Can you elaborate in some more detail on how you did that pommel section?

I made it from tubes in sizes 25, 28, 31, 34, 37 and 40 mm, each being 1.5 mm thick, but they had not been manufactured with good tolerances. The pairs of 25/28 and 31/34 slid together effortlessly and just needed glue, but the other pairs had to be combined using heat, cold and force.

You can combine up to three tubes together with force, but parts will start to shift when you force in the fourth one. The rule is that the largest and the smallest tube are added to the one in the middle.

One good thing with aluminum is that if you file hard over an edge where two pieces meet closely, the metal kind of frays hiding the seamline!

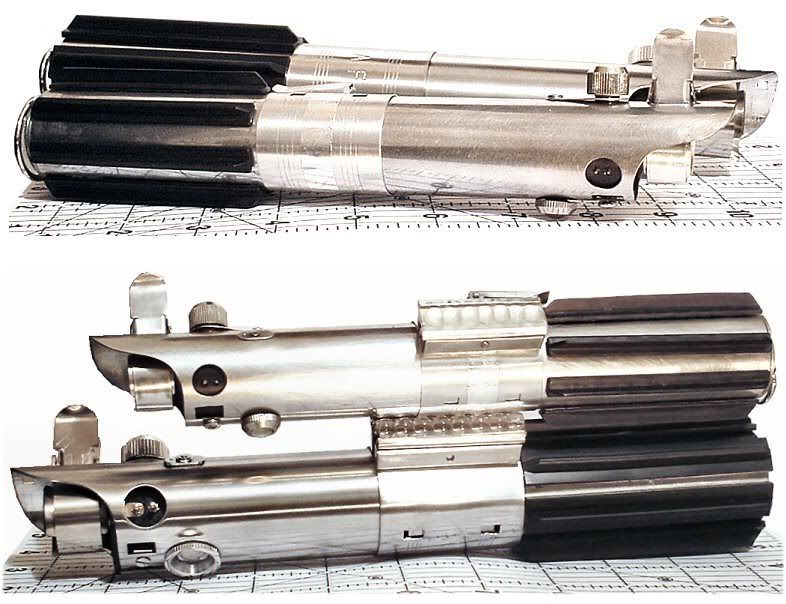

I had these pics on my harddrive, showing more of the pommel pieces. The first pic shows the second step right above the "cubes". The "cubes" go in-between the notches. Each notch fits under the edge of the lower conical part.

The tube used for the neck (25 mm) is the same that goes inside the handgrip.

The endcap was made from a 25 mm cylinder, where the end was slightly rounded and then cut off. There exists a type of bolt where the head has this exact shape, but I don't know the English word for it.

Each pommel cube was first drilled. Then I finished the edges and cut a notch so that it would fit over the edge of the lower conical part. Only after a "cube" was finished was it cut off from the bar.

I did not have a drill press, so I held a water-compass against the dremel to keep it drilling straight. A number of holes were off-center misses.

I think I'm gonna attempt the Secura promo-pic saber. Seems like the easiest to attempt for a first go. Any thoughts on the pommel or the emitter "retainer ring?" I've seen deadbolt parts that look close, but...that would be a part that's be worth machining in bulk for the various TPM sabers that use it!

Oh, I forgot, I have built that one too.

The pommel was made in the same technique mentioned above.

The emitter cup was made from a keyhole ring and a washer. I found that keyhole at a flea market, but I have never found a second one.

I drilled the pommel disc (not very well...) and put a sewing pin in the middle.

I had engraved most of the grooves and recesses on the hilt, which was tedious work. I recommend that you instead use a thinner inner tube and mount pieces made from the outer tube as panels onto that. Then most of the grooves would consist of space between pieces. I think that you would also get a better result making the rectanglar recesses using a drill and a needle file than with an engraving bit.

Also, the LED bezels and bar

should be slightly recessed - and I think it would work best to have them just sit on the inner tube.

For reference, I had used a

scan from the Visual Dictionary with an overlaid grid. Each square is 5x5 mm (1/5 of an inch).