cavx

Master Member

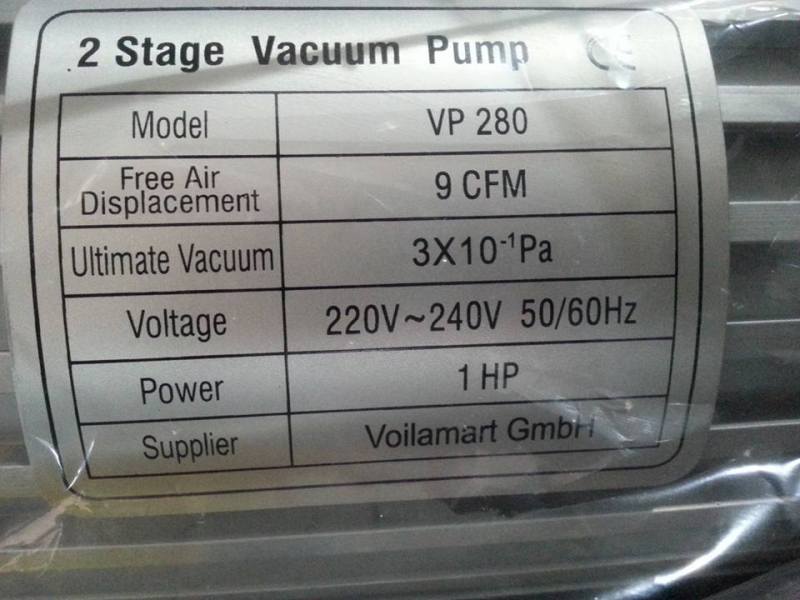

UPDATE: So I have upgraded my vacuum pump from a 1/4HP, single stage, 3CFM pump to this beast

I also wanted to make a vacuum chamber that is large enough to allow me to degas in the molds as well as double as a female tooled vacuum former.

Yesterday I picked this up.

My tube "buck" for the FOOTWEAR bag fits inside with a bit of room to spare. Because I am doing this as a "female" tool, I will be making the hollow slightly over sized and shimming the space with sheets of rubber. This will give me the ability to make both the lids (the larger diameter with the recessed handle) and the body (slightly smaller diameter) from the one tool. At this this stage, I am looking at 2 part rigid expanding foam to fill the voids around the pipe. Under vacuum, the foam will be porous enough to allow the air to be sucked out.

Rather than traditional "vacuuming forming" I am also looking at "thermo forming" the parts because you get a thicker walls and do not waste as much plastic. I am still to make and test the silicone sheet, but it seems that the silicone I use for my molds will be strong enough for this as it had a shore of A40 and stretches when poured into thin sheets.

So first step is to build this new rig which requires lids and bases to be made up, then ball valves to be fitted to allow my new 9CFM pump to be connected.

Then I will make the tools.

This section of pipe is OD 800mm/ID 706mm. Because it is PE, nothing sticks to it, so it will be perfect to use as the mold for the making of the tools with products like the expanding foam.

Keep watching this space. More to come soon.

I also wanted to make a vacuum chamber that is large enough to allow me to degas in the molds as well as double as a female tooled vacuum former.

Yesterday I picked this up.

My tube "buck" for the FOOTWEAR bag fits inside with a bit of room to spare. Because I am doing this as a "female" tool, I will be making the hollow slightly over sized and shimming the space with sheets of rubber. This will give me the ability to make both the lids (the larger diameter with the recessed handle) and the body (slightly smaller diameter) from the one tool. At this this stage, I am looking at 2 part rigid expanding foam to fill the voids around the pipe. Under vacuum, the foam will be porous enough to allow the air to be sucked out.

Rather than traditional "vacuuming forming" I am also looking at "thermo forming" the parts because you get a thicker walls and do not waste as much plastic. I am still to make and test the silicone sheet, but it seems that the silicone I use for my molds will be strong enough for this as it had a shore of A40 and stretches when poured into thin sheets.

So first step is to build this new rig which requires lids and bases to be made up, then ball valves to be fitted to allow my new 9CFM pump to be connected.

Then I will make the tools.

This section of pipe is OD 800mm/ID 706mm. Because it is PE, nothing sticks to it, so it will be perfect to use as the mold for the making of the tools with products like the expanding foam.

Keep watching this space. More to come soon.