Wicked!According to Stefan Otto's plans, 130°

View attachment 1541152

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 3D printed Proton Pack build

- Thread starter Galifreyscall

- Start date

Just a fellow pack builder!Didn't expect a community celeb to take note of my work! I'm honored-

Here's mine: My Proton Pack build (including Afterlife-to-1984 wand mod)

METATRON

Active Member

Hi, very nice build! I put my 3D files for my GB pack and gun parts I designed in CAD on Thingiverse with Step files, too. If you interested.

The measurements are mostly from the pictures of real movie used packs from picture you can find on GBfans.com like the Harold Ramis Hero Pack.

Link to: Thingiverse MakerGulbi Designs

Can you post your "leghose adapter" file?

The measurements are mostly from the pictures of real movie used packs from picture you can find on GBfans.com like the Harold Ramis Hero Pack.

Link to: Thingiverse MakerGulbi Designs

Can you post your "leghose adapter" file?

Last edited:

Galifreyscall

Active Member

Of course, I found them here: Ghostbusters 1 Leg Hose Connector by darrellcalkjrHi, very nice build! I put my 3D files for my GB pack and gun parts I designed in CAD on Thingiverse with Step files, too. If you interested.

The measurements are mostly from the pictures of real movie used packs from picture you can find on GBfans.com like the Harold Ramis Hero Pack.

View attachment 1541201

Link to: Thingiverse MakerGulbi Designs

Can you post your "leghose adapter" file?

I've seen your files around, they look pretty dang good! I've been using some of the same sources as you I believe. Wish I knew anything about proper CAD modeling, if I did I'd have most of my parts milled professionally.

thank you for sharingHi, very nice build! I put my 3D files for my GB pack and gun parts I designed in CAD on Thingiverse with Step files, too. If you interested.

The measurements are mostly from the pictures of real movie used packs from picture you can find on GBfans.com like the Harold Ramis Hero Pack.

View attachment 1541201

Link to: Thingiverse MakerGulbi Designs

Can you post your "leghose adapter" file?

METATRON

Active Member

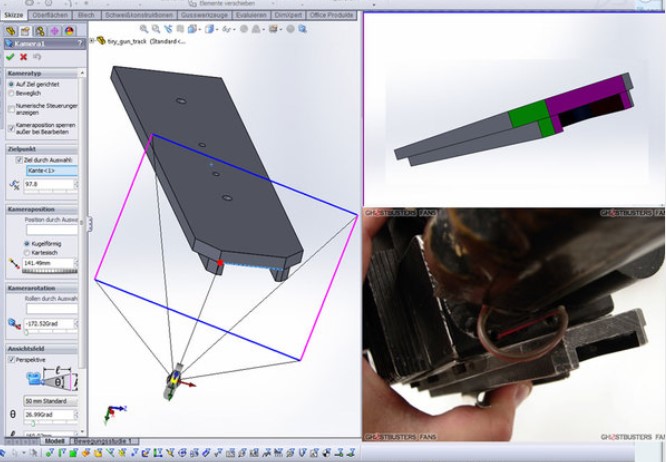

Ah, you used that leg hose connector. It’s looking good. I procrastinated on this part of the costume for a long time. I’m a trained designer and engineer and did my models for years during my break times at work, just for fun. It’s done with SolidWorks. Yes milled parts are nice, but it’s expensive. I milled some parts at work for free, but bought my knobs at gbfans. It’s way easier and cheaper to buy them. If you are based in the US, you have a lot of options. But I think it all depends on what you wanna do with it. I really like my aluminum Proton Gun with lights and everything, but with a costume I like the look hanging it from the belt.Of course, I found them here: Ghostbusters 1 Leg Hose Connector by darrellcalkjr

I've seen your files around, they look pretty dang good! I've been using some of the same sources as you I believe. Wish I knew anything about proper CAD modeling, if I did I'd have most of my parts milled professionally.

But a hard aluminum thing banging on you leg with every step just hurts. And the full aluminum packs are heavy, too. For a costume I really think someone will have more fun with foam and PVC-Pipe, with a really good weathering job for the pack.

But you project is looking really good! Keep the fun!

Last edited:

wicked nice setup, i have a aluminum thrower, but like you said it weights a lot.. one day i hope to make a light pack. i would love for someone to do fiberglass throwers.Ah, you used that leg hose connector. It’s looking good. I procrastinated on this part of the costume for a long time. I’m a trained designer and engineer and did my models for years during my break times at work, just for fun. It’s done with SolidWorks. Yes milled parts are nice, but it’s expensive. I milled some parts at work for free, but bought my knobs at gbfans. It’s way easier and cheaper to buy them. If you are based in the US, you have a lot of options. But I think it all depends on what you wanna do with it. I really like my aluminum Proton Gun with lights and everything, but with a costume I like the look hanging it from the belt.

View attachment 1541698

But a hard aluminum thing banging on you leg with every step just hurts. And the full aluminum packs are heavy, too. For a costume I really think someone will have more fun with foam and PVC-Pipe, with a really good weathering job for the pack.

But you project is looking really good! Keep the fun!

the resin throwers are great but one fall and they are done for.. every pack i built with a aluminum thrower i always made sure those v hookers her installed like iron, because this has always been on of my biggest fears..

also for some reason in my mind i feel so much more secure when i add a aluminum gun rack. but then it starts defeating the purpose of being light weight..

i dont know im a weird duck

Galifreyscall

Active Member

Slow progress on the pack, but I do have something to report:

My belt is now populated with a new belt gizmo holster!

![IMG_20220207_152548109[1].jpg IMG_20220207_152548109[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1186/1186157-75a9e28aed09f6e6a0ac16d0ce8a7572.jpg)

I found a measuring tape holster on amazon from a company called RJ Leather for about $15 bucks. The shape of the band seemed more accurate than the Klein tools holster, and it was a helluva lot cheaper than one from GBFans, so I hopped on and grabbed it. It came in a few days ago, and I let it sit for a bit before going to my local Tandy leatherworks and picking up some dye. Before, and after:

![IMG_20220207_145630224[1].jpg IMG_20220207_145630224[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1186/1186154-dbba0a3a9c2073a1a04e7a822263fb8b.jpg)

![IMG_20220207_151705953[1].jpg IMG_20220207_151705953[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1186/1186155-6f48ea72d70e9f5444d5e9759f3c29a4.jpg)

After letting the dye settle and wiping it off the rivets, I was left with a serviceable holster! What I haven't pictured is the state it arrived in, with the strap to keep the measuring tape in, and the lower section which I had to cut off and remove the rivets from. (see the 3 holes in the bottom). Overall I think this is a great cheap belt gizmo holster for the budget savvy buster, just make sure to dye it outside, these fumes are absolutely noxious- Hope to have some work done on the pack done soon, till the next!

-Galifreyscall

My belt is now populated with a new belt gizmo holster!

![IMG_20220207_152548109[1].jpg IMG_20220207_152548109[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1186/1186157-75a9e28aed09f6e6a0ac16d0ce8a7572.jpg)

I found a measuring tape holster on amazon from a company called RJ Leather for about $15 bucks. The shape of the band seemed more accurate than the Klein tools holster, and it was a helluva lot cheaper than one from GBFans, so I hopped on and grabbed it. It came in a few days ago, and I let it sit for a bit before going to my local Tandy leatherworks and picking up some dye. Before, and after:

![IMG_20220207_145630224[1].jpg IMG_20220207_145630224[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1186/1186154-dbba0a3a9c2073a1a04e7a822263fb8b.jpg)

![IMG_20220207_151705953[1].jpg IMG_20220207_151705953[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1186/1186155-6f48ea72d70e9f5444d5e9759f3c29a4.jpg)

After letting the dye settle and wiping it off the rivets, I was left with a serviceable holster! What I haven't pictured is the state it arrived in, with the strap to keep the measuring tape in, and the lower section which I had to cut off and remove the rivets from. (see the 3 holes in the bottom). Overall I think this is a great cheap belt gizmo holster for the budget savvy buster, just make sure to dye it outside, these fumes are absolutely noxious- Hope to have some work done on the pack done soon, till the next!

-Galifreyscall

progress is progress man! how does the dye hold up? ive seen some guys have it rub off onto their suit, and then ive seen many others never have a single issue. believe it or not all these years into GB props ive never attempted to dye my own in fear of screwing it up

hats off to you for having the guts to do it!

hats off to you for having the guts to do it!

Galifreyscall

Active Member

Thank you! It's lightened slightly, but I think that can be attributed to the dye fully drying and being absorbed. Other than that it's pretty solidly in there, haven't had any problems with it rubbing off on anything. Heck, I left the barcode sticker on while dyeing, and it hasn't even rubbed off that! For reference I've been using Fiebing's black Pro Dye with the leather finish removed and cleaned beforehand with Fiebing's Deglazer.progress is progress man! how does the dye hold up? ive seen some guys have it rub off onto their suit, and then ive seen many others never have a single issue. believe it or not all these years into GB props ive never attempted to dye my own in fear of screwing it up

hats off to you for having the guts to do it!

do you mind sharing your instructions?Thank you! It's lightened slightly, but I think that can be attributed to the dye fully drying and being absorbed. Other than that it's pretty solidly in there, haven't had any problems with it rubbing off on anything. Heck, I left the barcode sticker on while dyeing, and it hasn't even rubbed off that! For reference I've been using Fiebing's black Pro Dye with the leather finish removed and cleaned beforehand with Fiebing's Deglazer.

Galifreyscall

Active Member

Absolutely!do you mind sharing your instructions?

First of all, do this outside or in a garage. I mean it, the most ventilated room wont stop the smell from permeating through the house, and this stuff is noxious.

That being said; first I picked up a pack of wool daubers, you can find a pack of 10 for a couple bucks and they work way better than any paintbrush. I first give the leather a couple liberal coats of Fiebing's Deglazer, this will strip the leather of any prior finish that was on it while also cleaning it. While the leather is still damp, I'll apply the first coat of dye. We're going for a black finish, so the wetter the coats the better I've found. I'll usually apply 2-3 coats of dye until letting it dry. I can't stress this enough, you can't be too liberal, you want the leather to absorb the dye as much as possible and anything that doesn't soak in can be wiped off with a rag. Drying will take about an hour to the touch, but about a day to fully dry. After that, if you're worried about ruboff you can and probably should seal the leather with something like Resolene, applying it in light, even coats in a circular motion with a sponge or soft sheep wool.

Et voilà, a fine dyed leather addition to your costume! As with anything, I recommend testing your chosen products on scraps before going straight to your gizmo holster/pouch/belt/ etc. and don't forget to wear your shop clothes, lest you accidentally drip some on your fine Sunday best as i luckily didn't do. Hope this was helpful to anyone who needed it, till the next time-

-Galifreyscall

Galifreyscall

Active Member

Proton Pack, Continued...

I've had the spacer modeled for some time now, but only now have I divided it up for printing. I know it's nowhere near optimized; it's a massive filament hog, but Ive printed 2/5 of it so far. The tolerances for the alignment holes was perfect, which nearly brought me to tears after all the sanding I've done on previous parts to get them to align. Here it is, it all of its incomplete -but satisfying- glory:

![IMG_20220211_164735534[1].jpg IMG_20220211_164735534[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1187/1187950-66ed408ea525bf47972038b7cd161a60.jpg)

![IMG_20220211_164839011[1].jpg IMG_20220211_164839011[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1187/1187951-822377855d3e0963dadd659d3ce6e14f.jpg)

In other news, I've accidentally stumbled upon a good substitute for a belt gizmo, which is the motherboard from a CD/DVD drive:

![IMG_20220211_164932386[1].jpg IMG_20220211_164932386[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1187/1187954-414ba4ca2d7bff715958cc2411c7915a.jpg)

It'll take a little trimming to get it to fit in the holster, I'll cut the smaller board in half, and glue the halves side by side onto a piece of protoboard to make the daughterboard. Aside from that I'll trim the main board down to size, and print the nixie tube holder, then I believe I'll have a convincing gizmo!

In other other news, by the time I'm posting this, I'll be debuting the uniform sans pack at my local airsoft field for some... realistic weathering-

I hope I'll have a few pics from that; if not, then till the next update!

-Galifreyscall

I've had the spacer modeled for some time now, but only now have I divided it up for printing. I know it's nowhere near optimized; it's a massive filament hog, but Ive printed 2/5 of it so far. The tolerances for the alignment holes was perfect, which nearly brought me to tears after all the sanding I've done on previous parts to get them to align. Here it is, it all of its incomplete -but satisfying- glory:

![IMG_20220211_164735534[1].jpg IMG_20220211_164735534[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1187/1187950-66ed408ea525bf47972038b7cd161a60.jpg)

![IMG_20220211_164839011[1].jpg IMG_20220211_164839011[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1187/1187951-822377855d3e0963dadd659d3ce6e14f.jpg)

In other news, I've accidentally stumbled upon a good substitute for a belt gizmo, which is the motherboard from a CD/DVD drive:

![IMG_20220211_164932386[1].jpg IMG_20220211_164932386[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1187/1187954-414ba4ca2d7bff715958cc2411c7915a.jpg)

It'll take a little trimming to get it to fit in the holster, I'll cut the smaller board in half, and glue the halves side by side onto a piece of protoboard to make the daughterboard. Aside from that I'll trim the main board down to size, and print the nixie tube holder, then I believe I'll have a convincing gizmo!

In other other news, by the time I'm posting this, I'll be debuting the uniform sans pack at my local airsoft field for some... realistic weathering-

I hope I'll have a few pics from that; if not, then till the next update!

-Galifreyscall

seriously man, thank you for taking the time and writing this up, wicked appreciate it. keep up all the great work with the pack, i seriously enjoy watching the updates. I was around 14/15 when i first started building packs why back in the late 90sAbsolutely!

First of all, do this outside or in a garage. I mean it, the most ventilated room wont stop the smell from permeating through the house, and this stuff is noxious.

That being said; first I picked up a pack of wool daubers, you can find a pack of 10 for a couple bucks and they work way better than any paintbrush. I first give the leather a couple liberal coats of Fiebing's Deglazer, this will strip the leather of any prior finish that was on it while also cleaning it. While the leather is still damp, I'll apply the first coat of dye. We're going for a black finish, so the wetter the coats the better I've found. I'll usually apply 2-3 coats of dye until letting it dry. I can't stress this enough, you can't be too liberal, you want the leather to absorb the dye as much as possible and anything that doesn't soak in can be wiped off with a rag. Drying will take about an hour to the touch, but about a day to fully dry. After that, if you're worried about ruboff you can and probably should seal the leather with something like Resolene, applying it in light, even coats in a circular motion with a sponge or soft sheep wool.

Et voilà, a fine dyed leather addition to your costume! As with anything, I recommend testing your chosen products on scraps before going straight to your gizmo holster/pouch/belt/ etc. and don't forget to wear your shop clothes, lest you accidentally drip some on your fine Sunday best as i luckily didn't do. Hope this was helpful to anyone who needed it, till the next time-

-Galifreyscall

all vacuum formed back then. i would die if we had 3d printing back then...

seeing your progress brings back memories of a kid..

Galifreyscall

Active Member

So in my last post I showed what I'm using for the belt gizmo, just now I've found a better alternative. I disassembled an old pushbutton phone a while back for its keypad back when I was going to use it for an F-18 UFC panel, that never happened and the keypad's been lying around ever since. This morning I walked past it, flipped it over, and lo and behold, the circuit board on the back looked perfect for a gizmo daughterboard!

![IMG_20220213_132736128[1].jpg IMG_20220213_132736128[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1188/1188499-e0e369e998628c643ab0a397f0c3c353.jpg)

![IMG_20220213_132816061[1].jpg IMG_20220213_132816061[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1188/1188500-010fc1fe02d271084f9b332694aa41e4.jpg)

![IMG_20220213_133034638[1].jpg IMG_20220213_133034638[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1188/1188501-a14b5a4e0316bb2be3e409a328cee9a5.jpg)

The free coiled phone cable is a plus too! I think this is a great alternative cause you can get these old phones for pennies on the dime, and it's an authentic component of the era. Now I just gotta print the nixie tubes, then I'll be another step towards completion.

-Galifreyscall

![IMG_20220213_132736128[1].jpg IMG_20220213_132736128[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1188/1188499-e0e369e998628c643ab0a397f0c3c353.jpg)

![IMG_20220213_132816061[1].jpg IMG_20220213_132816061[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1188/1188500-010fc1fe02d271084f9b332694aa41e4.jpg)

![IMG_20220213_133034638[1].jpg IMG_20220213_133034638[1].jpg](https://therpf-f28a.kxcdn.com/forums/data/attachments/1188/1188501-a14b5a4e0316bb2be3e409a328cee9a5.jpg)

The free coiled phone cable is a plus too! I think this is a great alternative cause you can get these old phones for pennies on the dime, and it's an authentic component of the era. Now I just gotta print the nixie tubes, then I'll be another step towards completion.

-Galifreyscall

Galifreyscall

Active Member

Came back home tonight excited to collect the fruits of my printing:

![IMG_20220216_193143754[1].jpg IMG_20220216_193143754[1].jpg](https://www.therpf.com/forums/attachments/img_20220216_193143754-1-jpg.1547379/)

Guess it's time for another spool, at least I know the tolerances will ok with a little sanding/filling.

Guess it's time for another spool, at least I know the tolerances will ok with a little sanding/filling.

TazMan2000

Master Member

Real generous of you to share your design. This is too big for me though. I'm running out of room.

TazMan2000

TazMan2000

Must feel good to start seeing these big pieces come togetherCame back home tonight excited to collect the fruits of my printing:

View attachment 1547379

Guess it's time for another spool, at least I know the tolerances will ok with a little sanding/filling.

Galifreyscall

Active Member

Of course! I'm a firm believer in freedom of information, so I'm happy to provide any research, tutorials, measurements or techniques that I can.Real generous of you to share your design. This is too big for me though. I'm running out of room.

TazMan2000

Dang right, it's also relieving to see that these parts aren't coming out like pack shaped rubbish. Or even worse, one of Videobob's shells-Must feel good to start seeing these big pieces come together

Similar threads

- Replies

- 0

- Views

- 219