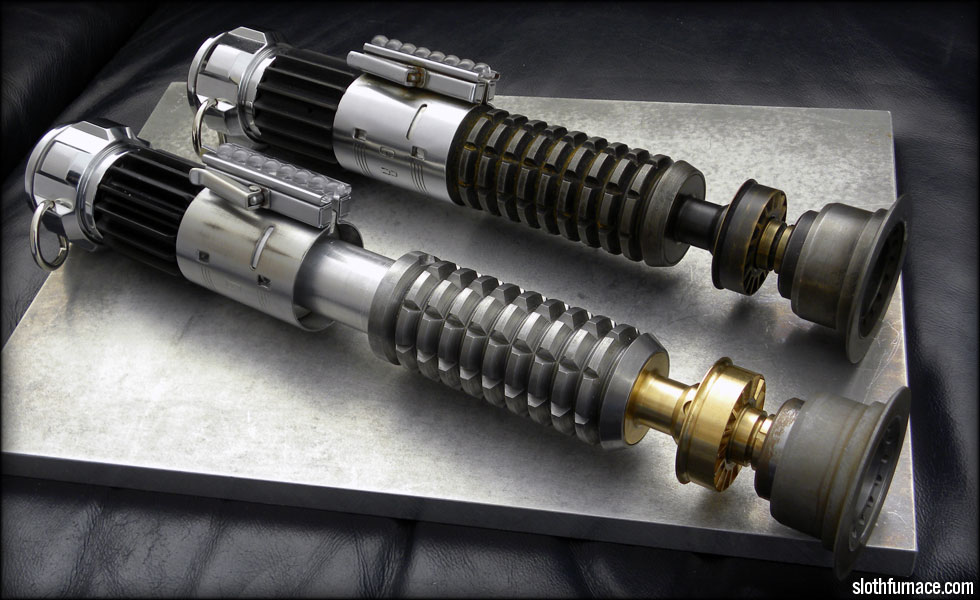

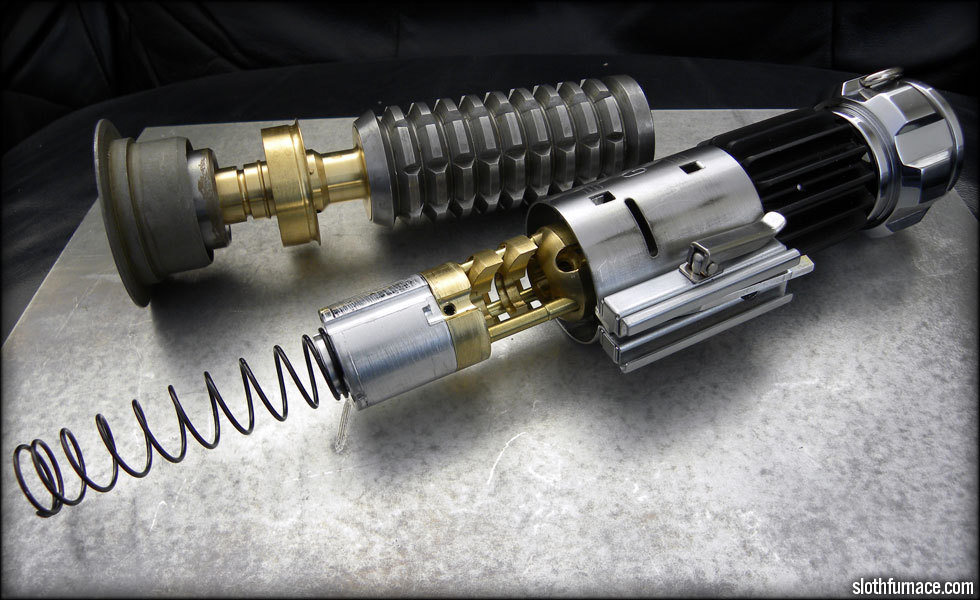

It's my "holy grail" saber. Everything leading up to this has been practice to me.

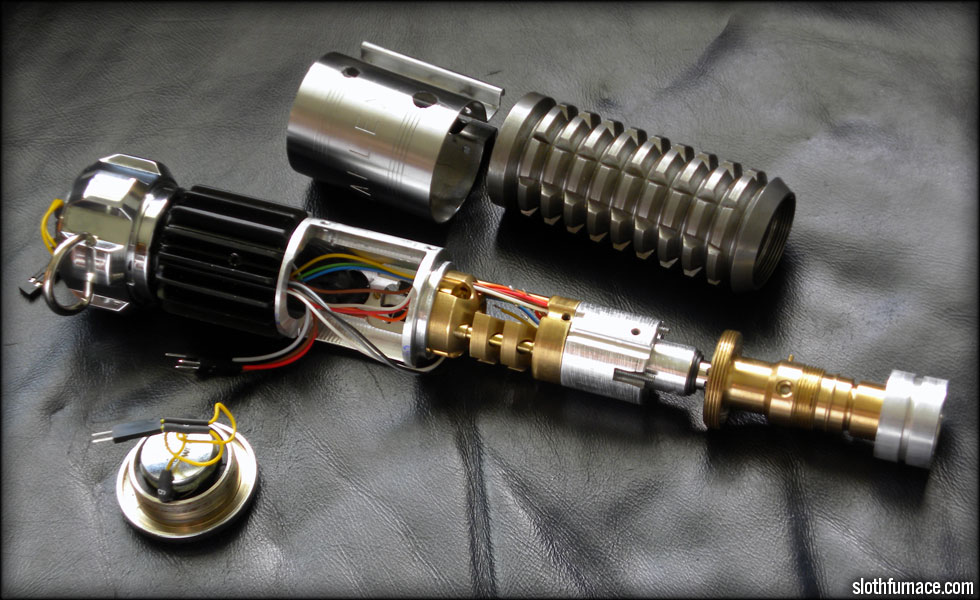

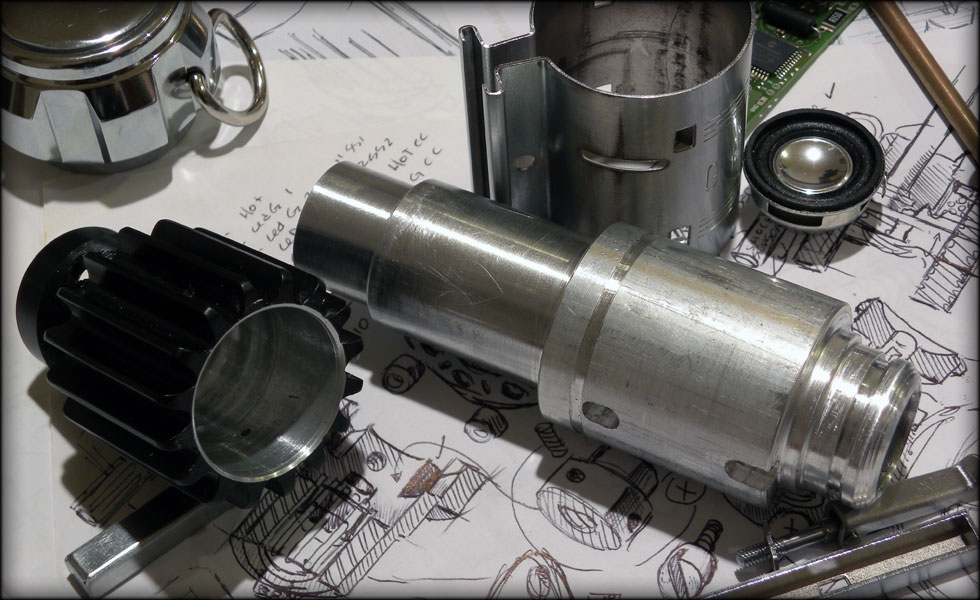

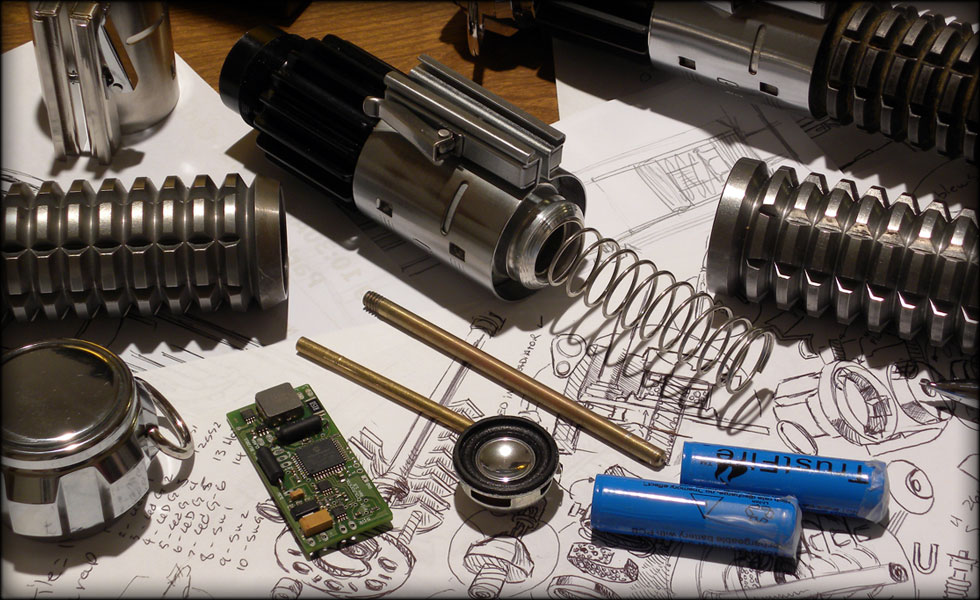

I plan (hope) to make this one a springloaded chamber reveal.

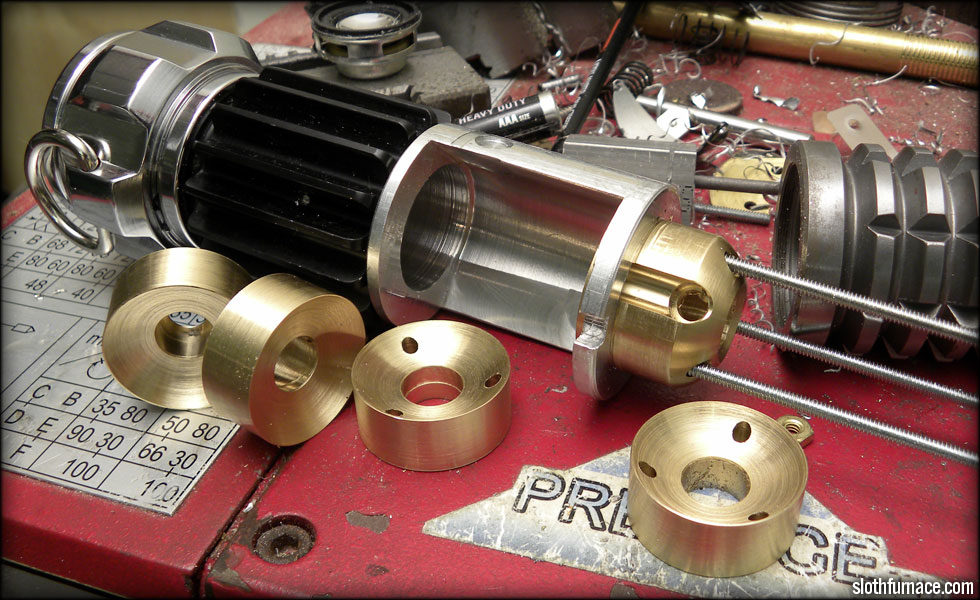

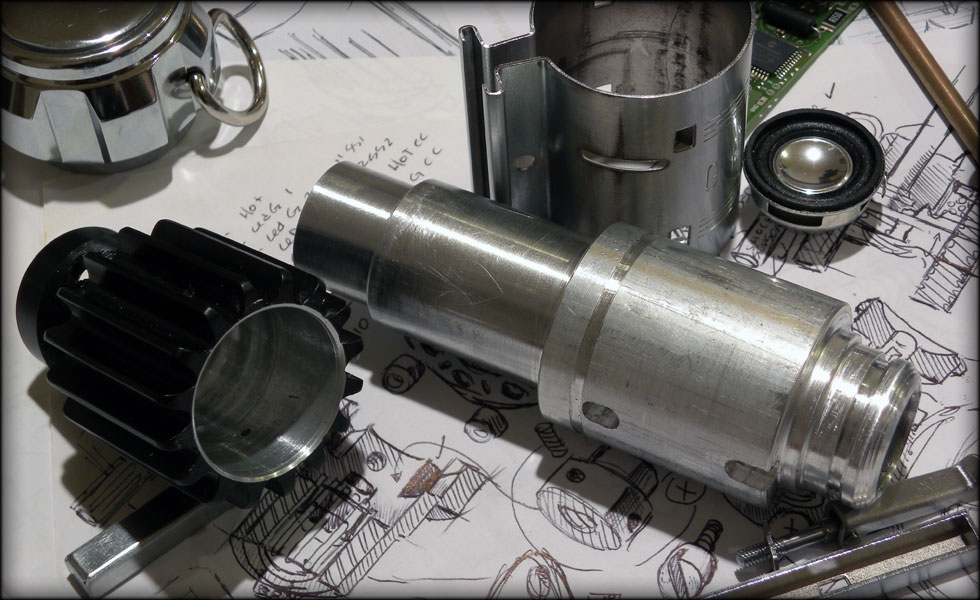

I have enough stuff from Russreps to do it, and a couple clamps. I also have a chromed emitter and powdercoated booster, which I might make an AFBB out of.

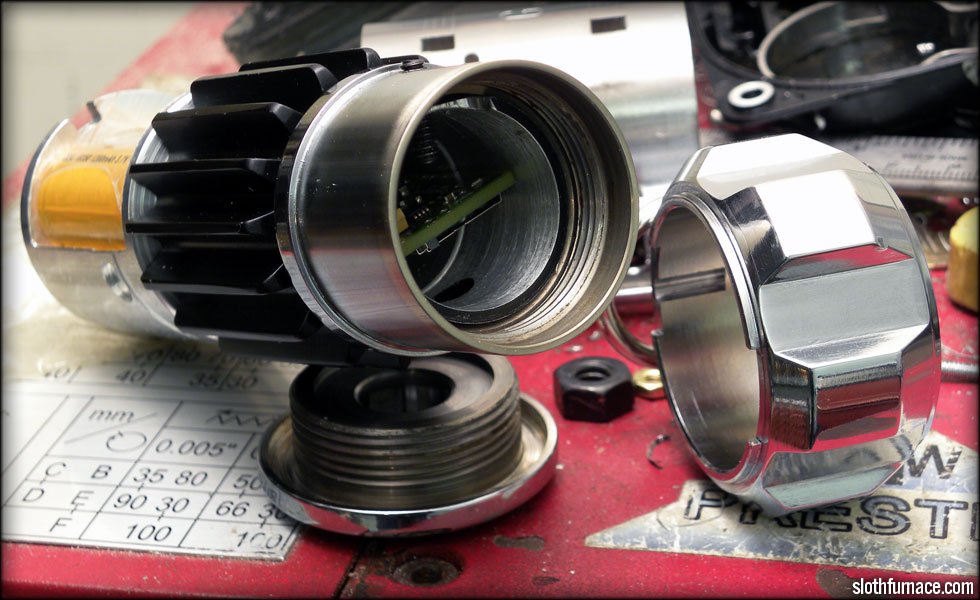

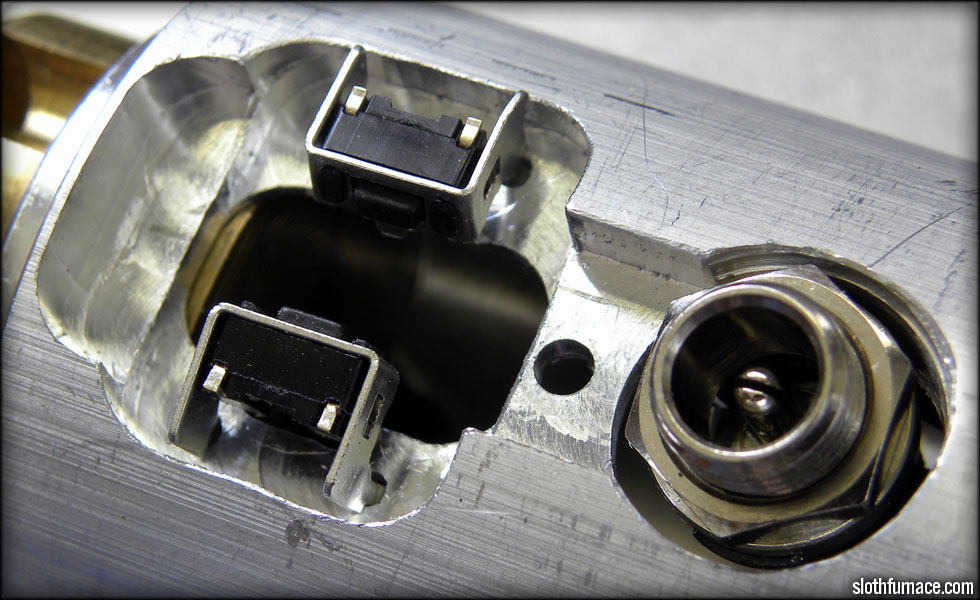

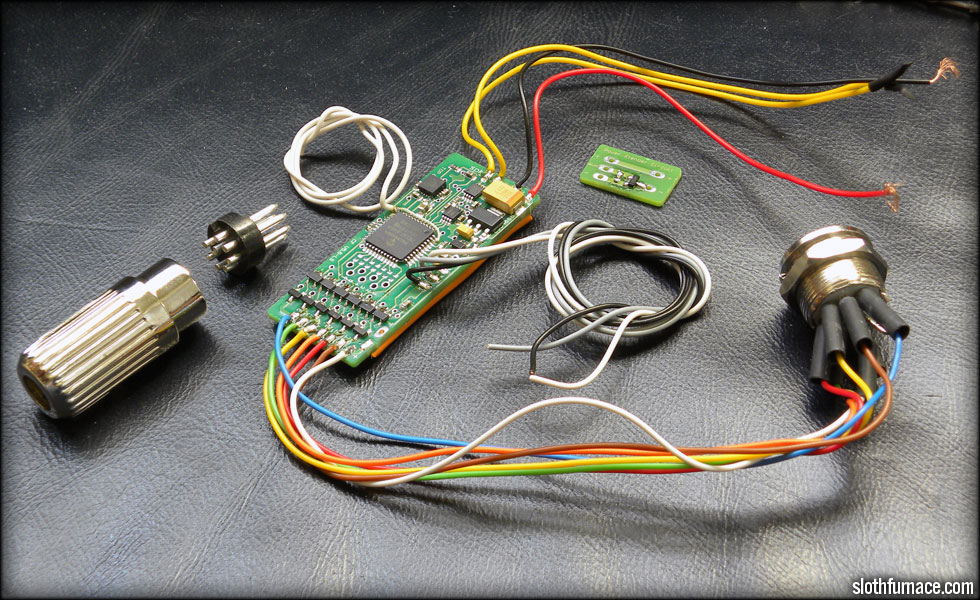

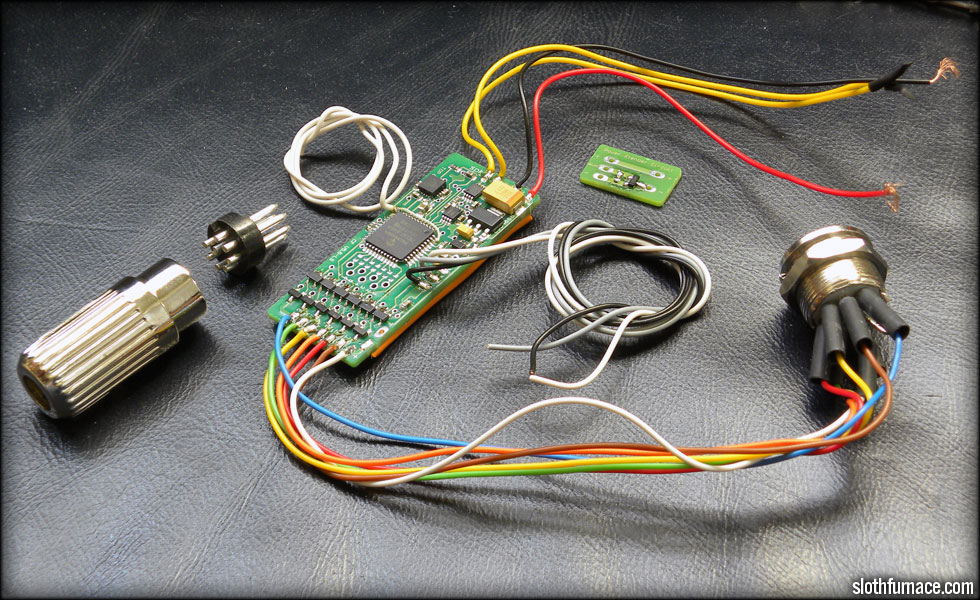

A nice bundle of wires, a connector, and....

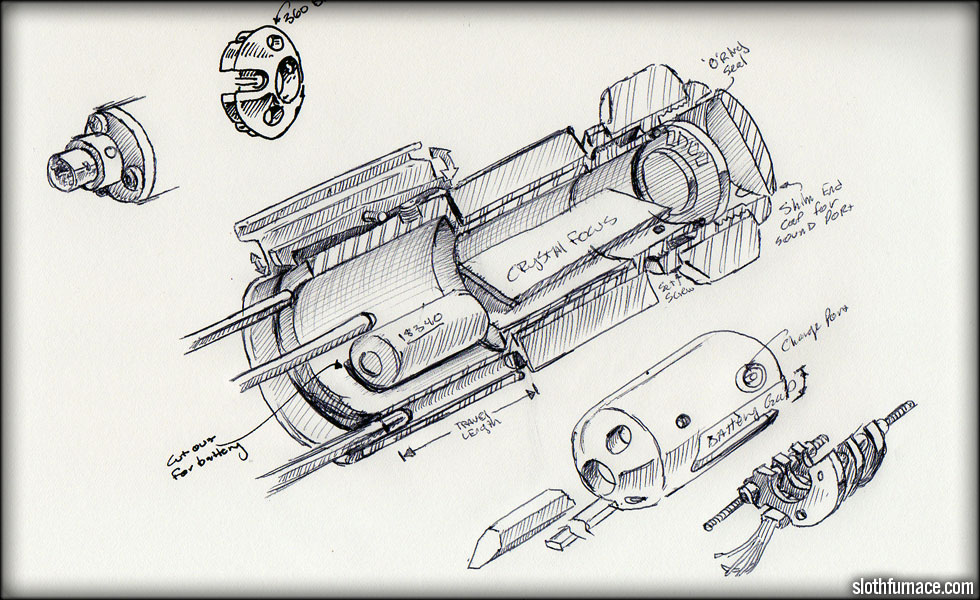

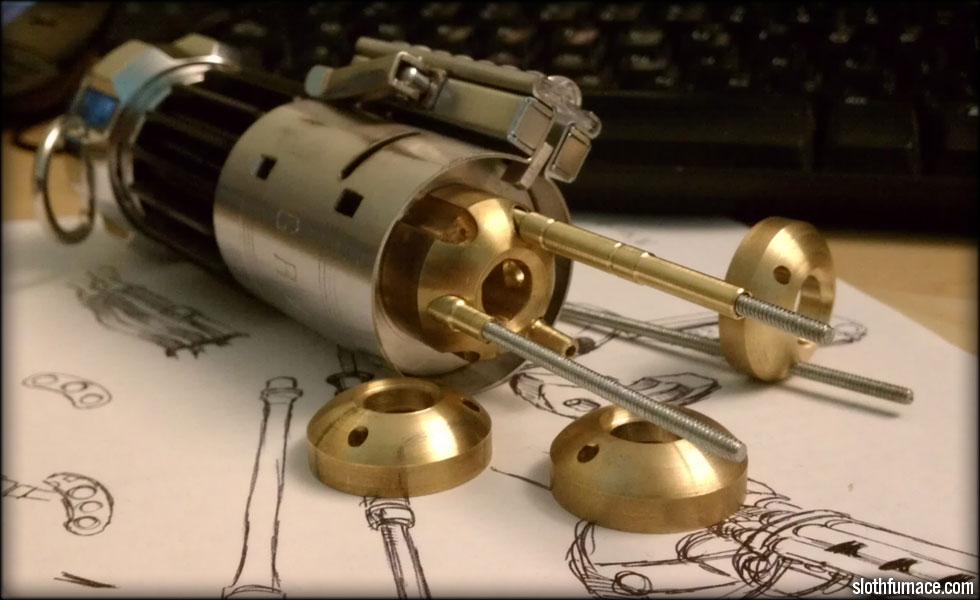

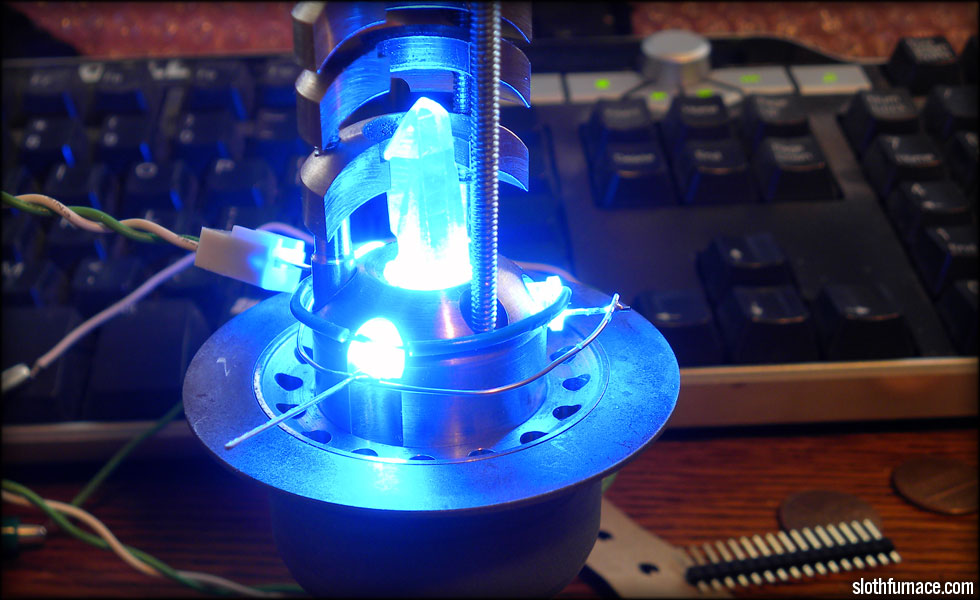

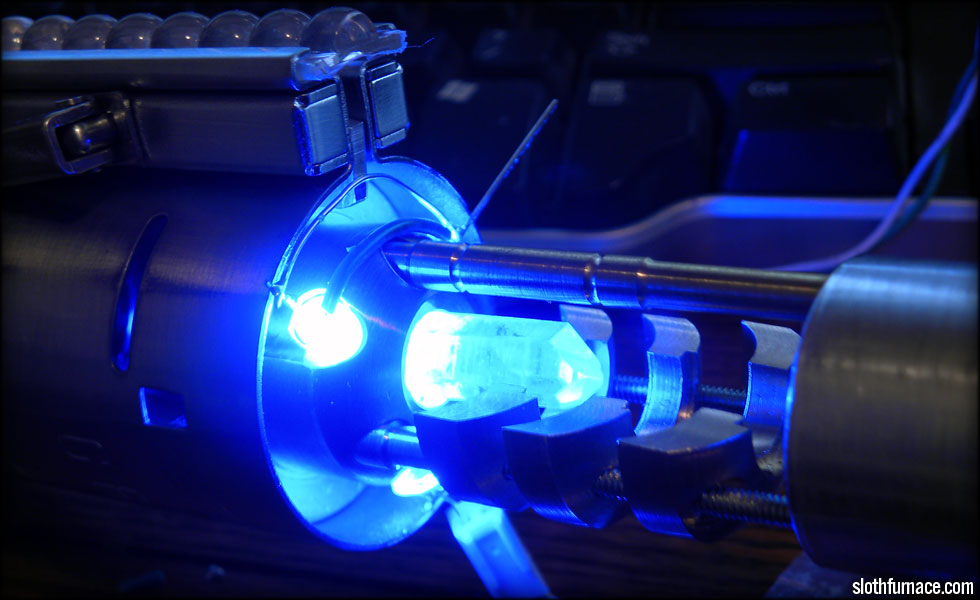

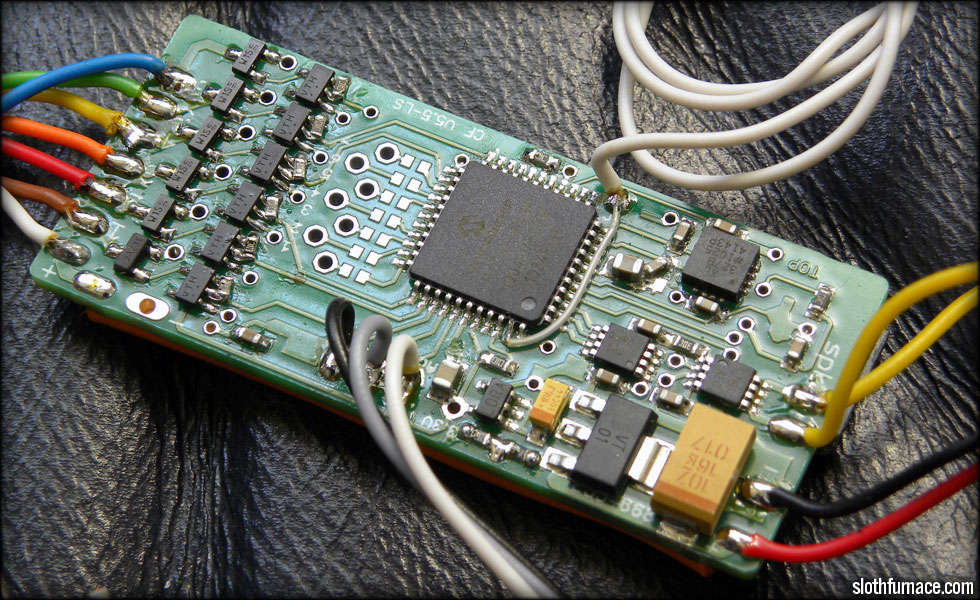

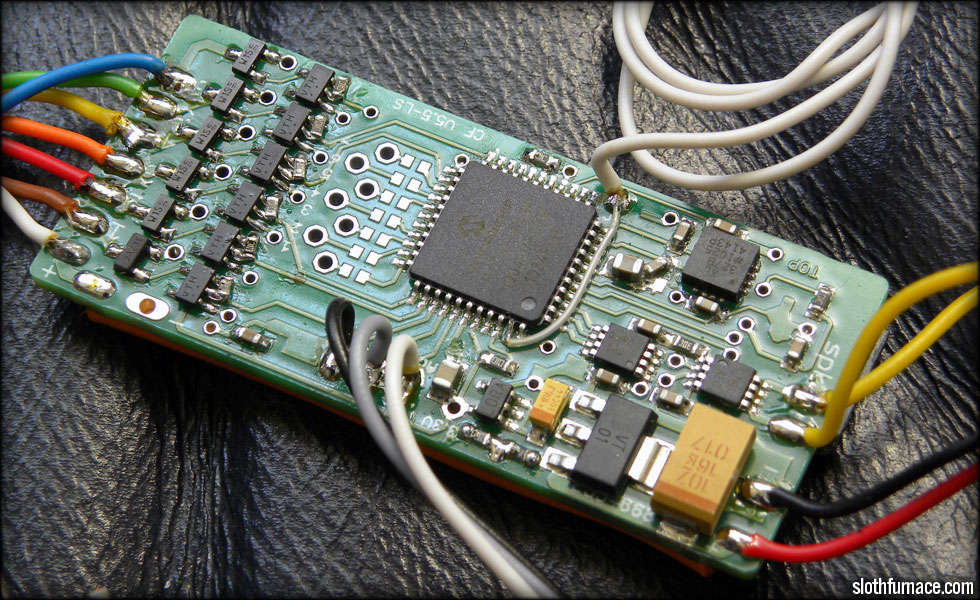

A Crystal Focus v5 LS version! Erv was so kind as to allow me to test the LS version, so this will the be the heart and soul of my ANH Obi chamber reveal saber.

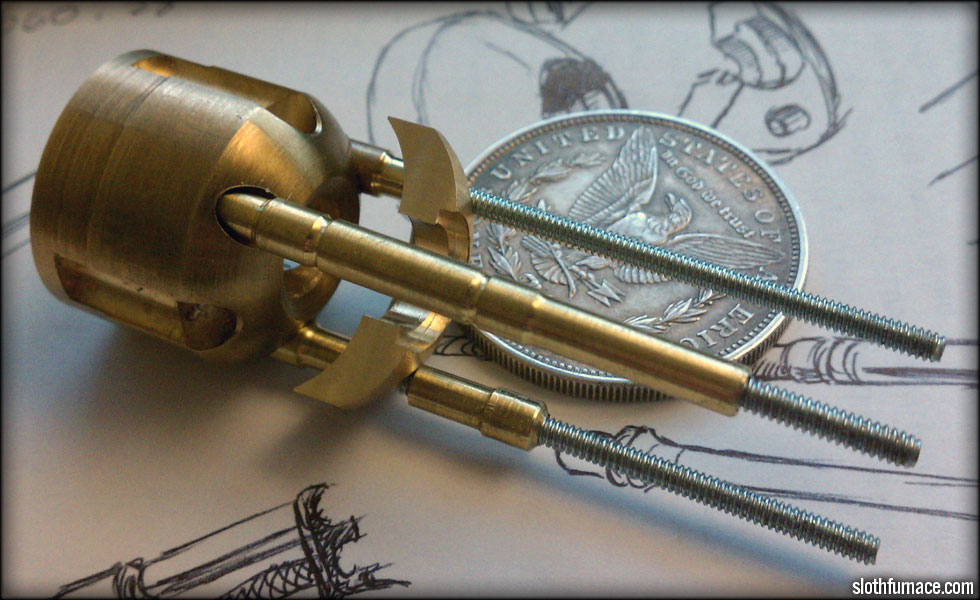

GORGEOUS! I cannot wait to get out in the garage to begin the housing for this. I have to clear a couple things off my plate first, but this one has my juices flowing. It's time to get the drawing paper out and start designing the mechanism, start the search for the right chamber crystals, etc.

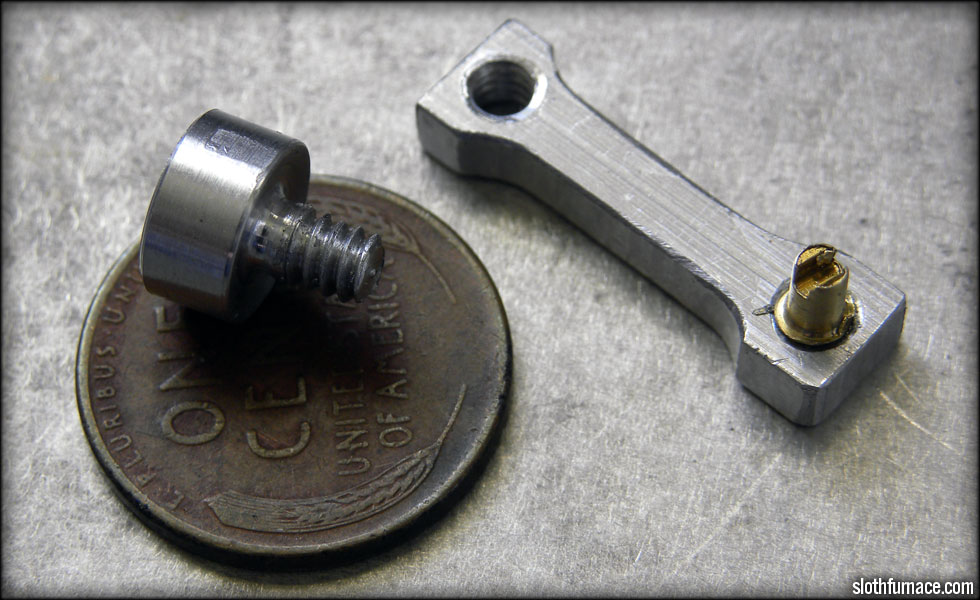

The PC is just there for size reference for the CF-LS.

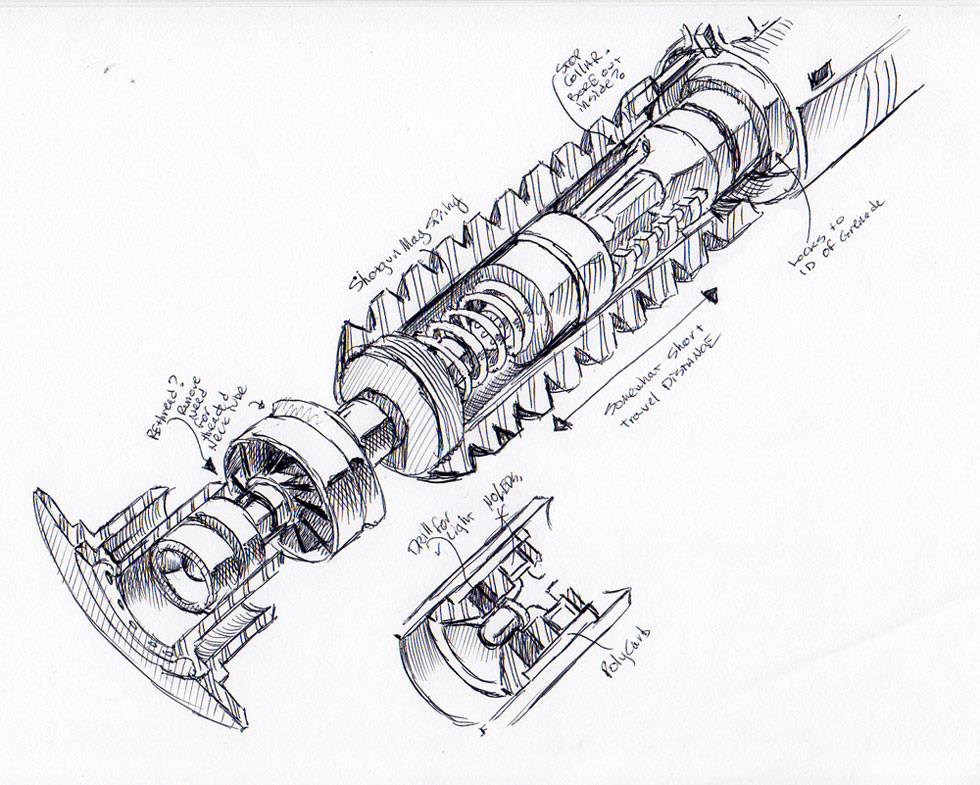

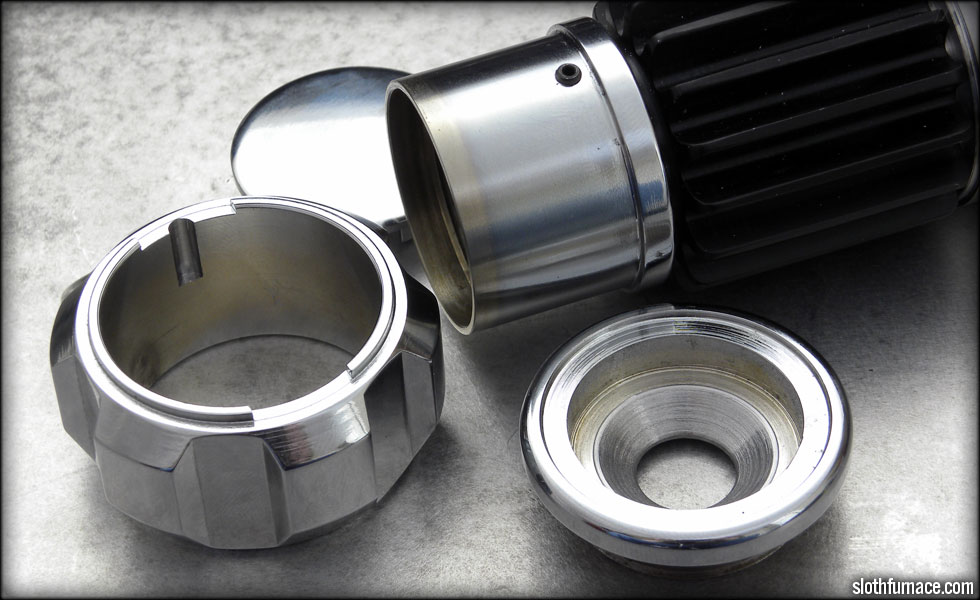

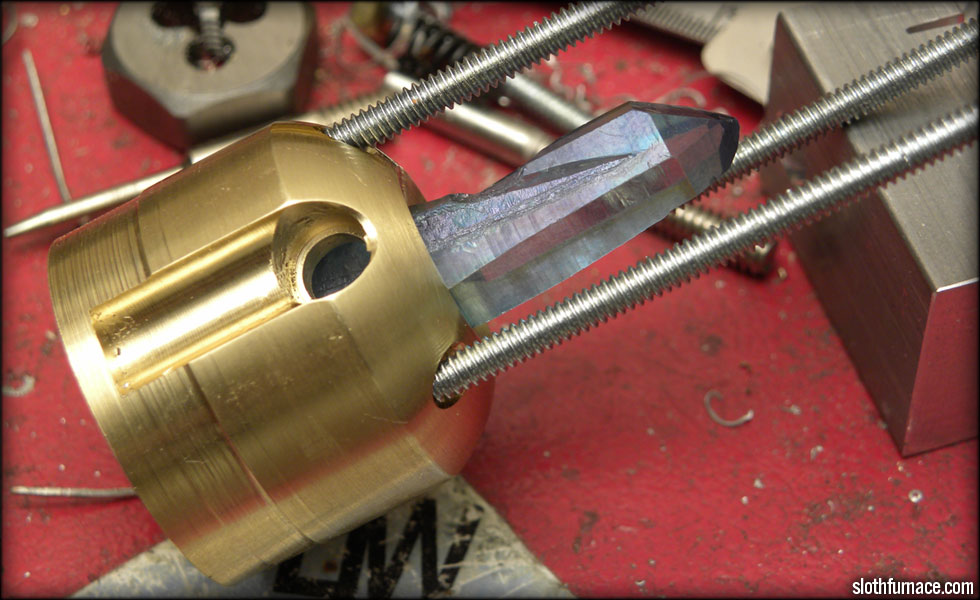

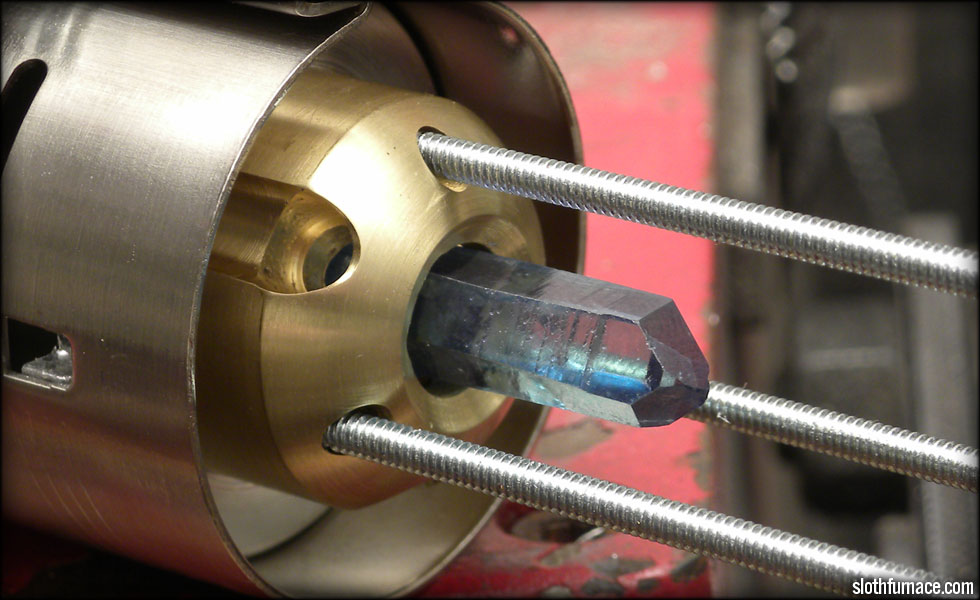

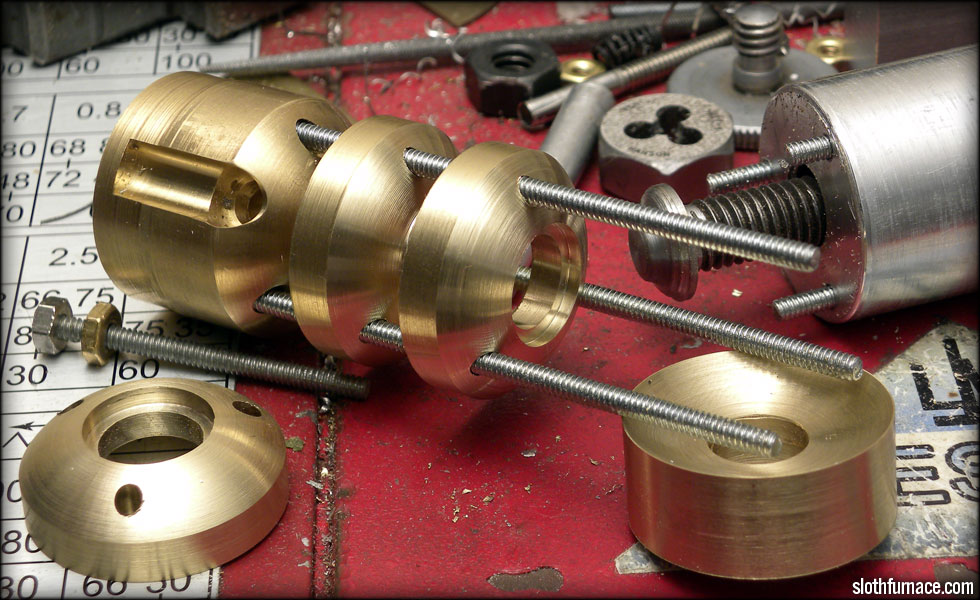

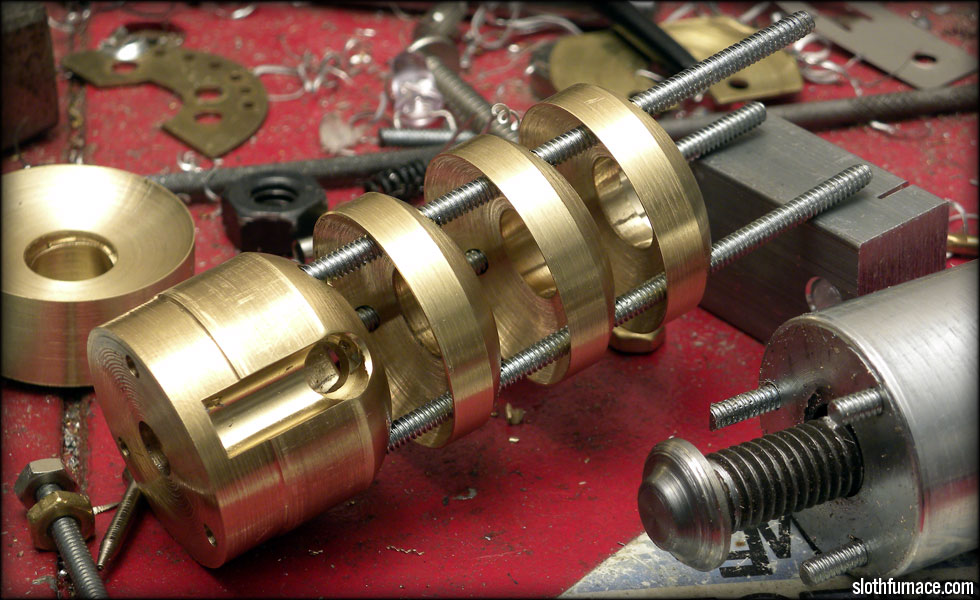

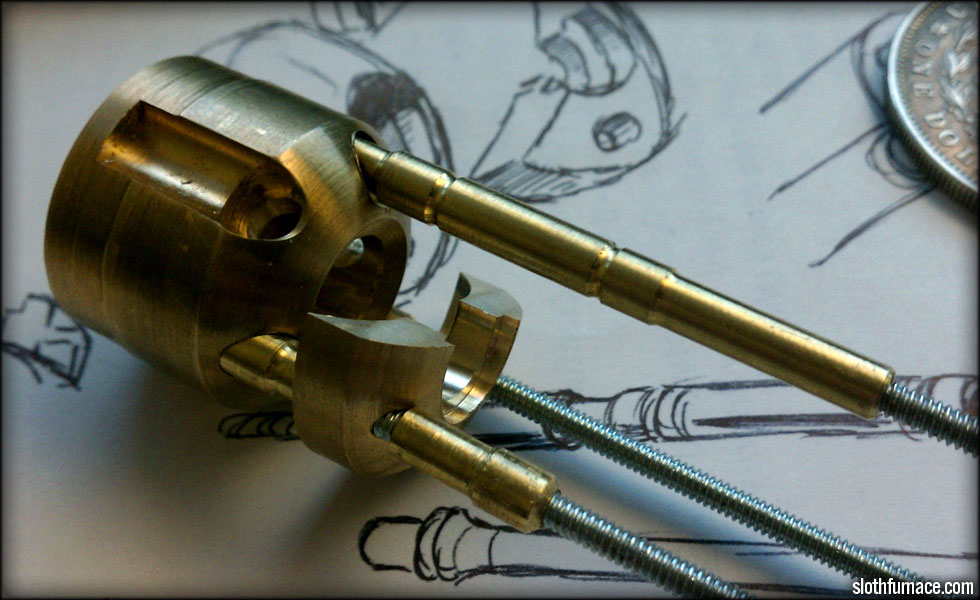

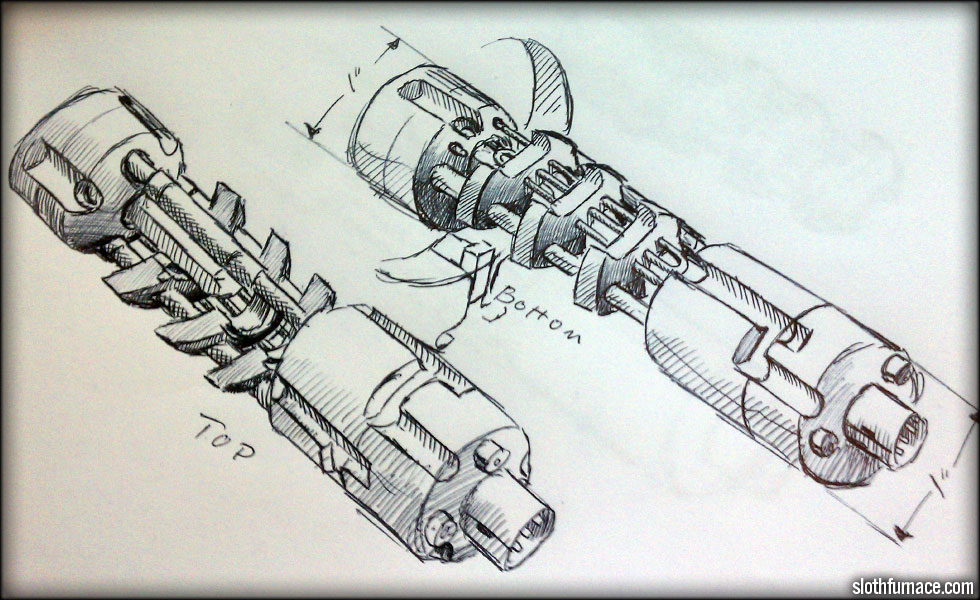

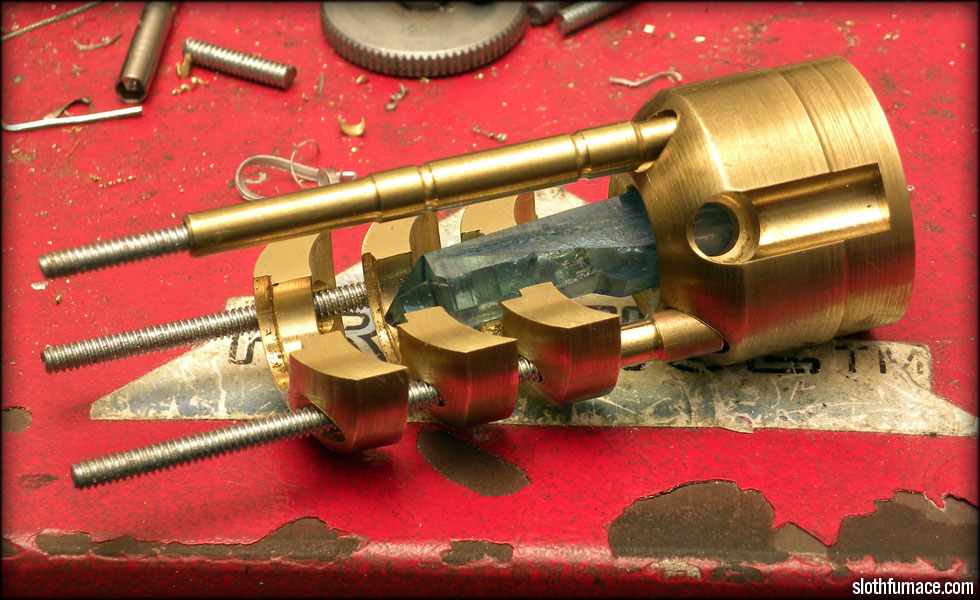

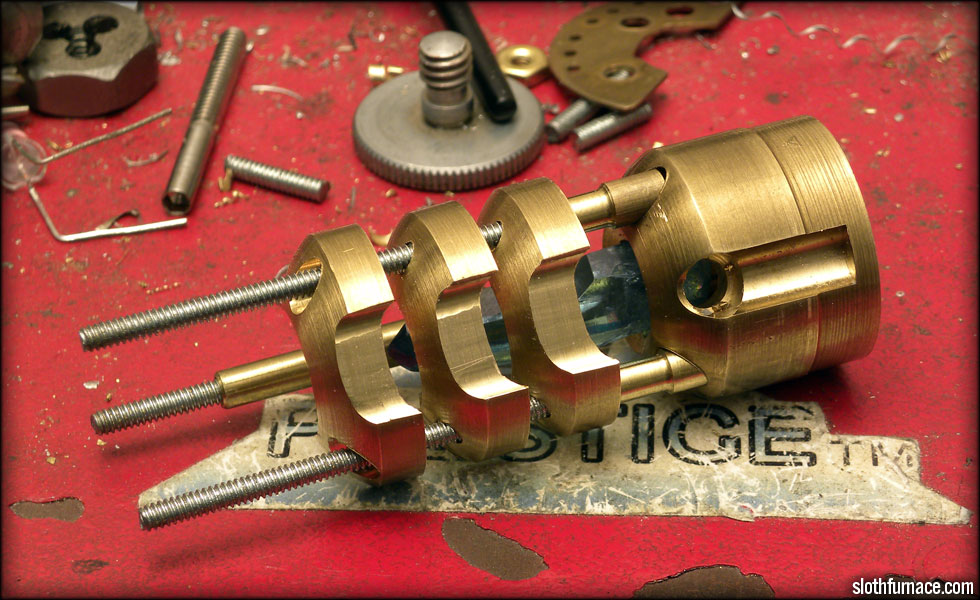

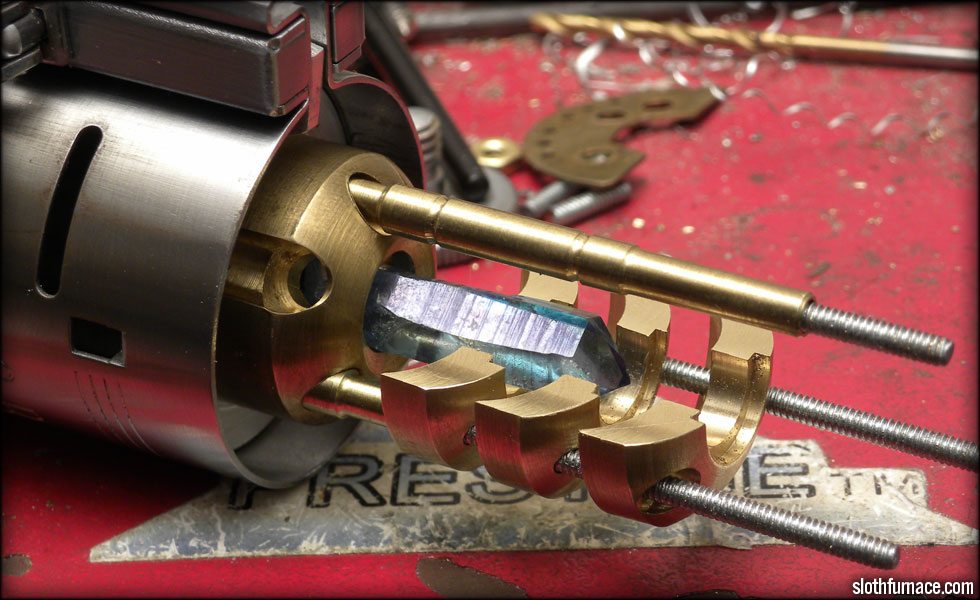

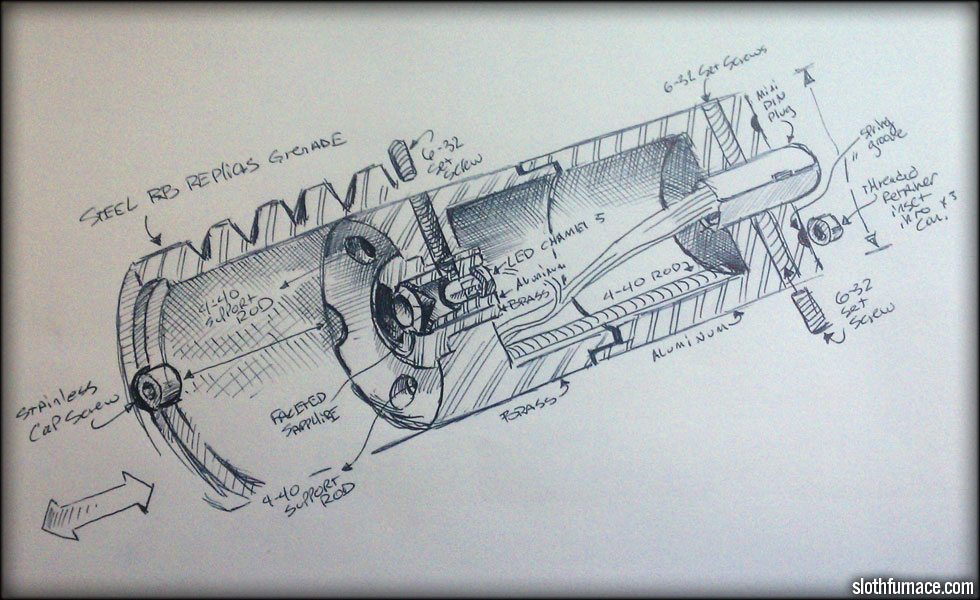

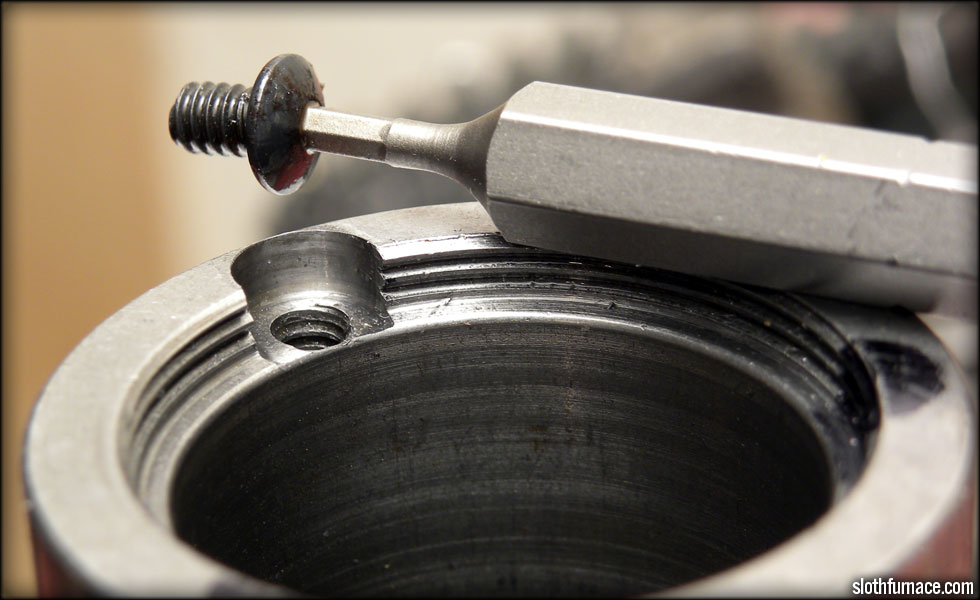

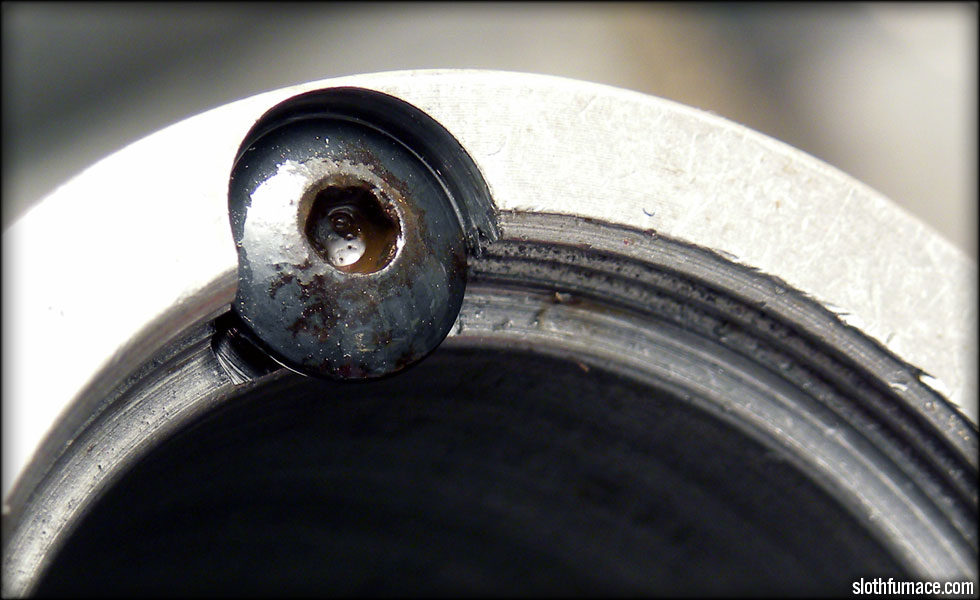

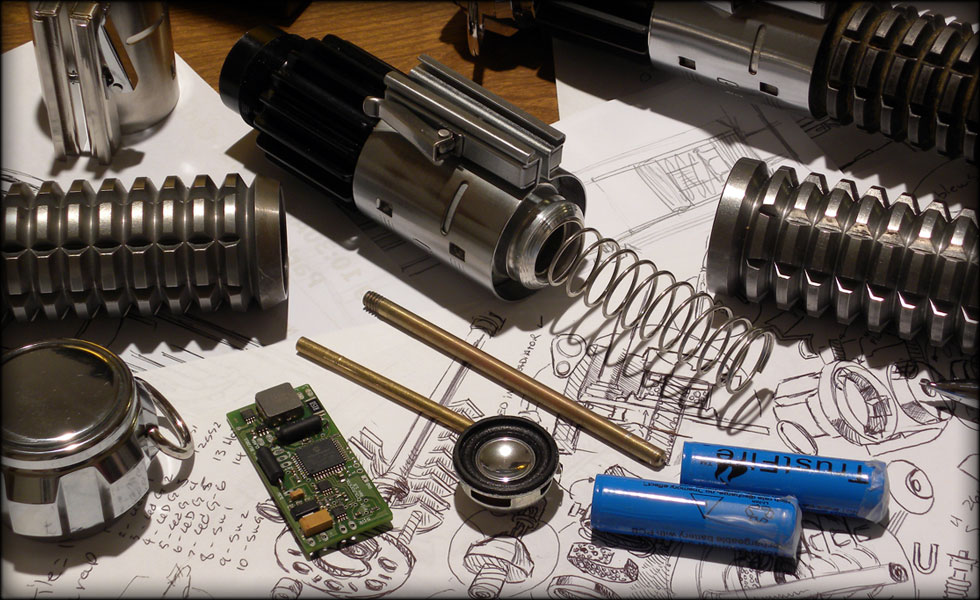

I had quite a lot of trouble getting my head wrapped around the chamber lock mechanism for this one. I was trying to make it too much like my ROTJ Luke. Then tonight I just scrapped it for a much more obvious and elegant solution, once I get something that works, I 'll post that.

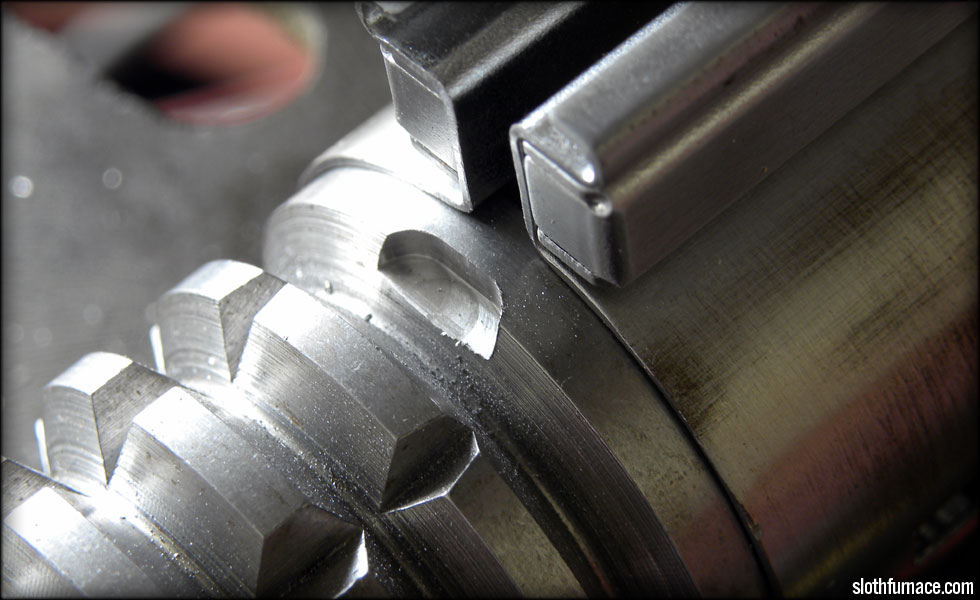

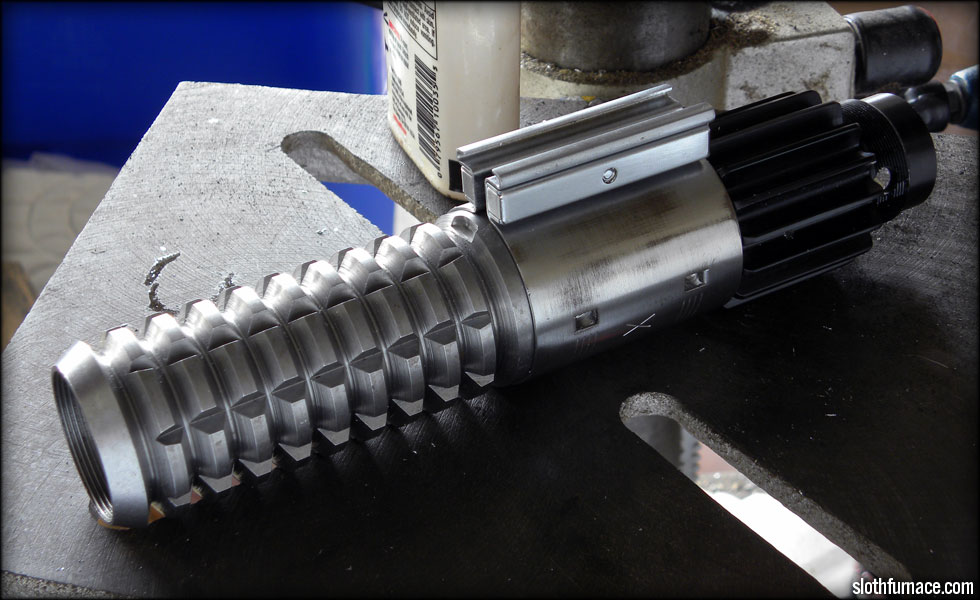

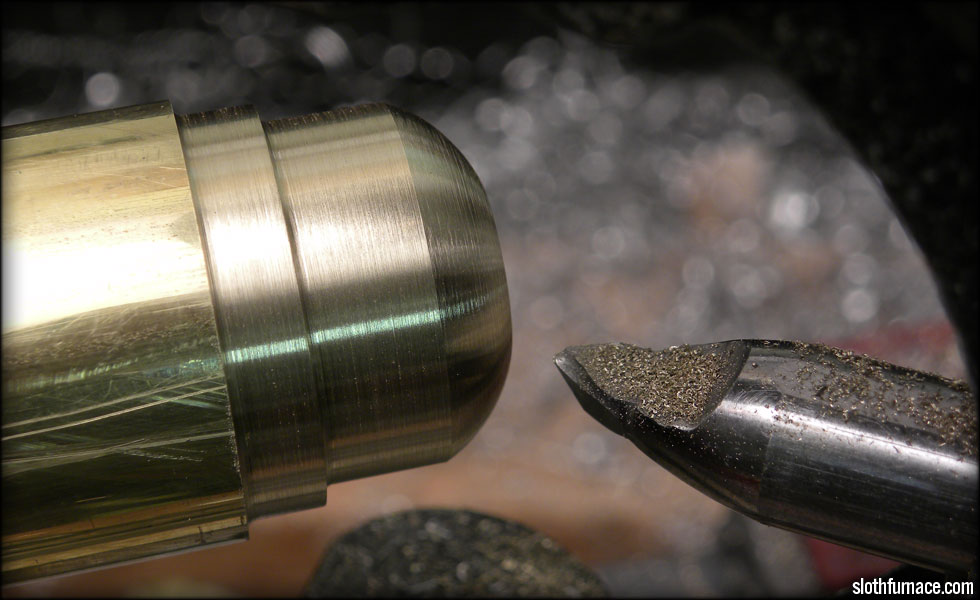

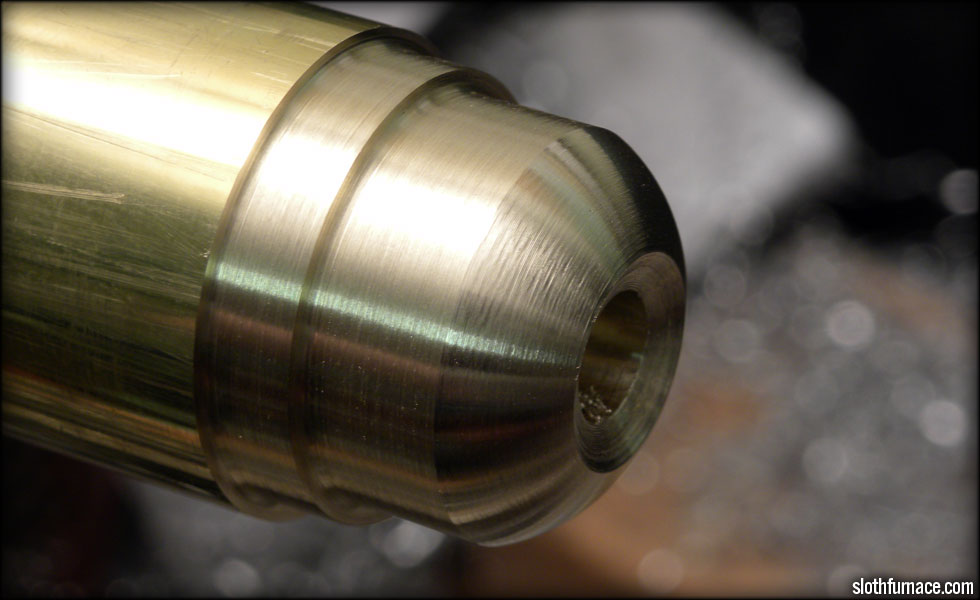

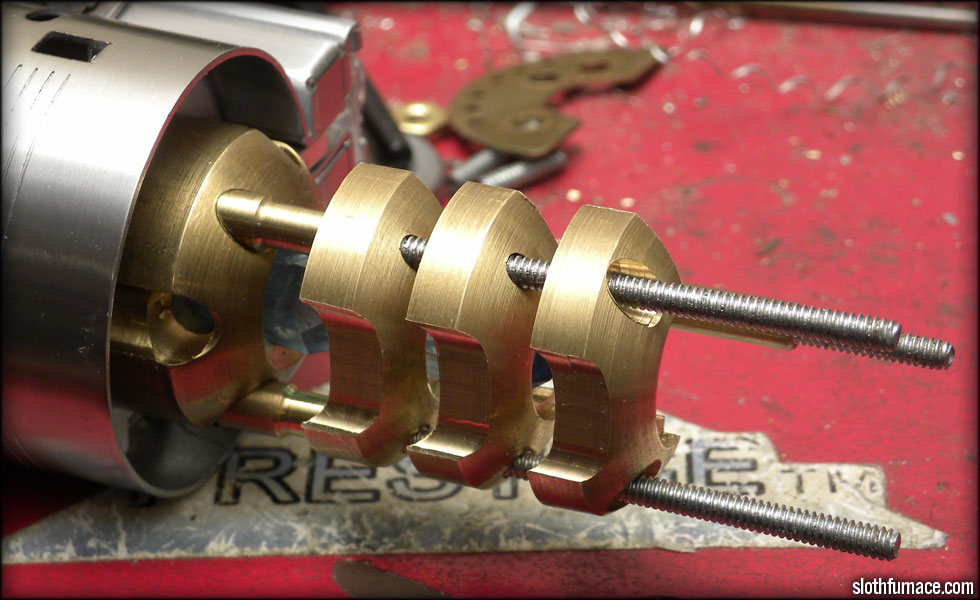

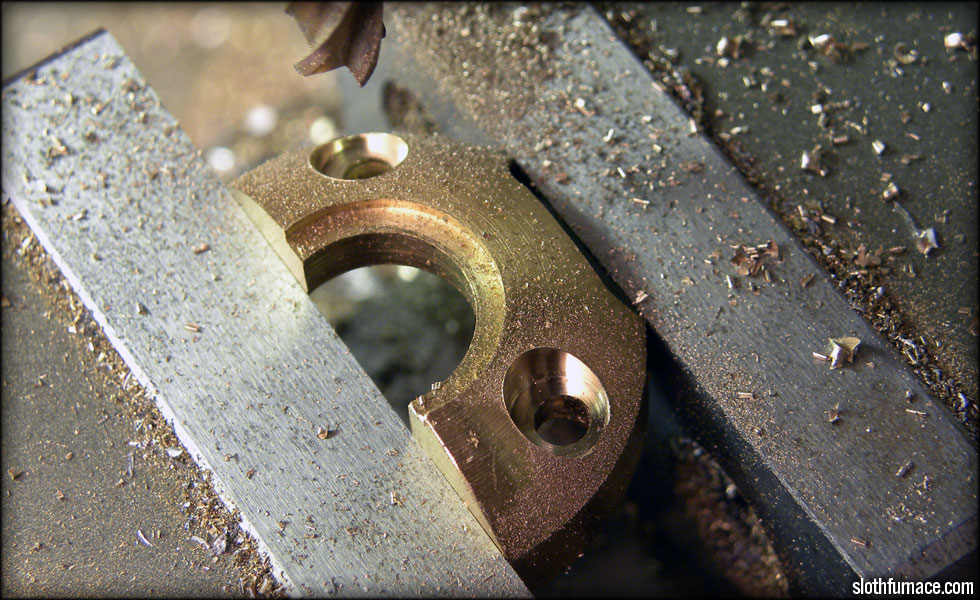

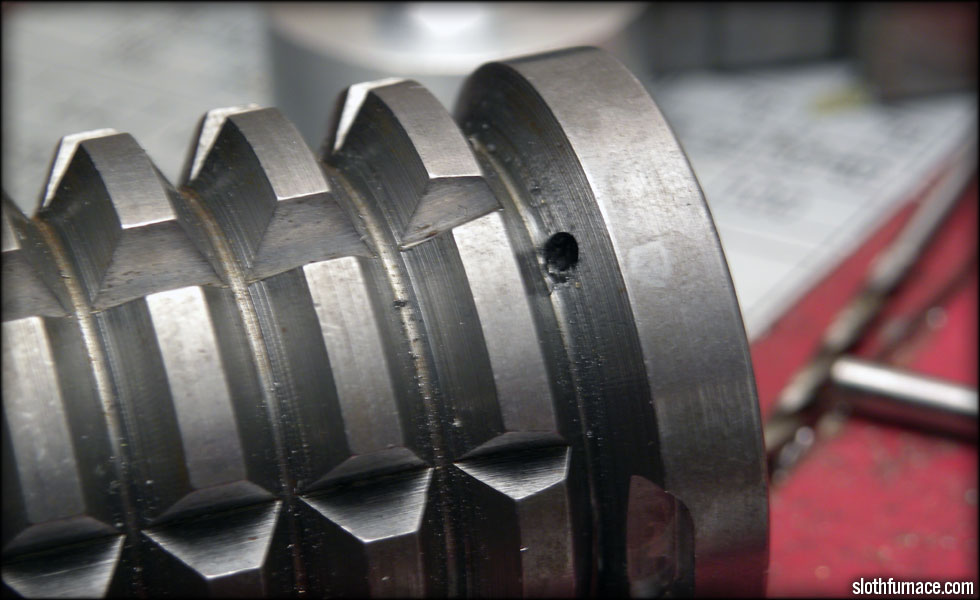

I started tonight with boring out the Russreplica's aluminum ANM2 booster piece, and fitting it to a hollow tube that also works as my main can and crystal chamber base.

It's been so long since I did any saber work, lately I am inspired to get back to it though.

I plan (hope) to make this one a springloaded chamber reveal.

I have enough stuff from Russreps to do it, and a couple clamps. I also have a chromed emitter and powdercoated booster, which I might make an AFBB out of.

A nice bundle of wires, a connector, and....

A Crystal Focus v5 LS version! Erv was so kind as to allow me to test the LS version, so this will the be the heart and soul of my ANH Obi chamber reveal saber.

GORGEOUS! I cannot wait to get out in the garage to begin the housing for this. I have to clear a couple things off my plate first, but this one has my juices flowing. It's time to get the drawing paper out and start designing the mechanism, start the search for the right chamber crystals, etc.

The PC is just there for size reference for the CF-LS.

I had quite a lot of trouble getting my head wrapped around the chamber lock mechanism for this one. I was trying to make it too much like my ROTJ Luke. Then tonight I just scrapped it for a much more obvious and elegant solution, once I get something that works, I 'll post that.

I started tonight with boring out the Russreplica's aluminum ANM2 booster piece, and fitting it to a hollow tube that also works as my main can and crystal chamber base.

It's been so long since I did any saber work, lately I am inspired to get back to it though.