You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you were to buy a resin printer today...

- Thread starter ID10T

- Start date

xeno

Sr Member

Try to stay away from the Ancycubic Photon style of mounting the buildplate,

not on ball mounting point, but rather a setup with brackets and 4 screws, that most newer printers use.

The ball mounting system is prone to moving while printing, and if resin get in there you will have to take it all apart to clean.

the brackets with screw work much better, and seldom have to be cleaned, and not prone to moving.

not on ball mounting point, but rather a setup with brackets and 4 screws, that most newer printers use.

The ball mounting system is prone to moving while printing, and if resin get in there you will have to take it all apart to clean.

the brackets with screw work much better, and seldom have to be cleaned, and not prone to moving.

Attachments

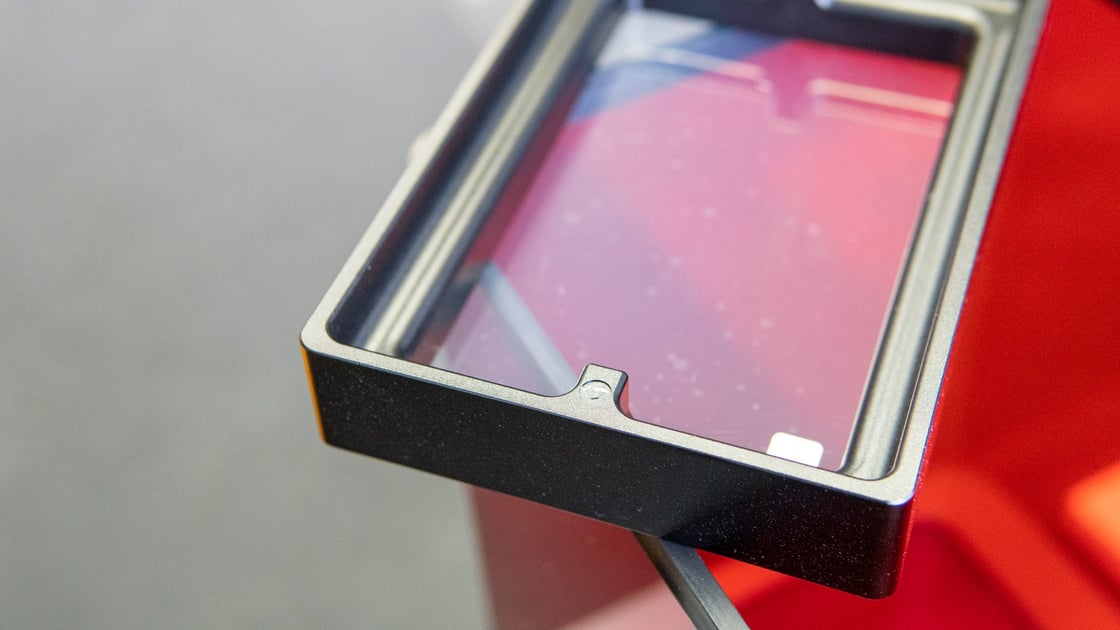

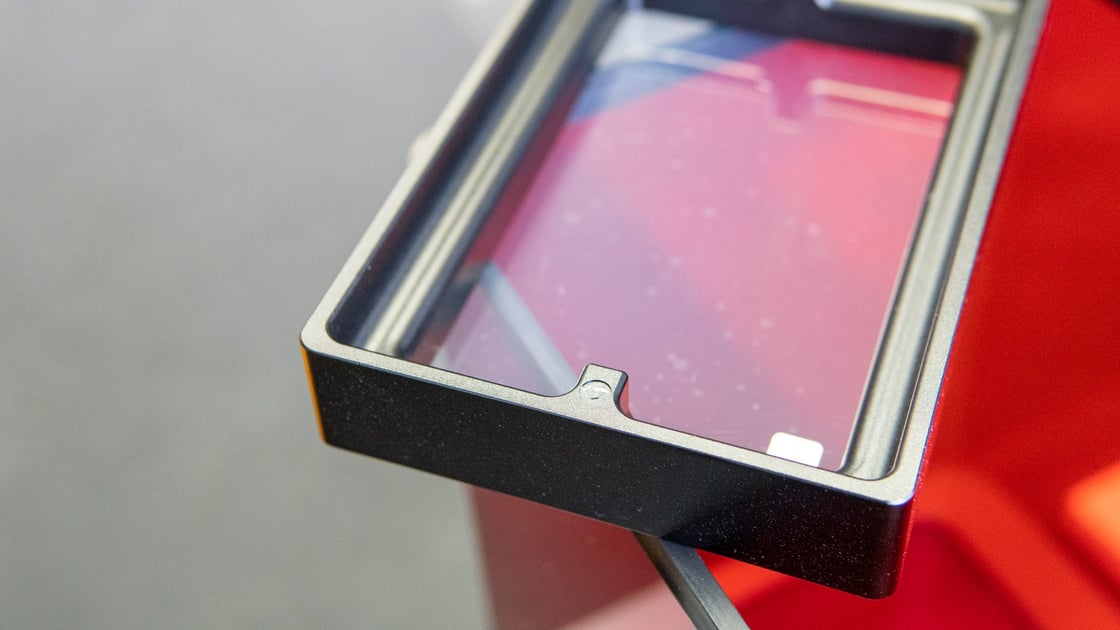

My new AnyCubic Photon Mono X has a bracket and 4-screw setup for the build plate.Try to stay away from the Ancycubic Photon style of mounting the buildplate,

not on ball mounting point, but rather a setup with brackets and 4 screws, that most newer printers use.

The ball mounting system is prone to moving while printing, and if resin get in there you will have to take it all apart to clean.

the brackets with screw work much better, and seldom have to be cleaned, and not prone to moving.

Sean

ID10T

Sr Member

I guess it’s a ball and socket.

The OEM upgrade replaces set screws with socket head cap screws apparently (and changes to a finely machined surface on the build plate). If a used one had the former, they can easily be changed. And I can lap off any coating on the plate and re-surface. I could also do a grit blasted surface if needed.

There shouldn’t be enough pressure to make it move, but I had a similar issue with drum mounting hardware a couple decades ago, and sorted that out. And that was under much more stress...

Still haven’t heard from my co-worker on this. Let me rattle his cage and get his input.

Meanwhile, does anyone know the difference in the “pro” version? I can’t figure that out.

The OEM upgrade replaces set screws with socket head cap screws apparently (and changes to a finely machined surface on the build plate). If a used one had the former, they can easily be changed. And I can lap off any coating on the plate and re-surface. I could also do a grit blasted surface if needed.

There shouldn’t be enough pressure to make it move, but I had a similar issue with drum mounting hardware a couple decades ago, and sorted that out. And that was under much more stress...

Still haven’t heard from my co-worker on this. Let me rattle his cage and get his input.

Meanwhile, does anyone know the difference in the “pro” version? I can’t figure that out.

ID10T

Sr Member

OK. As my que of parts to print is getting longer by the day, I think I'm getting closer to purchase.

As such, I did the noble thing, and activated google-foo. I found a review of the Mars, Mars Pro, and Mars Pro 2.

all3dp.com

all3dp.com

And, the summary, in this person's opinion:

"...owners of the Mars should probably stick with the printer they have. The print quality is identical, so you’re only paying for the small quality of life enhancements. How much they do or do not bother you are easier to quantify against the $60 of extra investment needed for the Pro. [over the regular Mars model]

Complete newcomers will have a nicer time with the Mars Pro and Mars 2 Pro, but the original Mars is no slouch and prints just as well.

However, if you are entirely Mars-less, we’d go for the Mars 2 Pro. The ~$100 upgrade is well worth the investment and should give you a smoother and faster printing experience."

Based on this single data point, I should spend a bit more. At least the Mars Pro, but the cure time is significantly faster (plus longer screen life) on the 2 Pro. I figure I can see my messed-up results faster, and get things sorted correctly for the next try, in less time... Slightly taller work envelope too (5mm, so not a deal maker or breaker in my opinion). And, if you are making tiny, super-detail prints, the 2 Pro has ever-so-slightly lower resolution (50 micron v. 47 micron of the Mars and Mars Pro). For stuff that fits in your hand- no difference. For stuff that fits on your fingernail? Maybe more of a concern.

Best overall bang-for-the-buck seems to be the Mars Pro. For a few reasons you can see in the linked article. Going up a few bucks more, gets the faster cure time, and longer screen life, but otherwise, not much difference. I think those details are worth the few bucks up-charge personally.

Shopping mode: ACTIVATE

As such, I did the noble thing, and activated google-foo. I found a review of the Mars, Mars Pro, and Mars Pro 2.

Elegoo Mars vs Mars Pro vs Mars 2 Pro: The Differences

Elegoo Mars, Mars Pro, or Mars 2 Pro? We simply explain the differences and help you pick the right one.

And, the summary, in this person's opinion:

"...owners of the Mars should probably stick with the printer they have. The print quality is identical, so you’re only paying for the small quality of life enhancements. How much they do or do not bother you are easier to quantify against the $60 of extra investment needed for the Pro. [over the regular Mars model]

Complete newcomers will have a nicer time with the Mars Pro and Mars 2 Pro, but the original Mars is no slouch and prints just as well.

However, if you are entirely Mars-less, we’d go for the Mars 2 Pro. The ~$100 upgrade is well worth the investment and should give you a smoother and faster printing experience."

Based on this single data point, I should spend a bit more. At least the Mars Pro, but the cure time is significantly faster (plus longer screen life) on the 2 Pro. I figure I can see my messed-up results faster, and get things sorted correctly for the next try, in less time... Slightly taller work envelope too (5mm, so not a deal maker or breaker in my opinion). And, if you are making tiny, super-detail prints, the 2 Pro has ever-so-slightly lower resolution (50 micron v. 47 micron of the Mars and Mars Pro). For stuff that fits in your hand- no difference. For stuff that fits on your fingernail? Maybe more of a concern.

Best overall bang-for-the-buck seems to be the Mars Pro. For a few reasons you can see in the linked article. Going up a few bucks more, gets the faster cure time, and longer screen life, but otherwise, not much difference. I think those details are worth the few bucks up-charge personally.

Shopping mode: ACTIVATE

TazMan2000

Master Member

I'm an impatient sort of guy. So I would recommend you spend the extra money on something faster. If you don't, you'll have a lot of time waiting for the older and smaller resin printers to finish. It gives you a lot of time to think...and wish that you purchased a printer with a faster cure time.

TazMan2000

TazMan2000

star-art

Sr Member

Just having gone through the process of researching all this recently, I would say don't buy anything that doesn't have a Mono 4K screen. Color LCDs are now completely obsolete and they fail much faster. Mono offers higher quality prints in less time and they last much longer. With 5K screens just around the corner, anything less than 4K would be an out-of-date setup.

basementdweller

Active Member

Phrozen mini 4k. Higher resolution than all of them* and also mono which is given when buying today. Check a video review - any of them. 3dprintingpro has extensive experience with printers and thus did a correct comparison with nice pictures of the same models printed with different printers. If you can buy it for about $300 go for it. Anycubic mono or elegoo mars 2 mono are about €170 frequently on EU amazon and aliexpress with EU stock. I am sure they have better US prices. I would never buy an old gen (non-mono) today because it's cripplingly slow compared to mono. ANy money you save will be gone in replacement screens and added time and whatnot.

*all of the usual cheap suspects. It has the usual size screen with smaller pixels compared to other 4K machines which are just larger and have the same real world resolution as smaller 2K machines.

*all of the usual cheap suspects. It has the usual size screen with smaller pixels compared to other 4K machines which are just larger and have the same real world resolution as smaller 2K machines.

Form 3 is finally working well so I can finally recommend that one - it's a laser based printer and not a screen. It's $150 a liter for the basic resins so I wager most of you guys would balk at that alone from the sound of things, but in three years I've been using the form 2 and 3, I have had less than ten print fails, and they were almost all my fault (bad design, or orientation). They are beasts. Majority of these are all made possible with parts I designed and printed: Original Works, Jason Eaton Studio

It changed my life.

It changed my life.

ID10T

Sr Member

I am way too cheap for $150 a liter. I’m more of a $15.00 a liter type of guy.

But yeah, monochrome screen it shall be. For all the reasons mentioned. Faster cure time means I can see if I screwed up faster or not. Rather than come in the next morning to find what looks like six monkeys humping a football...

And I was chatting with my co-worker today on the subject, and he thinks the pro 2 has the right features. He can’t comment on “best or worst” scenario, but I feel comfortable due to its popularity.

My only reservation at this point is the smell. I was planning to set it up in the inspection room, where the other one was, but not if it’s stinky. I’ll have to have it out in the shop.

But yeah, monochrome screen it shall be. For all the reasons mentioned. Faster cure time means I can see if I screwed up faster or not. Rather than come in the next morning to find what looks like six monkeys humping a football...

And I was chatting with my co-worker today on the subject, and he thinks the pro 2 has the right features. He can’t comment on “best or worst” scenario, but I feel comfortable due to its popularity.

My only reservation at this point is the smell. I was planning to set it up in the inspection room, where the other one was, but not if it’s stinky. I’ll have to have it out in the shop.

TazMan2000

Master Member

I've been doing some number crunching. If my math is off, let me know.

Anycubic Photon

The build area X&Y is 115x65mm which is 7475mm squared per layer.

The screen resolution is 2560x1440 which is 386400 pixels.

This means that each square mm gets about 493.2 pixels.

Anycubic Photon Mono X

The build area X&Y is 192x120 which is 23040mm squared per layer.

The screen resolution is 3840x2400 which is 9216000 pixels.

This means that each square mm gets 400 pixels.

The Mono X has 3 times more X&Y build area, but only 2.5 more pixels.

Technically it makes the printer have a lower X&Y resolution with 20 percent less pixels per square mm but larger build area. Volume notwithstanding.

Mind you with the dual Z-axis motors, and enhanced stepping technology, the Z resolution is far better, not to mention the monochrome screen which is a game changer in terms of speed.

TazMan2000

Anycubic Photon

The build area X&Y is 115x65mm which is 7475mm squared per layer.

The screen resolution is 2560x1440 which is 386400 pixels.

This means that each square mm gets about 493.2 pixels.

Anycubic Photon Mono X

The build area X&Y is 192x120 which is 23040mm squared per layer.

The screen resolution is 3840x2400 which is 9216000 pixels.

This means that each square mm gets 400 pixels.

The Mono X has 3 times more X&Y build area, but only 2.5 more pixels.

Technically it makes the printer have a lower X&Y resolution with 20 percent less pixels per square mm but larger build area. Volume notwithstanding.

Mind you with the dual Z-axis motors, and enhanced stepping technology, the Z resolution is far better, not to mention the monochrome screen which is a game changer in terms of speed.

TazMan2000

ID10T

Sr Member

I don’t know about the Anycubuc because I Haven been looking into it.

And I’m the last person to comment on math precision.

But the Mars is 47 micron resolution, and the Pro 2 is 50 micron resolution. I don’t think that matters for me. But, as I mentioned earlier, it may matter for others. It does reinforce the point that monochrome has lower resolution.

And I’m the last person to comment on math precision.

But the Mars is 47 micron resolution, and the Pro 2 is 50 micron resolution. I don’t think that matters for me. But, as I mentioned earlier, it may matter for others. It does reinforce the point that monochrome has lower resolution.

All of that is true. the other thing to realize is that after a certain point the resolution increase doesn't result in much better prints... once it reaches a "smooth" print, Smoother isn't a huge improvement. The pixels/mm is important to a degree. This is exactly why I use reviews from people that know to determine print quality once the numbers are known. But there definitely is a point where pixels/mm matter, but both of these printers produce smooth prints from what I've read. For full disclosure, I don't have either - but have an Elegoo Mars which is VERY similar.I've been doing some number crunching. If my math is off, let me know.

Anycubic Photon

The build area X&Y is 115x65mm which is 7475mm squared per layer.

The screen resolution is 2560x1440 which is 386400 pixels.

This means that each square mm gets about 493.2 pixels.

Anycubic Photon Mono X

The build area X&Y is 192x120 which is 23040mm squared per layer.

The screen resolution is 3840x2400 which is 9216000 pixels.

This means that each square mm gets 400 pixels.

The Mono X has 3 times more X&Y build area, but only 2.5 more pixels.

Technically it makes the printer have a lower X&Y resolution with 20 percent less pixels per square mm but larger build area. Volume notwithstanding.

Mind you with the dual Z-axis motors, and enhanced stepping technology, the Z resolution is far better, not to mention the monochrome screen which is a game changer in terms of speed.

TazMan2000

Jedi Dade

TazMan2000

Master Member

That's the thing. The output from my Mono X wasn't smooth. Mind you, I didn't do a side by side comparison against my Elegoo Mars. The Photon is pretty much identical screen-wise. Plus, I had the anti-aliasing feature turned down lower.All of that is true. the other thing to realize is that after a certain point the resolution increase doesn't result in much better prints... once it reaches a "smooth" print, Smoother isn't a huge improvement. The pixels/mm is important to a degree. This is exactly why I use reviews from people that know to determine print quality once the numbers are known. But there definitely is a point where pixels/mm matter, but both of these printers produce smooth prints from what I've read. For full disclosure, I don't have either - but have an Elegoo Mars which is VERY similar.

Jedi Dade

I am still mostly experimenting, but on the first few prints I did notice a difference so I did a little investigating. 20 percent pixels per square mm may not seem like much, but you would think that the pixel density would be greater on a bigger and newer printer.

I think this may improve on future model releases. I think the biggest reason that these new larger models were created, is that consumers were screaming for a larger build area for a price under $4K.

TazMan2000

This is one of the main reasons I purchased the EPAX 8.9 4k mono printer... They are developing a 5K 10" screen upgrade for it coming soon... also the anti-aliasing is a double edged sword - it definitely makes "smoother" prints, but it also tends to smooth highly detailed bits, that you don't want. it definitely effects print quality, and if you're doing comparisons should be "matched" on both prints.That's the thing. The output from my Mono X wasn't smooth. Mind you, I didn't do a side by side comparison against my Elegoo Mars. The Photon is pretty much identical screen-wise. Plus, I had the anti-aliasing feature turned down lower.

I am still mostly experimenting, but on the first few prints I did notice a difference so I did a little investigating. 20 percent pixels per square mm may not seem like much, but you would think that the pixel density would be greater on a bigger and newer printer.

I think this may improve on future model releases. I think the biggest reason that these new larger models were created, is that consumers were screaming for a larger build area for a price under $4K.

TazMan2000

Jedi Dade

TazMan2000

Master Member

Absolutely. I just wanted people to know exactly what they are getting with the Mono X and other printers that use the same screen, so they can look past the hype. I still love my purchase and can't get over the speed in curing.This is one of the main reasons I purchased the EPAX 8.9 4k mono printer... They are developing a 5K 10" screen upgrade for it coming soon... also the anti-aliasing is a double edged sword - it definitely makes "smoother" prints, but it also tends to smooth highly detailed bits, that you don't want. it definitely effects print quality, and if you're doing comparisons should be "matched" on both prints.

Jedi Dade

TazMan2000

Form 3 is finally working well so I can finally recommend that one - it's a laser based printer and not a screen.

You were expressing some dissatisfaction for a while regarding the 3. Did they fix something?

As for resin, it’s £150/litre in the UK for my Form 2. Urgh!

- nkg

Yes, firmware upgrades are frequent, and it's getting better and better!

Nice. I was wondering if the issues were hardware related (ie: fundamental design decisions) or firmware.

I really wanted a Form, largely based on what I’ve seen you print with yours, but the Form3’s print volume was a lot smaller compared to some of the other models I looked at. And since my primary objective with this thing is to print armor, print volume was a primary decision point for me.Form 3 is finally working well so I can finally recommend that one - it's a laser based printer and not a screen. It's $150 a liter for the basic resins so I wager most of you guys would balk at that alone from the sound of things, but in three years I've been using the form 2 and 3, I have had less than ten print fails, and they were almost all my fault (bad design, or orientation). They are beasts. Majority of these are all made possible with parts I designed and printed: Original Works, Jason Eaton Studio

It changed my life.

I looked at the Form 3L, but couldn’t sell my better half on dropping $10k+ on my first printer. Maybe when I make it big...

Sean