You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Studio Half Scale TOS Enterprise Scratch build

- Thread starter SteveNeill

- Start date

- Status

- Not open for further replies.

SteveNeill

Sr Member

Rel, thanks so much. And the same goes for for you guys too.

Steve

Steve

trekriffic

Sr Member

Just curious Steve are you going to leave the clear nipples in the centers of the domes or remove them somehow?

SteveNeill

Sr Member

I sure will. Sand, buff and polish.

Steve

Steve

Proper

Well-Known Member

Steve's model is looking exceptional. But I would be very interested in seeing what ingenious design measures and structural materials would be employed *in a kit* in order to solve the nacelles/saucer droop and alignment problems of this design, which have been the Achilles' heel of practically every kit to date; including the Master Replicas models whose metal armature fell short of what it was supposed to do. Both the nacelles and the saucer are drooping about 1º to 1.5º in opposite directions on my MR E. The combined effect is very noticeable.

Last edited:

SteveNeill

Sr Member

That is going to be up to the builder. And maybe that's the beauty of it all. I provide a hull kit only. No internal structure I can be chewed out for later if gravity has it's way. No lights to go out and be blamed for. No dying or too noisy nacelle motors. Like a big plastic model kit it's up to you to build and mod it as you see fit.

CR should have done this I suppose. There kits with all the above mentioned items included was 3100 bucks. My hull kit will be 1500 or less. Time will tell. That's less than half.

Steve

CR should have done this I suppose. There kits with all the above mentioned items included was 3100 bucks. My hull kit will be 1500 or less. Time will tell. That's less than half.

Steve

Chrisisall

Master Member

Styrene, resin or vinyl?I provide a hull kit only. . Like a big plastic model kit it's up to you to build and mod it as you see fit.

Onigiri

Sr Member

You really havent read this thread have you? Again, as has been covered repeatedly, these will be FIBERGLASS. This is the second question like this where youve come late to the party...dont make me give you a time out :lol

Your apparent enthusiasm for this thread is equaled only by your unwillingness to actually read it:lol

-Steve's Secretary

Your apparent enthusiasm for this thread is equaled only by your unwillingness to actually read it:lol

-Steve's Secretary

Chrisisall

Master Member

I'm so sorry; I've been working on my own stuff so hard I really can't keep up! I see these posts rather scattershot, and need nice secretaries like you to clear things up. Great job, BTW!You really havent read this thread have you? Again, as has been covered repeatedly, these will be FIBERGLASS. This is the second question like this where youve come late to the party...dont make me give you a time out :lol

Your apparent enthusiasm for this thread is equaled only by your unwillingness to actually read it:lol

-Steve's Secretary

Does Steve pay you well? You certainly deserve it.:cool

Chris

Chrisisall

Master Member

Lucy in the sky with Dilithium.... ?:lolbut I get to sniff the fumes....

SteveNeill

Sr Member

I got to say you guys are fun. A yes Chris. Do make a skim through the entire thread. You'll find out all kinds of things about this build.

Today worked on preening and finishing off all the small part masters. Tomorrow I'll clean up and finish off the nacelles. What that means is the masters are done. Next weekend I'll start making molds.

I am so glad to be at the end of this phase. Molds go quick so we'll be building and actual model very soon.

Steve

Today worked on preening and finishing off all the small part masters. Tomorrow I'll clean up and finish off the nacelles. What that means is the masters are done. Next weekend I'll start making molds.

I am so glad to be at the end of this phase. Molds go quick so we'll be building and actual model very soon.

Steve

Chrisisall

Master Member

Yeah, there's an actual online how-to book here- lots of valuable stuff I missed, clearly.Do make a skim through the entire thread. You'll find out all kinds of things about this build.

Thanks Steve!

DrMcoy

Sr Member

Naw...he doesnt pay me but I get to sniff the fumes....

you get to sniff Steve's WHAT? Moderators...it's getting a little weird in here....not that I'm complaining...

you get to sniff Steve's WHAT? Moderators...it's getting a little weird in here....not that I'm complaining...

I think you need to complain to the General Surgeon about missing warnings on the glue cannisters that Steve buys ...

Proper

Well-Known Member

Really great work Steve, I'm lovin' it!

BUT...

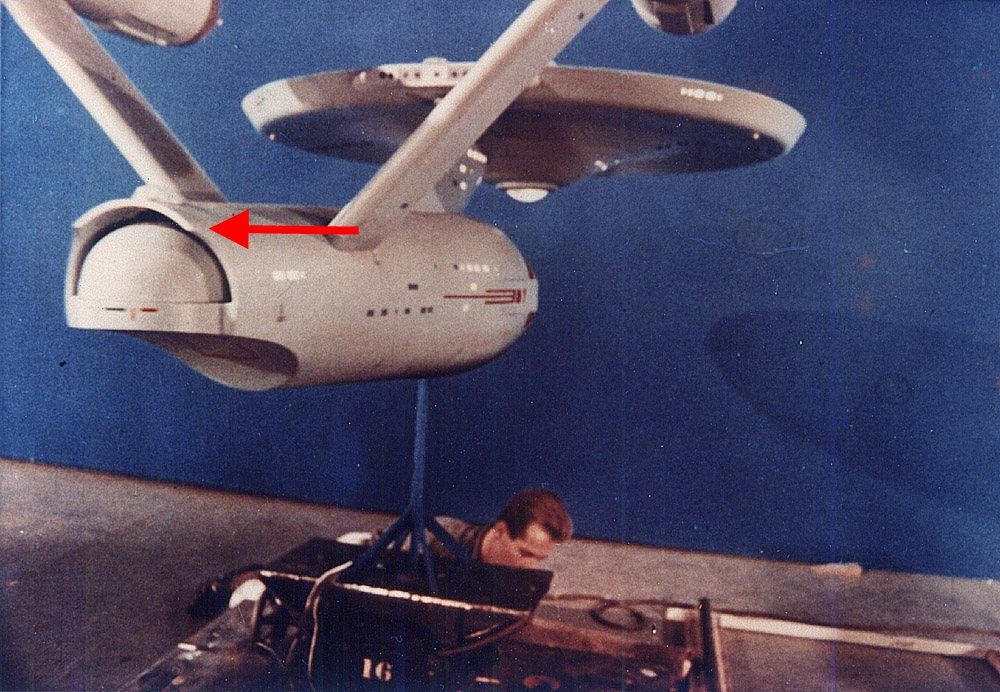

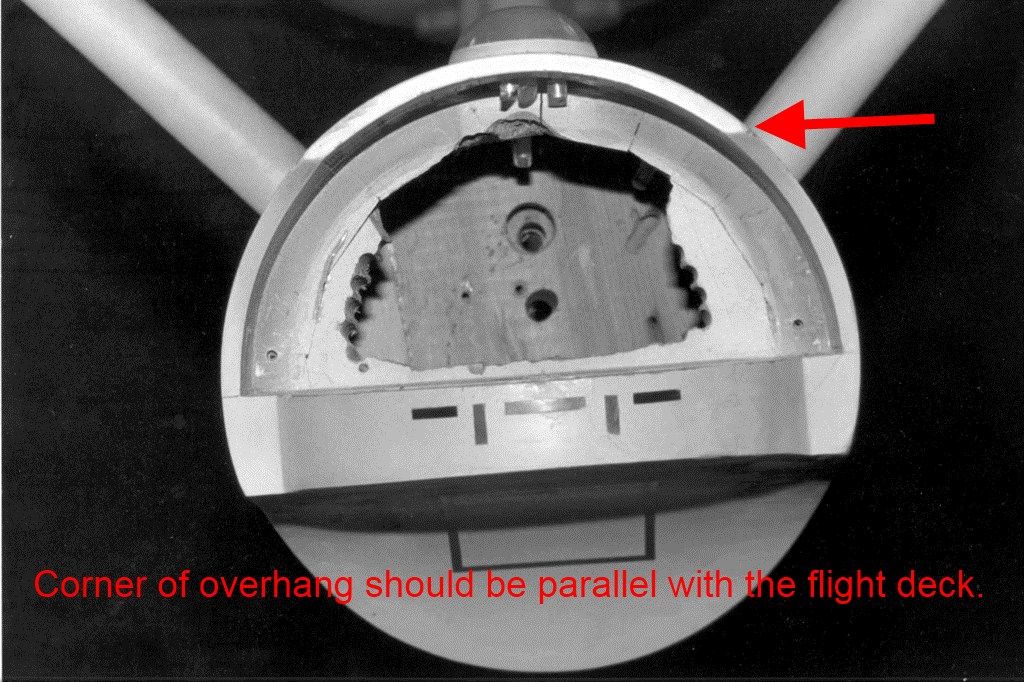

I spotted a problem I didn't see before. The hull overhang above the hangar doors has an angle that should be parallel with the flight deck. The angle on your part doesn't match.

Yes, good catch, Rob. It also appears that the overhang needs to be thicker and arc a bit further down along each side.

SteveNeill

Sr Member

Guys you not seeing the parts together or no how they work. The roof over hang backing gets cut out, attached to the open ended hull. Then the flight deck goes in to it's proper depth into the hull. There is plenty of over hang to the deck. These parts were cut from Kerr's plans. Pictures tell a lot of mis-truths. Look again.

I appreciate you pointing this out but you may think you find lots of little things off. It's impossible to get it exact. Even the clowns that restored her didn't. Close enough is good enough or this will never be done.

Close enough is good enough or this will never be done.

Thanks a bunch,

Steve

See that whole backing gets cut away and is only there for molding purposes and to keep the shape sound until it's placed on the hull.

I appreciate you pointing this out but you may think you find lots of little things off. It's impossible to get it exact. Even the clowns that restored her didn't.

Thanks a bunch,

Steve

See that whole backing gets cut away and is only there for molding purposes and to keep the shape sound until it's placed on the hull.

3d-builder

Sr Member

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 1,059

- Replies

- 117

- Views

- 11,946

- Replies

- 11

- Views

- 1,125