starting to cut some tubes

I remember my old version when I was cutting those 5mm thick tubes with a metal handsaw... that was fun!

small tip here, I'm actually spraying a tiny bit of WD40 PTFE anti friction lube on the blade when I cut metal tubes, you can instantly feel the blade cut smoother when you spray.

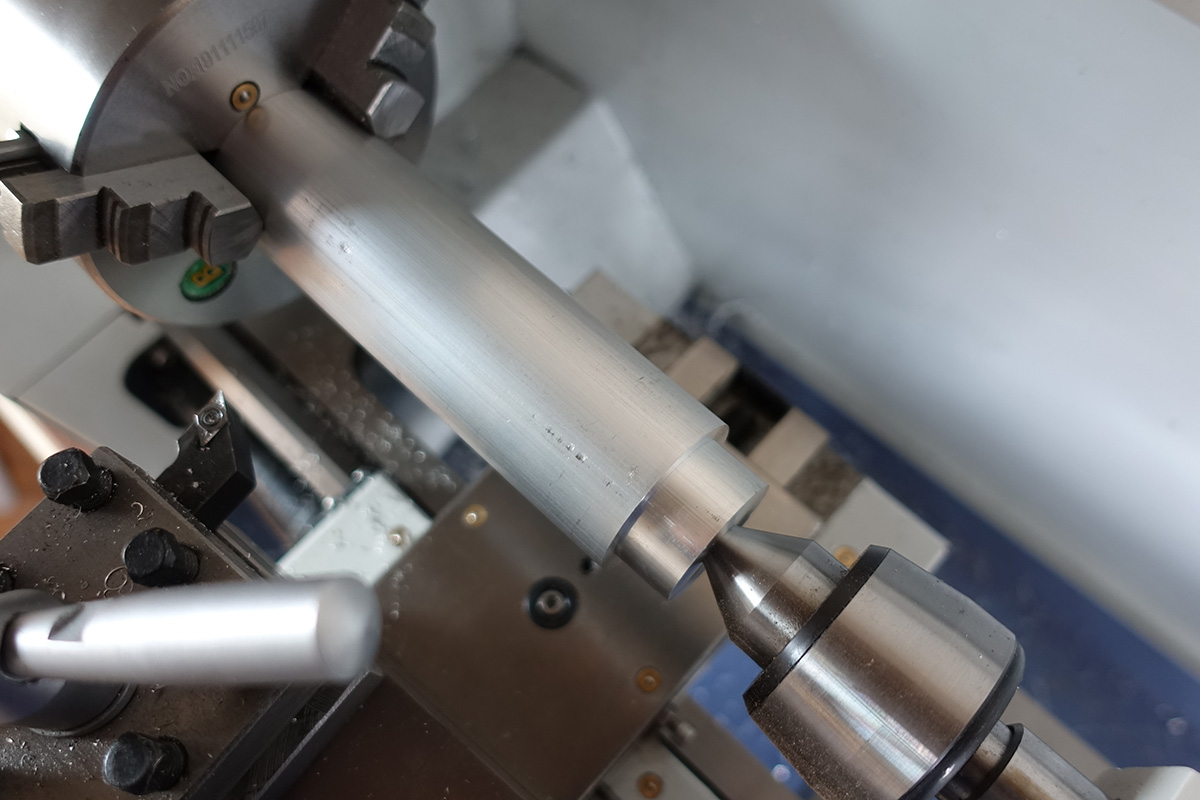

then, face turning the tubes on the lathe for a clean final look:

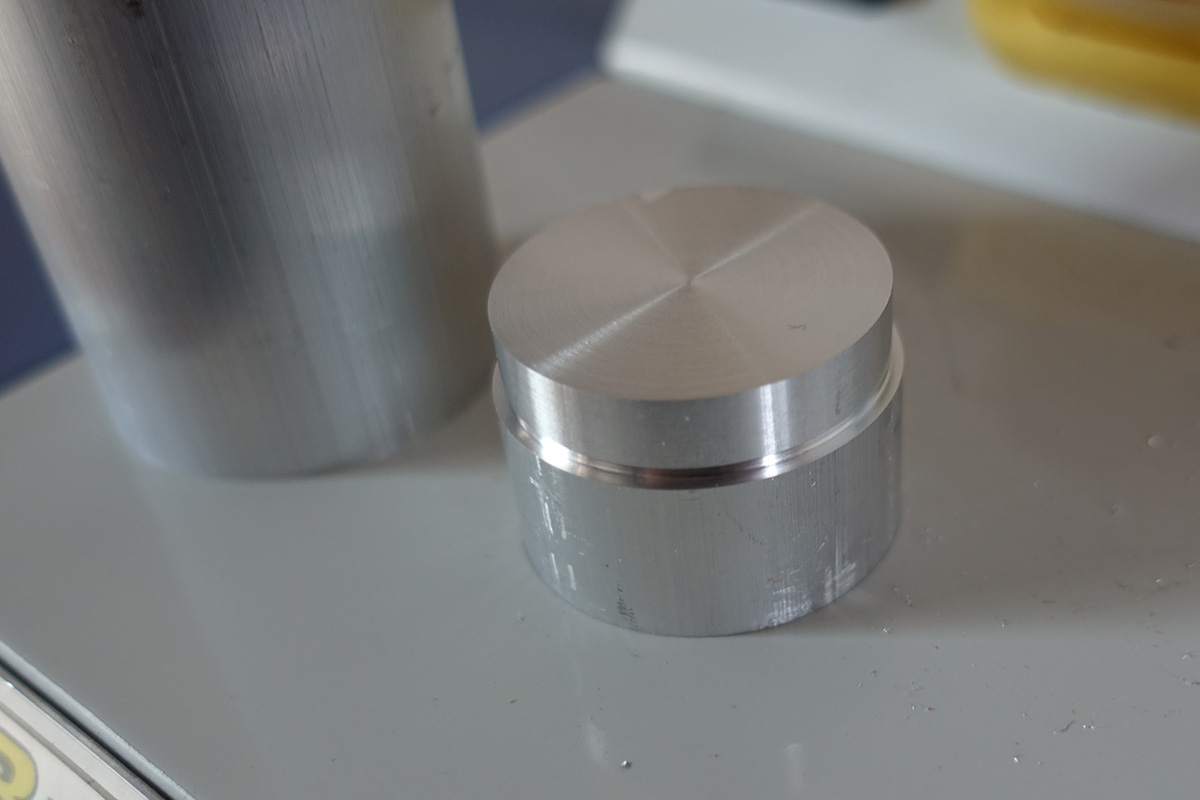

ok, now, the small jig of the day,

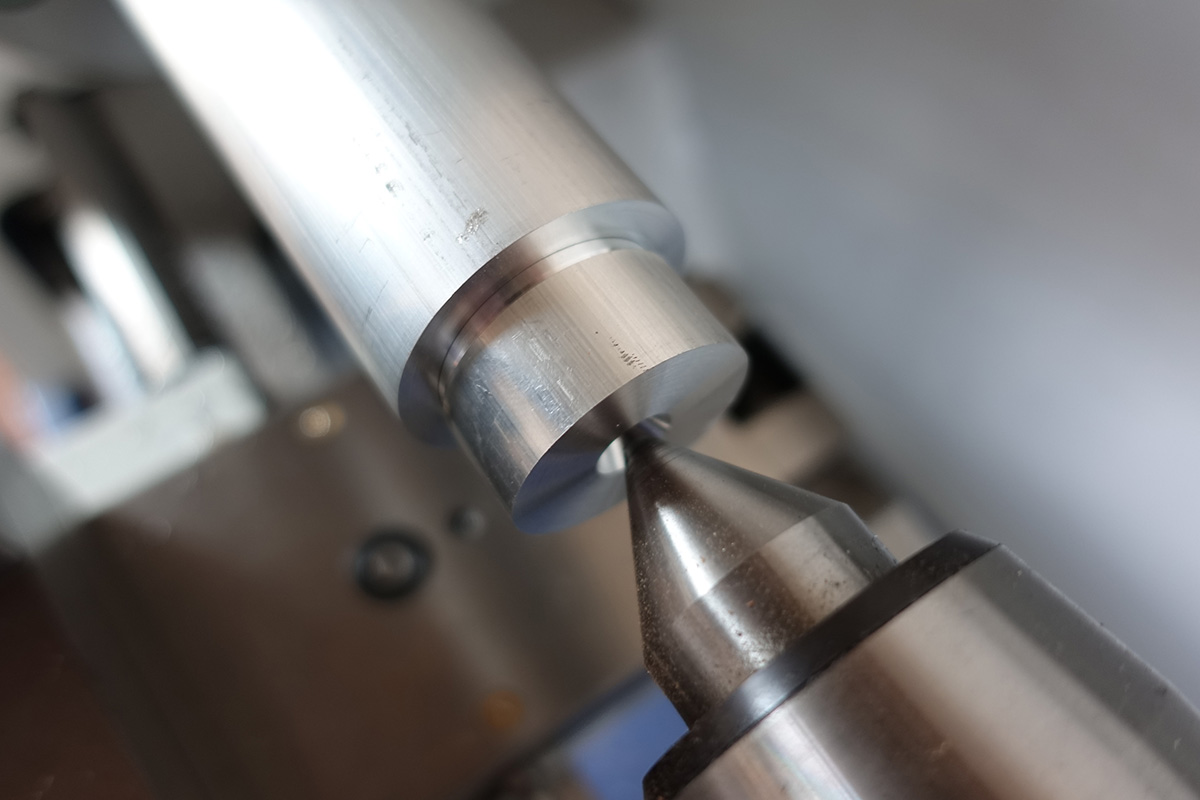

since those tubes are a bit long for the lathe to work safely, I need something to hold them from the oposite end from the chuck. Since it's a large open tube, I can't use the live counterpoint of the lathe, the diameter is too large.

to cheat that, I turned a 30mm rod that will slide in the end of the tube with a center hole to use the counterpoint of the lathe:

there we go!

cheers

I remember my old version when I was cutting those 5mm thick tubes with a metal handsaw... that was fun!

small tip here, I'm actually spraying a tiny bit of WD40 PTFE anti friction lube on the blade when I cut metal tubes, you can instantly feel the blade cut smoother when you spray.

then, face turning the tubes on the lathe for a clean final look:

ok, now, the small jig of the day,

since those tubes are a bit long for the lathe to work safely, I need something to hold them from the oposite end from the chuck. Since it's a large open tube, I can't use the live counterpoint of the lathe, the diameter is too large.

to cheat that, I turned a 30mm rod that will slide in the end of the tube with a center hole to use the counterpoint of the lathe:

there we go!

cheers