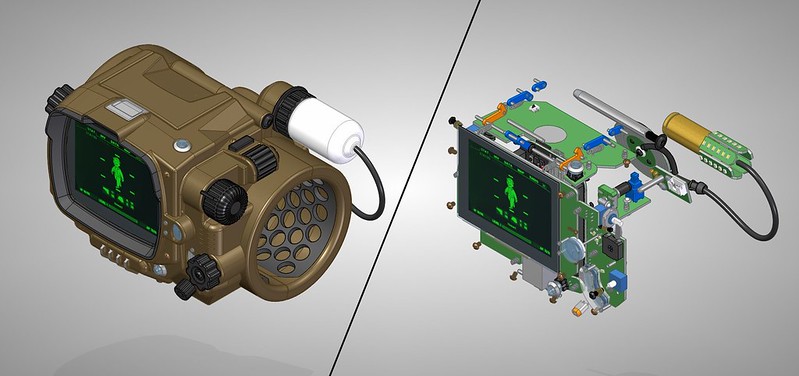

Lots of work on the Pip-boy CAD design. Mostly optimizing the design, but I also added a few new features.

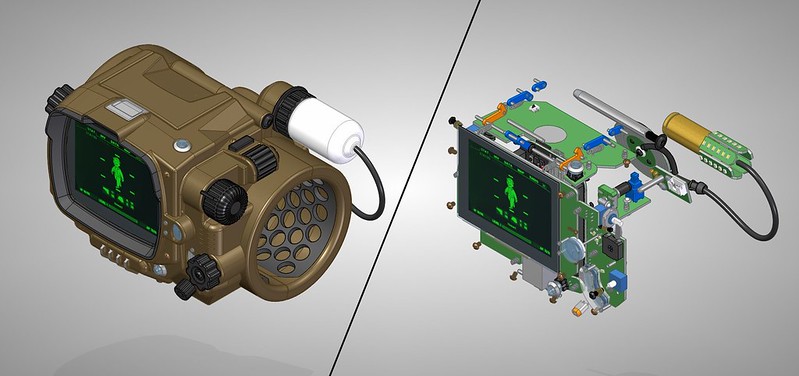

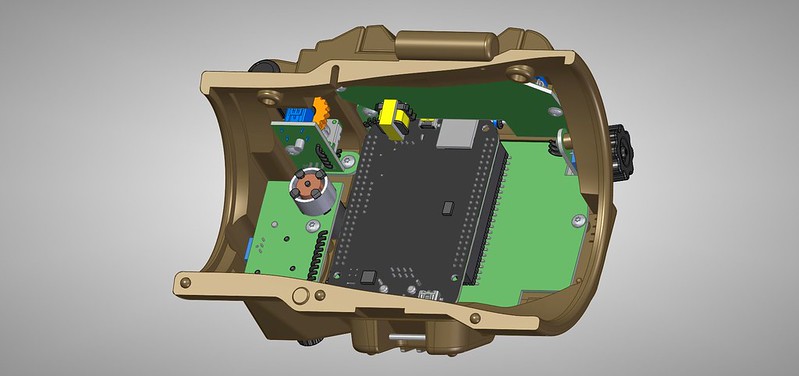

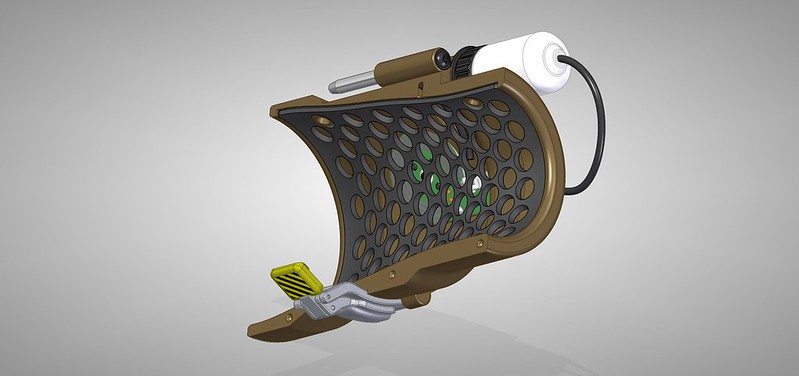

The image above shows just how much stuff is inside the pip-boy.

------------------------

There are 11 PCBs, as well as dozens of hardware components, wires and fasteners. Assembling one of these will take a bit of time and skill. The tolerances between some parts is as small as half a millimeter.

------------------------

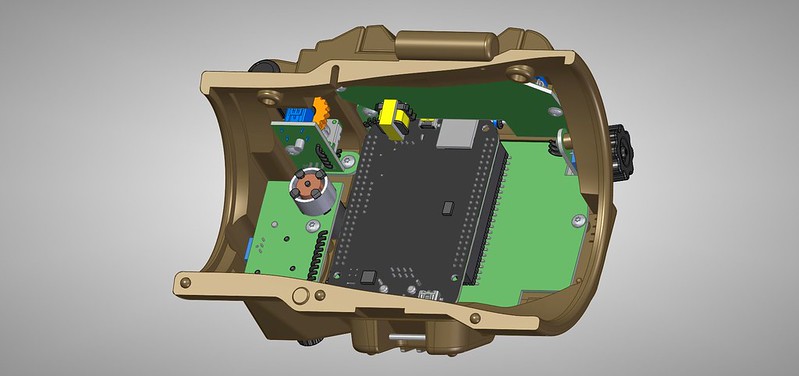

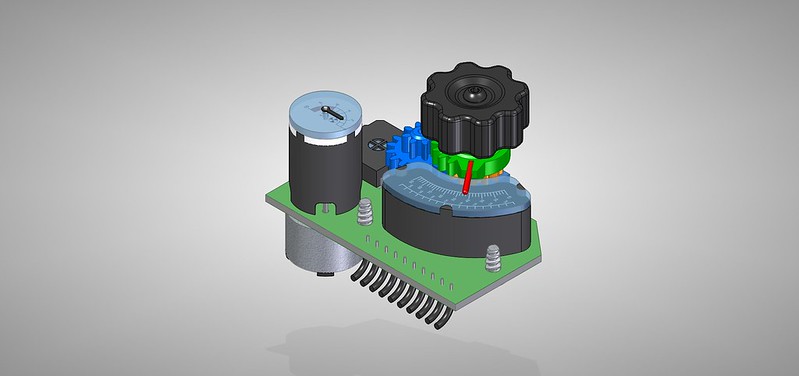

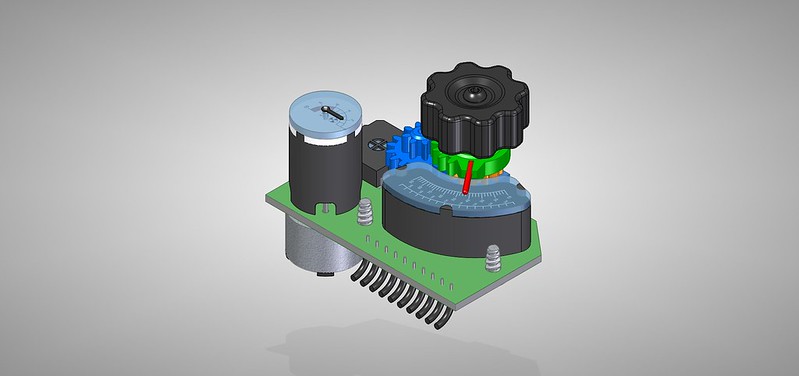

I was able to combine the rad-gauge and radio gauge assemblies into one. The good news is that the motor that runs the rad-gauge is available in low quantities. It costs a few dozen bucks, but allows for actual precise control over the gauge needle. I still haven't found a supplier of watch hands that fit the look I want. The gauge needle may need to be custom cut. I also removed most of the connectors from the PCBs, instead wires or cables will be installed on the small PCBs, and connectors will only be on the larger master PCB. This saves some bulk, weight, and cost.

------------------------

Shown here is the RFID PCB, with a grey disk where the antenna will be located.

The yellow item is a place holder for an audio transformer. This large part would be required for a full geiger counter. However, a full geiger counter is turning out to be a difficult addition to the pip-boy and adds a lot of cost and risk. I think I am going to change to a Pin-Diode type radiation detector. These can detect x-rays and gamma rays, as well as a few other forms of radiation. As cool as having a full geiger counter is, it instantly adds $100 to what will already be an expensive prop. It also adds a 500V circuit, which can be very difficult to contain and control. For example I can't find any 3mm diameter, 4 conductor shielded cable which is even rated for that voltage. Also a full geiger counter is pretty useless in real-life. You can't show it's function off at any Con, unless you want to try to take a uranium sample into a public space. If you had a real geiger counter and it was picking up enough radiation to make the gauge needle even move, you probably should be running away.

A Pin-diode detector would still be a real gamma ray detector, and can be built for just a few dollars. I also will skill keep an IR sensor as a option. At least with an IR temperature sensor you could scan a object and have the gauge show a interactive read-out.

------------------------

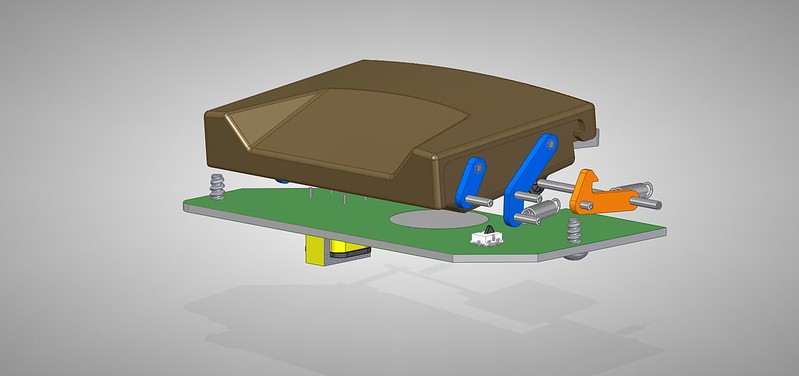

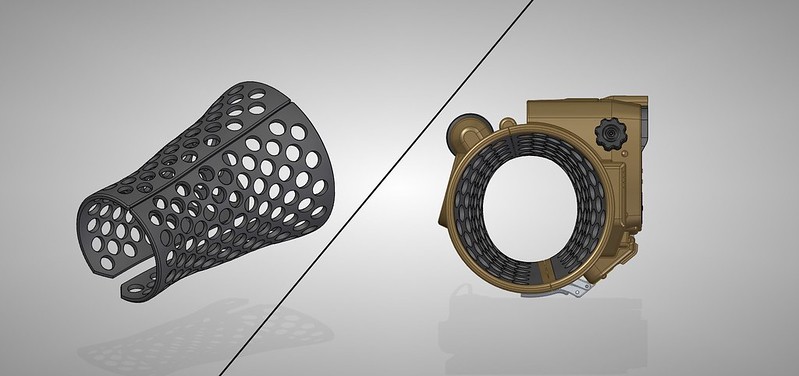

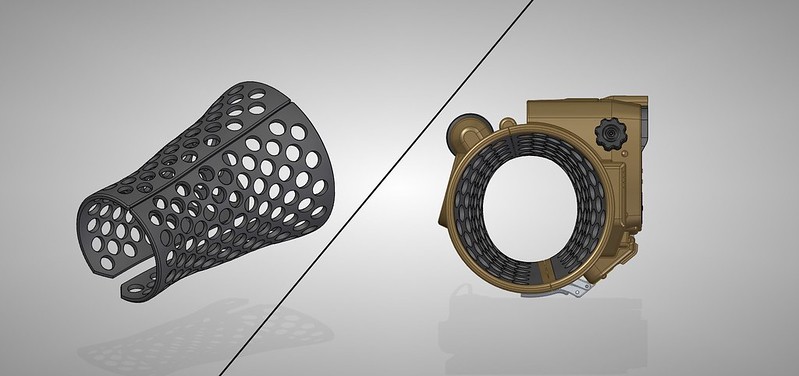

One item of concern in the design is heat, as well as comfort. My friend lent me his Pip-Boy 3000, which he modded from the Pip-Boy clock. Wearing it is a pain unless you have a thick sleeve or padding. So for my Pip-boy design I created a ventilated set of bands which fit into each half of the Pip-boy. These are designed with a round entry and exit, but a elliptical center. The ellipse does two things: It give me more precious room inside for electronics, and it also form fits the Pip-boy around my arm. In this way the Pip-boy shouldn't be prone to rotating around my arm. The center is designed to fit my arm when 1/4" of padding is used. If your arm happens to be larger, then you will need to use less padding. A pattern of vent holes will hopefully keep both the wearer and the electronics cooler, and also allow the bands to flex a bit.

------------------------

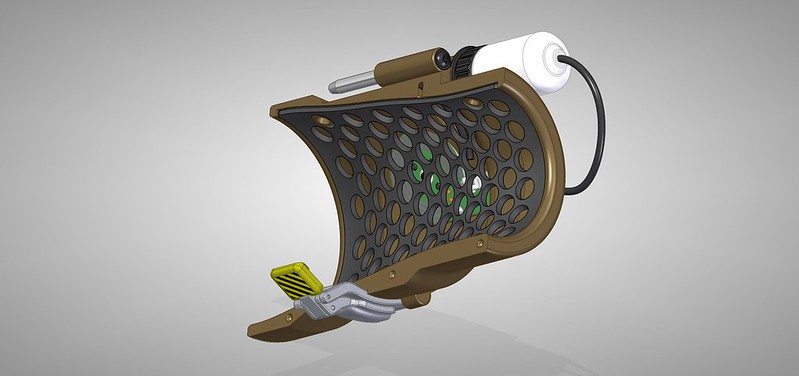

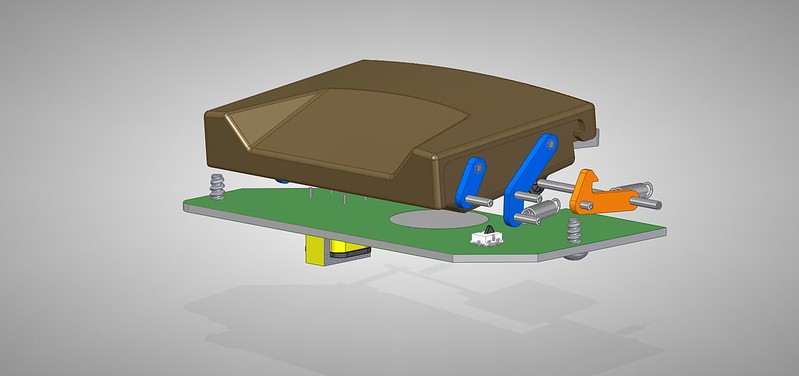

This image shows how the bands snap into each half. It also shows my new latch design in more detail.

------------------------

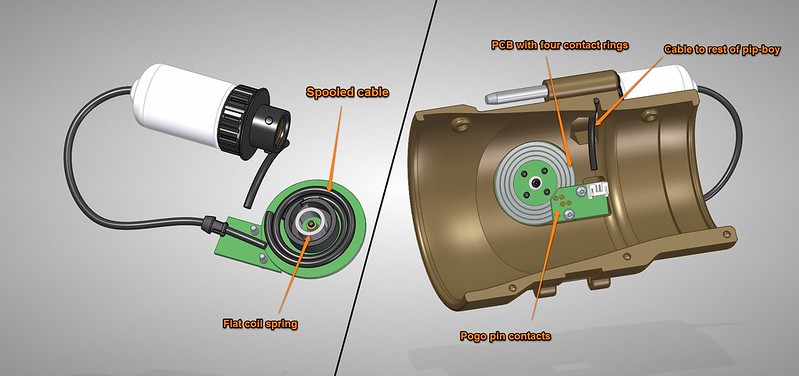

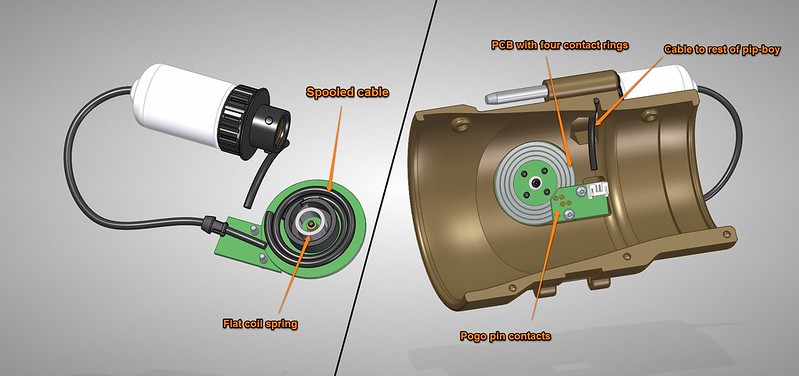

Also on the back is a whole new feature. A re-tractable cable reel. This was difficult to design into a compact size, while maintaining electrical contacts.

The reel uses a constant force spring to tug on the cable at all times, similar to a tape-measure. A 3D printed housing holds the spring to a PCB. The round PCB has four raceways, one for each of the four wires inside the cables. The rectangular PCB has four pogo-pins which bridge the connection between the internal cable, and cable reel. I estimate that a few feet of wire can be kept spooled up inside the pip-boy. The four wires are enough to run the LED lights, as well as a Pin-Diode, or IR sensor.

It is easy to design a one-way cable clamp, however it is more difficult to design one which has some sort of release. Yes, I can add a button or something. But I am trying my best to keep the external look of the Pip-boy accurate to the game, so I don't want to add any extra buttons or levers. I really want a "Tug-to-retract" mechanism, sort of like what is in a old-school vacuum cleaner. But so far I haven't been able to find any diagrams of how these worked, or figure out my own.