You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Studio Half Scale TOS Enterprise Scratch build

- Thread starter SteveNeill

- Start date

- Status

- Not open for further replies.

robn1

Master Member

well looks like you found an easy way to make a string ray. But its interesting that PU resin does that ever find the reason why it causes that?

My guess is shrinkage of the PU. It shrinks more than the polyester/epoxy and causes it to buckle. I would also worry about delamination.

ZOMBIEREPELLENT

Sr Member

Damn that sucks! I havent tried casting anything that thin or flat. So that may be why I havent gotten warpage like that. I mainly cast proton pack shells with it.

SteveNeill

Sr Member

You will not have this problem with pure epoxy. Rob is right BTW.

Video of the week is coming later as it uploads now. I will be ready to ship both kits out after tomorrow and get back to work on the build.

Had a nice visit today from Doug Drexler and part of his crew from Blood and Chrome. It was a nice visit and Doug got his Daedalus model finally and I got the new 2012 Ships of the Line Calender straight from the guys behind it.

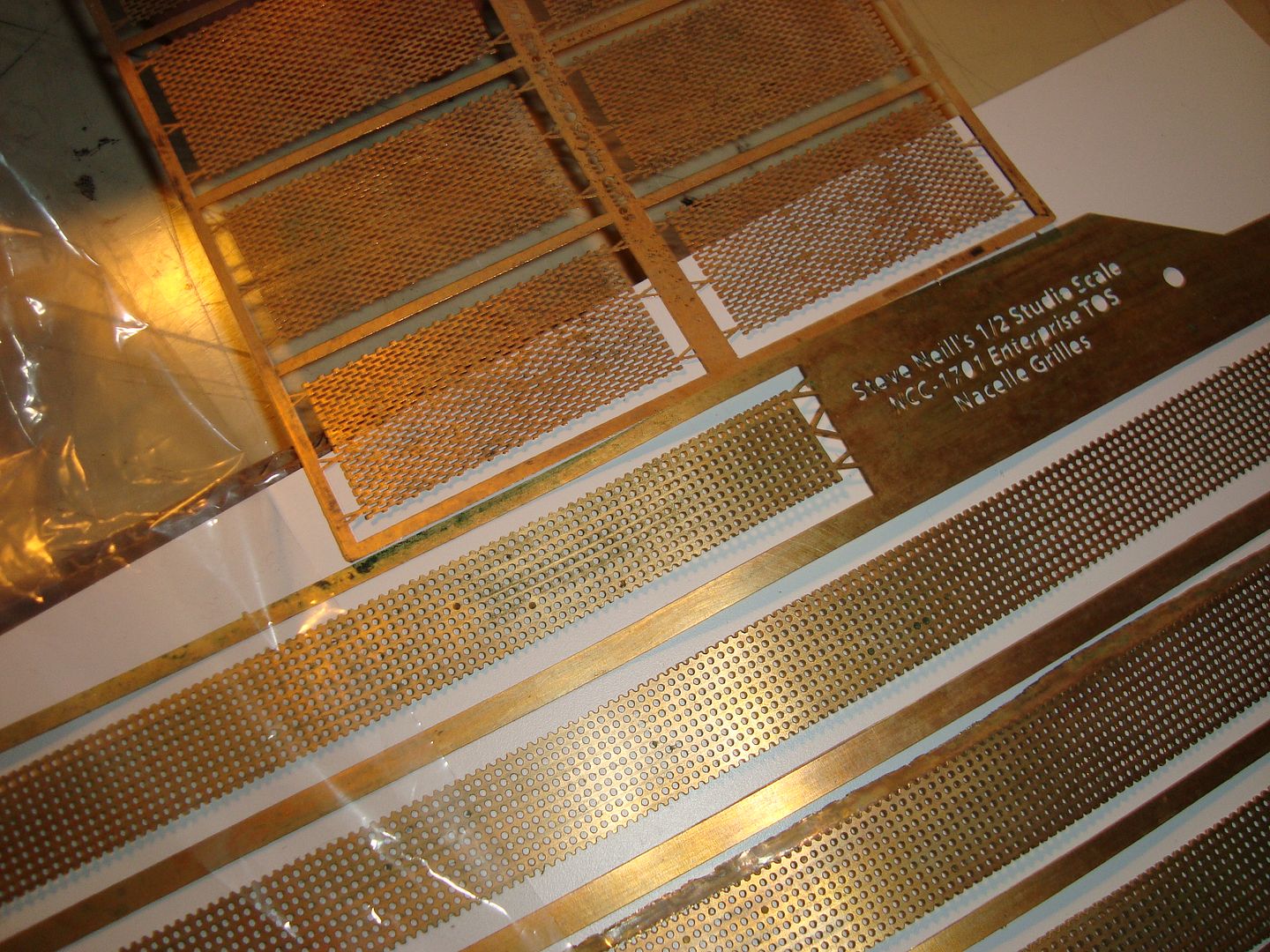

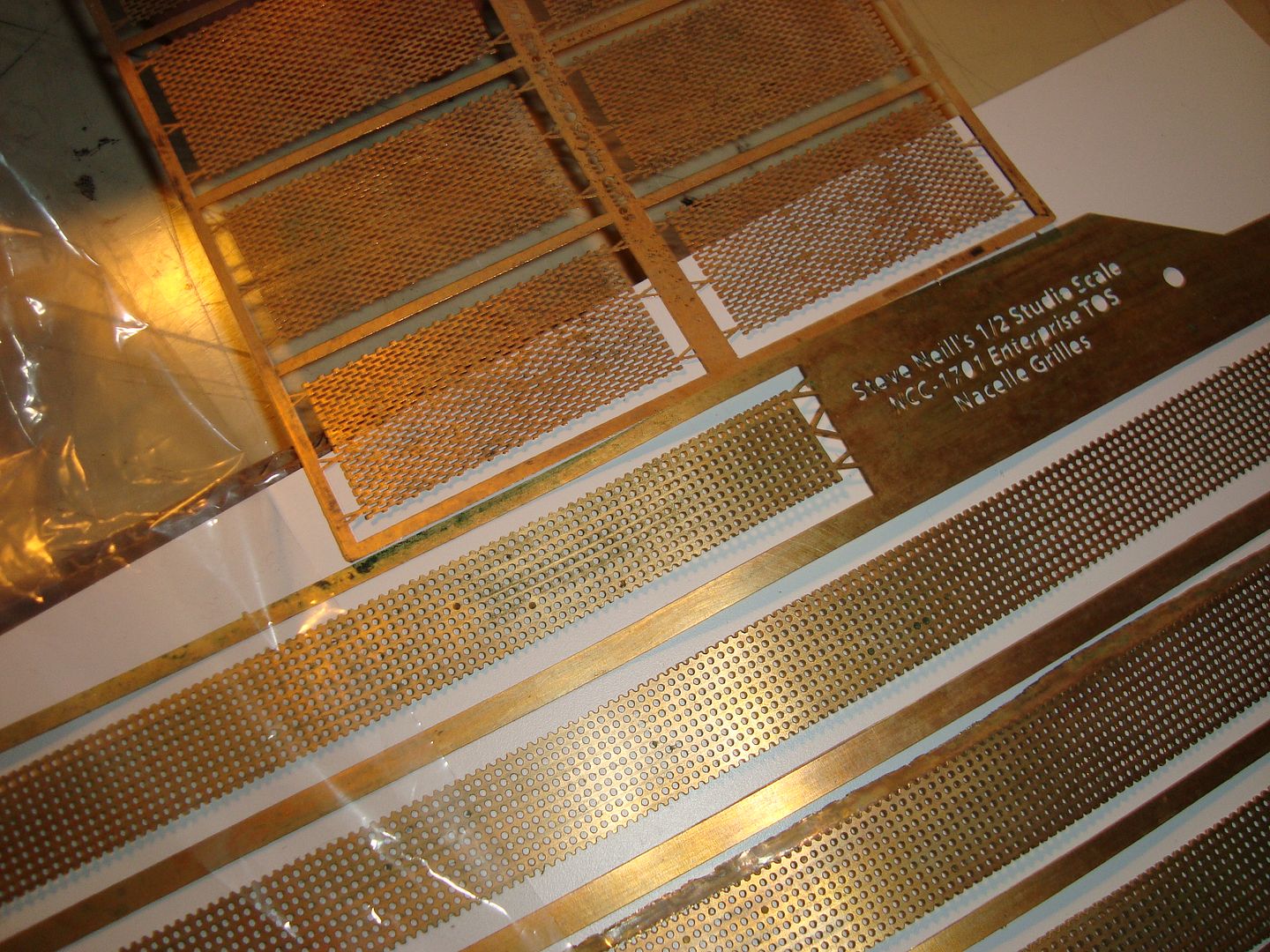

Real goos news on the PE front. Thanks to Eliot Brown and his hard work we have custom brassed etched grills!!! You can learn more about Eliot at his web site fedoratron.com I met him on line as he wanted to offer me a fusion core for my 12 inch J2 and when he heard about my problem with the expensive PE proposition offered to give me a hand and make them himself and so he did! Great job Eliot!

Video up later. Sort of a hodgepodge of the week.

Steve

Video of the week is coming later as it uploads now. I will be ready to ship both kits out after tomorrow and get back to work on the build.

Had a nice visit today from Doug Drexler and part of his crew from Blood and Chrome. It was a nice visit and Doug got his Daedalus model finally and I got the new 2012 Ships of the Line Calender straight from the guys behind it.

Real goos news on the PE front. Thanks to Eliot Brown and his hard work we have custom brassed etched grills!!! You can learn more about Eliot at his web site fedoratron.com I met him on line as he wanted to offer me a fusion core for my 12 inch J2 and when he heard about my problem with the expensive PE proposition offered to give me a hand and make them himself and so he did! Great job Eliot!

Video up later. Sort of a hodgepodge of the week.

Steve

SteveNeill

Sr Member

Aztek Dummy

Well-Known Member

steve,

what are your thoughts about using that clear resin on the windows instead of dental acrylic? would the cure time negate any benefits from not having to buy as many different materials?

what are your thoughts about using that clear resin on the windows instead of dental acrylic? would the cure time negate any benefits from not having to buy as many different materials?

Shizman

Well-Known Member

I was wondering that myself. I'm not sure of the advantages of the dental acrylic. I have clear resin that cures bubble-free without a pressure pot and usually use that for windows, but it's expensive and takes 24 hours to cure, and you also end up having to do windows like the saucer in stages.

ILMwannabe

Active Member

Shizman, may I ask you what you use? I've been looking for a product that cures clear without yellowing and without bubbles, but so far I'm not happy with anything that I've found - any info. would be greatly appreciated - thank you!I have clear resin that cures bubble-free without a pressure pot and usually use that for windows, but it's expensive and takes 24 hours to cure . . .

Shizman

Well-Known Member

I use the low viscosity version of this stuff. It claims to not yellow over time and the only bubbles I ever get are ones that get trapped near a window edge that I miss. I usually chase out edge bubbles with a toothpick.

ILMwannabe

Active Member

Thank you very much for that sir! Really appreciate it! :thumbsup

The brochure says that it has excellent optical properties and resists yellowing, so I really look forward to trying it on my USS Enterprise and other models with small windows.

Chasing bubbles with toothpicks - yes I've done that many times. Whatever works . . .

The brochure says that it has excellent optical properties and resists yellowing, so I really look forward to trying it on my USS Enterprise and other models with small windows.

Chasing bubbles with toothpicks - yes I've done that many times. Whatever works . . .

The Keeper

Active Member

I use a clear resin called Crystal Clear, it works better when you use a pressure tank. It comes out as clear as glass with no yellowing.

SteveNeill

Sr Member

Guys the clear cast in my video is perfect. It doesn't yellow and I found if you don't touch it it's pretty much bubble free but take 24 hours to set up.

The original 11.5 foot model didn't have clear windows. Clear dental acrylic isn't. It's more of a transparent making it a perfect match to what they might have used on the real model which is why I'm using it.

For 21 dollars try the clear cast I'm using this should end the debate.

Steve

The original 11.5 foot model didn't have clear windows. Clear dental acrylic isn't. It's more of a transparent making it a perfect match to what they might have used on the real model which is why I'm using it.

For 21 dollars try the clear cast I'm using this should end the debate.

Steve

trekriffic

Sr Member

Just watched the latest vid. That EasyCast clear epoxy is amazing stuff! Glad to see the nacelles lined up nice and even with the saucer.

Vidar 710

Well-Known Member

That's funny... I just found that same stuff at Micheals last Wednesday! A lady in the Crafts department took me right to it. I've mastered a new Bridge and B/C deck for the 18" kit - which I used on my Copernicus project from Star Trek Phase II's Blood and Fire episode. Just couldn't find one out there that was accurate enough, so I made my own using the Custom Replica's kit part as a guide.

I was hoping to slosh cast it, but I believe the long cure time will not allow it. Wish I had a roto-casting machine. ;-)

Tracy

I was hoping to slosh cast it, but I believe the long cure time will not allow it. Wish I had a roto-casting machine. ;-)

Tracy

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 1,111

- Replies

- 117

- Views

- 12,420

- Replies

- 11

- Views

- 1,149