TheScratcher

New Member

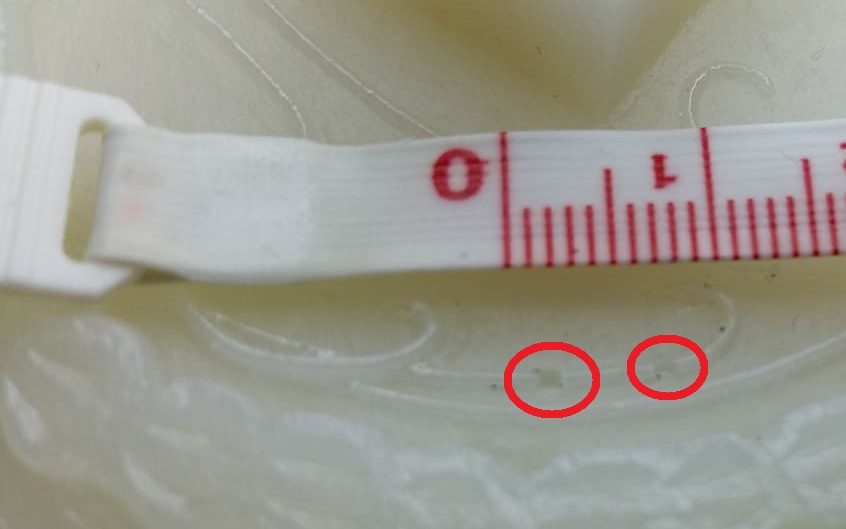

How would you repair pinholes from bubbles in a casting that are just a mm in diameter but can NOT just be filled with glue or whatever?

As you can see in the picture it is not only "holes" but rather missing parts of a thin, protruding line.

A 1mm diameter wire, in fact.

"Filling" it with a liquid like glue, would of course just result in the glue pouring outside of it...

Sorry if this is the most basic thing and only I am not aware of it, first time molding and casting.

Oh and of course I dont have a vaccuum chamber or anything of the sort and cant afford anything right now either.

This is probably even the wrong topic to post that question...

Thank you for your help.

As you can see in the picture it is not only "holes" but rather missing parts of a thin, protruding line.

A 1mm diameter wire, in fact.

"Filling" it with a liquid like glue, would of course just result in the glue pouring outside of it...

Sorry if this is the most basic thing and only I am not aware of it, first time molding and casting.

Oh and of course I dont have a vaccuum chamber or anything of the sort and cant afford anything right now either.

This is probably even the wrong topic to post that question...

Thank you for your help.