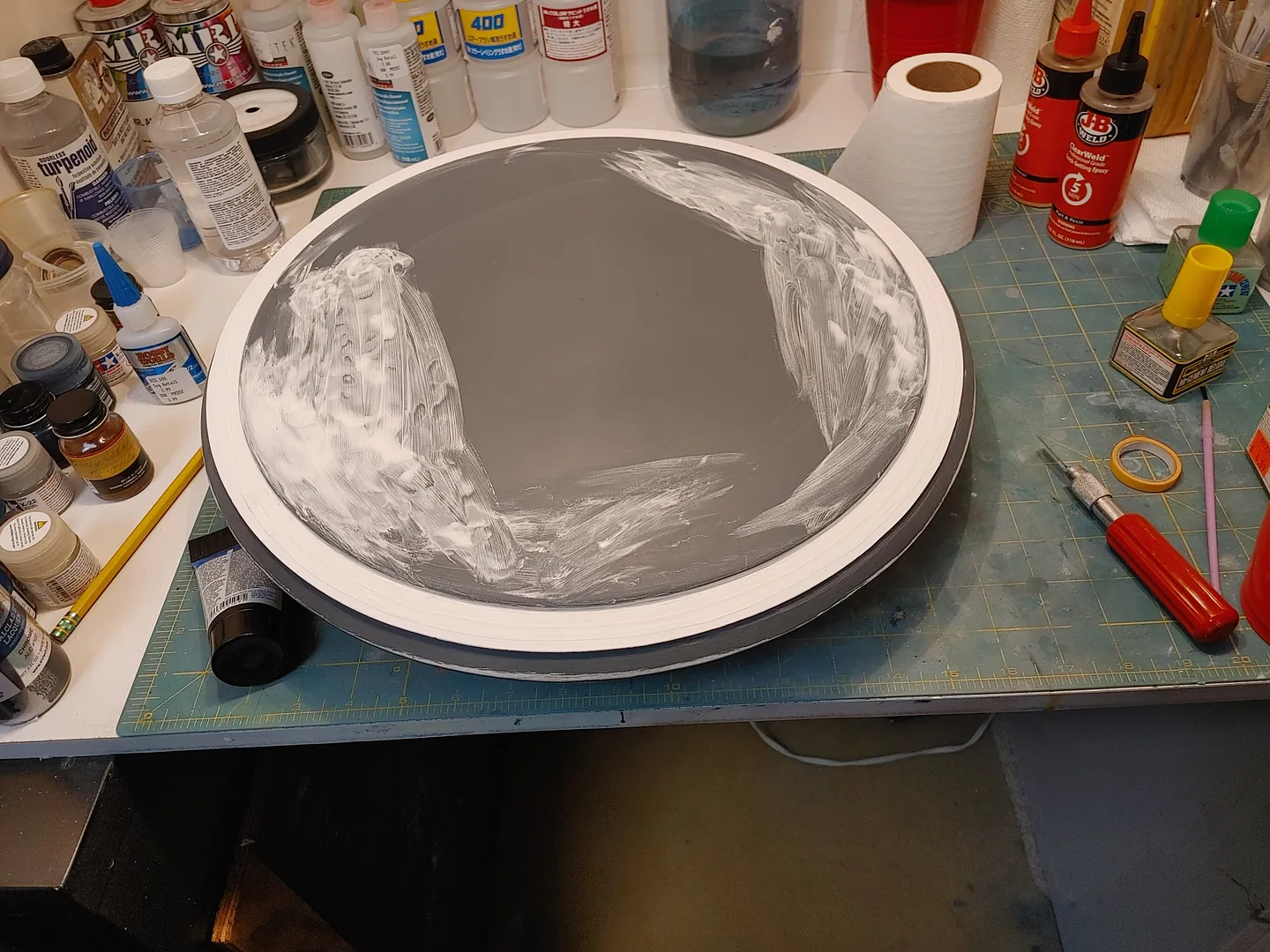

The new ring is masked to protect it, then the Smooth-On filler dough is roughly applied.

Next the filler is smoothed into the hull with water dampened hands. One or two more layers are expected before putty, sanding, and re-priming is done.

More to come.

Tracy

Here you can see the difference in the angles.

The saucer's edge is sanded and stripped down so a new ring section can be cemented into place.

The new ring to correct the profile is cemented into place.

Then filled in at the inner radius at the base of the dome.

Side view of the new angle before the filler is applied.

The new ring is masked to protect it, then the Smooth-On filler dough is roughly applied.

Next the filler is smoothed into the hull with water dampened hands. One or two more layers are expected before putty, sanding, and re-priming is done.

More to come.

Tracy

Last edited:

Vidar 710

Well-Known Member

The second layer of filler dough was applied, then sanded down. Here the first layer of putty has been roughed in...

Sanding done to level the new contour...

Next, the Red Micro filler is applied to fill in scratches and continue leveling the new surface.

Then sanded to its final shape.

BTW, all this work done with the master mounted on a Kitchen Lazy Suzan. ;-)

I took the liberty in adding the two recessed grid radius' in the ringed shelf to see how they would look. I don't think they'll pop during the vacuum forming process, but hey... they look cool being there.

I'm still deciding if scribing the grid pattern in the master would be futile. The plan has always been to scribe in all grid/panel lines on the vacuum formed parts for crisper detail.

Primer to go, and I'll FINALLY call correcting the saucer section (top and bottom halves) done!

Tracy

Sanding done to level the new contour...

Next, the Red Micro filler is applied to fill in scratches and continue leveling the new surface.

Then sanded to its final shape.

BTW, all this work done with the master mounted on a Kitchen Lazy Suzan. ;-)

I took the liberty in adding the two recessed grid radius' in the ringed shelf to see how they would look. I don't think they'll pop during the vacuum forming process, but hey... they look cool being there.

I'm still deciding if scribing the grid pattern in the master would be futile. The plan has always been to scribe in all grid/panel lines on the vacuum formed parts for crisper detail.

Primer to go, and I'll FINALLY call correcting the saucer section (top and bottom halves) done!

Tracy

Last edited:

modelerdave

Sr Member

Please tell me you're going to make molds of this.

Similar threads

- Replies

- 3

- Views

- 531