SteveNeill

Sr Member

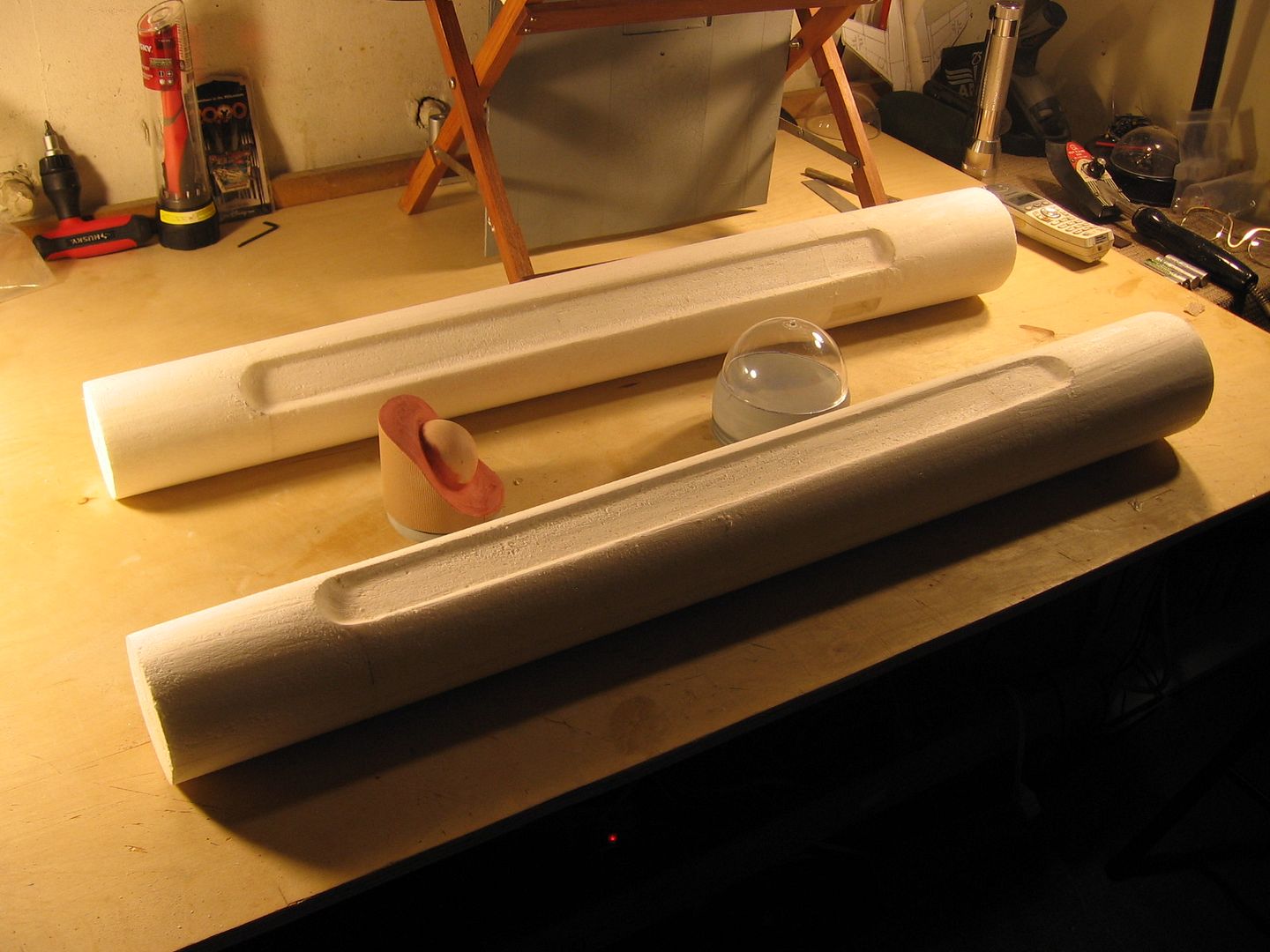

West Systems Epoxy. There are others but I like the way it cures nice an firm and easy to sand after 24 hours. I'll be using 2 oz. fine weave glass cloth. The actual model will be made from the same. The engineering hull and neck will be made using matt instead of cloth and cloth for the saucer and nacelles to keep those sections light.

Steve

Steve