You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solo’s Blaster

- Thread starter chubsANDdoggers

- Start date

So am I! But it will be a while unfortunately. ಠ_ಠ

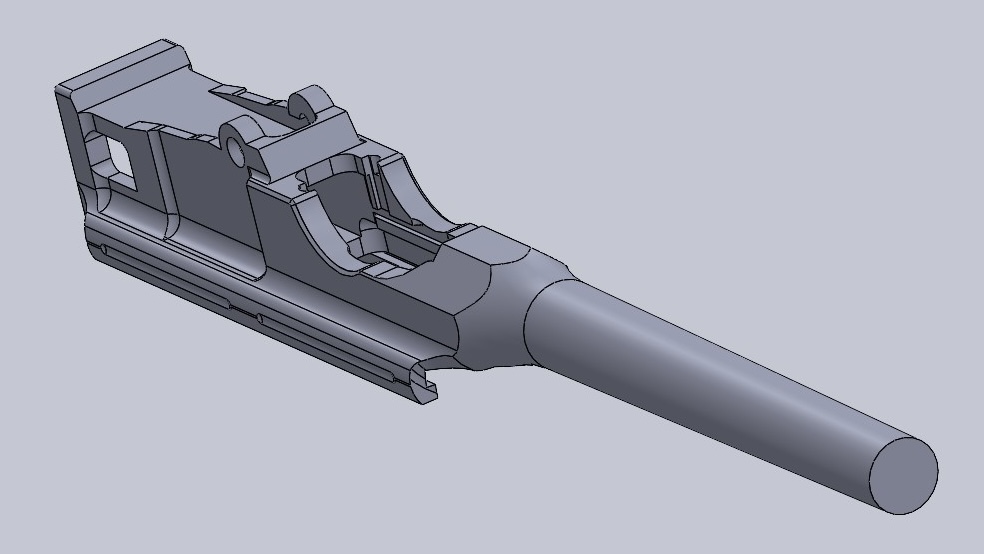

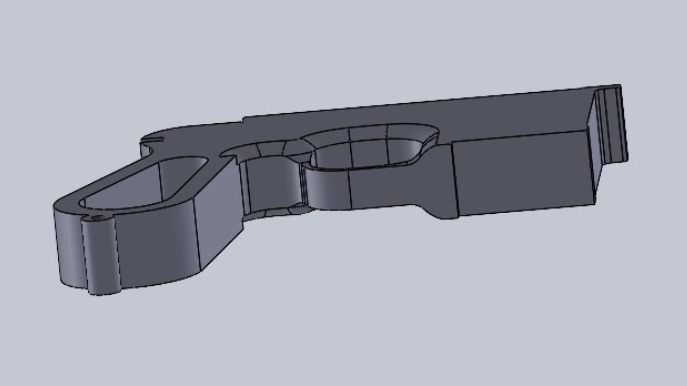

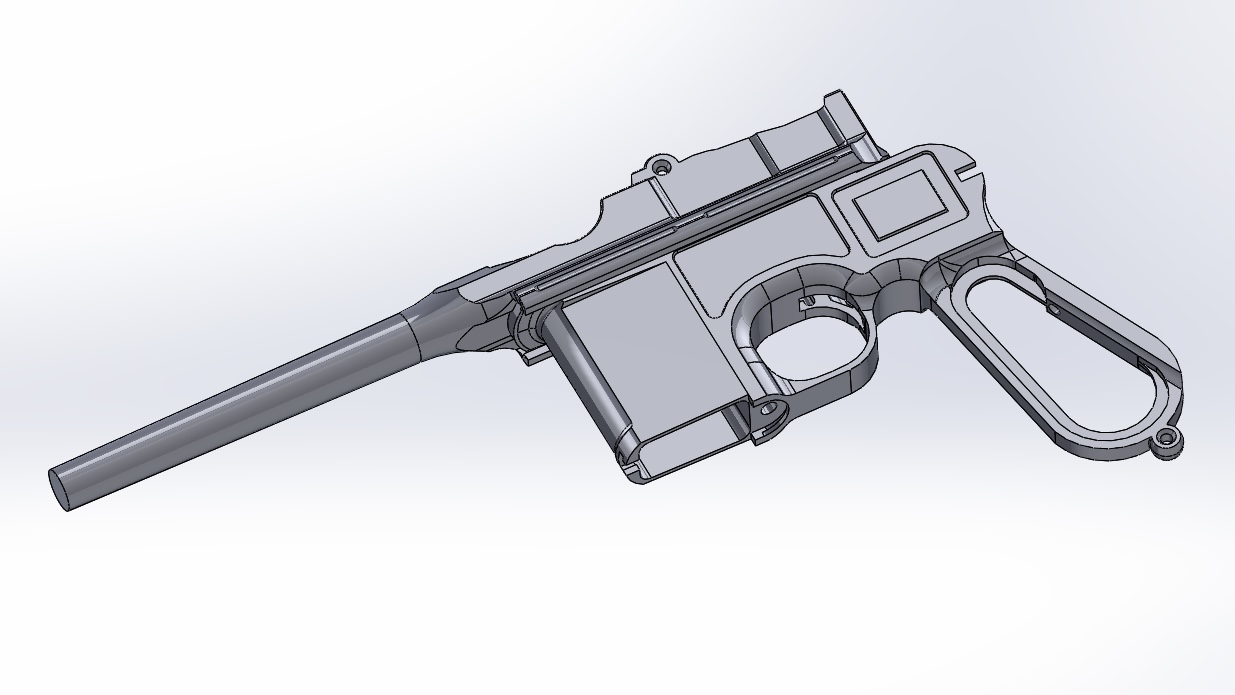

Stretch run of the upper receiver..

I’ve renamed this threat very appropriately for what I’m presently working on.

“My deadbolt c96 CAD project”

This Mauser replica journey started out trying to duplicate both a c96 and an MGC into CAD as detailed and as accurate as I possibly could. I’m not a professional but I definitely have the passion.. and that’s where a lot of this begins. My original journey was to start with the MGC and work backwords towards the c96. I have an actual MGC and for a c96 I have 1:1 casting so once the files for the MGC were created I was going to use that as my template to recreate the c96. BUT things took an unexpected turn very recently as I was given a gift that a simply thank you could not express the true gratitude I feel.

After reaching out to deadbolt to ask for some CAD guidance as I was having trouble recreated the outside filet/radius around the MGC trigger area he in turn gifted me his c96 model that has already been broken down in extreme detail. The language of CAD doesn’t always translate to the written word. Everyone has their own approach and their own methods. So he shared with me his c96 .iges files. Amazing to look at! A truly beautiful c96 recreated in EXTREME detail! A project that he himself was working on at one point. Unfortunately it got derailed along the way yet he was still graciously enough to shared what he’s done to help me along this new path I’m presently on. All these parts he shared will have to be remodeled (for me to use them that is.. they are already scaled perfectly fyi).. A challenge and learning experience I’m excited to tackle and hopefully fully up for!

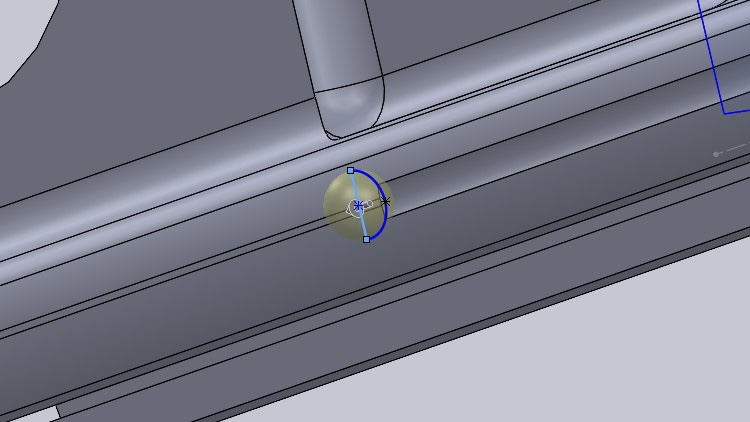

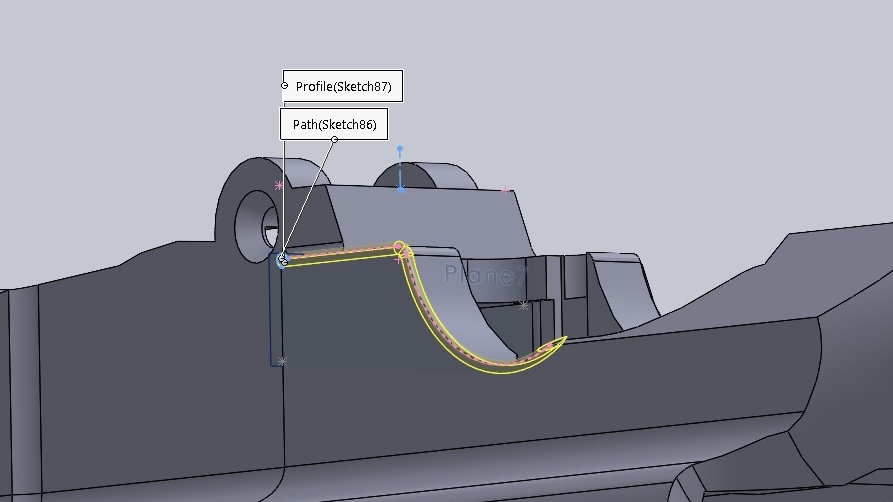

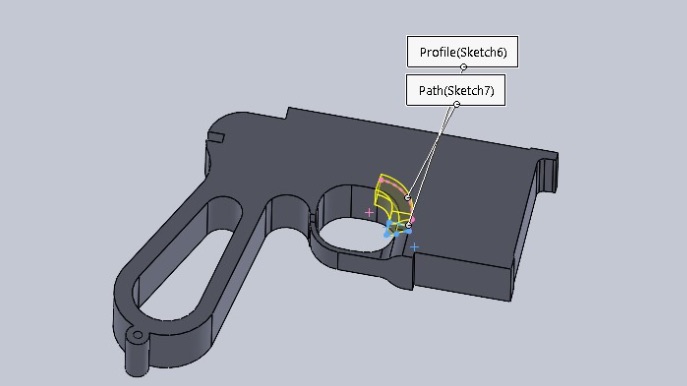

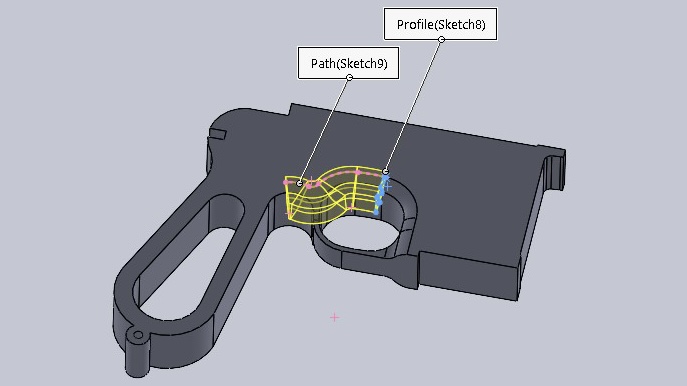

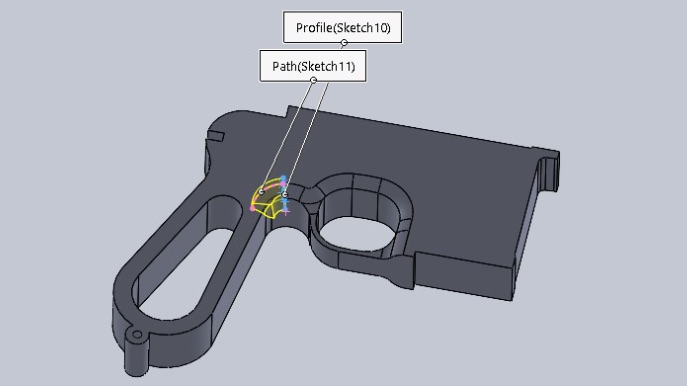

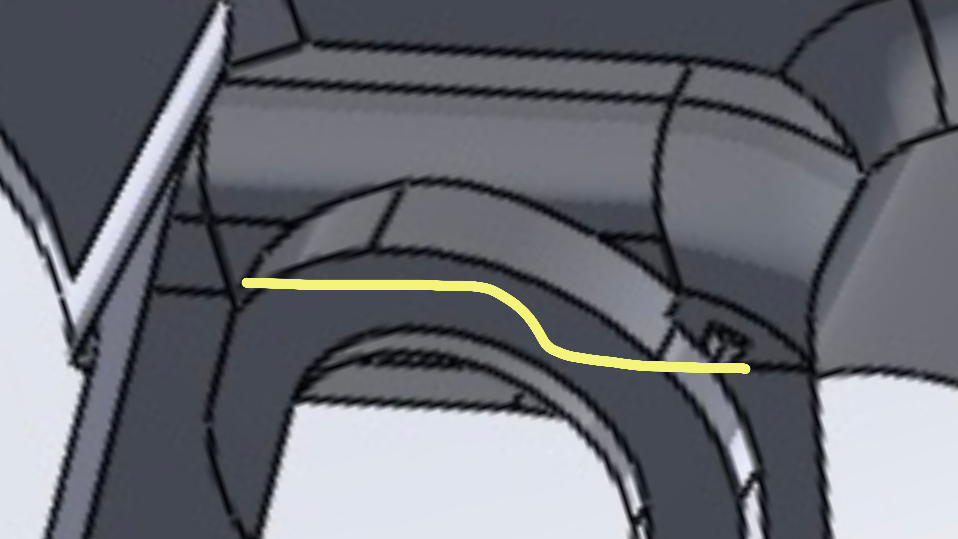

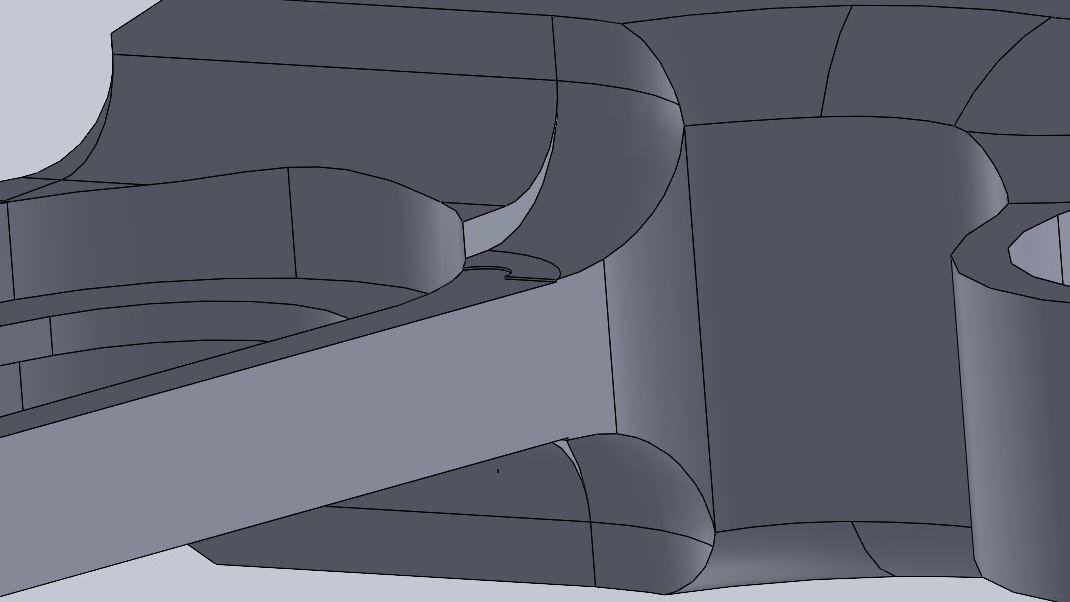

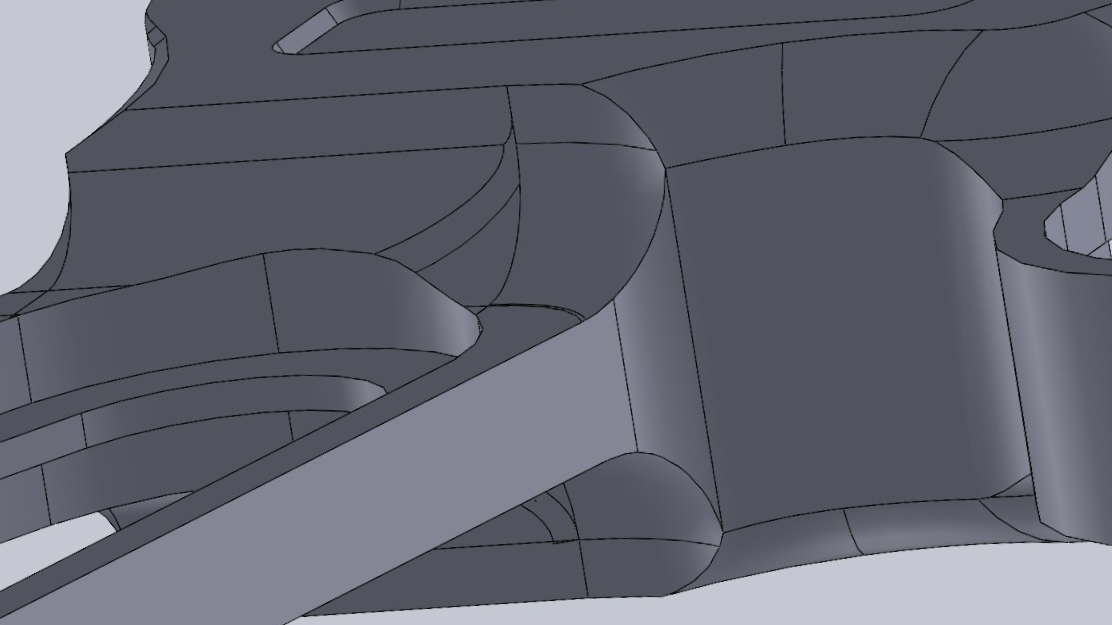

Here for example was the part I was working on that gave me trouble on the MGC but with the recreation of the c96 and using @deadbolts files as a guidance it’s made this so much easier to say the least. Only issue is why I couldn’t simply create one path for the cut to follow?. I don’t know why but I had to do 4 individual swoop cuts for this to work. Regardless this is the best CAD learning tool I’ve had to date and I couldn’t be more grateful.

So instead of doing the MGC first I’m reversing it.. going to do the c96 and then use that as my template for the MGC!

Just as an FYI I don’t know deadbolt very well and not at all outside TheRPF. But between him and kpax I have never received anything other than support, guidance and kind words. I don’t know either of them yet they are truly generous individuals who could have led with ego about all they have accomplished in regards to the ANH Hero. Yet they don’t. They continue to share openly and encourage new members who have the same passion that started them each I’m sure on their own individual journeys.

The best way I can say thank you I believe is to continue to do what I’m trying to do. Learn, continue to grow and pay it forward the best I can within this replica prop world.

Hats off to two strangers who have inspired me over the years.. and continue to do so! Thank you.

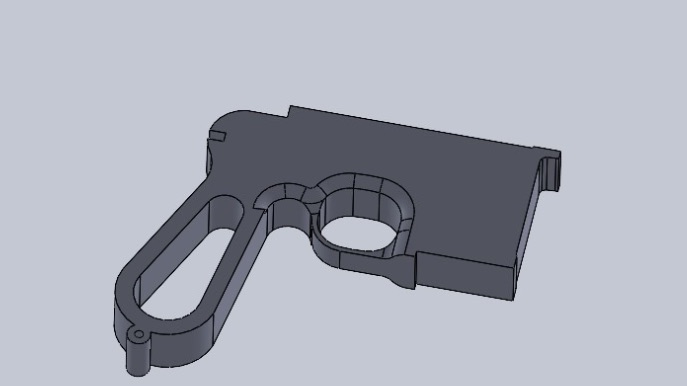

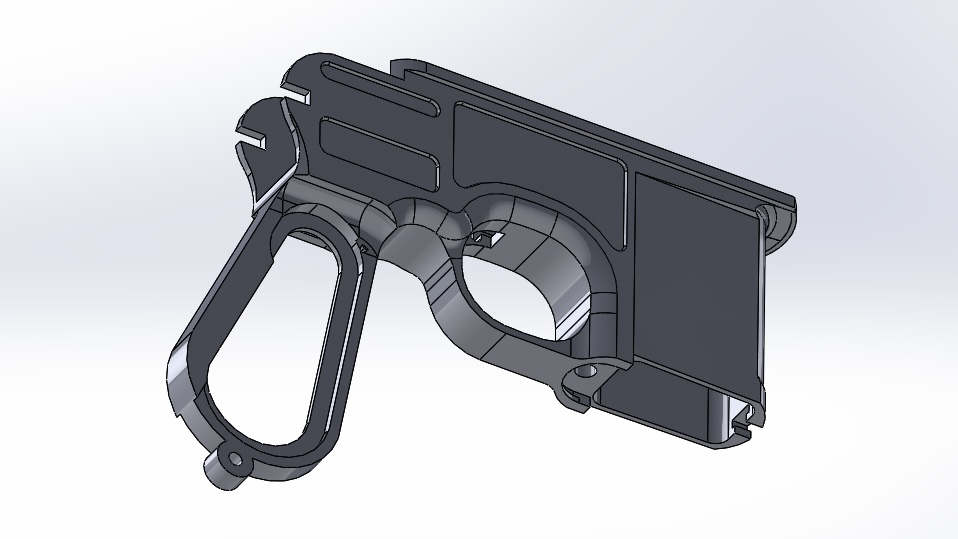

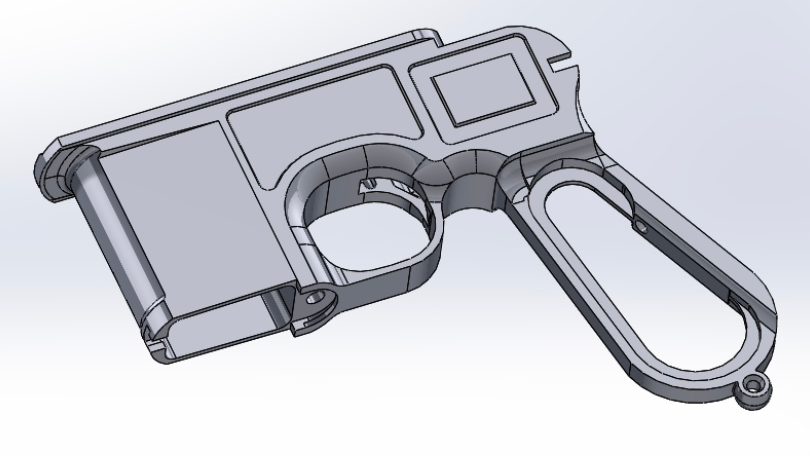

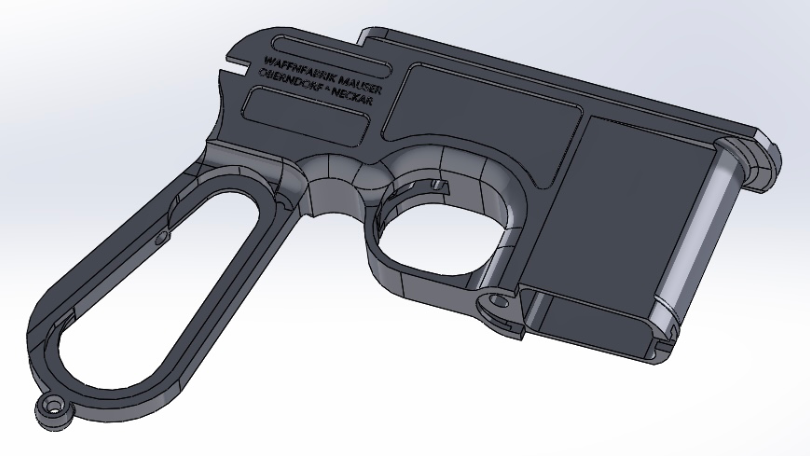

Now here is the progress pics of the lower receiver as mentioned in this post..

“My deadbolt c96 CAD project”

This Mauser replica journey started out trying to duplicate both a c96 and an MGC into CAD as detailed and as accurate as I possibly could. I’m not a professional but I definitely have the passion.. and that’s where a lot of this begins. My original journey was to start with the MGC and work backwords towards the c96. I have an actual MGC and for a c96 I have 1:1 casting so once the files for the MGC were created I was going to use that as my template to recreate the c96. BUT things took an unexpected turn very recently as I was given a gift that a simply thank you could not express the true gratitude I feel.

After reaching out to deadbolt to ask for some CAD guidance as I was having trouble recreated the outside filet/radius around the MGC trigger area he in turn gifted me his c96 model that has already been broken down in extreme detail. The language of CAD doesn’t always translate to the written word. Everyone has their own approach and their own methods. So he shared with me his c96 .iges files. Amazing to look at! A truly beautiful c96 recreated in EXTREME detail! A project that he himself was working on at one point. Unfortunately it got derailed along the way yet he was still graciously enough to shared what he’s done to help me along this new path I’m presently on. All these parts he shared will have to be remodeled (for me to use them that is.. they are already scaled perfectly fyi).. A challenge and learning experience I’m excited to tackle and hopefully fully up for!

Here for example was the part I was working on that gave me trouble on the MGC but with the recreation of the c96 and using @deadbolts files as a guidance it’s made this so much easier to say the least. Only issue is why I couldn’t simply create one path for the cut to follow?. I don’t know why but I had to do 4 individual swoop cuts for this to work. Regardless this is the best CAD learning tool I’ve had to date and I couldn’t be more grateful.

So instead of doing the MGC first I’m reversing it.. going to do the c96 and then use that as my template for the MGC!

Just as an FYI I don’t know deadbolt very well and not at all outside TheRPF. But between him and kpax I have never received anything other than support, guidance and kind words. I don’t know either of them yet they are truly generous individuals who could have led with ego about all they have accomplished in regards to the ANH Hero. Yet they don’t. They continue to share openly and encourage new members who have the same passion that started them each I’m sure on their own individual journeys.

The best way I can say thank you I believe is to continue to do what I’m trying to do. Learn, continue to grow and pay it forward the best I can within this replica prop world.

Hats off to two strangers who have inspired me over the years.. and continue to do so! Thank you.

Now here is the progress pics of the lower receiver as mentioned in this post..

Last edited:

deadbolt

Sr Member

Just as Pat said, keep at it and keep the motivation! That's the only way these project will ever move forward.

Time works as usual, slow, but resultful with interest and dedication.

Just as my favorite physicist Isaac Newton realized Gravity after thousands of years of our species existence...kinda sad it took us that long, but still a super significant realization for the 'real' world outside of our hobbies.

-Carson

Time works as usual, slow, but resultful with interest and dedication.

Just as my favorite physicist Isaac Newton realized Gravity after thousands of years of our species existence...kinda sad it took us that long, but still a super significant realization for the 'real' world outside of our hobbies.

-Carson

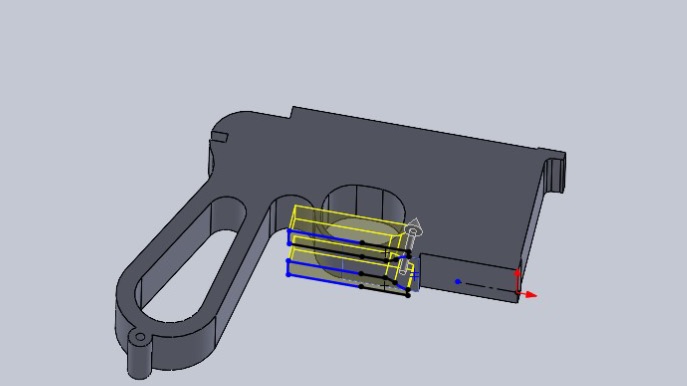

Got most of this figured out. Just one issue I’m struggling with is to figure out how to cut an angle on two different levels..

Ya sorry forgive my vocabulary here. Honestly I’m just not sure how to explain what I’m trying to accomplish. The cuts (path) are on two levels basically. It’s the one part I’ve yet to figure out but everything else is done. I’ll mess around with different planes to create paths on to see if that can solve it. Cosmetically the grips would simply cover it anyhow but would be nice to have it quote unquote perfect.

The font for the lettering I can’t find so I’ll probably end up doing it by hand. This is just temporary as I wanted to see what it would look like..

The font for the lettering I can’t find so I’ll probably end up doing it by hand. This is just temporary as I wanted to see what it would look like..

deadbolt

Sr Member

Yeah, the transition from the rear to the front of the upper-side of the grip cutout was a real challenge to model cleanly. The back side at the top of the cutout has a smaller radius then transfers to a larger radius towards the front/trigger guard side.

Not sure why they did that on the originals, it doesn't serve any purpose as far as I could tell, but I don't doubt it was even more difficult back then..I think they used two ball endmills and blended the transition by hand. As Pat said, everything was done manually and I don't doubt that there was a lot of hand work all over those babies. Really inspiring and unique work those Mauser designers and machinists pulled off back in the day.

-Carson

Not sure why they did that on the originals, it doesn't serve any purpose as far as I could tell, but I don't doubt it was even more difficult back then..I think they used two ball endmills and blended the transition by hand. As Pat said, everything was done manually and I don't doubt that there was a lot of hand work all over those babies. Really inspiring and unique work those Mauser designers and machinists pulled off back in the day.

-Carson

It’s really fun to go through it with fine comb and seeing all the details involved with this Mauser. I think I figured something out.. or at least I got it to look somewhat how your original looked. It’s not 100% but I think it works. I just had to create a offset plane and curve the cut so it ends outside the Mauser. Confusing probably but it works..

Wow! I'm just seeing this now. Great job modeling! Looks awesome

Thanks Anakin Starkiller! deadbolt gave me some serious sized breadcrumbs to follow which is making this adventure all the more fun.

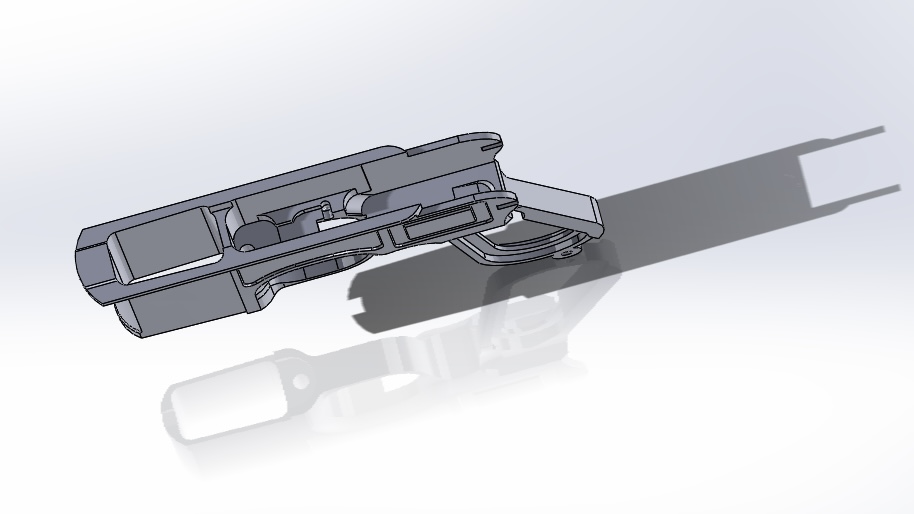

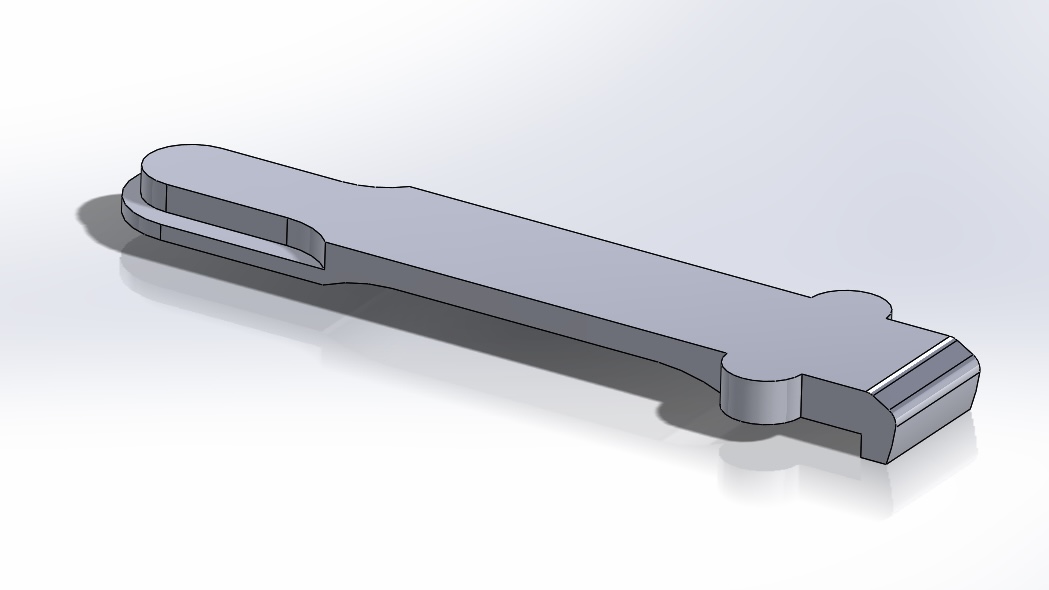

Here’s the extractor I did very quickly before heading off to work this morning. I’ll have to do a little more research and digging but I think from what I’ve gathered this is what the c96 extractor looks like?

And a quick assembly progress pic..

Last edited:

It’s funny sometimes you don’t even know what you are looking at until you are breaking these things down. Thats been my experience anyhow with all these props. It’s one of the most addictive things about designing or re-engineering everything in as great detail as possible.

Looking for extractions to see if I got it right I found a couple interesting pictures. First ya I’m pretty sure the extraction as designed above is on point. Just need to add a little outside radius on the bottom front..

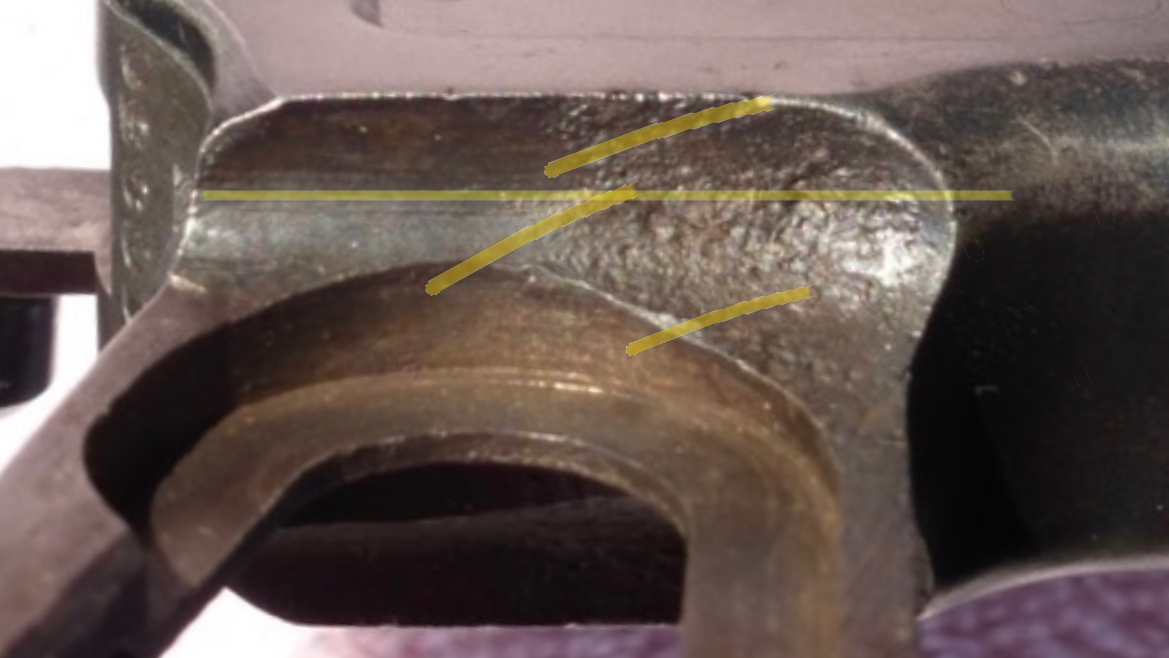

Second I found a picture of the part on the c96 that was giving me trouble and you can see how they cut it here. Possible 4 separate cuts maybe?

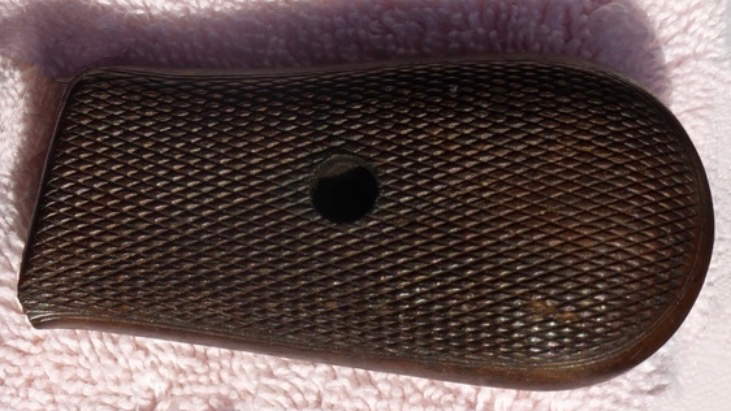

And lastly I found some “Stembridge” styled fish scaled grips. These however are not exactly like the film prop as these scales go all the way to the top. Still a cool find..

Looking for extractions to see if I got it right I found a couple interesting pictures. First ya I’m pretty sure the extraction as designed above is on point. Just need to add a little outside radius on the bottom front..

Second I found a picture of the part on the c96 that was giving me trouble and you can see how they cut it here. Possible 4 separate cuts maybe?

And lastly I found some “Stembridge” styled fish scaled grips. These however are not exactly like the film prop as these scales go all the way to the top. Still a cool find..

Last edited:

Nice!! I knew Carson had modeled a C96, but I guess I never really saw any photos of it. Very generous, and cool!  And I respect and admire your dedication to re-build it yourself.

And I respect and admire your dedication to re-build it yourself.

I'm not familiar with SolidWorks, but in Fusion 360 you can use a variable radius fillet to do this, basically you specify points along the edge by distance, and can set different radii. A loft would be another less automated option. It is a weird piece of geometry, particularly when you consider that it was actually cut by a mill!

Looking at your new pics John, what I think I see is a regular fillet cut going about half way forward from the rear, then a larger ball shaped cut to finish the front edge, though not entirely clear on the direction of the larger cut(s). Might be completely off though! There's got to be some practical reason it was done this way.

I found these original (?) mechanical drawings the other day, might help on your quest.

Yeah, the transition from the rear to the front of the upper-side of the grip cutout was a real challenge to model cleanly. The back side at the top of the cutout has a smaller radius then transfers to a larger radius towards the front/trigger guard side.

I'm not familiar with SolidWorks, but in Fusion 360 you can use a variable radius fillet to do this, basically you specify points along the edge by distance, and can set different radii. A loft would be another less automated option. It is a weird piece of geometry, particularly when you consider that it was actually cut by a mill!

Looking at your new pics John, what I think I see is a regular fillet cut going about half way forward from the rear, then a larger ball shaped cut to finish the front edge, though not entirely clear on the direction of the larger cut(s). Might be completely off though! There's got to be some practical reason it was done this way.

I found these original (?) mechanical drawings the other day, might help on your quest.

Last edited:

Hey Pedro that’s a great reference! Thank you much. It looks like it was drawn in inches as well which is much more to my vocabulary. I’ve noticed a lot of people use mm? Those blueprints show the extraction. I had to estimate at the bottom thickness and it looks like I was about .010 off. That’s pretty cool to see.

In all honesty I think I would’ve been a little disappointed if I didn’t have to remodel these parts. The whole point is to learn but Carson’s c96 takes a LOT of the guessing out. It’s been a lot of fun I can tell you that for sure! Very challenging as well.

The grips will be another challenge all together but I do have a resin set on hand to help draw from. That male/female part from the grips to the handle should be interesting. I’m hoping I can simply mirror the cuts??

In all honesty I think I would’ve been a little disappointed if I didn’t have to remodel these parts. The whole point is to learn but Carson’s c96 takes a LOT of the guessing out. It’s been a lot of fun I can tell you that for sure! Very challenging as well.

The grips will be another challenge all together but I do have a resin set on hand to help draw from. That male/female part from the grips to the handle should be interesting. I’m hoping I can simply mirror the cuts??

Oh also I’m still learning solidworks myself. I’m pretty sure that there’s a lot of things it can do that I’m not aware of that would probably make my life a lot easier

Similar threads

- Replies

- 2

- Views

- 413

- Replies

- 29

- Views

- 4,856

- Replies

- 19

- Views

- 3,539

- Replies

- 24

- Views

- 3,494