You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anakin Starkiller’s Darth Maul Assembly Tutorial Thread

- Thread starter Halliwax

- Start date

jorged123

Well-Known Member

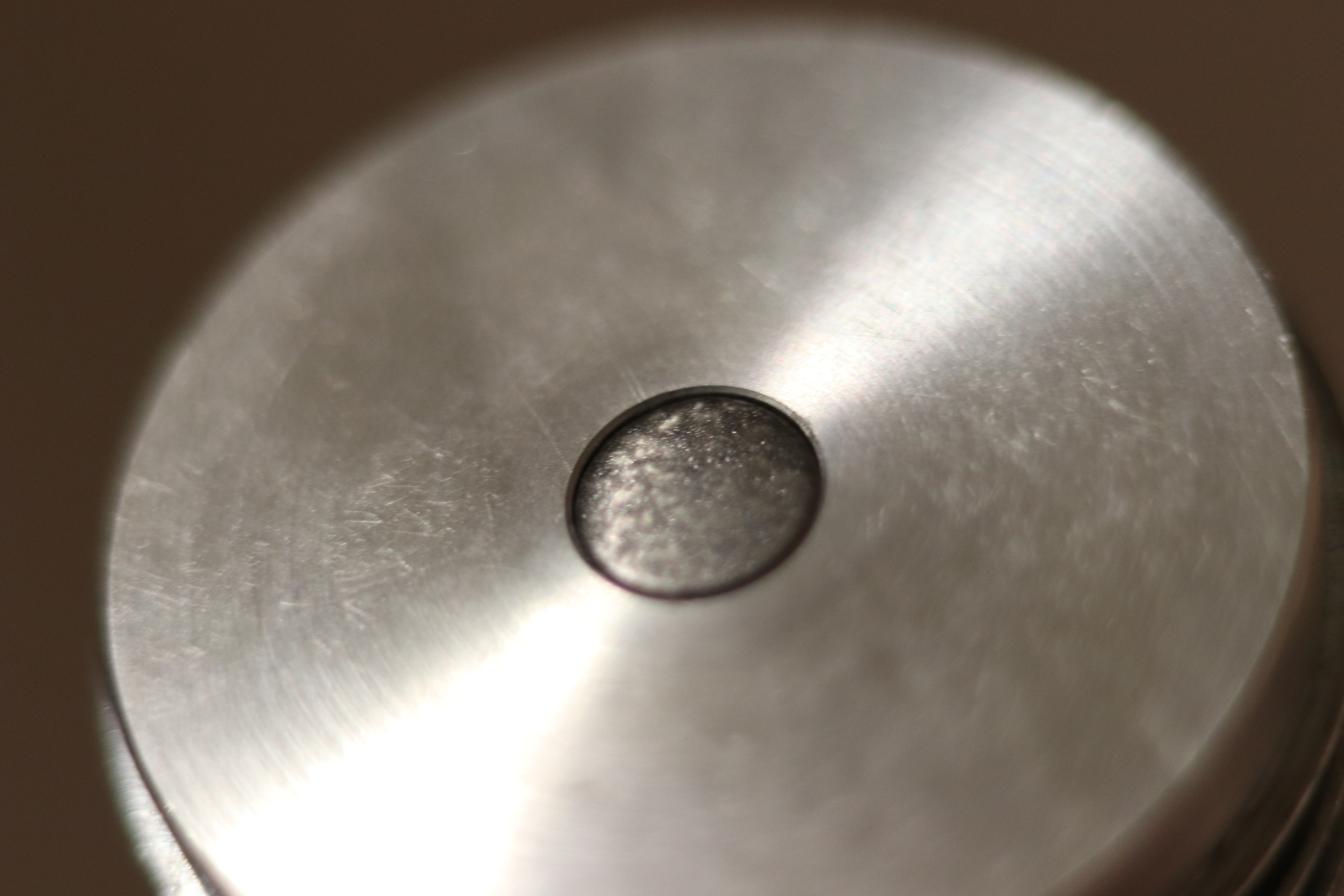

Got mine together. Thanks, Halliwax, for the threaded rod tutorial and assembly tutorial. I used a thin brass center washer from Hillman, it works great. I like the ability to slide the center alignment with a more slippery material. I asked Mister starkiller what he used, and he said a metal washer that he found in his spare parts. I like that choice, too-so I did similarly. I didn't even have to bore the center of the hilts to get them aligned. Guess I'll weather the washers and end cap when I get my V2 out.

As Reel Fakes noted upthread, an aluminum undercoat with a topcoat of Dupli-Color MetalCast Red Anodized. Looks spot-on.

Depending on how far people want to go with their buttons, Roman has had these accurate blanking caps on his site for a few years:

Blanking Cap - Roman Props | Roman's Empire

Patlegrand

Active Member

Hello !

I recently received 2 kits. Its just amazing!

But, I have some difficulties to get the materials... The threaded rod especially, i live in France, should i get a PNC threaded with 8,5 mm diameter ? Same problem with the washer ! ( can i use a steel washer or nylon si betterave ?)

Thanks!

I recently received 2 kits. Its just amazing!

But, I have some difficulties to get the materials... The threaded rod especially, i live in France, should i get a PNC threaded with 8,5 mm diameter ? Same problem with the washer ! ( can i use a steel washer or nylon si betterave ?)

Thanks!

any washer will work, just pick a thickness that will allow your O ring to sit correctly without going between both halves.

I'm also in France and used a M10 rod after rethreading the end emiters. I don't recommend that if you are not experienced with threading long metal parts.

apart from that, there is a run in the junkyard for 3/8 rods from US and you can find some on ebay in germany or england.

good luck

I'm also in France and used a M10 rod after rethreading the end emiters. I don't recommend that if you are not experienced with threading long metal parts.

apart from that, there is a run in the junkyard for 3/8 rods from US and you can find some on ebay in germany or england.

good luck

any washer will work, just pick a thickness that will allow your O ring to sit correctly without going between both halves.

I'm also in France and used a M10 rod after rethreading the end emiters. I don't recommend that if you are not experienced with threading long metal parts.

apart from that, there is a run in the junkyard for 3/8 rods from US and you can find some on ebay in germany or england.

good luck

I just quoted your instructions in the run thread not realizing it was you lol

Hey mate, well I just used a metric tapping set that I have, any tap in M10 with a handle will do, but I repeat, this is quite hard to do by hand, the piece was probably tapped with a machine initially, taping an aluminium tube of that length in M10 is no easy task by hand.

I used a pair of pliers to hold the tube while tapping because you need to hold it with quite some force.

The 3/8 and M10 are pretty close, I couldn't see a difference after tapping was finished, it didn't ruin the threads so the pitch must be quite similar.

The M10 rod is a tiny bit larger than a 3/8 rod but it will fit inside the resin halves. One of mine was tighter and I used Halliwax great tip to put the rod on a drill to screw the rod inside the resin half, this was super fast and easy that way and the resin half is well secured.

There is really nothing different with the rest of the assembly, just do that if you feel super confident about rethreading a 3/8 thread to an M10, this is not something you want to try if you never used a tap set.

cheers

It like ethan said, there is a run right now of 3/8-16 rod, might want to hunt down the European organizer who’s gathering a large number of rod to ship over from the states, then he’s going to distribute them once he receives them all to all the euro guys

Hello !

I recently received 2 kits. Its just amazing!

But, I have some difficulties to get the materials... The threaded rod especially, i live in France, should i get a PNC threaded with 8,5 mm diameter ? Same problem with the washer ! ( can i use a steel washer or nylon si betterave ?)

Thanks!

Better act today, he’s closing the run tonight

Limited Run - Threaded Rod for Anakin Starkiller's 2019 Maul Run

I'm wondering how accurate these remake Covertec clips are to originals... I had one back in the day and I recall them being glossy plastic without the mold lines. I know you can still get a later version official coverte clip that comes with the same wheel, I'm curious if those are cleaner.

I went ahead and did the button color repaint and painted the inner washers and emitter inserts and still finished in in about an hour.

I went ahead and did the button color repaint and painted the inner washers and emitter inserts and still finished in in about an hour.

I seem to remember other posts speculating that the Covertec position varied on the Ep 1 props but of course now I can't find them. Maybe this was it along with the next several posts Limited Run - Darth Maul TPM screen accurate lightsaber prop

In the steel emitter image, the covertec looks not aligned with the buttons, but in the opposite direction to the image above. So does that support the idea that the position varied? Limited Run - Darth Maul TPM screen accurate lightsaber prop

In the steel emitter image, the covertec looks not aligned with the buttons, but in the opposite direction to the image above. So does that support the idea that the position varied? Limited Run - Darth Maul TPM screen accurate lightsaber prop

Mine, too. I've had mine since 1999. It's not glossy.My OEM wheel also has a seam line

I used photos of the EFX replica when aligning my Covertec (which has a flat-finish and mold lines, as have all of the others I've ever bought). I went with somewhere around 6:00-7:00 for the positioning (with the red button at 12:00). Just slightly off-center, rather than 180 degrees from the red button. The emitter fins are not evenly spaced. One of them is closer to 6:00 than the next one over.

so does that mean this cone design was sculpted? I think it's crazy they found a machine part for the similar looking junk part from TFA. Was there a real world item that was used to inspire this cone shape on the ep. 1 sabers?I used photos of the EFX replica when aligning my Covertec (which has a flat-finish and mold lines, as have all of the others I've ever bought). I went with somewhere around 6:00-7:00 for the positioning (with the red button at 12:00). Just slightly off-center, rather than 180 degrees from the red button. The emitter fins are not evenly spaced. One of them is closer to 6:00 than the next one over.

Similar threads

- Replies

- 2

- Views

- 138

- Replies

- 1

- Views

- 102

- Replies

- 6

- Views

- 431

- Replies

- 311

- Views

- 48,484