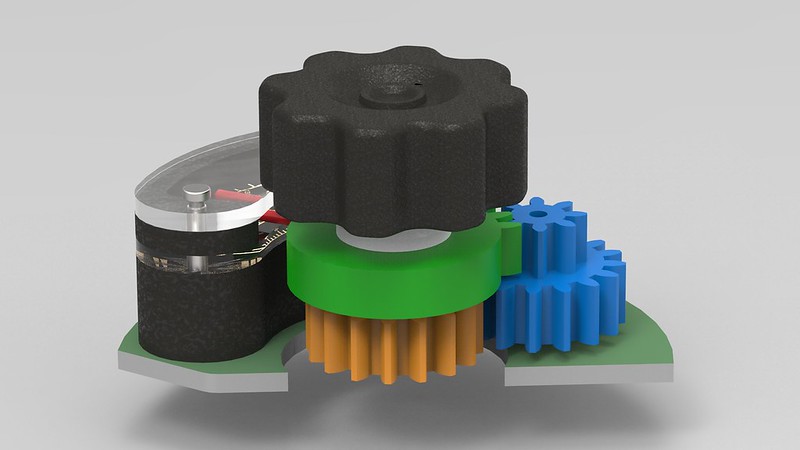

August 2018 3D design rendering

-------

The latest updates:

-------

/2018 Status:

The project is continuing, just in fits and starts.

-------

/2017 status:

Howdy folks,

Well, after much thought, I have decided to do what many have asked for: I will be releasing the full CAD files for the Functional Pip-Boy 3000 MK4.

I am releasing these files as a unfinished work. I still intend on going back and making my “master” version someday. But currently I have a new home with its own projects to work on.

If you want to check out my home projects, I will be publishing that project at: www.halfwayupthehill.com. (There isn’t much up at the moment yet)

I am releasing these files for the sake keeping a huge amount of work from going to waste.

I put a ton of work into this design. I have used my years of experience with product design to create what I feel is the most accurate, and faithful version of the Pip-Boy 3000 Mk IV. The design uses real metal hardware, and mixed materials to achieve a look as good as if RobCo built it themselves.

To that end, this design is expensive. There is no way around that without losing out on quality. This is an unfinished design. Do not expect to just order all the parts, and put it together like a model airplane. Lots of work is still needed to even build just one of these.

It is up to the community to continue the work.

/May 2018 Edit:

-I am releasing the CAD files for those looking to build the next Pip-Boy, or finish my 3000 Mk IV design.

-----------------

Hello, this is my first post to the RPF, but this isn't my first major project by far.

My goal is to create a Pip-boy 3000 Mk IV from the game Fallout 4. Why not just get one of the limited edition models? For one, they are sold out. Two, I don't want a glorified plastic phone case. I want a Pipboy that at least has all the knobs and buttons functional.

-----------------

Click here for the original rendering (5-days into the project)

Click here for the newest renderings

The model was created in Solid Edge, and rendered in Keyshot.

-----------------

Click here for the original early rendering

My plan is to 3D print the model, however to get the level of detail I want, I will probably use SLS printing. However, the expense of that may change my mind. Currently I am focusing on getting a CAD model that has everything laid out. Making it real can come later.

-----------------

Click here for the original early rendering

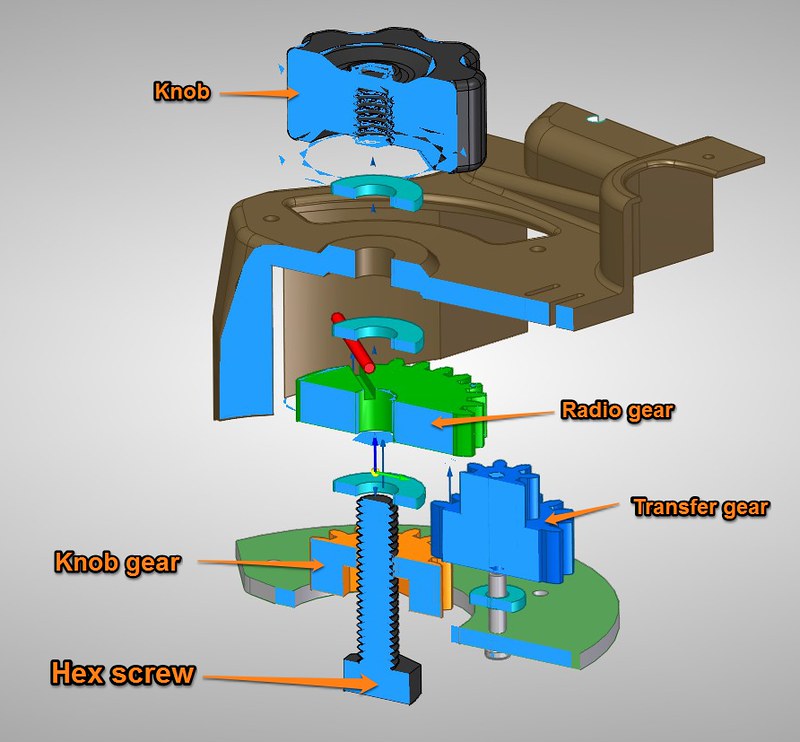

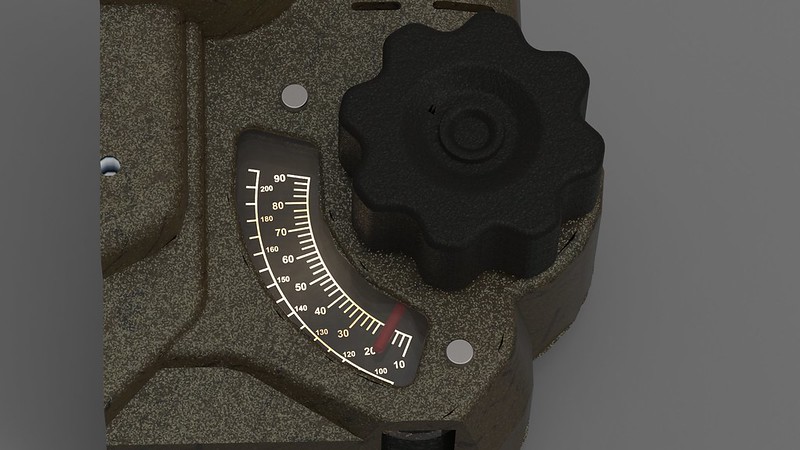

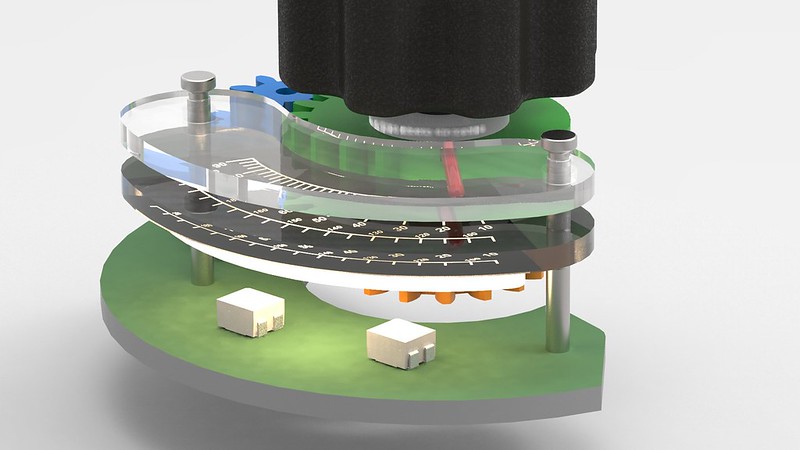

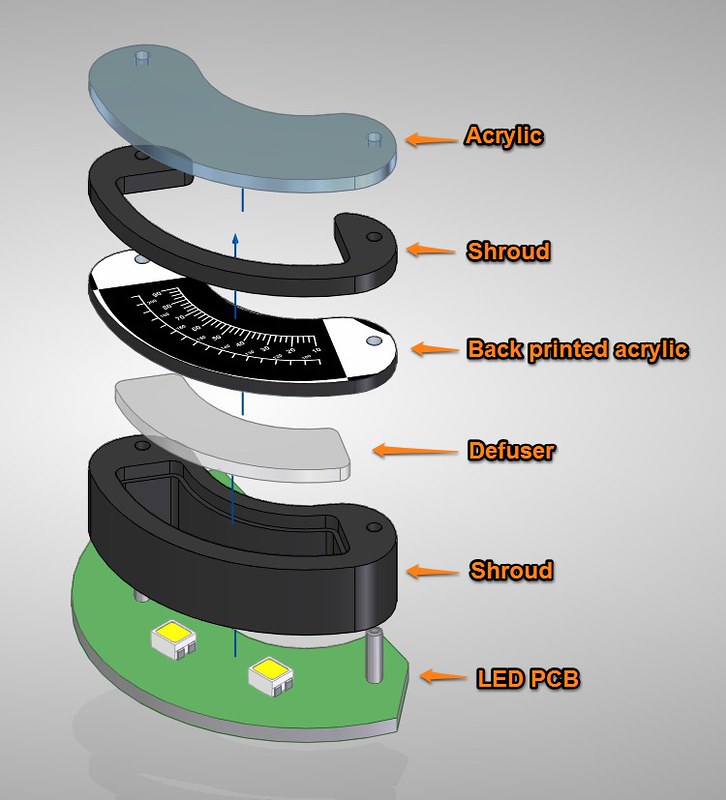

I want to have everything that should be lit up, lit up. Currently the plan is to try to directly print the RAD gauge and Radio gauge artwork onto a piece of thin acrylic. If that doesn't work, then perhaps a vinyl transfer. To that end I have re-created the two gauges as vector art in CorelDraw.

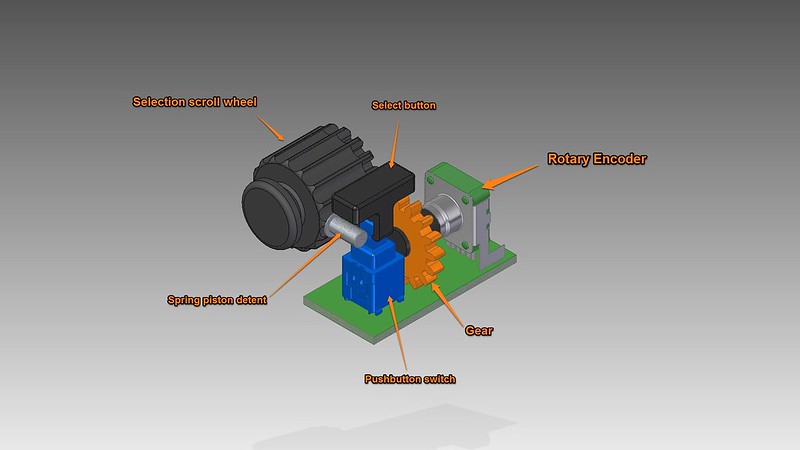

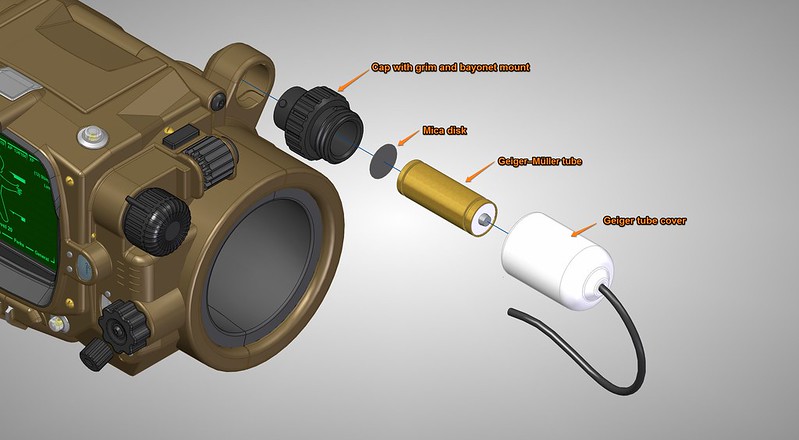

The RAD gauge will be driven either sudo randomly by a small motor, or perhaps driven like a compass using a set of electromagnets. I don't think I will be able to fit a true Geiger counter in, plus they can be expensive. So currently the plan is to drive the RAD meter with data from a contactless IR temperature sensor. The radio gauge will be connected to a microcontroller and FM radio chip. It may also simply scan through pre-programmed sounds taken from the game. I haven't decided yet.

-----------------

Solid Edge has been my CAD software of choice for almost a year. It is overkill for a prop, but allows for some serious modeling in a short period of time.

The model as shown here was started just 5 days ago and done in my spare time. By day I am a product engineer so this type of design is right up my alley.

It was created from scratch using reference photos from the game trailer, images of the limited edition model, as well as referencing dragonator's 3D printable model.

-----------------

The LCD screen will be a 3.5" 4x3 LCD. That is if I can find a android device that can drive it.

-----------------

The bottom latch will be functional. Thanks again to dragonator for creating a latch that I could then reference. Mine works basically the same as his but with a few changes to make it possibly hold tighter. I also plan on putting magnets it to hold it together until the latch is secured.

-----------------

The opening in the Pip-boy is scaled to fit my own arm, with some padding added. The rest of the model was scaled by referencing the size of the character's thumb in the demo video of the Pip-Boy.

-----------------

The holotape mechanism will also be functional and spring loaded. The release button will act as both a latch, and a kicker to push it open. The actual yellow holotape is the only model I copied from dragonator's model, although I scaled it down by 75%. The plan is to put RFID tags into the holotapes, and have those kick off a program on the Android device.

-----------------

More to come as I get stuff done. I may share the model at some future time when it is more complete. Currently only the outside is done and I have yet to make a scale mock-up.

Last edited: