Risu

Master Member

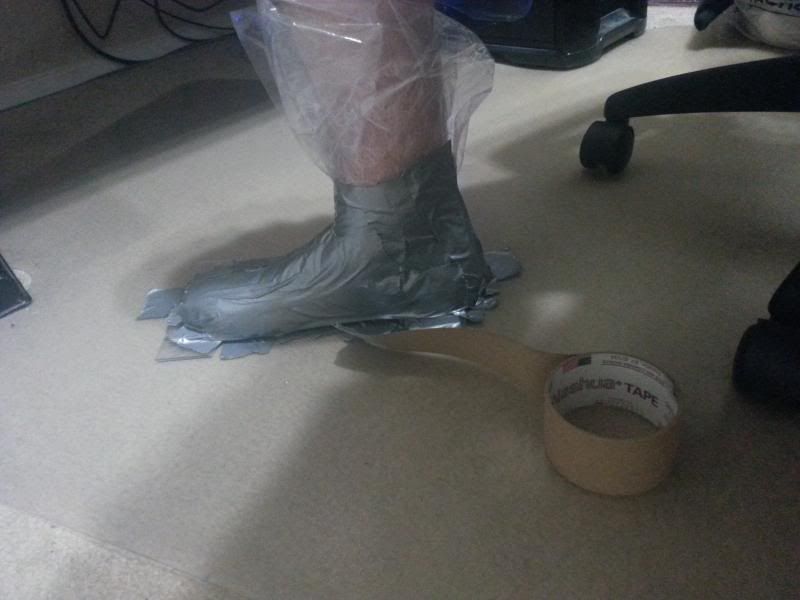

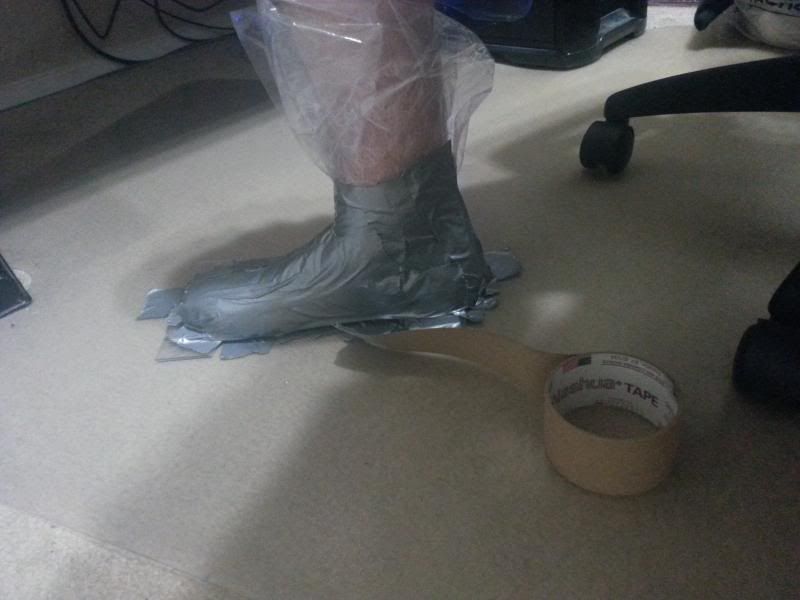

So after watching some videos on youtube last night ,I decided to jump right into this next step tonight and didn't plan it out so well. I'm making my own lasts ( shoe forms) for the boots. Basically I patterned the bottom of the last by averaging a trace of my foot and of the existing soles. Then I built a 7/8" tall toe box with duct tape, built up the toe shape with play-doh, put my foot in a plastic bag, and started wrapping it in duct tape, securing the bottom edge to the floor as I went. Aaaaaaaand then I ran out of duct tape. So I'm sitting here typing this up with my foot covered in play-doh and tape and cemented to the floor while my roommate runs to the store to buy more tape.

Once I put the second coat of tape on, it should be pretty rigid. Then I can carefully cut the tape free from the floor, wrap the bottom of the foot, cut myself out of it, remove the play-doh, tape it back up, and fill it with plaster. Then I get to do it all over again with the left foot.

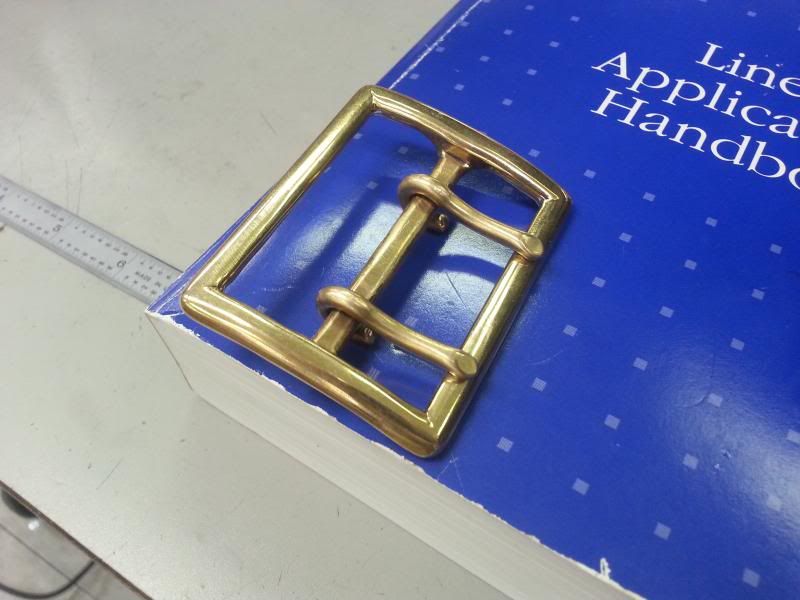

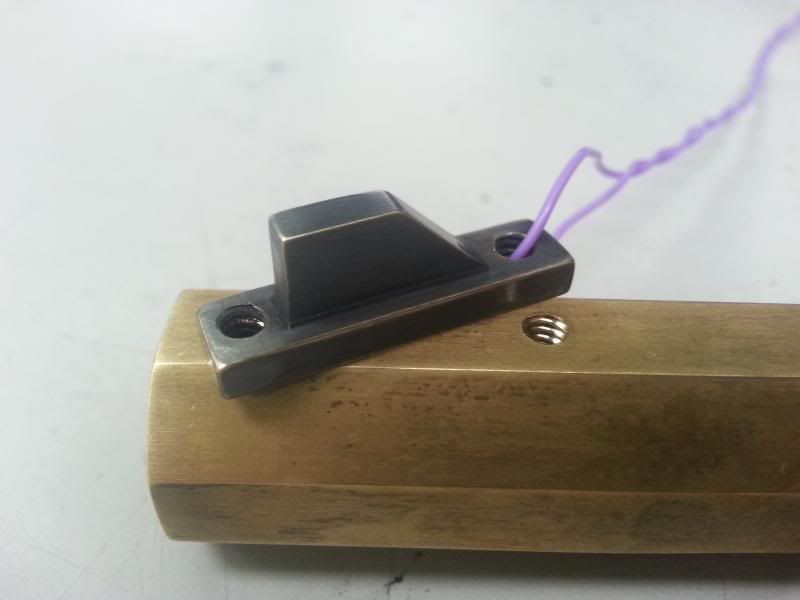

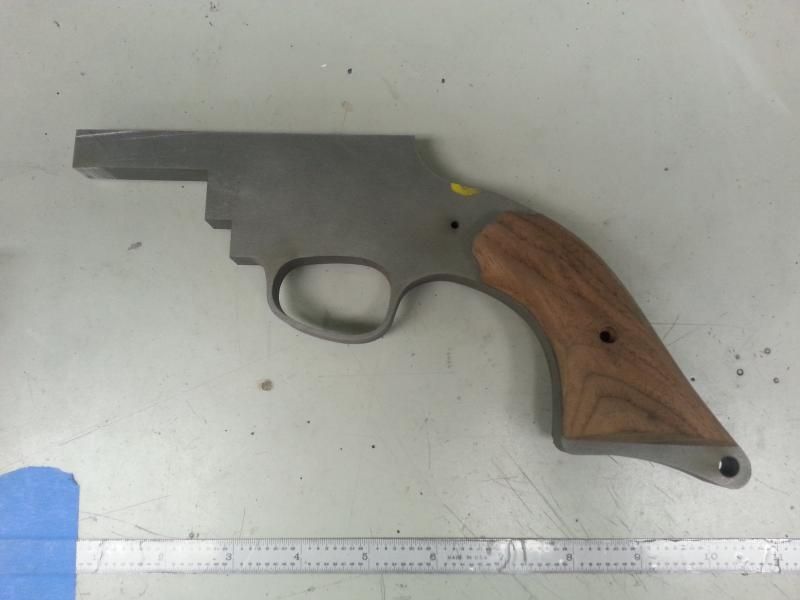

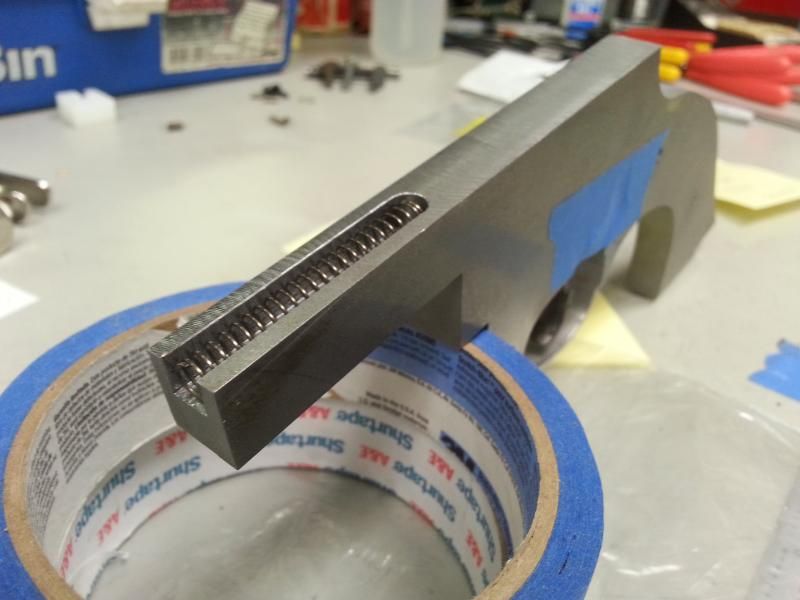

In regard to the other machining project, it's most of the way done, just needs a little fine sanding and it's done. Also, does anybody know where to get a good brass blackening chemical? Brass Black by Birchwood Casey is absolute garbage, like their aluminum black. I've also tried Jax brand and I've made a half-assed atempt at ammonia and calcium carbonate. None of them create a good, durable black patina. There was some stuff I used to have access to at my old job years ago that was perfect, but we never knew the name of it or where it came from. It would turn brass parts completely black in seconds when submerged and the finish was durable and basically permanent.

Once I put the second coat of tape on, it should be pretty rigid. Then I can carefully cut the tape free from the floor, wrap the bottom of the foot, cut myself out of it, remove the play-doh, tape it back up, and fill it with plaster. Then I get to do it all over again with the left foot.

In regard to the other machining project, it's most of the way done, just needs a little fine sanding and it's done. Also, does anybody know where to get a good brass blackening chemical? Brass Black by Birchwood Casey is absolute garbage, like their aluminum black. I've also tried Jax brand and I've made a half-assed atempt at ammonia and calcium carbonate. None of them create a good, durable black patina. There was some stuff I used to have access to at my old job years ago that was perfect, but we never knew the name of it or where it came from. It would turn brass parts completely black in seconds when submerged and the finish was durable and basically permanent.