Hi guys,

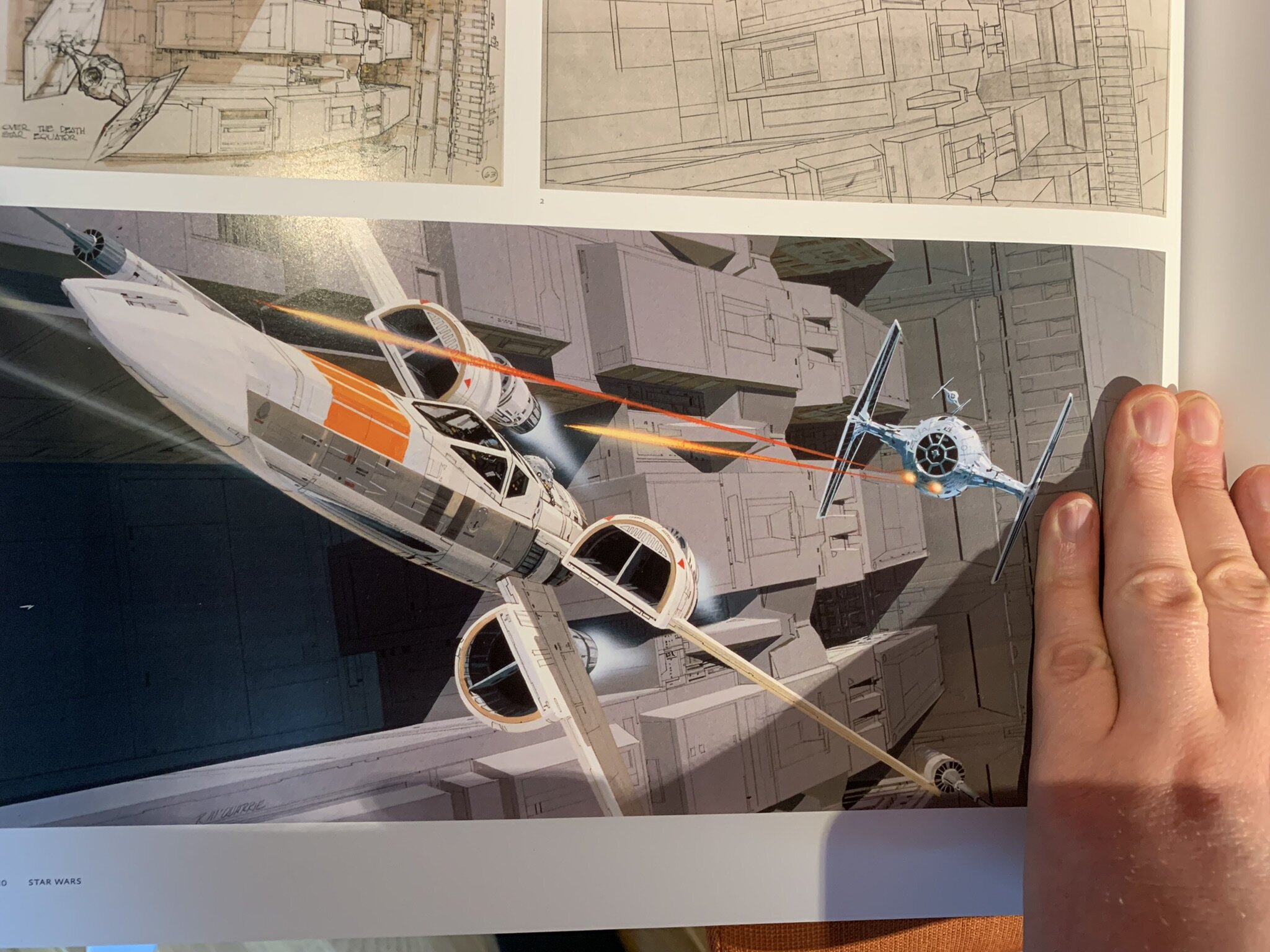

Ever since I had the image of the McQ X-wing in my childhood room growing up I always wanted a kit of it. I'm aware there are several kits out there but they're not that easy to find and if found, pretty expensive. Added to that this sort of build is kind of artist interpretation type of work so I decided to make my own model. Currently I'm midst of the modelleing work and I'm putting in the hours as I find them but they're few and sometimes far apart.

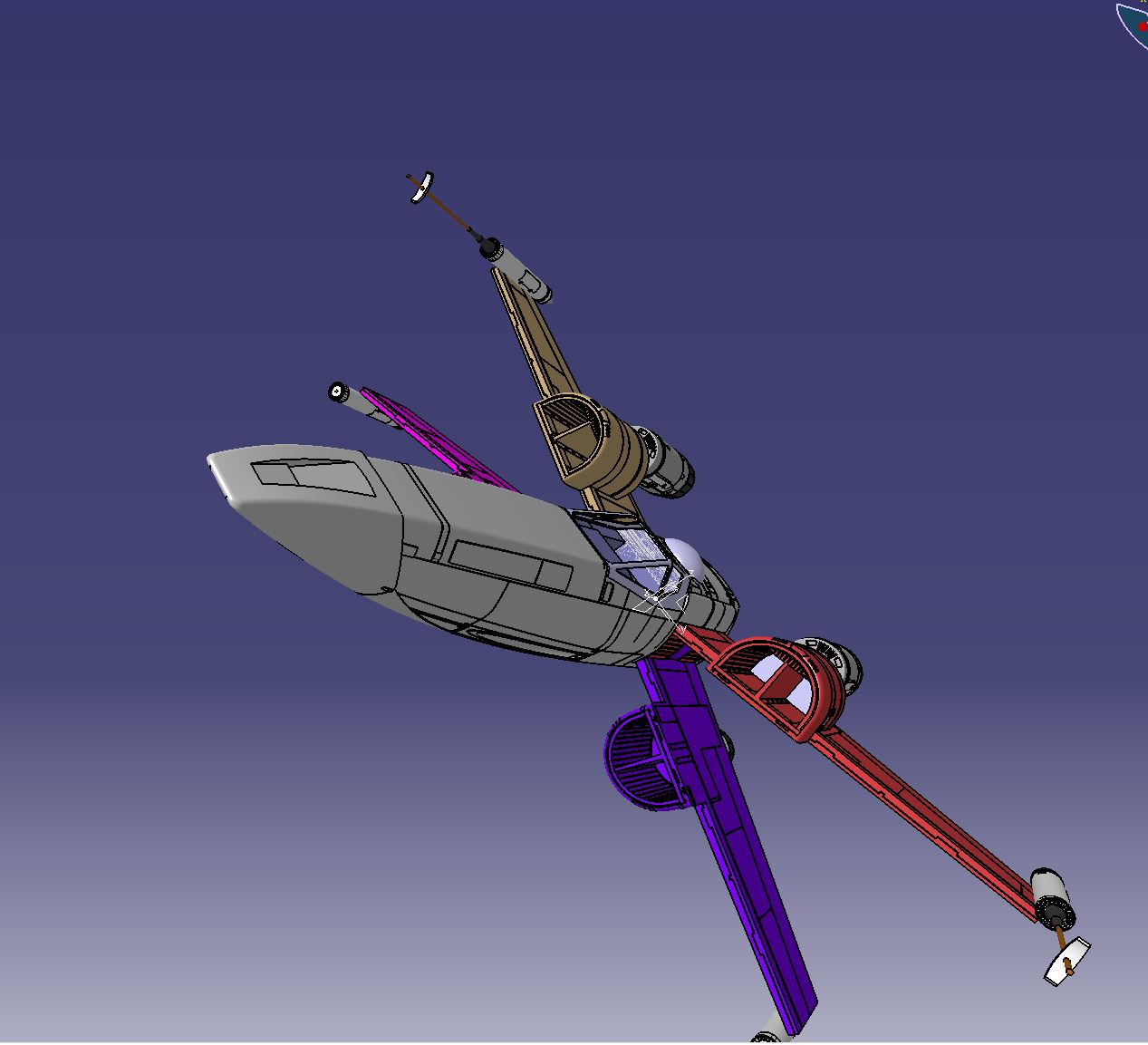

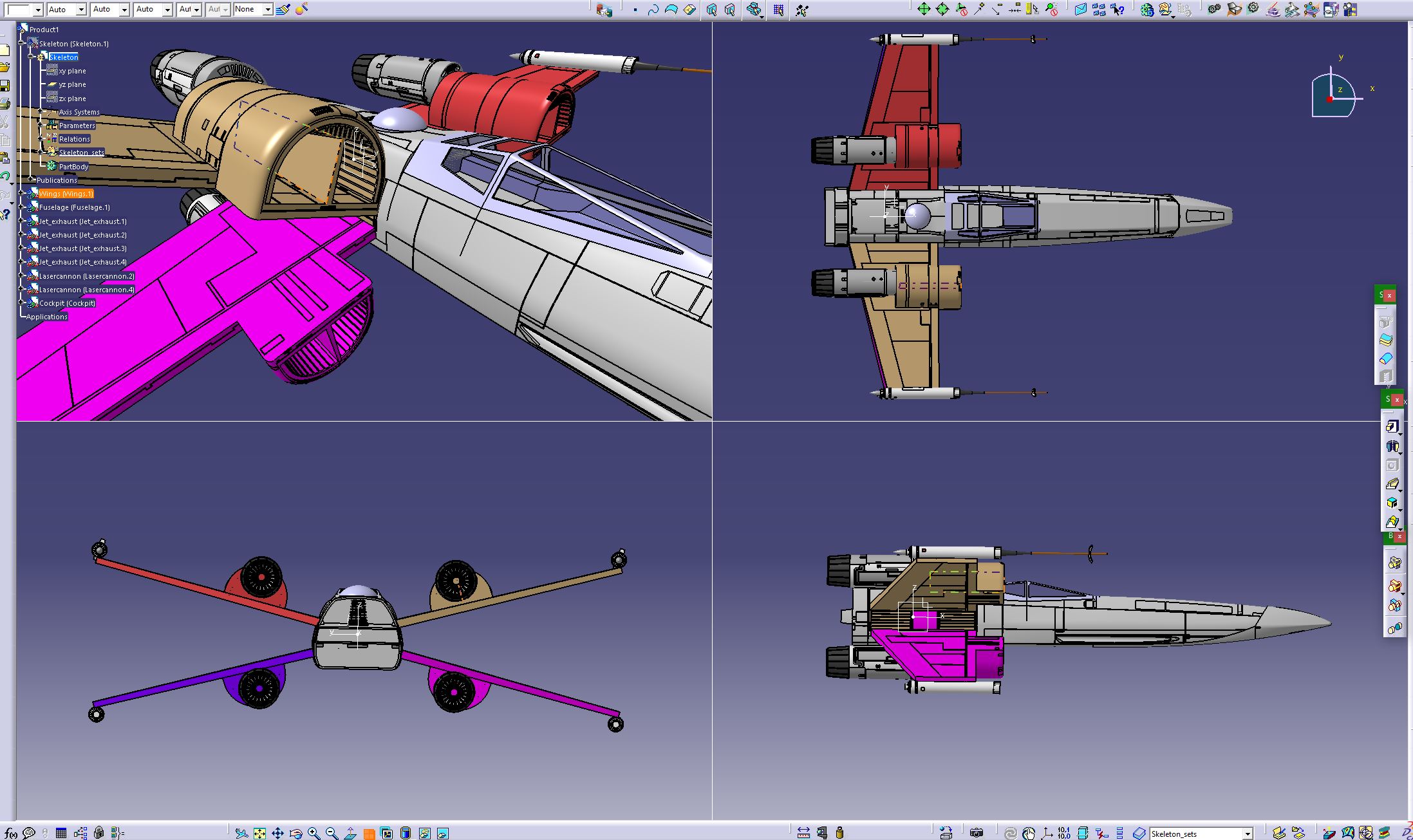

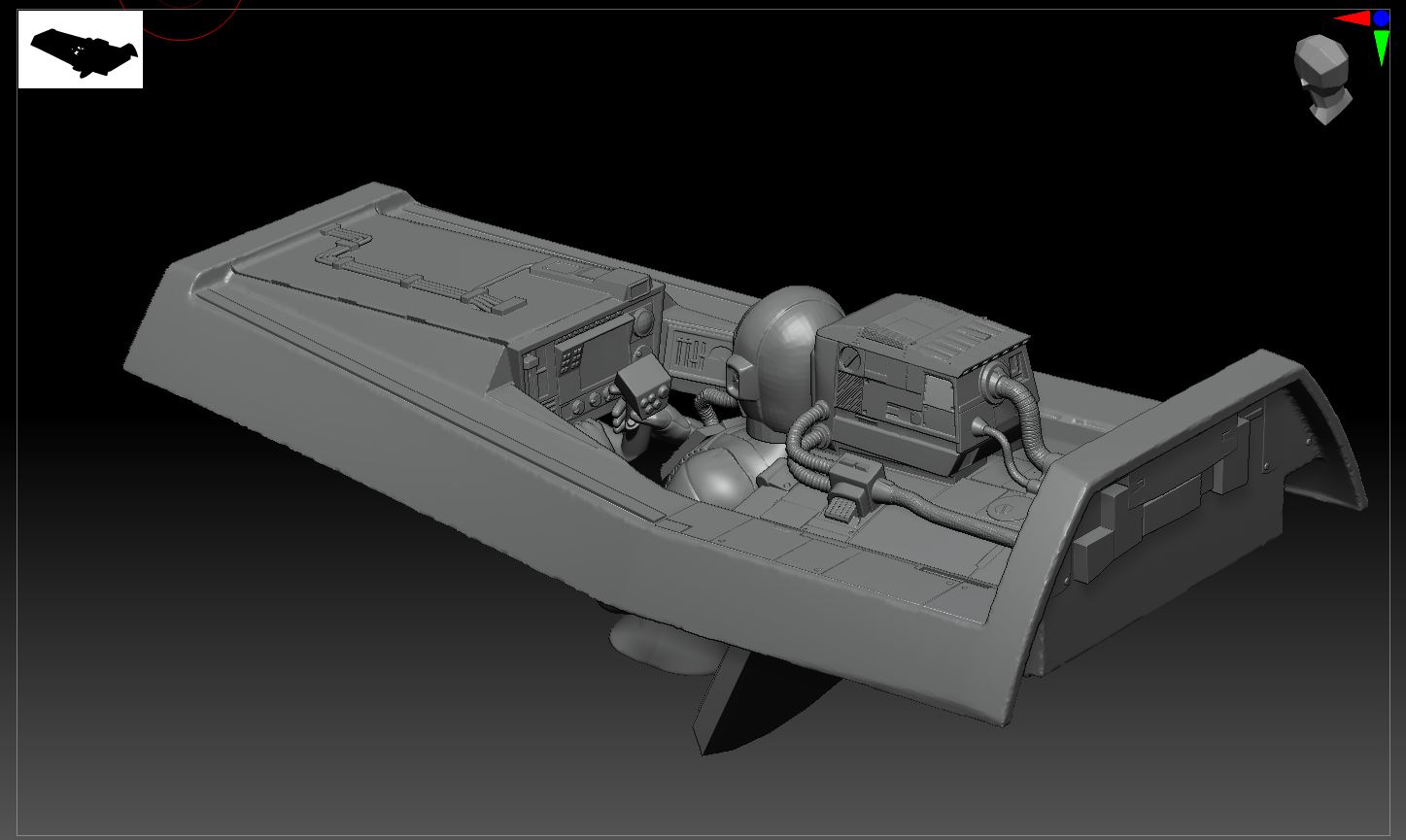

I'm using Catia V5 and Zbrush for the modelling work, I'll show some pictures of the current status and update as the build progresses.

Fuselage is modelled in Catia

Main reference picture

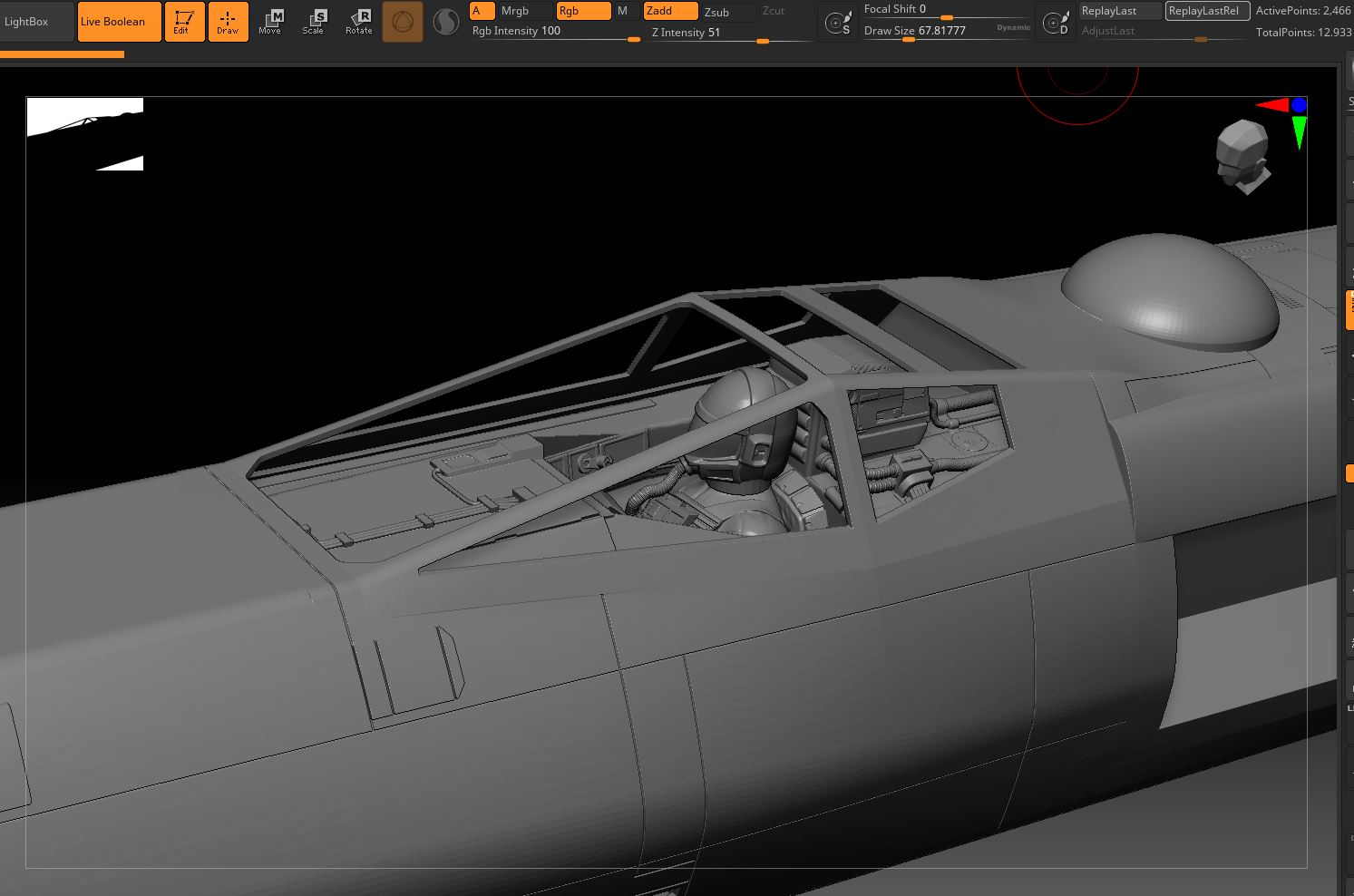

Pilot and cockpit is modelled in Zbrush

Cockpit module, more details to be added

Pilot as he sits right now. Not decided yet if I'll add a lower body or not

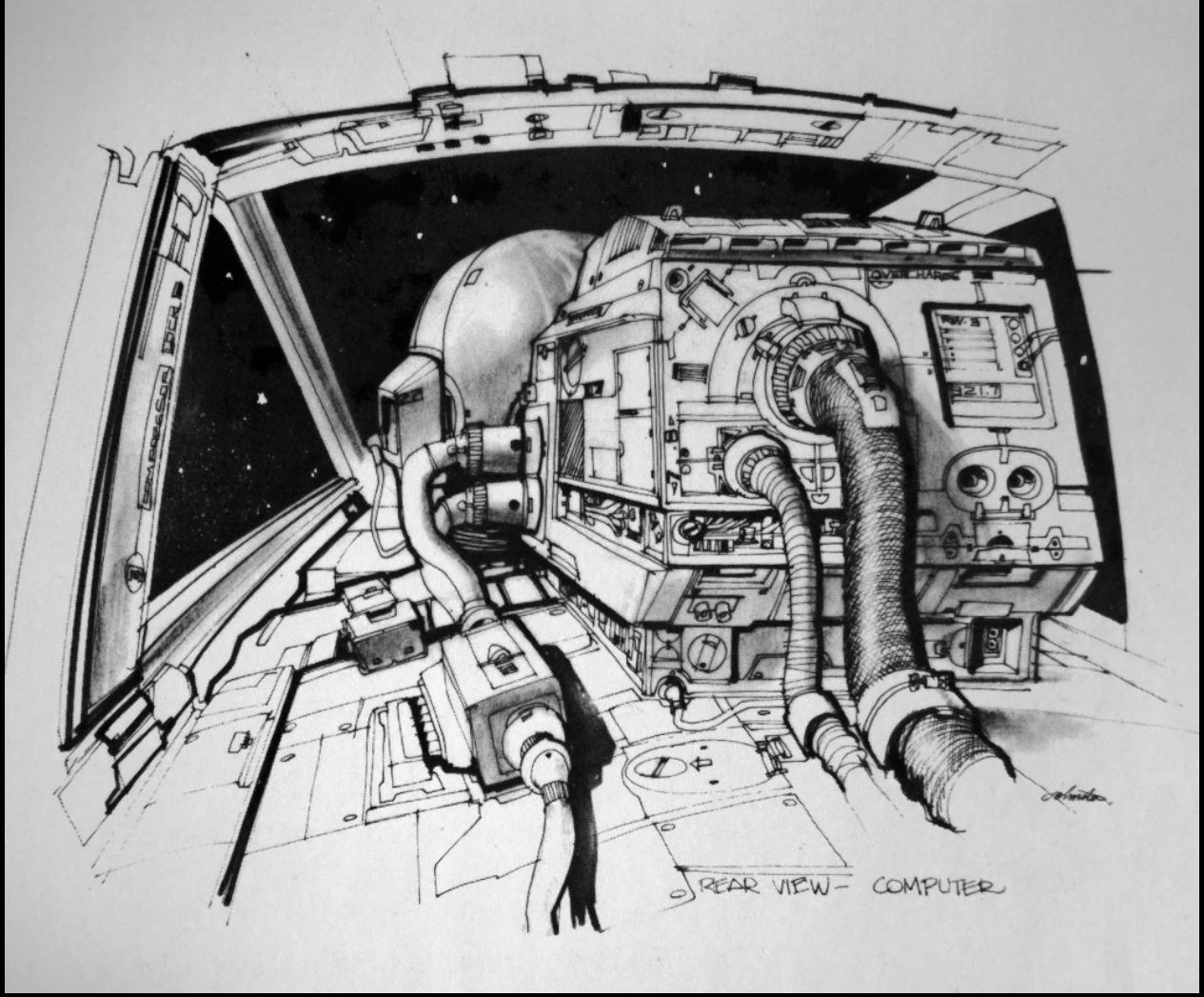

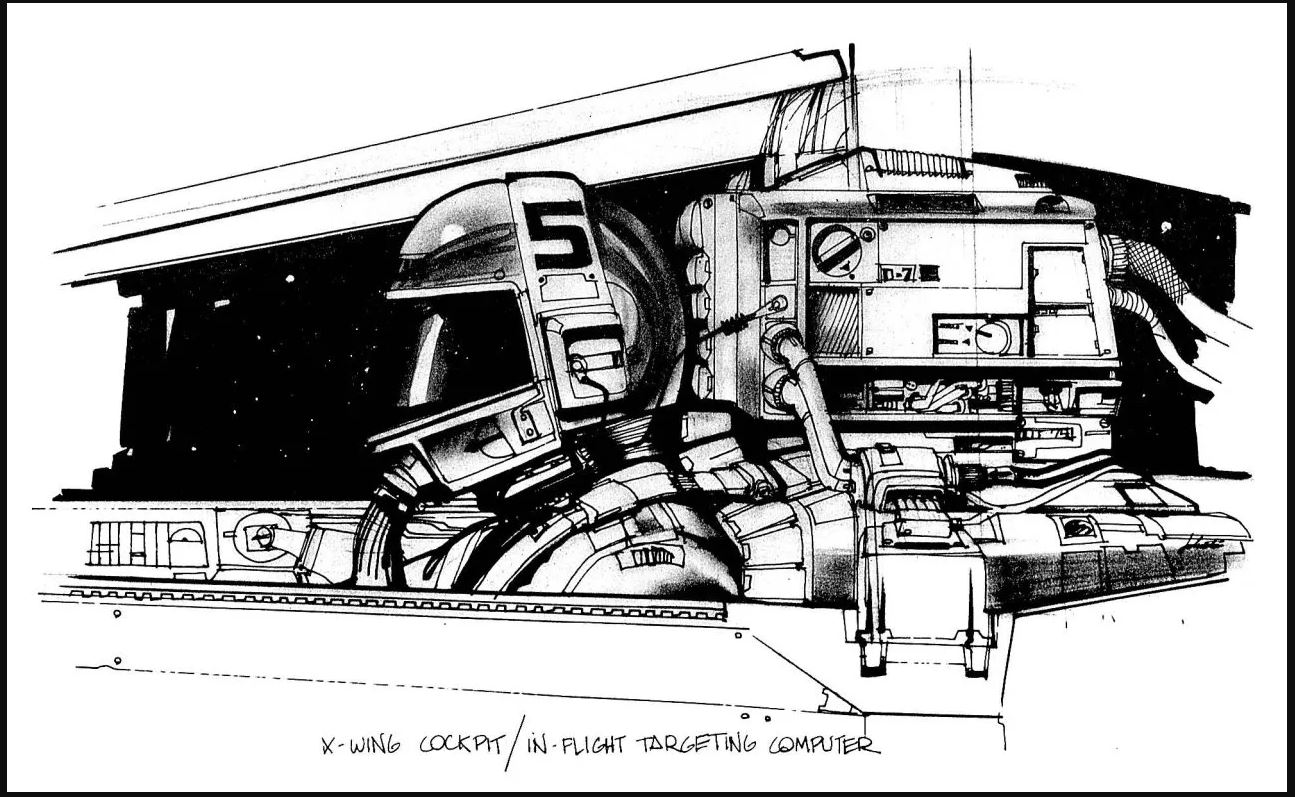

Main references for the cockpit and Pilot are these Joe Johnston sketches

Ever since I had the image of the McQ X-wing in my childhood room growing up I always wanted a kit of it. I'm aware there are several kits out there but they're not that easy to find and if found, pretty expensive. Added to that this sort of build is kind of artist interpretation type of work so I decided to make my own model. Currently I'm midst of the modelleing work and I'm putting in the hours as I find them but they're few and sometimes far apart.

I'm using Catia V5 and Zbrush for the modelling work, I'll show some pictures of the current status and update as the build progresses.

Fuselage is modelled in Catia

Main reference picture

Pilot and cockpit is modelled in Zbrush

Cockpit module, more details to be added

Pilot as he sits right now. Not decided yet if I'll add a lower body or not

Main references for the cockpit and Pilot are these Joe Johnston sketches