You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Padme's blaster project - ELG-3A - screenaccurate details and proportions - idealized metal and wood materials

- Thread starter eethan

- Start date

OlivierC

Well-Known Member

wow, beautiful! I want to say "looks straight out of the movie" but no, looks 10 times better than the actual prop

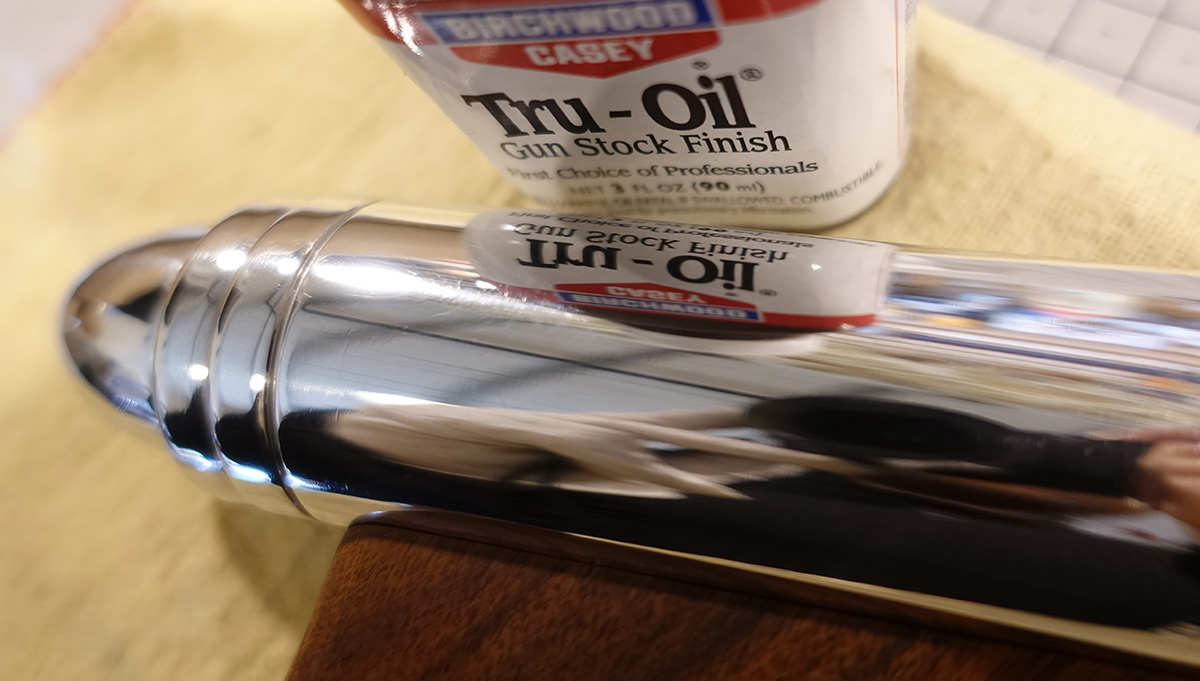

Edit : now that I see how more saturated the walnut handle looks when treated, I wonder if the Pao Ferro isn't going to be too red and too dark once it receive the same.

Edit : now that I see how more saturated the walnut handle looks when treated, I wonder if the Pao Ferro isn't going to be too red and too dark once it receive the same.

thanks Oliv!wow, beautiful! I want to say "looks straight out of the movie" but no, looks 10 times better than the actual prop

Edit : now that I see how more saturated the walnut handle looks when treated, I wonder if the Pao Ferro isn't going to be too red and too dark once it receive the same.

the Walnut has the tendancy to change a LOT with oil or wax. The Pao Ferro is changing a bit but clearly not as much.

Now, those two woods are clearly chosen to replicate the blasters in different lighting conditions and the original handle is a real cameleon!

(edit: oh, I forgot to mention as well, the dry fit above is with an untreated Pao Ferro handle. In case people are wondering)

Walnut was chosen to replicate this hue of the handle on the stunt and also in the movie:

Pao Ferro is I think the closest wood to what we see on the Hero blaster seen in the exhibits or in that book with the really red handle:

I could hold it today assembled in my hand. I was super crazy, and I have PEW PEW all in the house. It was hard for Eethan to get it back

AnubisGuard

Master Member

Beautiful.

AnubisGuard

Master Member

How do the handles attach to the barrels?

thanks manHow do the handles attach to the barrels?

hum! so, the handle attachment! so hard! this blaster is so simple exteriorly but it's quite hard to figure out... Since I want to incorporate a working trigger with a pre-wired switch, I don't have much room. since there are absolutely no holes visible anywere, I can't put a screw on the outside. the original was just one big piece of resin, so that's a bit hard to replicate with metal and wood...

so, for the prototypes, the handle is secured by one M4 screw from the inside of the body tube that goes into a threaded insert screwed into the handle, like so:

this is pretty strong, it doesn't move and the tube sits well in the handle but I'm a bit scared so far so I'm trying to figure out something to make it stronger. I had an idea of a screw in the front that would slide into a slot in the handle to secure it, then it would be held firmly by the screw on the back, but this is a bit hard to put in place too.

FolkyPatrol

Well-Known Member

Mind - blown

Thank you for sharing the whole process ! It is so enjoyable

Thank you for sharing the whole process ! It is so enjoyable

thank you guys!

ok, first message for today, followed by a second message later when I sorted out the photos.

I assembled the first blaster today, this one goes right away to the US tomorrow morning for the person that commissioned the run

As I explained before, the body was held on to the handle by one unique M4 screw. Although this was pretty secure, I wanted to find some way to make it more secure. This is all quite in the rush as the blaster needed to be sent but I finally figure out something that worked very well. for this one at least. This one is fully static and has a steel rod filling the inside and adding 250g to the blaster, so it really needed to be extra secure.

so here is what I did, the screw on the body goes into the slot screwed to the handle, then the whole thing is secured with the M4 screw from the inside of the tube. This makes 2 really strong points spaced by 2.4cm, it's really strong:

here I am holding it with only the screw stuck in the slot, no M4 screw here:

no screw inside yet:

OK! finally ready for assembly!

so, here comes the fun part, the screw is put inside the tube with long and thin pliers:

then gently threaded with a shorten hex key:

AND, VOILA!

having some fun with the reflexions:

Shiny!

there we go, I hope you like it, I'll post later tonight some photos taken outside. I've made some studio photos for the client as well but will wait until the other two blasters are finished, I'll photograph them again and start the interest thread

cheers

ok, first message for today, followed by a second message later when I sorted out the photos.

I assembled the first blaster today, this one goes right away to the US tomorrow morning for the person that commissioned the run

As I explained before, the body was held on to the handle by one unique M4 screw. Although this was pretty secure, I wanted to find some way to make it more secure. This is all quite in the rush as the blaster needed to be sent but I finally figure out something that worked very well. for this one at least. This one is fully static and has a steel rod filling the inside and adding 250g to the blaster, so it really needed to be extra secure.

so here is what I did, the screw on the body goes into the slot screwed to the handle, then the whole thing is secured with the M4 screw from the inside of the tube. This makes 2 really strong points spaced by 2.4cm, it's really strong:

here I am holding it with only the screw stuck in the slot, no M4 screw here:

no screw inside yet:

OK! finally ready for assembly!

so, here comes the fun part, the screw is put inside the tube with long and thin pliers:

then gently threaded with a shorten hex key:

AND, VOILA!

having some fun with the reflexions:

Shiny!

there we go, I hope you like it, I'll post later tonight some photos taken outside. I've made some studio photos for the client as well but will wait until the other two blasters are finished, I'll photograph them again and start the interest thread

cheers

Last edited:

AnubisGuard

Master Member

Super smart on that slide-locking screw.

JUSTINSW619

New Member

Simply a MASTERPIECE! My goodness I didn’t think this day would ever come! The most screen accurate there’s ever been! Like some people in this thread have said, it’s 1000x times better than the screen used because it’s actual metal and wood! Amazing work my friend! Can’t thank you enough for the hard work and time you put into this. It’s simply a masterpiece!

Philbeey

New Member

I made an account just to comment and follow this project. This is the project that finally got me to stop lurking.

Reading the process has been fantastic and you’ve done such a good job.

I am infinitely excited someone tackled this rare and seemingly (surprisingly) unique project

Reading the process has been fantastic and you’ve done such a good job.

I am infinitely excited someone tackled this rare and seemingly (surprisingly) unique project

thank you so much Phil, that is very nice of you!I made an account just to comment and follow this project. This is the project that finally got me to stop lurking.

Reading the process has been fantastic and you’ve done such a good job.

I am infinitely excited someone tackled this rare and seemingly (surprisingly) unique project

I have to admit I was extremely worried about the interest there would be for this project since it's a prop from the prequel trilogy. I'm glad to see the prop still brings some enthousiasm

Similar threads

- Replies

- 6

- Views

- 419

- Replies

- 4

- Views

- 665

- Replies

- 7

- Views

- 2,025