franz bolo

Sr Member

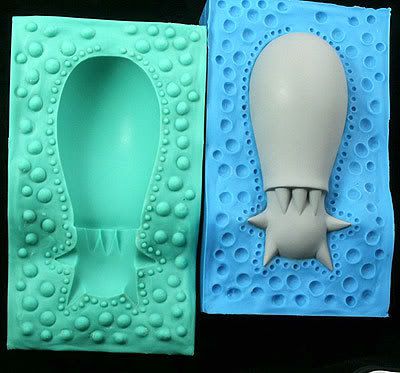

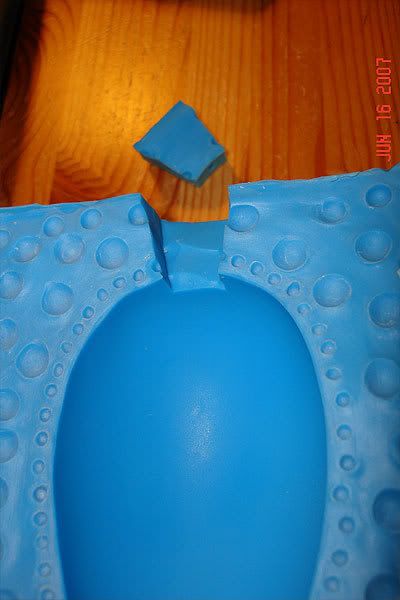

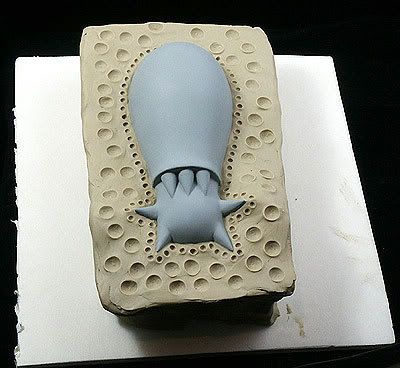

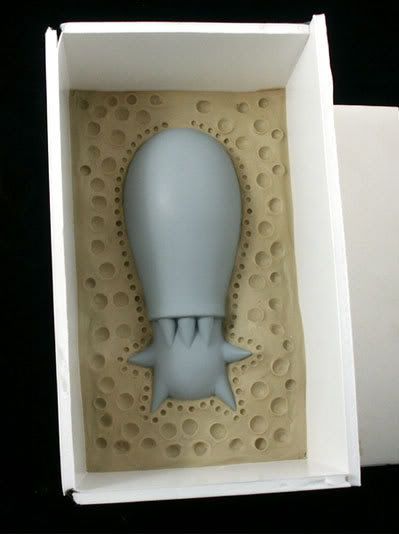

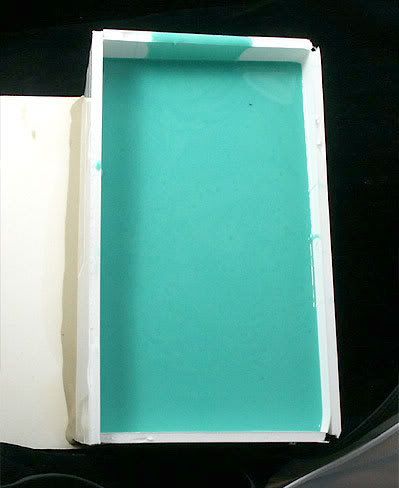

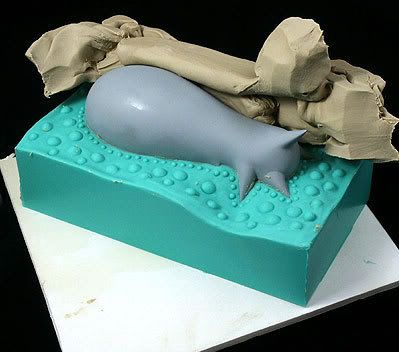

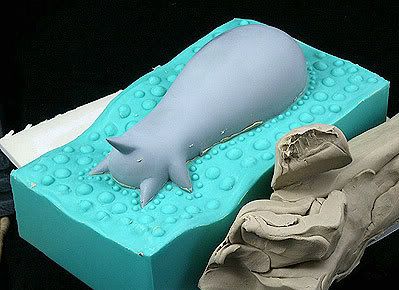

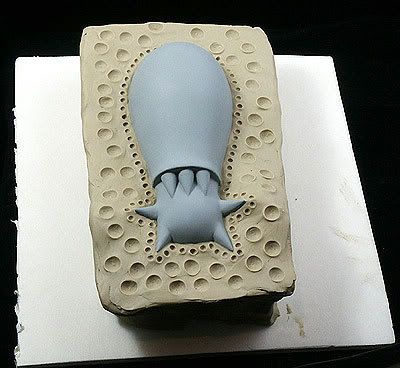

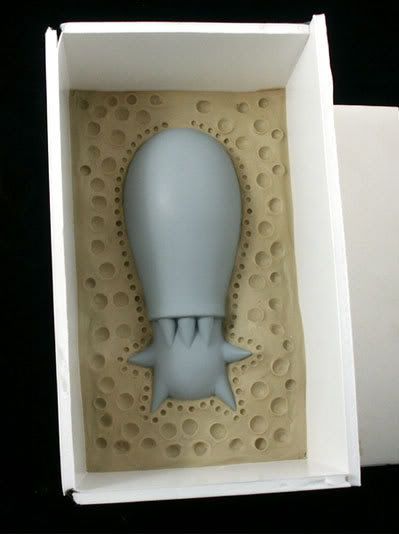

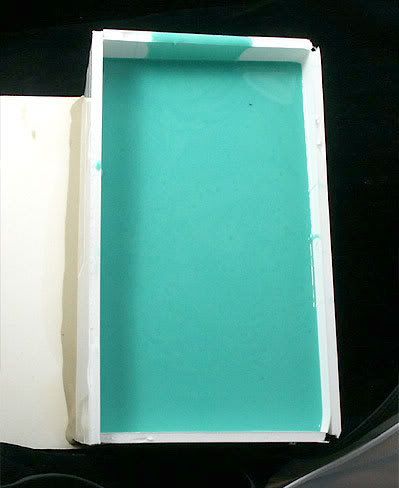

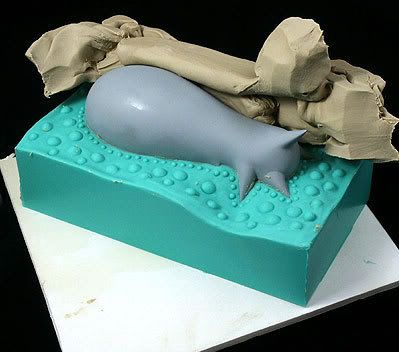

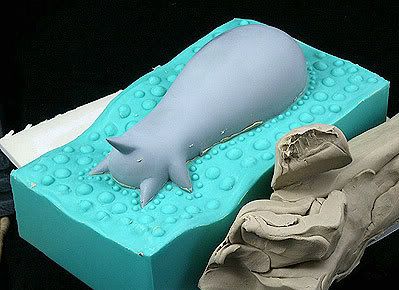

So the sculpt was done, now comes the mold making. Here are some progress pics.

I will end up doing them solid resin but my friend has a rotocast machine and I want to try it out.

-FB->

I will end up doing them solid resin but my friend has a rotocast machine and I want to try it out.

-FB->

Last edited: