FreddySchramm

Active Member

Would love some opinions on my molding process from the think tank.

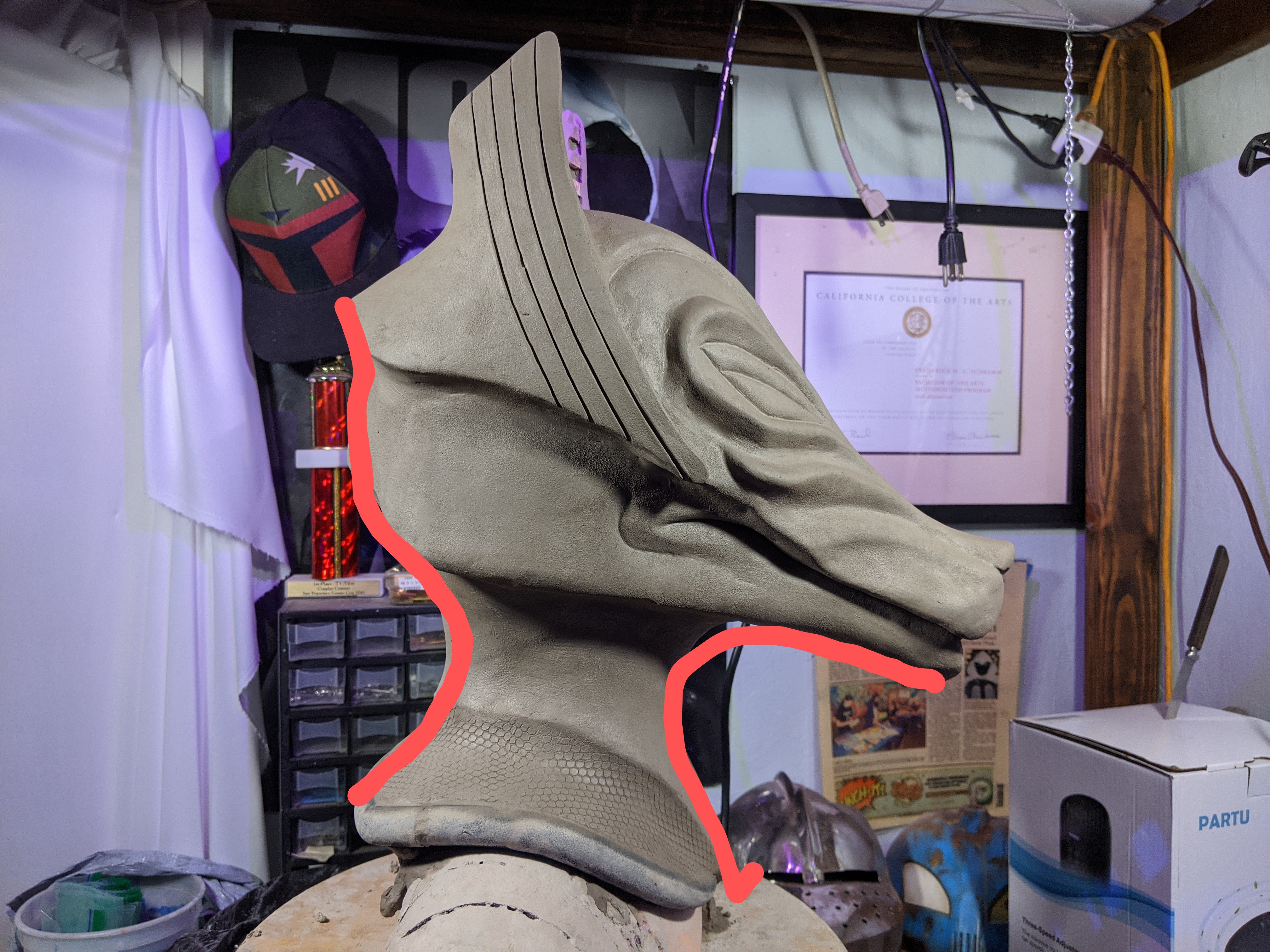

I'm planning on molding this Wed clay sculpt using a brush on silicone. (Hoping to get a very long life out of this mold) Im going to crystal clear it beforehand. As far as my part line goes, I'm thinking of jewel cutting a slit along The back and below the chin exactly where I marked in the photo tomake it easier to demold like a glove and invert. Any opinions?

Another thing, there's two silicon paths I can go, mold Max 30 or rebound 25.

By default I was going to use mold Max 30 since I've used it many times before as a universal silicone, just not on a particular shape like this. I had mold Max 30 in mind when I was choosing where to jewl cut the mold. Id prefer to use mold Max 30 because I'd be able to pour it all over the clay sculpt and it will easily flow into all of the pour detail of without using a brush too much to disturb the first layer.

In comparison, I'm thinking I could use rebound 25 instead because it's more stretchy than mold max 30 so it will more than likely last longer given my suggested partline location. However, Ive never used this particular silicone before. What I've seen online is it's very viscous, so I can't necessarily pour it on like I would with mold Max. I'm afraid when I brush it on it will disturb my clay sculpture and not necessarily pick up all the pour detail or even worse push it down and deform the clay as I brush. Another downside would be because this is so flexible, I'm afraid the mold might sag a bit if I make it too thin, since I'm so used to the rigidity of mold Max 30. But I could probably combat this by just making a hell of amount of keys and strategically placing them.

Either way, Im planning on reinforcing the mold with some spandex all over, especially a strip above my jewel cut line.

What do you think of my jewel cut placement, and what are your opinions on the silicone?

I'm planning on molding this Wed clay sculpt using a brush on silicone. (Hoping to get a very long life out of this mold) Im going to crystal clear it beforehand. As far as my part line goes, I'm thinking of jewel cutting a slit along The back and below the chin exactly where I marked in the photo tomake it easier to demold like a glove and invert. Any opinions?

Another thing, there's two silicon paths I can go, mold Max 30 or rebound 25.

By default I was going to use mold Max 30 since I've used it many times before as a universal silicone, just not on a particular shape like this. I had mold Max 30 in mind when I was choosing where to jewl cut the mold. Id prefer to use mold Max 30 because I'd be able to pour it all over the clay sculpt and it will easily flow into all of the pour detail of without using a brush too much to disturb the first layer.

In comparison, I'm thinking I could use rebound 25 instead because it's more stretchy than mold max 30 so it will more than likely last longer given my suggested partline location. However, Ive never used this particular silicone before. What I've seen online is it's very viscous, so I can't necessarily pour it on like I would with mold Max. I'm afraid when I brush it on it will disturb my clay sculpture and not necessarily pick up all the pour detail or even worse push it down and deform the clay as I brush. Another downside would be because this is so flexible, I'm afraid the mold might sag a bit if I make it too thin, since I'm so used to the rigidity of mold Max 30. But I could probably combat this by just making a hell of amount of keys and strategically placing them.

Either way, Im planning on reinforcing the mold with some spandex all over, especially a strip above my jewel cut line.

What do you think of my jewel cut placement, and what are your opinions on the silicone?