Mauiman

Well-Known Member

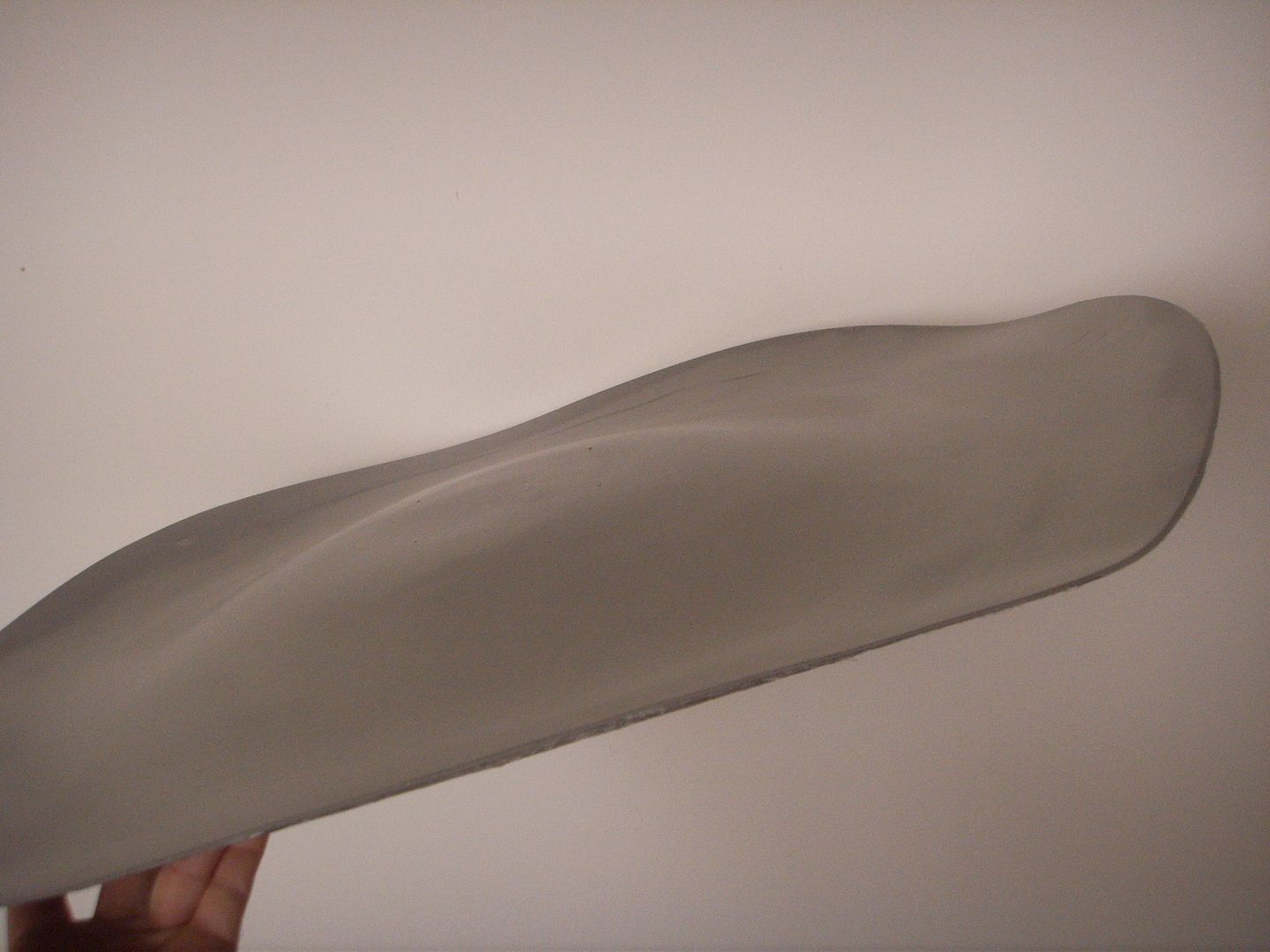

That deformed saucer part looks like you are making a hand tossed pizza. :lol

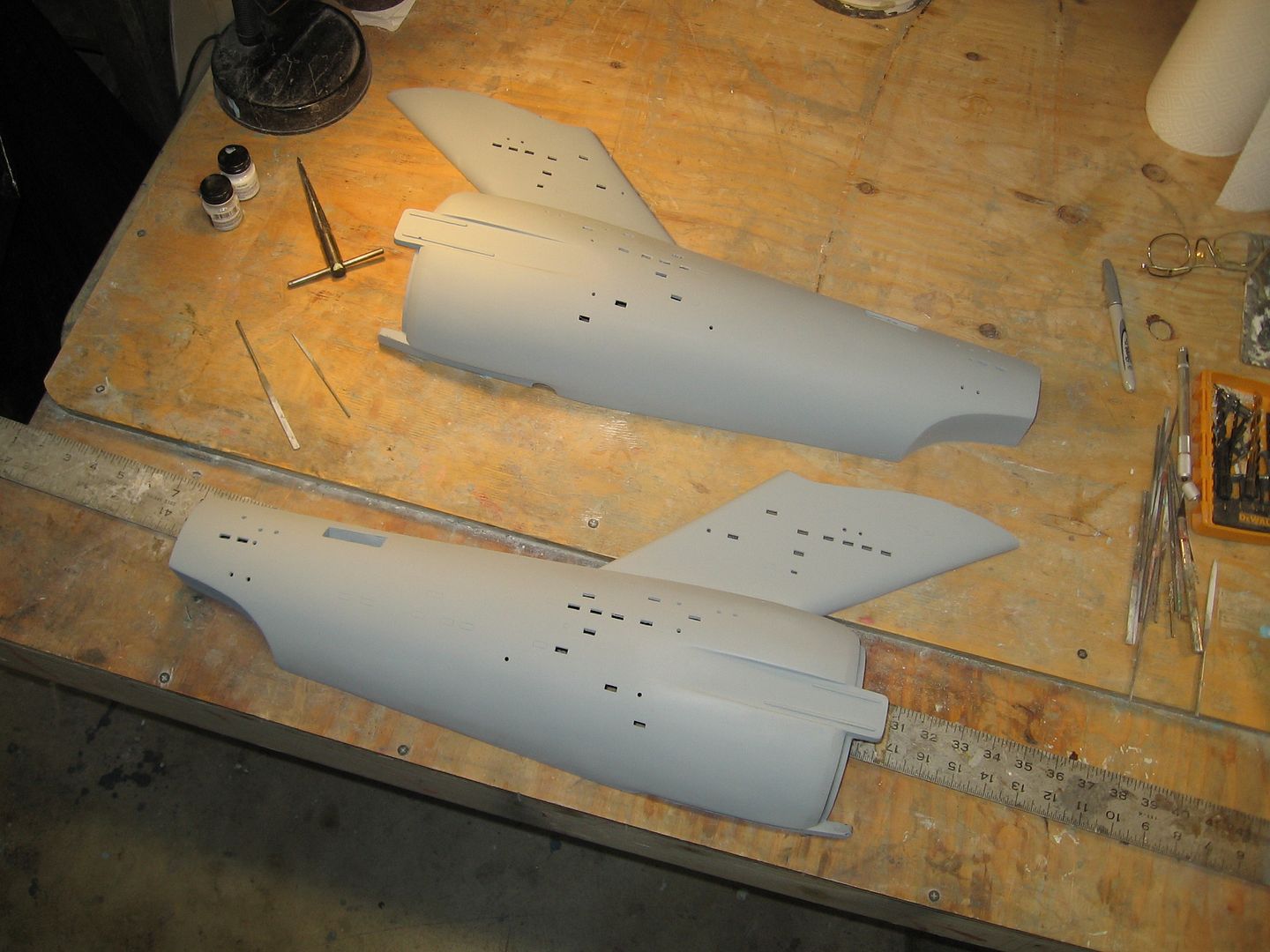

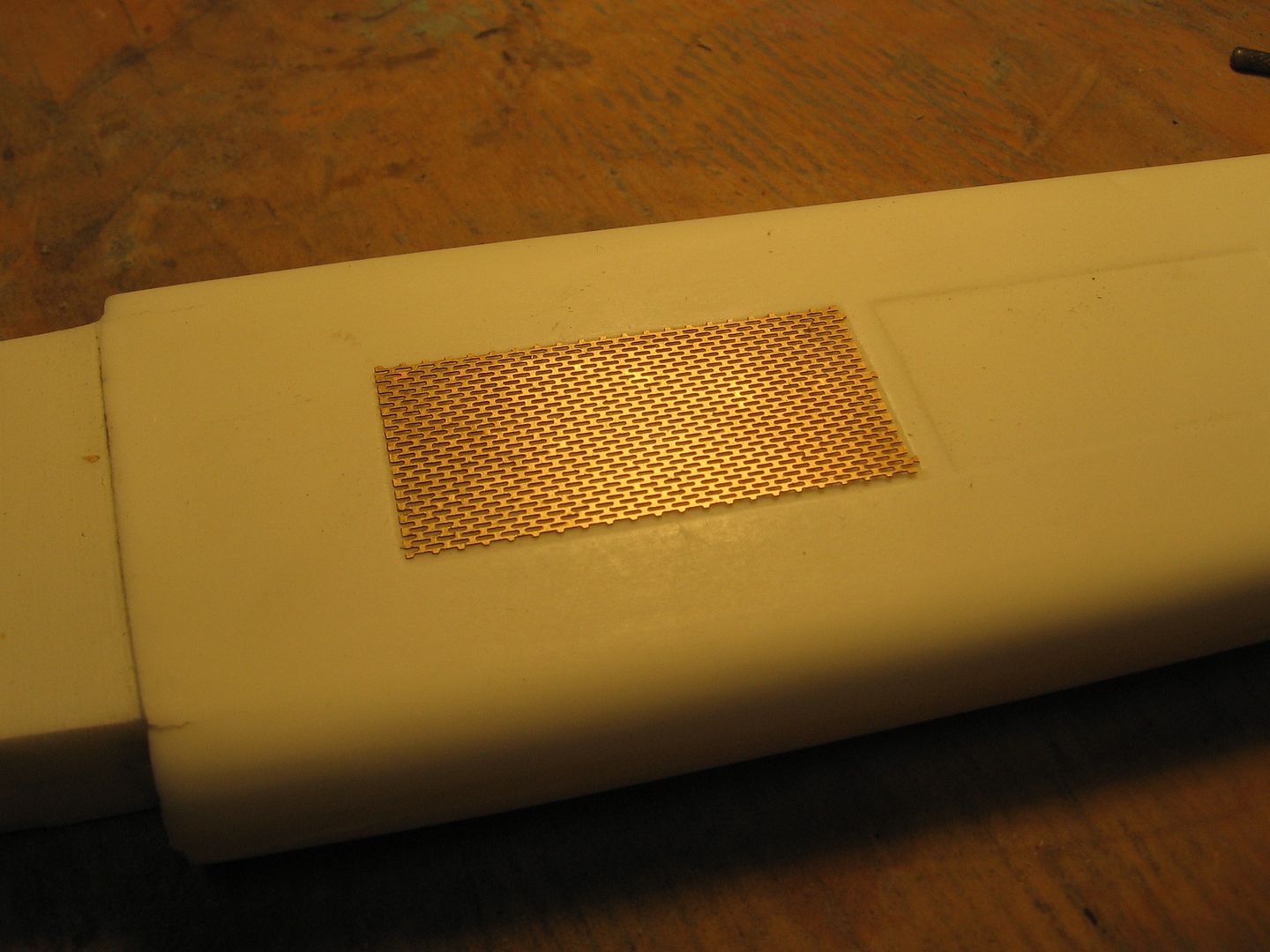

But really I am sorry that you had such horrible luck with that product. Wish you could get your money back. Your shop is looking like you are going to need to hire your self a helper. Which it is a cool and great looking shop. That car looks very sexy. The Enterprise is also looking very good.

But really I am sorry that you had such horrible luck with that product. Wish you could get your money back. Your shop is looking like you are going to need to hire your self a helper. Which it is a cool and great looking shop. That car looks very sexy. The Enterprise is also looking very good.