While that dries I moved on to modify the Denix. My dremel broke in the middle of it so I had to do most of the sanding by hand. Because of that distraction I forgot to take progress pics on the denix body itself being modified..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DL-44 FDM c96 & MGC replicas…

- Thread starter chubsANDdoggers

- Start date

I used lead fishing weights. I don’t recall the weight of each but rather I bought them based on their size.mgoob did u do that for the added weight?

I have used steel shot in the feet of a dinosaur to keep it weighted down.

They weigh more than steel and this worked in this small space. I had more room in the dino so the larger steel shot balls were sufficient.

Got everything thing painted, weathered and assembled..

Here are some full shots..

Last edited:

Last edited:

russellsch

Master Member

I've said it before, & I'll say it again.... I love all of your builds!!!

russellsch thanks pal! Very much appreciated

Thank youAmazing job!

just some updates I started years ago but now got around to finishing..

McKeePhoto

Active Member

Wow, I had no idea how much of that was 3D printed until I went back through the thread. That is an amazing finish!

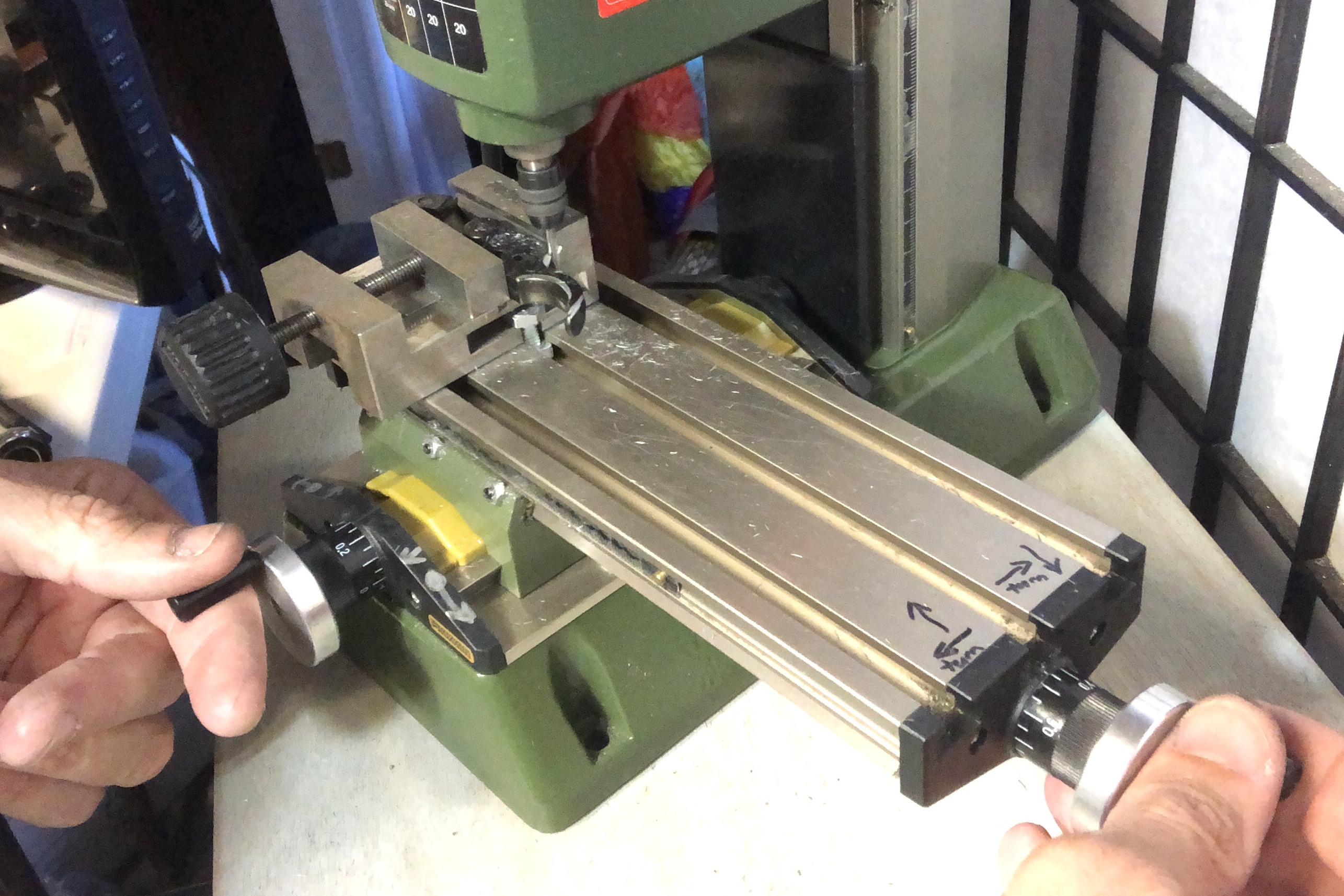

Just spotted the little milling machine, too. What is it if I may ask?

Just spotted the little milling machine, too. What is it if I may ask?

McKeePhoto thanks man. It’s a mini mill but I can’t recommend it unless all you want to do is mill in details like the extraction marking on ur denix. It’s really small and can’t do much else unfortunately. For me it’s perfect as that’s all I use it for pretty much..

McKeePhoto

Active Member

Ah. I see. I was tempted because I tried to “mill” the extraction port with my drill press. It was a disaster. Lol.

The Hammer mod looks great. What did you do here?just some updates I started years ago but now got around to finishing..View attachment 1292478View attachment 1292476View attachment 1292477

What kind of drill press do u have? Thinking of getting one of these but I got u one worse. I tried to ”mill” in details with a drillAh. I see. I was tempted because I tried to “mill” the extraction port with my drill press. It was a disaster. Lol.

Hence the upgrade to the mini mill. Lol. talk about a disaster!

McKeePhoto

Active Member

Oh, man! My drill press is a hand me down Chicago electric from my father in law.

I do have access to end mills from my (just turned 18 years old) son who is learning metal fab.

However, without a vise that can be shifted on an axis (like a milling machine), the work wandered around. And I never got the height right. Made a mess!

Drill presses are great and I like them a lot for making straight holes but not really meant for lateral work. And I would run the risk of bending the spindle, too.

I do have access to end mills from my (just turned 18 years old) son who is learning metal fab.

However, without a vise that can be shifted on an axis (like a milling machine), the work wandered around. And I never got the height right. Made a mess!

Drill presses are great and I like them a lot for making straight holes but not really meant for lateral work. And I would run the risk of bending the spindle, too.

McKeePhoto ya not sure if I can get what I need out of a drill press but I’m tempted to try as they are more affordable than larger milling machines. I truly hate outsourcing anything im building honestly. I find my attention to detail and my subtle but present ADD keeps me up at nights if I can’t control what ever it is I’m doing. This is the basic reason I created all my own parts..

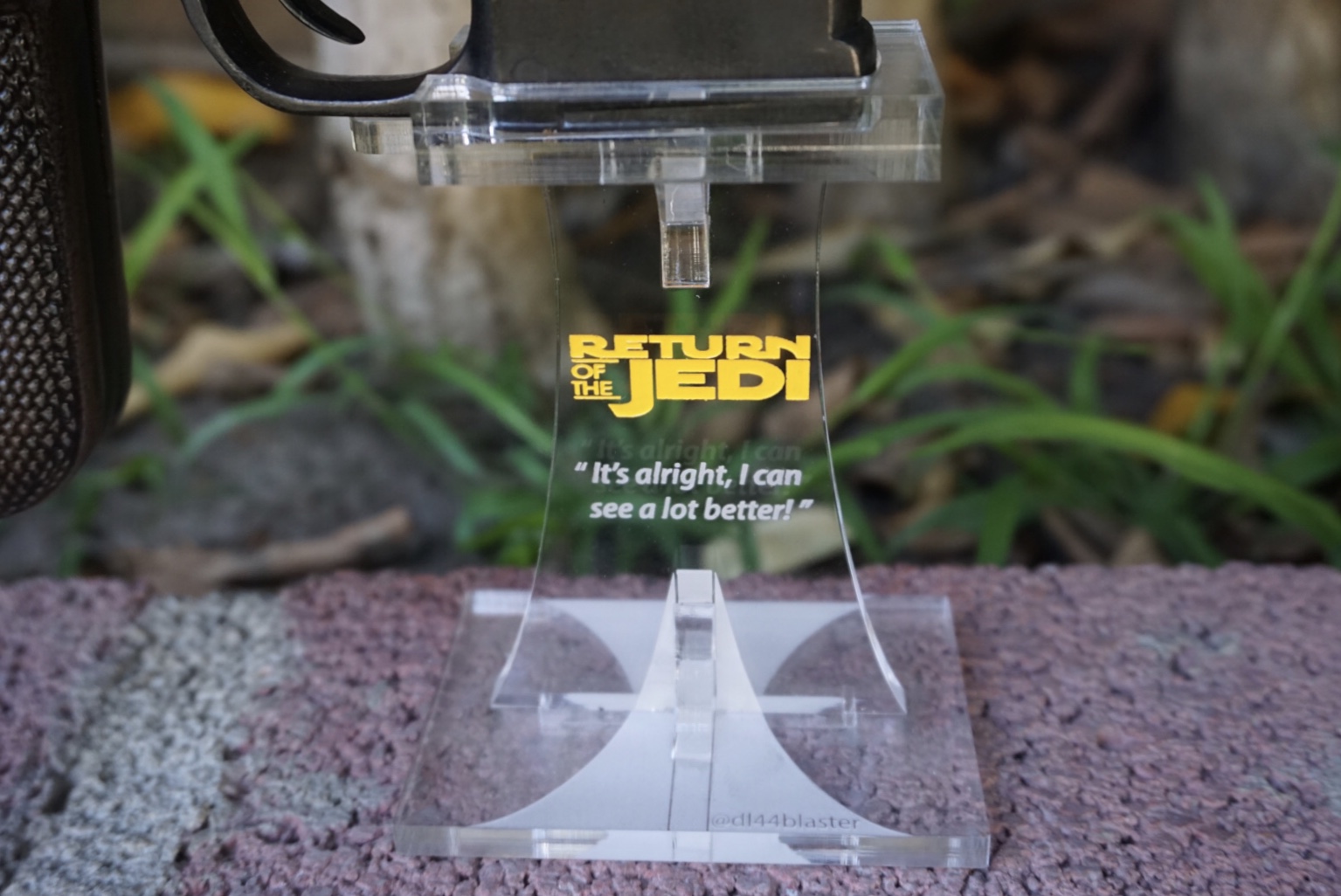

Right now the only thing I have to outsource is the milling on my ROTJ Endor blaster as the mini mill just isn’t big enough to get the job done. I can mill everything else though which is nice. But for the Endor I generally drive the guy who does it for me crazy as I stand over his shoulder the whole time directing traffic.. If I didn’t though it would be a mess. If anyone knows a good mill for under a grand I’m all ears!

Right now the only thing I have to outsource is the milling on my ROTJ Endor blaster as the mini mill just isn’t big enough to get the job done. I can mill everything else though which is nice. But for the Endor I generally drive the guy who does it for me crazy as I stand over his shoulder the whole time directing traffic.. If I didn’t though it would be a mess. If anyone knows a good mill for under a grand I’m all ears!

The Hammer mod looks great. What did you do here?

Thanks! It’s not a modification though but new designs I just finished up. I actually started them over a year ago but shelved the project for a while. But each are 1:1 to the real thing and definitely improves the overall look for sure. Here is a Endor and Dagobah blaster I’m presently working on. Naked so you can see the details..

Here is a couple more pics of just these upgrades on the Stembridge..

Similar threads

- Replies

- 2

- Views

- 604

- Replies

- 9

- Views

- 752

- Replies

- 0

- Views

- 351