Has anyone tried printing canopies with clear resin? I’ve never printed anything that thin with clear resin, but if you could get a print that is bubble-free, and you manage to arrange the supports so they’re on the edges then I think you could get a good result. Although for canopies that consist of flat surfaces I expect cutting the glazing out of acetate or acrylic would yield better results.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Razor Crest

- Thread starter Analyzer

- Start date

Analyzer

Master Member

Looking awesome already. As I doubt Bandai will come up with one in the near future, I guess my next bigger investment will be a resin printer

Just curious, do you think your used files would scale down to 144 ? Just my prefered scale for ships like Falcon, Slave 1...

For DLP/SLA printers scaling the 1/68 files down to 1/144 should be doable. I am actually going to give that a try after I finish this. THere may be some parts that would have to be "thickened" though.

for clear, resin cast of the windshield, try Epoxacast 690. Degass the you-know-what out of it. Use Eco-flex for the mold. Since it is going to be thin, you won't notice the refractive error. Holding it up to your eye, you may not be able to read an eye chart 20 feet away, but an object an inch or two away will be easily visible.

A thin cast of most transparent resins usually does give a good result if it is thin. I don't think you will be casting thicker than 1mm.

thanks, I'll have to look into that

Has anyone tried printing canopies with clear resin? I’ve never printed anything that thin with clear resin, but if you could get a print that is bubble-free, and you manage to arrange the supports so they’re on the edges then I think you could get a good result. Although for canopies that consist of flat surfaces I expect cutting the glazing out of acetate or acrylic would yield better results.

I have seen a few videos where people have printed clear stuff, but I am not sure they are 100% clear. Still have to do some more digging

Analyzer

Master Member

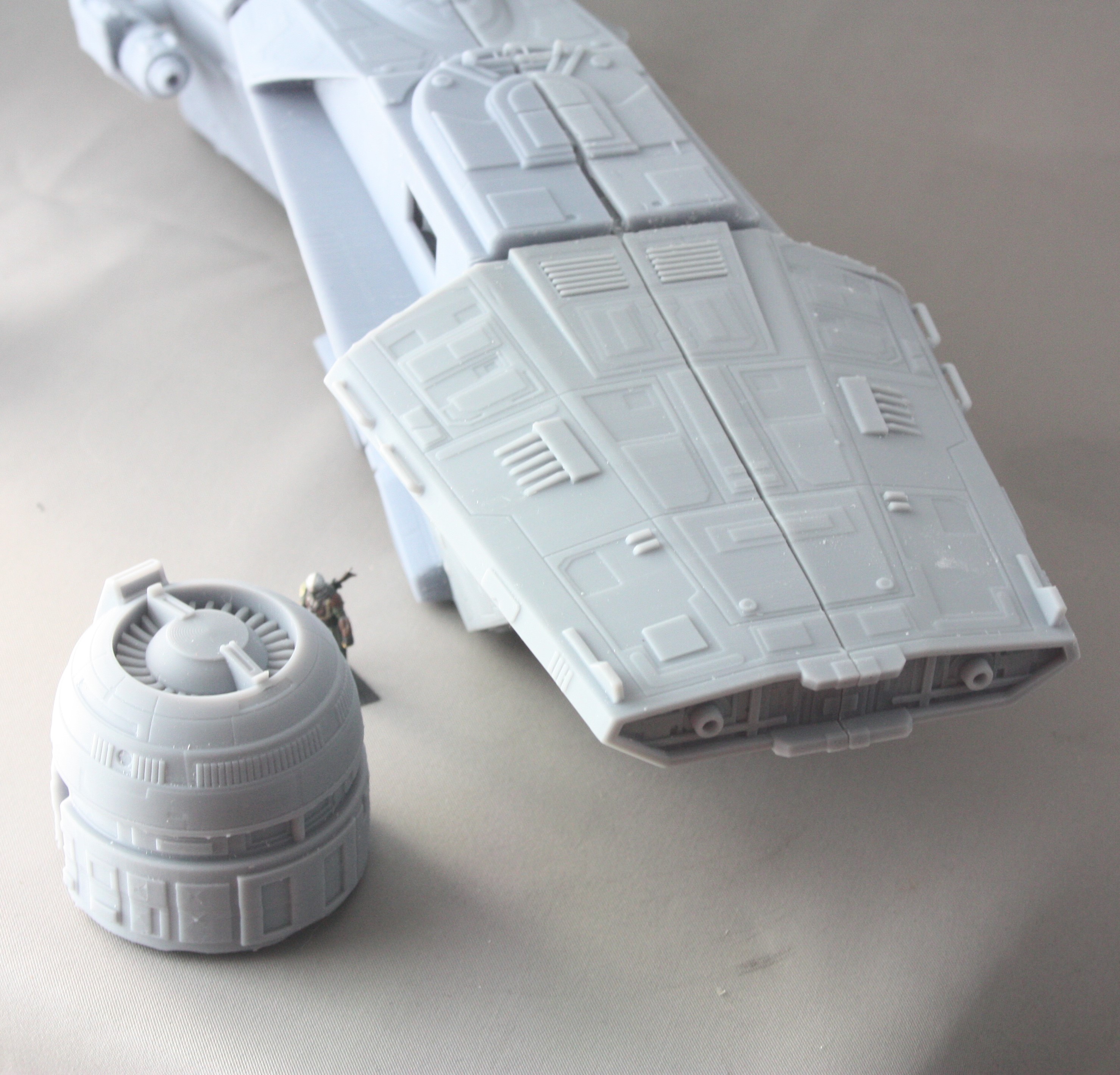

New bottle of resin and new FEP arrived.

Got the other half of the center hull printed.

I may try redoing the front, or at least the one side that has bigger gaps at the back where it meets the center

Since I printed it upright, and that was the bottom, it tends to deform slightly on the first few layers of the edge. Add more supports going out the corners and edge helps. Ideally I believe you would print at an angle to alleviate those issues, but the pieces barely fit the build volume of my Photon standing straight up

I am considering scratch building an interior and displaying it landed with the doors open

At any rate, progress...

Got the other half of the center hull printed.

I may try redoing the front, or at least the one side that has bigger gaps at the back where it meets the center

Since I printed it upright, and that was the bottom, it tends to deform slightly on the first few layers of the edge. Add more supports going out the corners and edge helps. Ideally I believe you would print at an angle to alleviate those issues, but the pieces barely fit the build volume of my Photon standing straight up

I am considering scratch building an interior and displaying it landed with the doors open

At any rate, progress...

Analyzer

Master Member

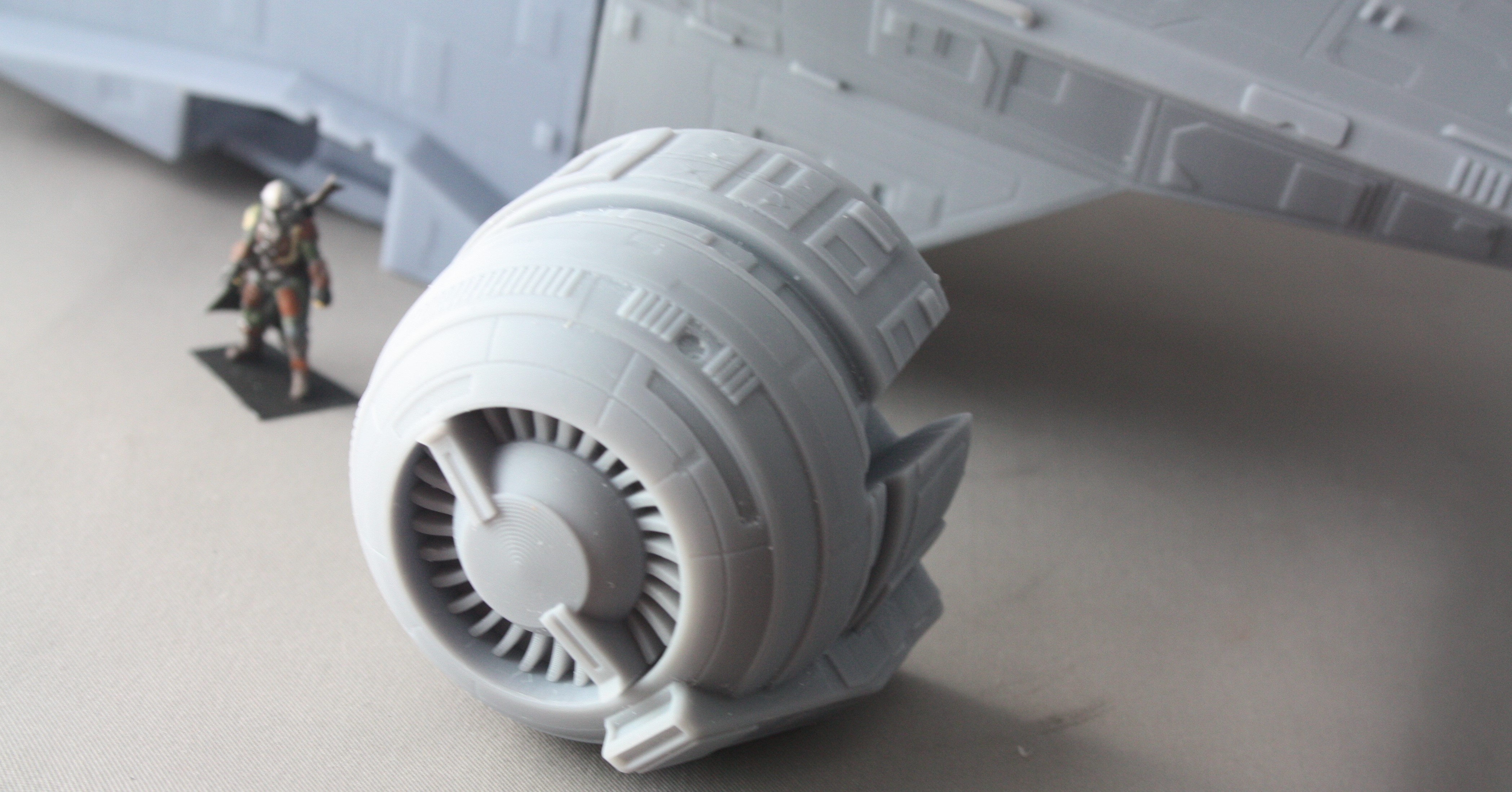

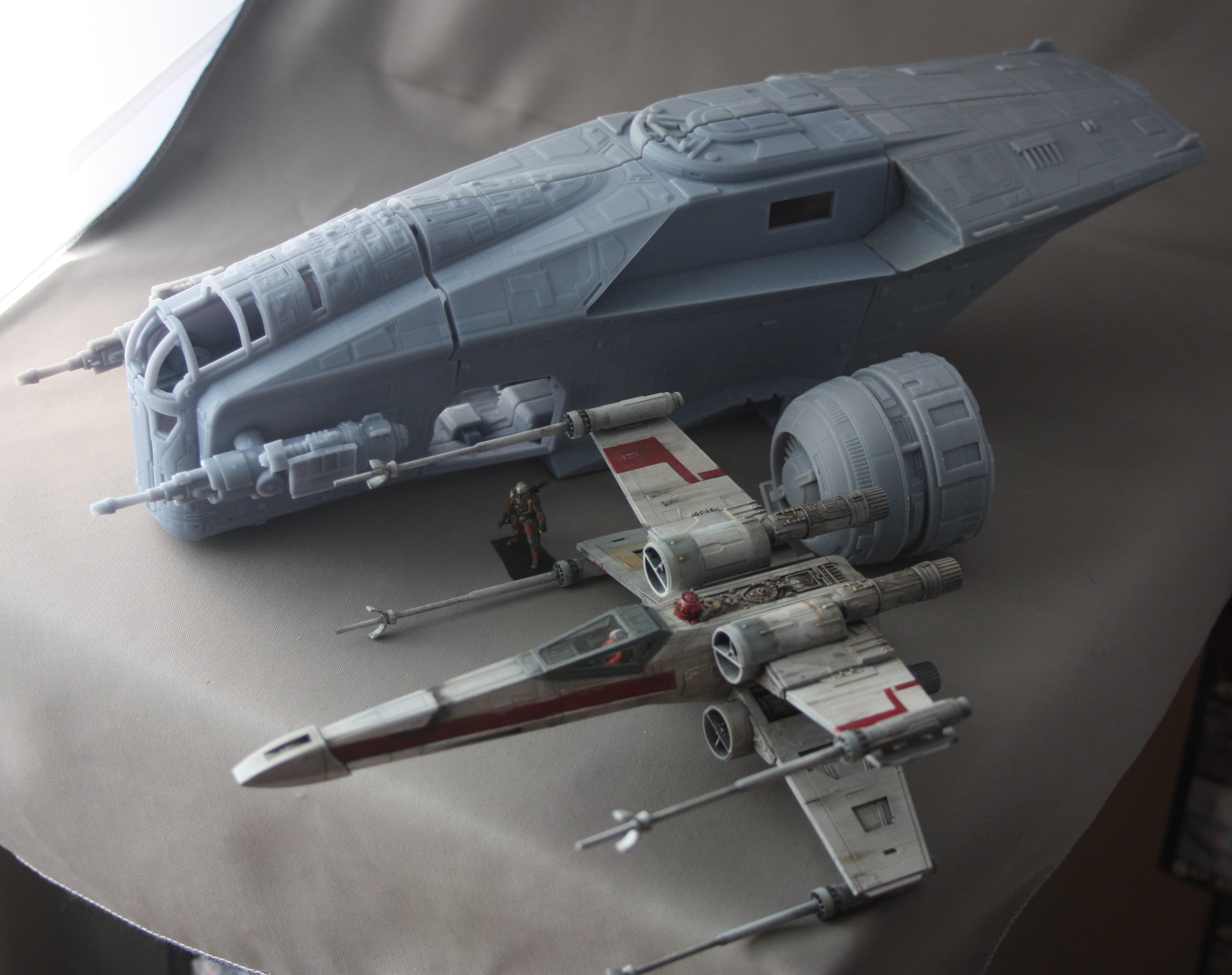

Main body done, only bug parts left now are the wings and turbines

I wish I could find a better way to prevent the bottom layer (where the back joins to the center) from getting so deformed. It is only loosely dry fitted right now but there will definitely be gap filling required

Again, if I had a larger build volume I think printing at an angle would help fix that issue?

Size reference

Also, primed the cockpit so I can start lighting and painting

I wish I could find a better way to prevent the bottom layer (where the back joins to the center) from getting so deformed. It is only loosely dry fitted right now but there will definitely be gap filling required

Again, if I had a larger build volume I think printing at an angle would help fix that issue?

Size reference

Also, primed the cockpit so I can start lighting and painting

That's a nice looking Red Leader as well!

SB

SB

Madhatter

Sr Member

like the others before me have said - this is a really nice print you have going on here! Cool subject as well

What type of printer are you using? I'd like to get into 3D printing but haven't really done anything about it as I don't like the lines it leaves - but this resin printing is beautiful.

What type of printer are you using? I'd like to get into 3D printing but haven't really done anything about it as I don't like the lines it leaves - but this resin printing is beautiful.

Analyzer

Master Member

thanks everyone

slowly trudging on. I had decided to redo how I split the turbine and engine can parts, doing it in two instead of 3. However, I had a failed print 4 hours into an 8 hour print because I forgot to check up on the resin vat and ran out of resin

But I did manage to get the one wing printed

I am using the Anycubic Photon. They are very cheap now on sites like Amazon. I think at one point you could get them for around $149. Amazon currently has them for $189.

There is also the Photon S which has a few minor improvements over the Photon

The details it can print is amazing. I am printing at the default layer thickness of .05 mm and using 2 for the anti-aliasing. It can go down to .02 mm for resolution, but of course increases printing time. For something like this, I find .05 is enough

I use the Anycubic grey resin over the green that came with the printer. I find it more reliable

There are also the Elegoo line of printers which are basically the same type of thing

For small miniatures with fine details, resin printers are night and day compared to FDM prints of the same subjects that I have or have seen

Edited: I will say when first thinking about getting a printer and what would be involved, the whole process seemed daunting, but the Photon made the whole thing about as plug-n-play as taking it out of the box, level the plate, and hit print. I think the Elegoo Mars is the same way. The main challenge is getting the supports set up right for your models, that is the main cause of failure for me. I have gotten a lot better at it and rarely have one now though

slowly trudging on. I had decided to redo how I split the turbine and engine can parts, doing it in two instead of 3. However, I had a failed print 4 hours into an 8 hour print because I forgot to check up on the resin vat and ran out of resin

But I did manage to get the one wing printed

like the others before me have said - this is a really nice print you have going on here! Cool subject as well

What type of printer are you using? I'd like to get into 3D printing but haven't really done anything about it as I don't like the lines it leaves - but this resin printing is beautiful.

I am using the Anycubic Photon. They are very cheap now on sites like Amazon. I think at one point you could get them for around $149. Amazon currently has them for $189.

There is also the Photon S which has a few minor improvements over the Photon

The details it can print is amazing. I am printing at the default layer thickness of .05 mm and using 2 for the anti-aliasing. It can go down to .02 mm for resolution, but of course increases printing time. For something like this, I find .05 is enough

I use the Anycubic grey resin over the green that came with the printer. I find it more reliable

There are also the Elegoo line of printers which are basically the same type of thing

For small miniatures with fine details, resin printers are night and day compared to FDM prints of the same subjects that I have or have seen

Edited: I will say when first thinking about getting a printer and what would be involved, the whole process seemed daunting, but the Photon made the whole thing about as plug-n-play as taking it out of the box, level the plate, and hit print. I think the Elegoo Mars is the same way. The main challenge is getting the supports set up right for your models, that is the main cause of failure for me. I have gotten a lot better at it and rarely have one now though

Last edited:

Real Scooby

Well-Known Member

Photon S is what I am looking at too, currently. Do you use their Cleaner Device too or are you cleaning the prints per hand ?thanks everyone

slowly trudging on. I had decided to redo how I split the turbine and engine can parts, doing it in two instead of 3. However, I had a failed print 4 hours into an 8 hour print because I forgot to check up on the resin vat and ran out of resin

But I did manage to get the one wing printed

View attachment 1353065

I am using the Anycubic Photon. They are very cheap now on sites like Amazon. I think at one point you could get them for around $149. Amazon currently has them for $189.

There is also the Photon S which has a few minor improvements over the Photon

The details it can print is amazing. I am printing at the default layer thickness of .05 mm and using 2 for the anti-aliasing. It can go down to .02 mm for resolution, but of course increases printing time. For something like this, I find .05 is enough

I use the Anycubic grey resin over the green that came with the printer. I find it more reliable

There are also the Elegoo line of printers which are basically the same type of thing

For small miniatures with fine details, resin printers are night and day compared to FDM prints of the same subjects that I have or have seen

Edited: I will say when first thinking about getting a printer and what would be involved, the whole process seemed daunting, but the Photon made the whole thing about as plug-n-play as taking it out of the box, level the plate, and hit print. I think the Elegoo Mars is the same way. The main challenge is getting the supports set up right for your models, that is the main cause of failure for me. I have gotten a lot better at it and rarely have one now though

Analyzer

Master Member

Photon S is what I am looking at too, currently. Do you use their Cleaner Device too or are you cleaning the prints per hand ?

Their wash machine is quite handy and easy to use, especially since you can supposedly hang the build plate right in it. If I had the money to spare I would definitely get one as I have heard great things about it

However, I am on a bit of a budget and would rather spend the money I do have for hobby on resin and FEP supplies or even nice stl files

I simply use Chinese quart soup containers filled with Isoprophyl alcohol and drop the parts in there, put the lid on, and shake it up or swirl it around

Analyzer

Master Member

Also, of note regarding the Photon S (or Upgraded Photon), depending on what firmware version, you may or may not be able to use files with the .Photon extension straight from Chitubox. The latest firmware update for them supports both .photon and .pws (the new Anycubic "proprietary" format), but some of the older one can only read .PWS format, and Chitubox can only slice as a .PHOTON.

However, if you prefer Chitubox over the Anycubic Photon Workshop software (which is essentially a skin of Chitbubox with a few streamlined options added) all you have to do is use Save As... to save your supported file in Chitbox as an .stl file, open that .stl file in Photon Workshop, and just hit the slice button to slice as a PWS file

Although the latest version of Photon Workshop is actually pretty good in it's own right, especially for beginners, and you may not even find the need to use Chitubox unless you want a bit more manual control. There are also some features of it that I think are better than Chitubox and sometimes I find myself doing things in both.

However, if you prefer Chitubox over the Anycubic Photon Workshop software (which is essentially a skin of Chitbubox with a few streamlined options added) all you have to do is use Save As... to save your supported file in Chitbox as an .stl file, open that .stl file in Photon Workshop, and just hit the slice button to slice as a PWS file

Although the latest version of Photon Workshop is actually pretty good in it's own right, especially for beginners, and you may not even find the need to use Chitubox unless you want a bit more manual control. There are also some features of it that I think are better than Chitubox and sometimes I find myself doing things in both.

I simply use Chinese quart soup containers filled with Isoprophyl alcohol and drop the parts in there, put the lid on, and shake it up or swirl it around

OMG... That's exactly what I use to clean my prints! Effective and free...

Hias looking great, i noticed your failed prince with bad layers, whats your layer cure time? On my photon, Ive found anything bellow 15 seconds a layer is risky. Even on quick cure resins. I think its just because the base photo has such a weak UV light....

But anyway again looking great.

But anyway again looking great.

Analyzer

Master Member

OMG... That's exactly what I use to clean my prints! Effective and free...

Great minds think a like?

I needed something to do with those containers, plus you can put the lid on an keep the stuff for a few tries. I keep one that has fresh stuff, and one that is "dirty" as a pre-wash to get most of the resin off initially without wasting newer stuff

Hias looking great, i noticed your failed prince with bad layers, whats your layer cure time? On my photon, Ive found anything bellow 15 seconds a layer is risky. Even on quick cure resins. I think its just because the base photo has such a weak UV light....

But anyway again looking great.

I have been using 8 second layers. I think for some things i have upped it to 10 seconds.

I know some of the Elegoo and Siraya resins need longer times, but the Anycubic grey seems to mostly be ok with 8 to 10 seconds. Maybe next time something fails, instead of resupporting it or adding more supports, maybe I should consider upping the exposure time instead

Usually when I do have a failure, the base partially lifted off the build plate, or the supports were not strong enough to hold on to the model. But I do occasionally get some odd ones

ohhhh thats another thing if its coming off your bed.... Scuff up your bed, I used some 80 grit glass paper to give it a good scuffing, and its worked really well, even now my fep is getting a bit old, the bed usually wins... But i think 10 really is too low, i would never dare go bellow 12 but even 13 ive had failures on... 15 seemed like the best good round number, also 80 on base layers... I usually use elegoo abs like resin. Mostly because i cant get siraya in the uk...

Similar threads

- Replies

- 5

- Views

- 795

- Replies

- 44

- Views

- 7,922