You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Studio Half Scale TOS Enterprise Scratch build

- Thread starter SteveNeill

- Start date

- Status

- Not open for further replies.

kahn1701

Well-Known Member

shizman

Sounds like a plan. Just let me know when and where..

I know I'm going to need all the help I can get.

I'm going to start rebuilding my shop/office work

bench. I’m going to make the build bench 6x4.

It might just be enough room for building the BIG E..

LOL

Thanks

Sounds like a plan. Just let me know when and where..

I know I'm going to need all the help I can get.

I'm going to start rebuilding my shop/office work

bench. I’m going to make the build bench 6x4.

It might just be enough room for building the BIG E..

LOL

Thanks

SteveNeill

Sr Member

Thanks!

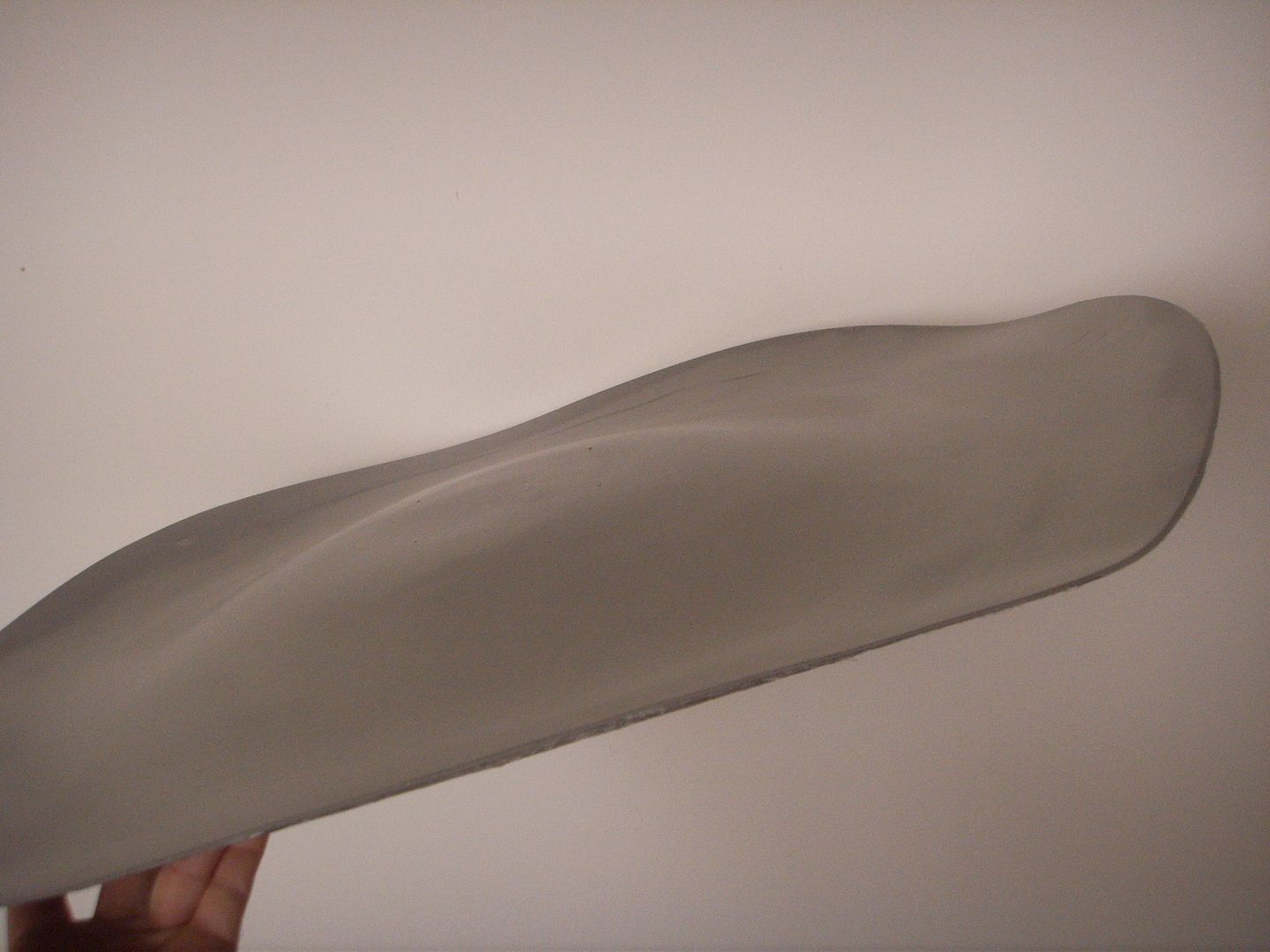

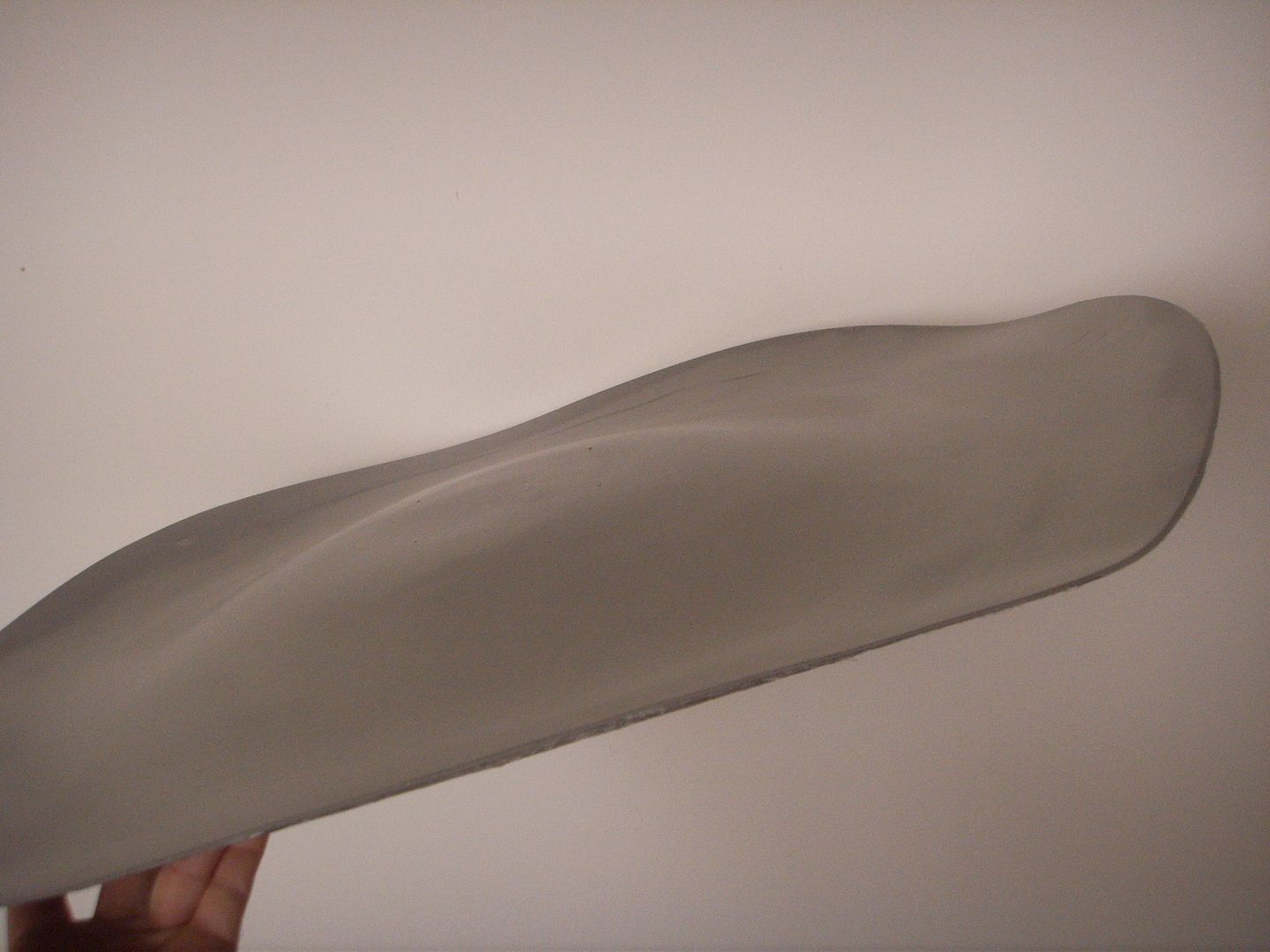

Kahn I'll put up some pictures later. I got your hulls out this morning and they look good. I have to go back over the two hull kits today and fix a few bubbles, clean off the PVA and make them ready to ship. So bare with me guys it's another busy day of customers first.

Steve

Kahn I'll put up some pictures later. I got your hulls out this morning and they look good. I have to go back over the two hull kits today and fix a few bubbles, clean off the PVA and make them ready to ship. So bare with me guys it's another busy day of customers first.

Steve

SteveNeill

Sr Member

Still in fiber glass hell. Washing and preening parts. Trimming the flash and flat sanding so you guys don't have to do it.

More later.

Steve

More later.

Steve

trekriffic

Sr Member

What about a small belt sander for the rims? The one thing about sanding on a flat surface though is you can be sure it will be perfectly flat as you sand it.

The Keeper

Active Member

Where can I find the FS post for this bad boy?

Mauiman

Well-Known Member

Steve

Thanks you for Trimming the flash and flat sanding..

I was kind of dreading that part..

Yes I do agree with Kahn.

You are a kind hearted person for doing the flash trimming and flat sanding for these good people. Hope you all leave him a nice tip. I would if I had the money to buy the kit.

SteveNeill

Sr Member

All the hull parts are preened up. I hate fiber glass layup because no mater how careful you are you get bubbles. I filled 90 % and all the edges are clean. All you guys have to do is a Little more flat sanding-maybe and fill a few bubbles.

I took all the PVA off too and sanded the surface and primered the hull parts. Took all day but this way you guys can get right to work.

I'm tempted to use a polyurethane gel coat. BJB has a good one but after see the warping caused by backing it up with epoxy and matt I would rather have the bubbles to fill.

CR big E had this problem bad. Monday I'll start packing.

Thanks guys.

Steve

I took all the PVA off too and sanded the surface and primered the hull parts. Took all day but this way you guys can get right to work.

I'm tempted to use a polyurethane gel coat. BJB has a good one but after see the warping caused by backing it up with epoxy and matt I would rather have the bubbles to fill.

CR big E had this problem bad. Monday I'll start packing.

Thanks guys.

Steve

kahn1701

Well-Known Member

Steve

You have by fare proven to me you are

the best man for this undertaking.

Your craftsmanship, work ethic

and kindness is an inspiration to all.

I know I have said this before but

Your BIG E will live on as one of you

shinning accomplishment for all to see.

I for one will be talking about this well

into my old age.

Thank you once again

I’m humbled......

You have by fare proven to me you are

the best man for this undertaking.

Your craftsmanship, work ethic

and kindness is an inspiration to all.

I know I have said this before but

Your BIG E will live on as one of you

shinning accomplishment for all to see.

I for one will be talking about this well

into my old age.

Thank you once again

I’m humbled......

Last edited:

star-art

Sr Member

I'm tempted to use a polyurethane gel coat. BJB has a good one but after see the warping caused by backing it up with epoxy and matt I would rather have the bubbles to fill.

CR big E had this problem bad.

Was this due to the combination of different materials (i.e. PU resin + epoxy)? I've often wondered if you could put a surface coat of PU resin in the mold and then back it with glass cloth, etc. for strength and stability. I heard it can be done, but it can be very tricky. Is there an issue getting the PU resin to bond with whatever is backing it?

Although extremely popular, PU resin doesn't seem to be very dimensionally stable, at least to me. I feel most comfortable using it for plant-on details and I get a bit nervous when I see it being used for the actual structure of a model. That's because every large, structural part I've ever seen has been warped or distorted in some fashion. I know it can be corrected, but who's to say it won't happen again in the future?

It would be great to hear about some of your experience with these issues. Thanks!

ZOMBIEREPELLENT

Sr Member

I've had no issues fiberglassing over BJB's 1630 polyurethane resin. But on the same note, I use polyester fiberglass resin. I'm not sure if That makes a difference or not.

SteveNeill

Sr Member

Well...

After seeing this I changed my mind. You guys will like bubbles better than the above pictures of a CR 66 E kit that sat unbuilt for some time only to open the box to a taco. This is polyester backed PU. And it happened to a few people.

Today I had to clean shop and get the place cleaned up for dignitaries visiting from Warner's tomorrow. I also tied up the nacelles in there to be final positions to find out all is truly correct and well.

Tomorrow I'll get some work done on her but I still have some pre-shipping work to do and that CD. After I ship next week I will have the entire week and weekend to work on her. Finally.

Steve

After seeing this I changed my mind. You guys will like bubbles better than the above pictures of a CR 66 E kit that sat unbuilt for some time only to open the box to a taco. This is polyester backed PU. And it happened to a few people.

Today I had to clean shop and get the place cleaned up for dignitaries visiting from Warner's tomorrow. I also tied up the nacelles in there to be final positions to find out all is truly correct and well.

Tomorrow I'll get some work done on her but I still have some pre-shipping work to do and that CD. After I ship next week I will have the entire week and weekend to work on her. Finally.

Steve

crackerjazz

Sr Member

From Warner - wow! Sounds like a big project coming!

SteveNeill

Sr Member

Not really just three friends from over there that want to see the Enterpise.

Steve

Steve

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 1,111

- Replies

- 117

- Views

- 12,420

- Replies

- 11

- Views

- 1,149