You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show your custom Lightsabers!

- Thread starter GreenCircleCube

- Start date

-

- Tags

- custom highrepublic lightsaber

AnubisGuard

Master Member

So how would a guy get into building lightsabers in the OT style? I know I’ll need some flashgun handles and such, but what else should I be keeping my eyes peeled for in my scavenger hunts?

Knurled knobs and thumbscrews of any kind

1/4-20 screws and threaded rods

Hard drive motor spindles & parts

Champagne stoppers

Circuit board edge connectors

Vintage calculators w/ bubble displays

Vintage camera & projector lenses, as long as they're around 1.5" OD

D-rings

Bicycle headset spacers, and other bicycle parts

Car shifter knobs

Timing pulley, idler pulley, and other types of pulley wheels

Stainless steel fender washers

Anything interesting looking that's bare aluminum, chrome, or brushed metal and is either hollow in the middle, or looks easy to drill a 1/4" hole through for a threaded rod (this is such a broad category that I can't give you any pointers)

And you'll want to buy t-track from places like Wannawanga and Todd's Costumes.

Last edited:

AnubisGuard

Master Member

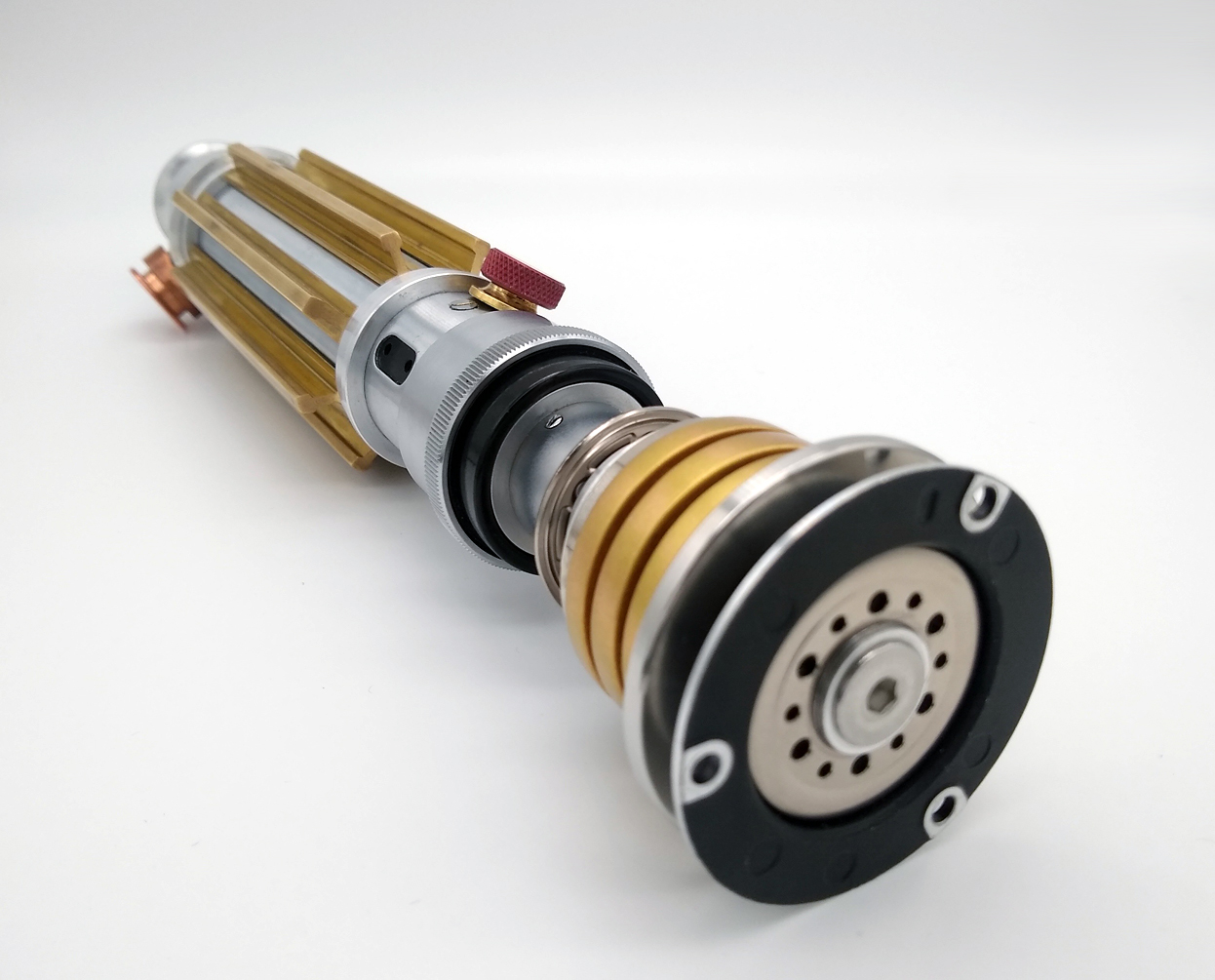

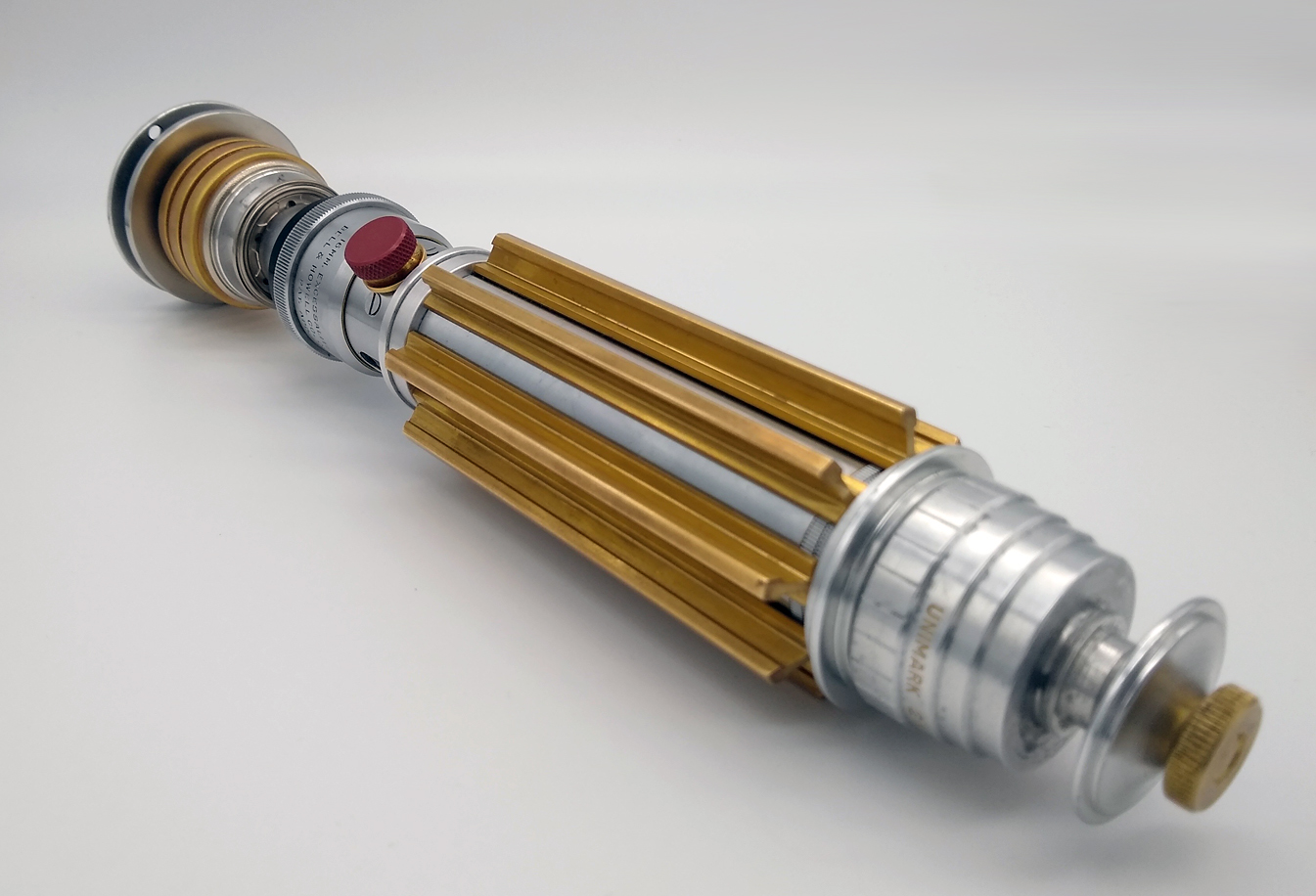

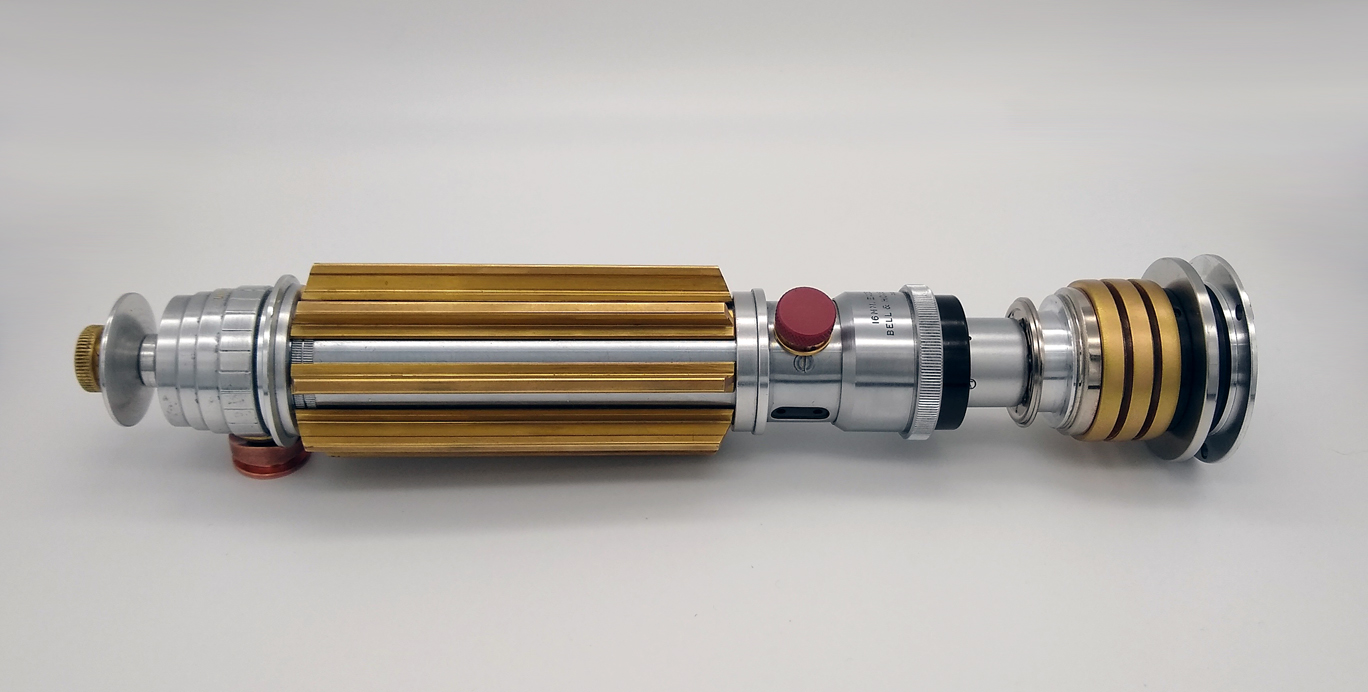

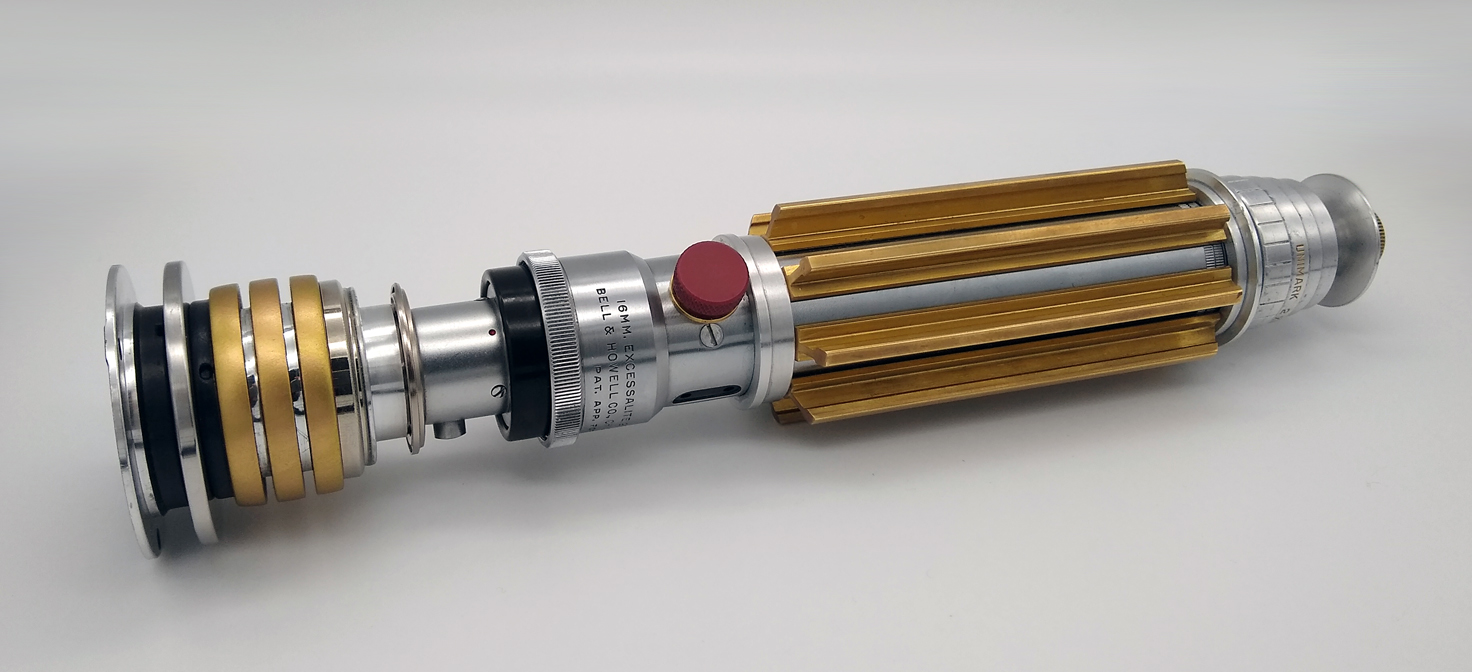

Finished what turned out to be a Prequelized take on Leia's TROS saber. It started with a Minicam Jr., and sort of escalated from there.

Full parts list, from top down:

Emitter:

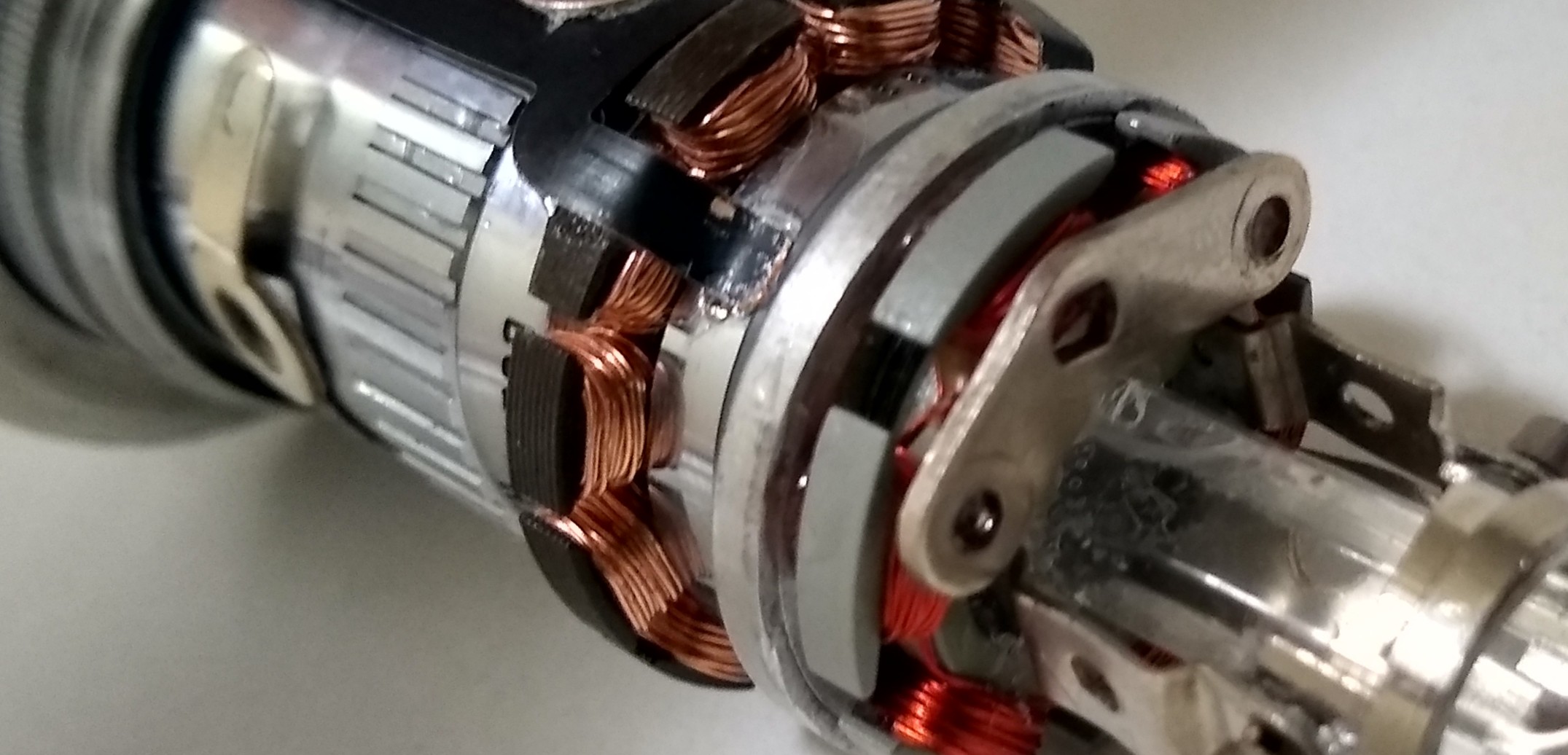

Hard drive spindle....cap? (The disk with holes that screws on the end to hold the platter in place.)

Hard drive motor base

18-8 stainless machined washer

3D printed "brass" rings

Hard drive motor spindle

Another HD spindle cap

Leitz flash top

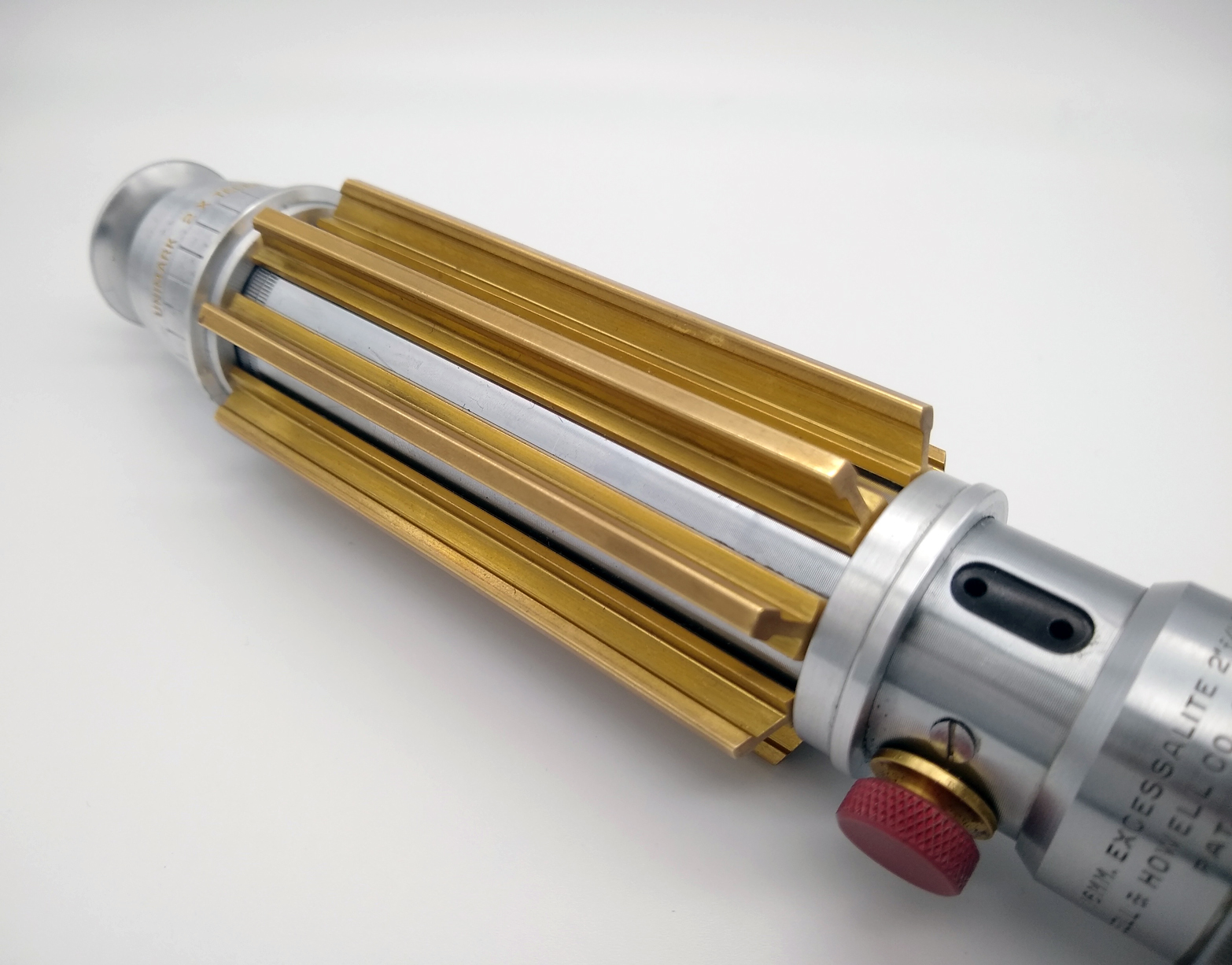

Body:

Minicam Jr (for the body core)

Bell & Howell 16mm projector lens

Roman's Props blanking cap replica (aka Prequel saber red button)

1/4-20 brass knurled nut (bottom half only)

Two 1-1/8 bicycle headset spacers

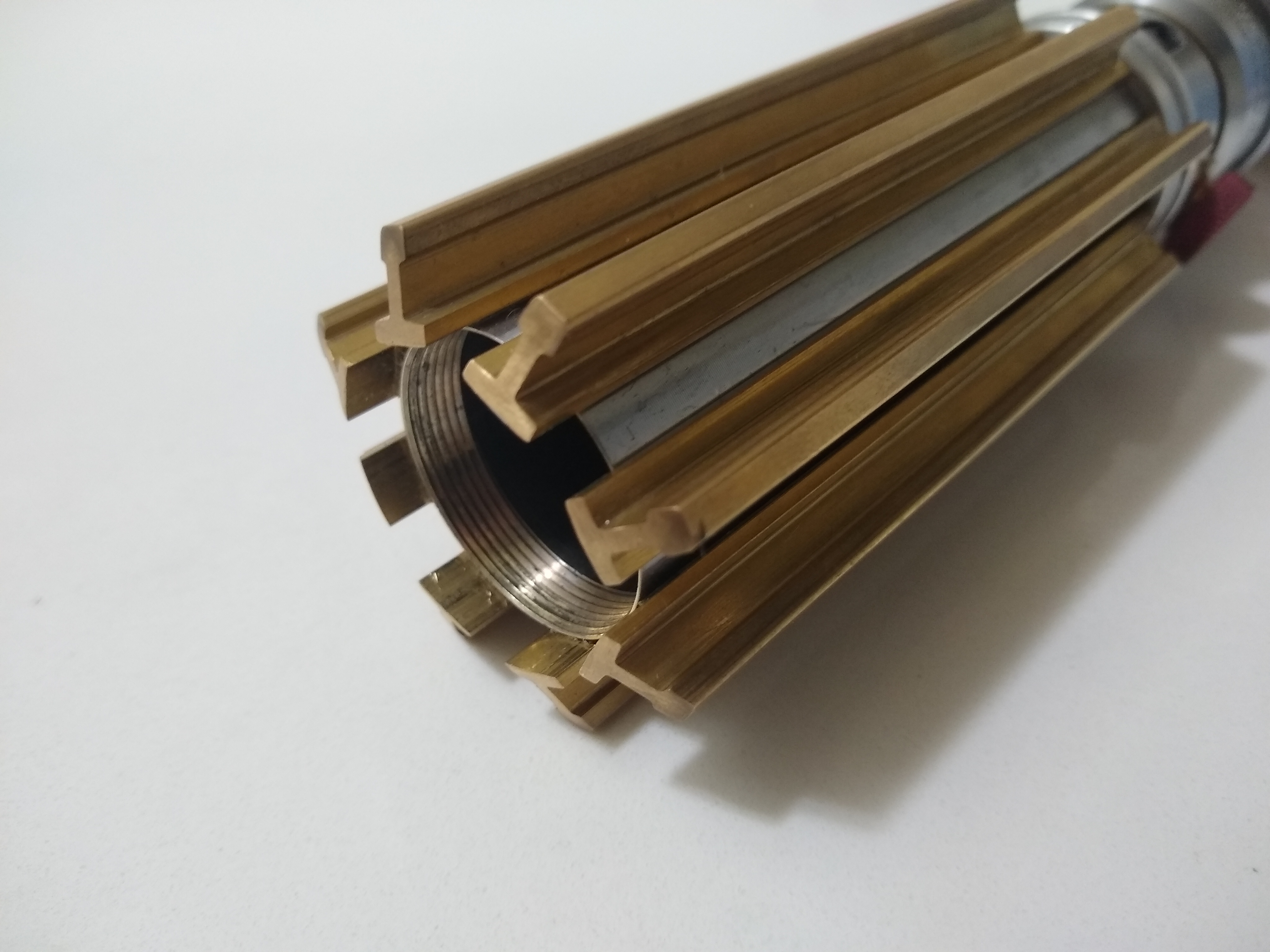

Eight 102mm G-gauge brass train track

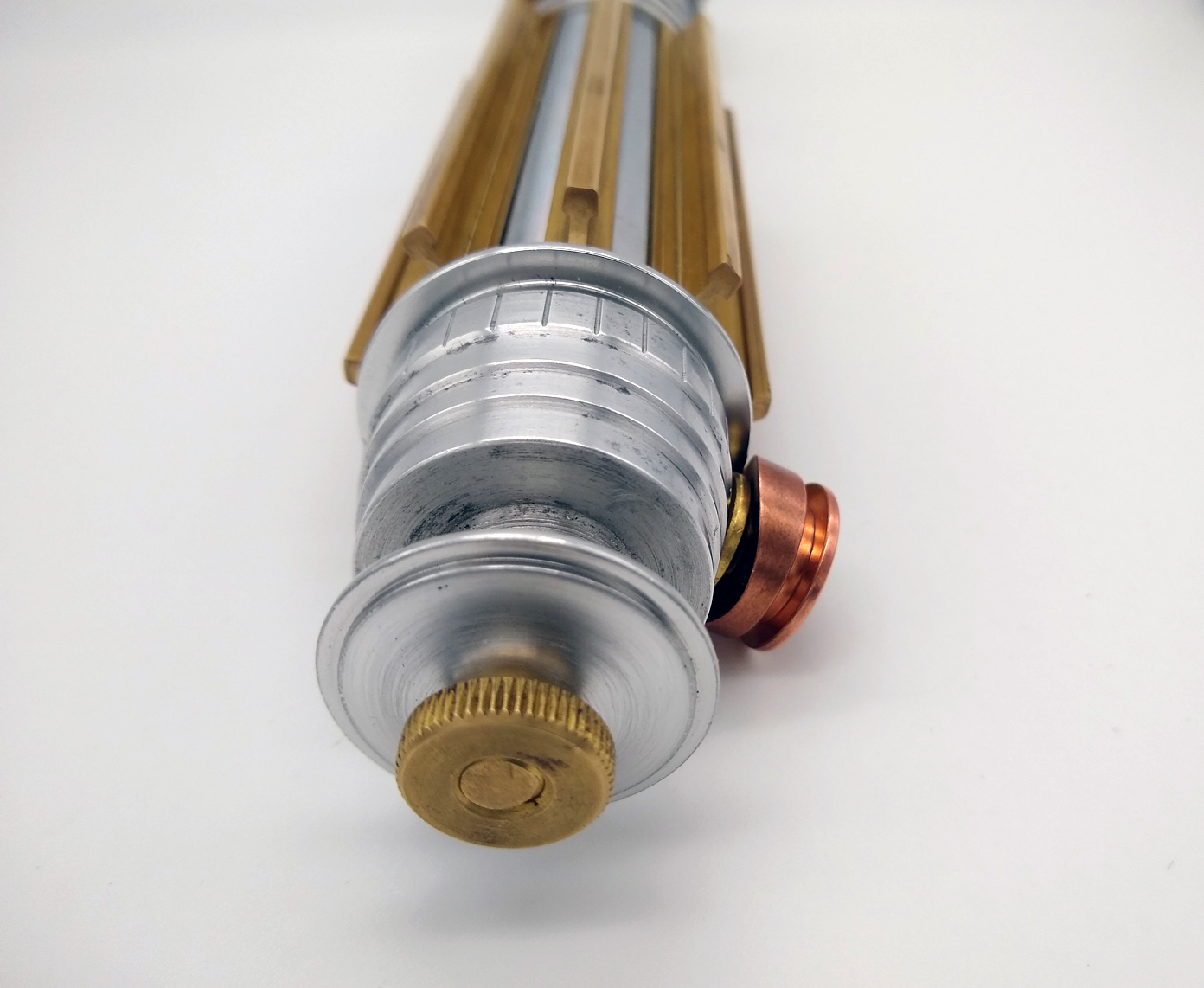

Pommel:

Another 1-1/8 bicycle headset spacer

Bicycle headset crown race

Unimark 2x telephoto lens, off an Eumig C3R 8mm camera

Copper TCSS Covertec wheel

Another 1/4-20 brass knurled nut (bottom half only)

Bicycle headset stem cap

1/4-20 brass knurled nut (top half only)

I'm really happy with this one; probably in my top 5 I've ever done. It's got a great feel in-hand, with a nice heft from the brass grips, and the diameter changes keep it comfortable to grip.

Full parts list, from top down:

Emitter:

Hard drive spindle....cap? (The disk with holes that screws on the end to hold the platter in place.)

Hard drive motor base

18-8 stainless machined washer

3D printed "brass" rings

Hard drive motor spindle

Another HD spindle cap

Leitz flash top

Body:

Minicam Jr (for the body core)

Bell & Howell 16mm projector lens

Roman's Props blanking cap replica (aka Prequel saber red button)

1/4-20 brass knurled nut (bottom half only)

Two 1-1/8 bicycle headset spacers

Eight 102mm G-gauge brass train track

Pommel:

Another 1-1/8 bicycle headset spacer

Bicycle headset crown race

Unimark 2x telephoto lens, off an Eumig C3R 8mm camera

Copper TCSS Covertec wheel

Another 1/4-20 brass knurled nut (bottom half only)

Bicycle headset stem cap

1/4-20 brass knurled nut (top half only)

I'm really happy with this one; probably in my top 5 I've ever done. It's got a great feel in-hand, with a nice heft from the brass grips, and the diameter changes keep it comfortable to grip.

Last edited:

That is gorgeous!Finished what turned out to be a Prequelized take on Leia's TROS saber. It started with a Minicam Jr., and sort of escalated from there.

View attachment 1372956

View attachment 1372957

View attachment 1372954

View attachment 1372955

View attachment 1372958

View attachment 1372959

View attachment 1372960

View attachment 1372961

View attachment 1372962

Full parts list, from top down:

Emitter:

Hard drive spindle....cap? (The disk with holes that screws on the end to hold the platter in place.)

Hard drive motor base

18-8 stainless machined washer

3D printed "brass" rings

Hard drive motor spindle

Another HD spindle cap

Leitz flash top

Body:

Minicam Jr (for the body core)

Bell & Howell 16mm projector lens

Roman's Props blanking cap replica (aka Prequel saber red button)

1/4-20 brass knurled nut (bottom half only)

Two 1-1/8 bicycle headset spacers

Eight 102mm G-gauge brass train track

Pommel:

Another 1-1/8 bicycle headset spacer

Bicycle headset crown race

Unimark 2x telephoto lens, off an Eumig C3R 8mm camera

Copper TCSS Covertec wheel

Another 1/4-20 brass knurled nut (bottom half only)

Bicycle headset stem cap

1/4-20 brass knurled nut (top half only)

AnubisGuard

Master Member

The brass grips on my last build didn't adhere all the way down the length like I expected, with the pleasant result that I can still unscrew the bottom of the flash.

This means only one thing....

This means only one thing....

harrisonp

Sr Member

Oh great I get to follow a post like that

the pictures ended up out of order but here’s what I’m working on. Turning a Budget mass market Chinese saber (the gold one in the second picture) into a scrapped together Fallen Order inspired saber. The masking tape is temporary, holding the piece as epoxy dries

For the money and my tendency to mess with things I really like the features these sabers have

the pictures ended up out of order but here’s what I’m working on. Turning a Budget mass market Chinese saber (the gold one in the second picture) into a scrapped together Fallen Order inspired saber. The masking tape is temporary, holding the piece as epoxy dries

For the money and my tendency to mess with things I really like the features these sabers have

Finished what turned out to be a Prequelized take on Leia's TROS saber. It started with a Minicam Jr., and sort of escalated from there.

So cool, I love the idea of 'prequelizing' the newer designs. The glossy, perfect finish of some of the more recent hilts never felt right. This should have been the design. Thanks for sharing!

Finished what turned out to be a Prequelized take on Leia's TROS saber. It started with a Minicam Jr., and sort of escalated from there.

View attachment 1372956

View attachment 1373294

View attachment 1372957

View attachment 1372955

View attachment 1372958

View attachment 1373295

View attachment 1372959

View attachment 1372960

View attachment 1372961

View attachment 1372962

Full parts list, from top down:

Emitter:

Hard drive spindle....cap? (The disk with holes that screws on the end to hold the platter in place.)

Hard drive motor base

18-8 stainless machined washer

3D printed "brass" rings

Hard drive motor spindle

Another HD spindle cap

Leitz flash top

Body:

Minicam Jr (for the body core)

Bell & Howell 16mm projector lens

Roman's Props blanking cap replica (aka Prequel saber red button)

1/4-20 brass knurled nut (bottom half only)

Two 1-1/8 bicycle headset spacers

Eight 102mm G-gauge brass train track

Pommel:

Another 1-1/8 bicycle headset spacer

Bicycle headset crown race

Unimark 2x telephoto lens, off an Eumig C3R 8mm camera

Copper TCSS Covertec wheel

Another 1/4-20 brass knurled nut (bottom half only)

Bicycle headset stem cap

1/4-20 brass knurled nut (top half only)

I'm really happy with this one; probably in my top 5 I've ever done. It's got a great feel in-hand, with a nice heft from the brass grips, and the diameter changes keep it comfortable to grip.

We may as well close the thread. This saber will never be topped.

AnubisGuard

Master Member

I absolutely hate cutting stainless steel; sometimes it's the exact right part you need, but give me aluminum or brass any day.

I needed a weekend project, so I dug through my parts boxes and came up with this:

Thanks - Yeah - I was going for sort of an art deco kinda vibe...

There's a real McQuarrie feel to that saber! Fits in with his earlier concept art.

harrisonp

Sr Member

I’ve been poring over this thread and got caught up in being unhappy with the look of my saber. I felt it was too much like the Fallen Order saber and wanted something more OT/Old EU like Corran Horn or Kyle Katarn looking so I’ve redone the emitter. Much happier with the look now (still needs some smoothing and weathering) and I think I achieved my design intent.

veektohr

Sr Member

Finished what turned out to be a Prequelized take on Leia's TROS saber. It started with a Minicam Jr., and sort of escalated from there.

Holy ****, dude. [emoji7]

AnubisGuard

Master Member

I just watched this Canon Y shoot up in a last-minute bidding war. Granted it's got it's leather case and some other accessories, but jeez.

What have we done, boys. What have we done.

What have we done, boys. What have we done.

What is the most economical lathe you would recommend for something like stainless or titanium?Aircraft-grade aluminum (like 6061) is my main material. I also use brass for some of the knobs and other accent pieces. Those are both pretty easy to cut, even dry. I have some stainless steel stock but honestly I've never tried to cut it. I'm sure its tough as hell.

I have a Sherline 4400 lathe (picture below)...I also have the milling column, which converts it to a milling machine, and the knurling attachment. The biggest problem is that its powered by an electric motor, so its not terribly powerful. You can't take off a lot of metal in a single pass, so it takes a while - probably 15 hours on average - to make a saber. But I typically make everything on a saber, including the knobs/thumbscrews and the Covertec. The only things I don't make are the LEDs and any screws I may use (like the one that holds on the Covertec).

View attachment 430283

BastianEstrella

New Member

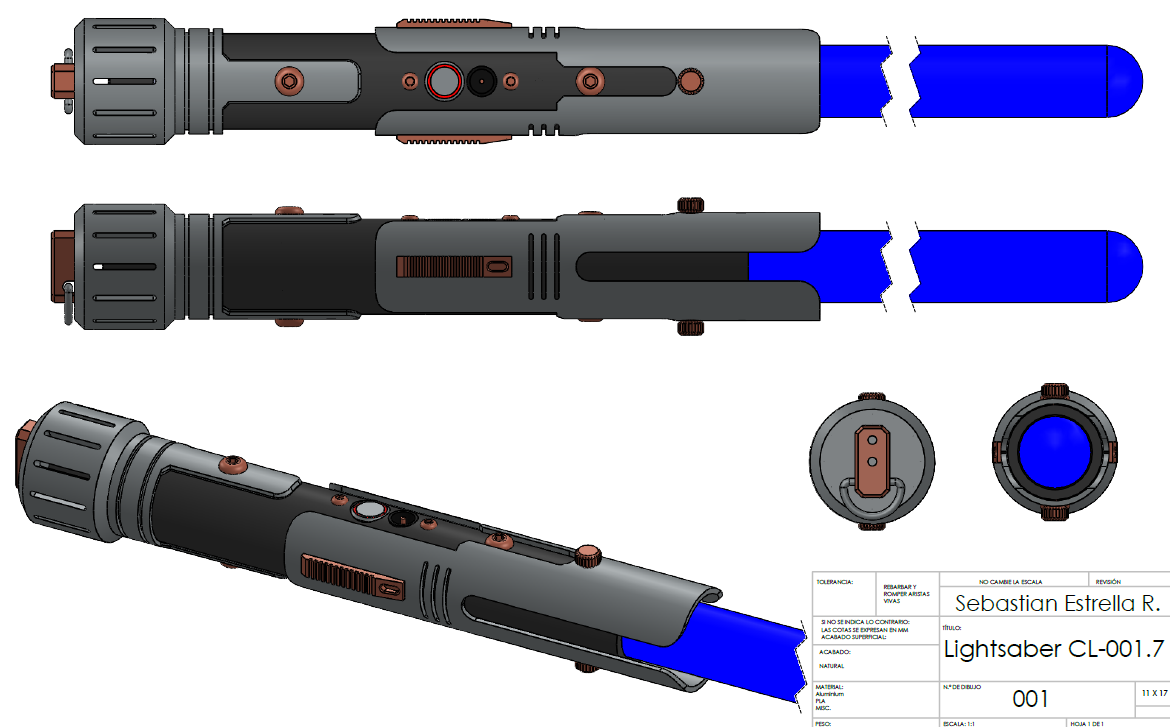

I´m about to start making this.

3D printed wth an aluminium tube as the core and some electronics from a cheap kit. I guess I´ll have to paint the screws, might not be able to get them in copper.

3D printed wth an aluminium tube as the core and some electronics from a cheap kit. I guess I´ll have to paint the screws, might not be able to get them in copper.

Similar threads

- Replies

- 25

- Views

- 3,747

- Replies

- 52

- Views

- 6,160

- Replies

- 111

- Views

- 15,090

- Replies

- 8

- Views

- 1,234

- Replies

- 18

- Views

- 2,904