You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dewy and Anakin Starkiller's Accurate Obi-Wan Kenobi Episode 1 Lightsaber Design

- Thread starter Dewy

- Start date

He’s a starkiller, the force is strong with himHey sir! How are you and your son doing? Hoping you're on the mend, that stuff is no fun!!

Just checking I haven't missed any updates. Hope you're feeling better Anakin Starkiller!!

The sign up thread is now live in the junkyard

www.therpf.com

www.therpf.com

Limited Run - Obi-wan Episode 1 saber sign up thread!

Hello everyone, After a long period of redesign and prototyping by Drew and myself, I am now excited to announce that I am finally ready to start signing people up for my Obi-wan Episode 1 saber kit. If you're not caught up on the design process that this project has undergone, you can check...

Anakin Starkiller just posted the signup thread:

www.therpf.com

www.therpf.com

Limited Run - Dewy and Anakin Starkiller's Obi-wan Episode 1 saber sign up!

Hello everyone, After a long period of redesign and prototyping by Drew and myself, I am now excited to announce that I am finally ready to start signing people up for my Obi-wan Episode 1 saber kit. If you're not caught up on the design process that this project has undergone, you can check...

Do you have an idea as to when you will have the parts in hand and therefore request payment? I’d love to sign up but it’s looking to be an expensive year and would just like a rough month/ time so that I can make sure I put the money away for it.

I'd guess two months. But it's really hard to say. Shipping and shop times have been all over the place lately.Do you have an idea as to when you will have the parts in hand and therefore request payment? I’d love to sign up but it’s looking to be an expensive year and would just like a rough month/ time so that I can make sure I put the money away for it.

Thankyou - That is very helpful!I'd guess two months. But it's really hard to say. Shipping and shop times have been all over the place lately.

Since we are transitioning to production, and this thread is getting a little long with over 400 posts I wanted to post a summary of the various features of this replica.

Overview and Philosophy

From the very beginning this replica was intended to be a 100% accurate replica of the original hero prop. That means a completely static replica where no detail was too small to replicate. All of the idiosyncrasies of the original prop are present and virtually nothing is symmetrical or evenly spaced. The original hero prop includes various tell-tale signs about the specific manufacturing processes and even machine setups that were used. As such, this replica aims to recreate those to the maximum extent practical.

Approach

The 3D CAD model for this replica was iterated using high resolution non-publicly available reference images of the original hero prop. Dimensions were scaled using known parts. Then, using Solidworks Parametric CAD and Rhino 7 3D design software each reference image was painstakingly replicated using virtual cameras within the 3D design space. This is an incredibly time consuming process that takes into account exact orientation, distance from camera, and even the focal length of lens that was originally used to take each reference image. This allowed the model to be precisely overlayed on the reference images to iterate and verify geometry and positioning of all features. Additionally, Anakin Starkiller's original production made resin stunt saber was used for relative sizing of features and to validate general qualitative aspects of the model.

Details

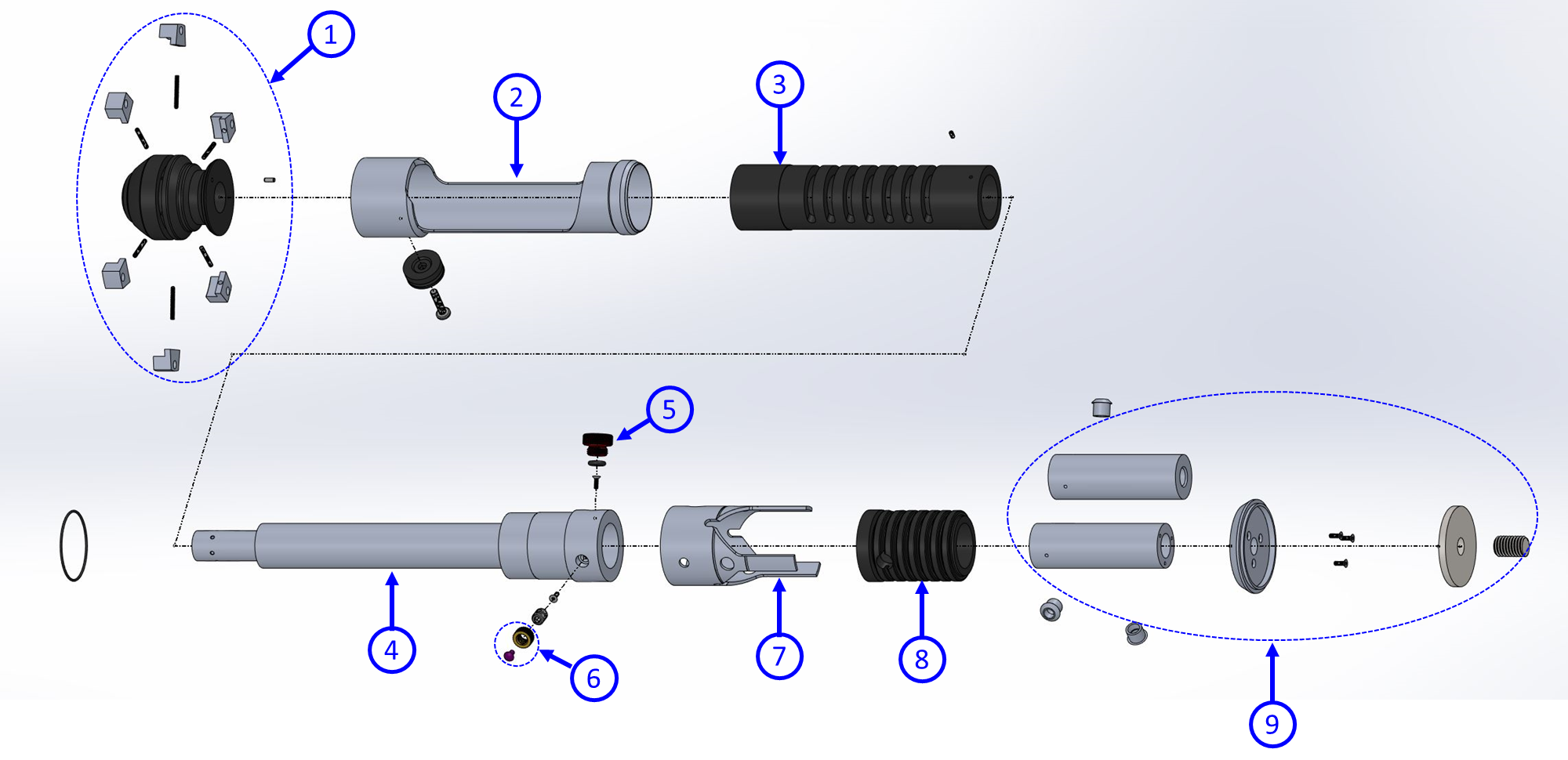

1. Pommel & Cubes – Each of the various angles and organic curves of the original pommel are accurately represented on this replica. As evidenced by careful inspection of the hero reference images and damage present on the original hero prop, the pommel cubes are 6 individual pieces. This leaves slight gaps under the edges of the cubes recessed within the groove of the pommel. The backside of each cube features a very small chamfered edge where it comes into contact with the pommel, just like the original prop. Additionally, the cubes are very slightly unevenly spaced. This replica features setscrews and pins to ensure proper alignment of the pommel cubes to each other and the assembled pommel to the rest of the saber.

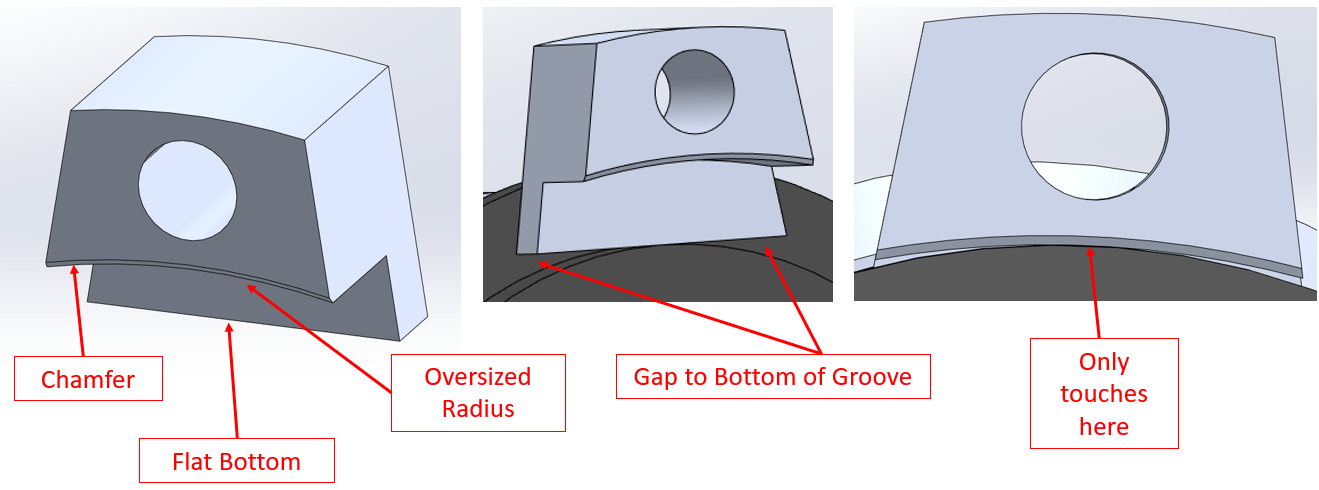

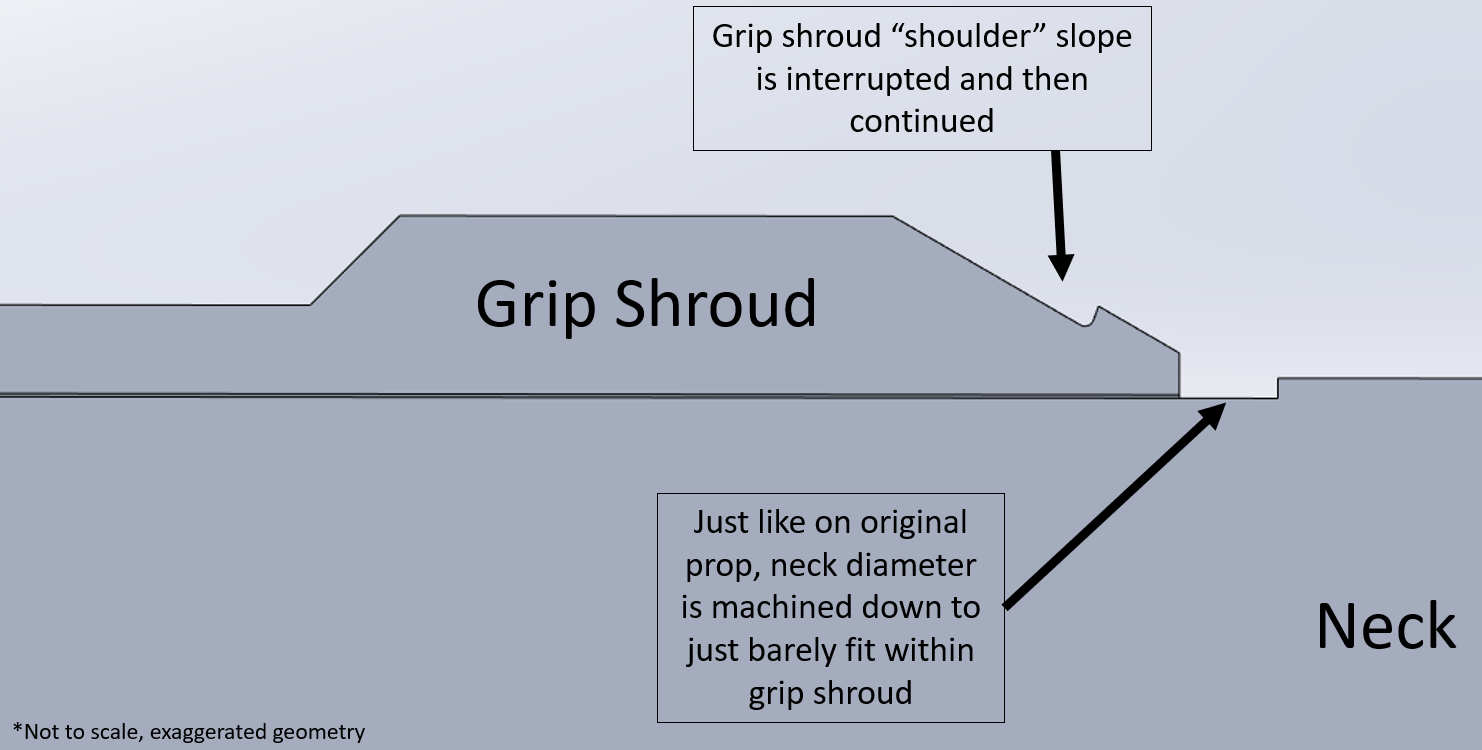

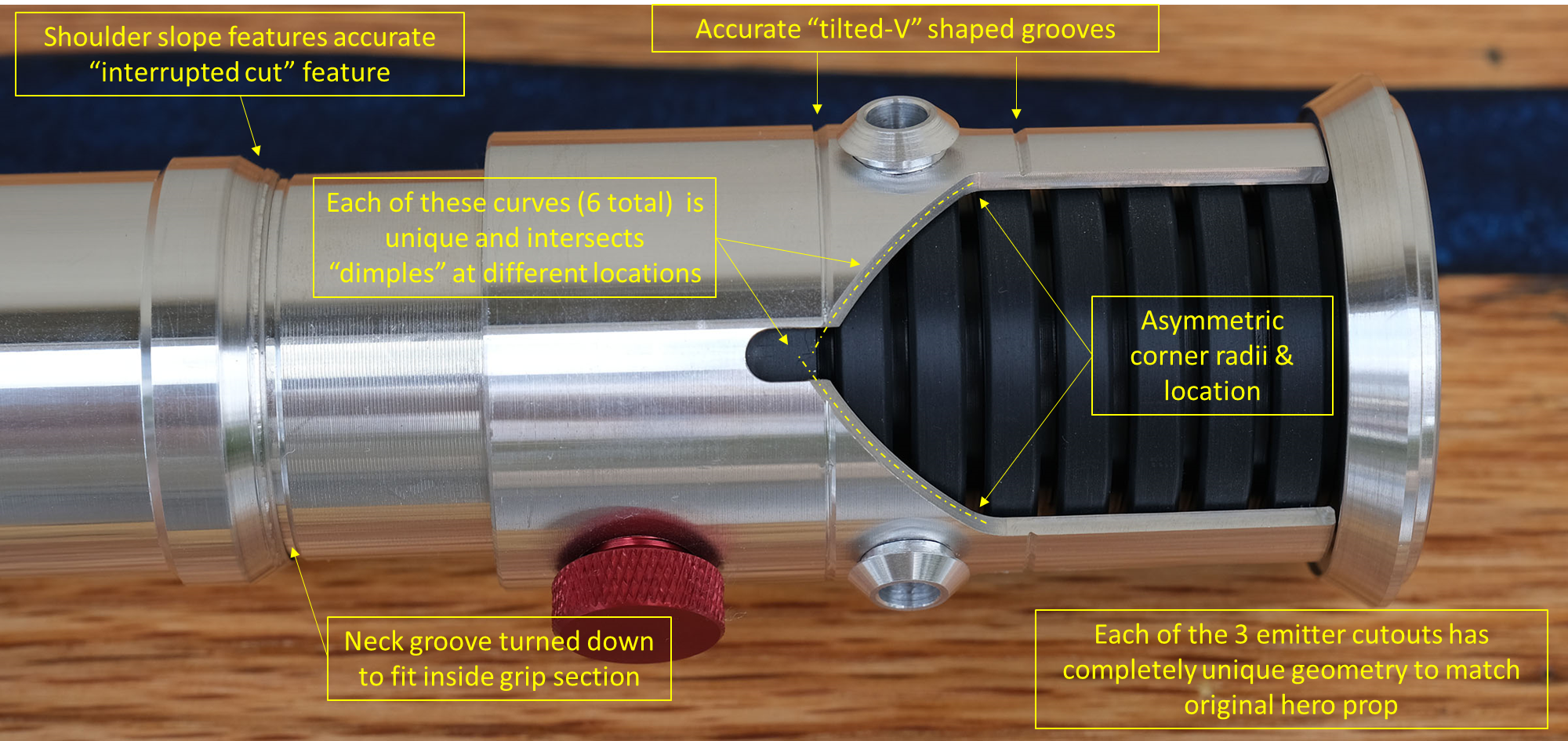

2. Grip Shroud – This is one of the trickiest parts of the saber to replicate. Previous replicas have come very close but there are several small details that have never been nailed. The main cutout has various compound radii and terminates at an odd angle rather than a perfectly perpendicular to the saber’s axis. Additionally, just like the original prop, the inner diameter of the grip shroud is slightly oversized leaving a noticeable gap between the inner diameter of the aluminum shroud and the outer diameter of black grip section. The angled face of the “shoulder” that transitions to the neck features an accurate interrupted cut where the lathe tool was very touched off and then slightly backed off again before the angled cut was continued. This results in essentially a slight groove in the middle of the angle and two separate very slightly offset angled faces.

3. Grip Section - As previously mentioned, the grip section OD is undersized leaving a gap between it and the grip shroud. The exact spacing, and size of each groove in the grip section was recreated down to the 1/10th of a millimeter to accurately replicate this section that is a key contributor to the overall look of this saber.

4. Core & Neck - At the core of this saber is one solid aluminum piece that is visible through the grooves in the grip section and as the neck of the saber. This part is critical to the accurate clocking of the pommel, covertech knob, and emitter section. This part is the main driver of the heft and overall solid feel/construction of this replica.

5. Red Button / Port Plug (The Part Formerly Known as Blanking Cap) - I was very fortunate, thanks to my experience in the aerospace industry, to be able to find a parts distributor that had several original blanking caps in stock. Let me tell you, since these are real aerospace parts with certifications and pedigree, these were not cheap or easy to obtain. With the original parts in hand Anakin Starkiller and myself were able to completely accurately replicate the original part. I was able to reference the various aerospace standards that govern parts such as these, and we were even able to source the standard knurling wheel that was used. Below is a picture of one of my original blanking caps meshed with the correct knurling wheel.

6. Brass Knob & Purple Hemi - Again turning to aerospace, it is my belief that these parts were originally a modified Parker Hose Barb/Plug (or similar part) and a standard aerospace aluminum rivet (the purple coating is intentionally used on these to indicate the specific material). I was even able to source several thousand of the correct original purple rivets. I am very pleased to say that each replica saber will include a modified authentic Parker Hose Barb with a real purple aerospace rivet. All original parts, no replicas here!

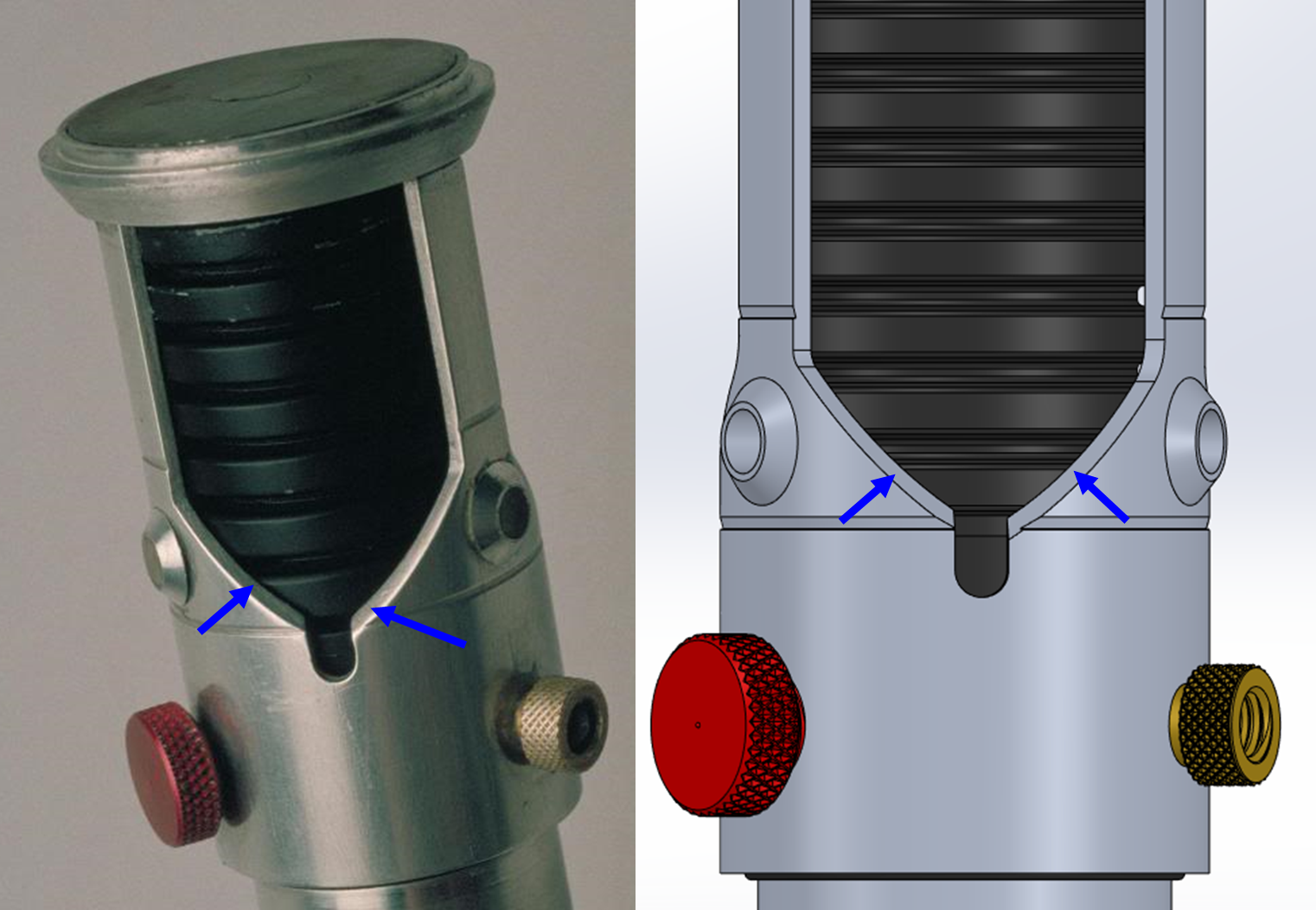

7. Emitter Shroud - This is one of the more nuanced parts of this saber and easily the area I spent the most time replicating (by an order of magnitude). The geometry and spacing of the three cutouts in this section are another area that has never been accurately replicated and something I became completely obsessed with. I have over 50 separate model files of this part, with each file including countless iterations. Believe me when I say there is not a single feature within the emitter cutouts that is A) symmetric/consistent within that one cutout, or B) consistent with the equivalent features in the other cutouts. Every curve, radius, angle, etc. Even the spacing of the three cutouts is inconsistent. Before I even started this thread I was pulling my hair out for months trying to figure out how they got the angled faces indicated below by the blue arrows:

Thankfully, I took a step back and applied a little bit of Occam's Razor. It turns out the angled nature of these faces (present on all three emitter cutouts) is a natural result of the specific milling setup and approach that was used. In fact, once I realized this, I realized it is incredibly simple to replicate and does not require any complex 4+ axis machines. From the perspective of the machinist these features are essentially machined in 2 dimensions (since the mill tool can be kept at a consistent Z height and only moved on X & Y). I truly believe that the original prop was machined with your standard three axis knee mill, no fancy CNC machines or anything like that. So what was the big breakthrough I had? Well I always thought about these features as cutouts in the emitter shroud. To put it another way I was focused on the material that was removed, instead I needed to think about the material that remained. The machinist wasn't trying to machine cutouts, he was trying to machine three emitter "posts":

<image removed>

The red circles and lines show the mill tool and its path to machine one side of one emitter "post". See how simple the geometry looks from this perspective? It really was that simple. The asymmetric corner radii on each side of the emitter post are simply the result of the angle of the cut on each side of the emitter post and the point at which the angle starts being different. This makes perfect sense for someone that was doing this manually and just eyeballing it. Thankfully, the high resolution reference images include several aligned closeups of the emitter section with the saber rotated between images, so we have good views of each of the emitter posts/cutouts. This allowed me to really, really nail everything on the emitter shroud. Some more details can be seen in this image of the prototype saber:

8. Black Emitter Section - I believe this portion of the original saber was clearly cast resin, in fact, based on the reference images its clear it was even slightly warped/out of round. Since accurately replicating that would be too challenging for very little noticeable difference, several of the imperfections were incorporated into the machined delrin replica. For example, the spacing and depths of the grooves vary ever so slightly (seen in the model screenshot above with the red lines).

9. Emitter Bezel & Fender Washer - It is very clear from both the reference images of the original hero prop and Anakin Starkiller's resin stunt saber that at some point the saber was damaged or assembled incorrectly, because the emitter bezel is angled and off axis with the rest of the saber. This is something that Dan was adamant about replicating accurately. As such there are two interchangeable aluminum cores that can be used to assemble the saber. The first ensures that the bezel and washer are correctly angled and off center, just like in the reference images this results in slight gaps between the tops of one or two of the emitter posts and the bottom of the emitter bezel. The second emitter core allows for the bezel and washer to be assembled on to the saber centered and level. This swapable configuration is a really cool detail that I'm really glad we were able to incorporate into this replica.

There are dozens of additional details that I have not outlined in this post. This is really just a summary of how we got to where we are. Hopefully it is totally apparent that Dan and I are obsessed with this saber and made no compromises when it comes to accurately replicating this prop.

Overview and Philosophy

From the very beginning this replica was intended to be a 100% accurate replica of the original hero prop. That means a completely static replica where no detail was too small to replicate. All of the idiosyncrasies of the original prop are present and virtually nothing is symmetrical or evenly spaced. The original hero prop includes various tell-tale signs about the specific manufacturing processes and even machine setups that were used. As such, this replica aims to recreate those to the maximum extent practical.

Approach

The 3D CAD model for this replica was iterated using high resolution non-publicly available reference images of the original hero prop. Dimensions were scaled using known parts. Then, using Solidworks Parametric CAD and Rhino 7 3D design software each reference image was painstakingly replicated using virtual cameras within the 3D design space. This is an incredibly time consuming process that takes into account exact orientation, distance from camera, and even the focal length of lens that was originally used to take each reference image. This allowed the model to be precisely overlayed on the reference images to iterate and verify geometry and positioning of all features. Additionally, Anakin Starkiller's original production made resin stunt saber was used for relative sizing of features and to validate general qualitative aspects of the model.

Details

1. Pommel & Cubes – Each of the various angles and organic curves of the original pommel are accurately represented on this replica. As evidenced by careful inspection of the hero reference images and damage present on the original hero prop, the pommel cubes are 6 individual pieces. This leaves slight gaps under the edges of the cubes recessed within the groove of the pommel. The backside of each cube features a very small chamfered edge where it comes into contact with the pommel, just like the original prop. Additionally, the cubes are very slightly unevenly spaced. This replica features setscrews and pins to ensure proper alignment of the pommel cubes to each other and the assembled pommel to the rest of the saber.

2. Grip Shroud – This is one of the trickiest parts of the saber to replicate. Previous replicas have come very close but there are several small details that have never been nailed. The main cutout has various compound radii and terminates at an odd angle rather than a perfectly perpendicular to the saber’s axis. Additionally, just like the original prop, the inner diameter of the grip shroud is slightly oversized leaving a noticeable gap between the inner diameter of the aluminum shroud and the outer diameter of black grip section. The angled face of the “shoulder” that transitions to the neck features an accurate interrupted cut where the lathe tool was very touched off and then slightly backed off again before the angled cut was continued. This results in essentially a slight groove in the middle of the angle and two separate very slightly offset angled faces.

3. Grip Section - As previously mentioned, the grip section OD is undersized leaving a gap between it and the grip shroud. The exact spacing, and size of each groove in the grip section was recreated down to the 1/10th of a millimeter to accurately replicate this section that is a key contributor to the overall look of this saber.

4. Core & Neck - At the core of this saber is one solid aluminum piece that is visible through the grooves in the grip section and as the neck of the saber. This part is critical to the accurate clocking of the pommel, covertech knob, and emitter section. This part is the main driver of the heft and overall solid feel/construction of this replica.

5. Red Button / Port Plug (The Part Formerly Known as Blanking Cap) - I was very fortunate, thanks to my experience in the aerospace industry, to be able to find a parts distributor that had several original blanking caps in stock. Let me tell you, since these are real aerospace parts with certifications and pedigree, these were not cheap or easy to obtain. With the original parts in hand Anakin Starkiller and myself were able to completely accurately replicate the original part. I was able to reference the various aerospace standards that govern parts such as these, and we were even able to source the standard knurling wheel that was used. Below is a picture of one of my original blanking caps meshed with the correct knurling wheel.

6. Brass Knob & Purple Hemi - Again turning to aerospace, it is my belief that these parts were originally a modified Parker Hose Barb/Plug (or similar part) and a standard aerospace aluminum rivet (the purple coating is intentionally used on these to indicate the specific material). I was even able to source several thousand of the correct original purple rivets. I am very pleased to say that each replica saber will include a modified authentic Parker Hose Barb with a real purple aerospace rivet. All original parts, no replicas here!

7. Emitter Shroud - This is one of the more nuanced parts of this saber and easily the area I spent the most time replicating (by an order of magnitude). The geometry and spacing of the three cutouts in this section are another area that has never been accurately replicated and something I became completely obsessed with. I have over 50 separate model files of this part, with each file including countless iterations. Believe me when I say there is not a single feature within the emitter cutouts that is A) symmetric/consistent within that one cutout, or B) consistent with the equivalent features in the other cutouts. Every curve, radius, angle, etc. Even the spacing of the three cutouts is inconsistent. Before I even started this thread I was pulling my hair out for months trying to figure out how they got the angled faces indicated below by the blue arrows:

Thankfully, I took a step back and applied a little bit of Occam's Razor. It turns out the angled nature of these faces (present on all three emitter cutouts) is a natural result of the specific milling setup and approach that was used. In fact, once I realized this, I realized it is incredibly simple to replicate and does not require any complex 4+ axis machines. From the perspective of the machinist these features are essentially machined in 2 dimensions (since the mill tool can be kept at a consistent Z height and only moved on X & Y). I truly believe that the original prop was machined with your standard three axis knee mill, no fancy CNC machines or anything like that. So what was the big breakthrough I had? Well I always thought about these features as cutouts in the emitter shroud. To put it another way I was focused on the material that was removed, instead I needed to think about the material that remained. The machinist wasn't trying to machine cutouts, he was trying to machine three emitter "posts":

<image removed>

The red circles and lines show the mill tool and its path to machine one side of one emitter "post". See how simple the geometry looks from this perspective? It really was that simple. The asymmetric corner radii on each side of the emitter post are simply the result of the angle of the cut on each side of the emitter post and the point at which the angle starts being different. This makes perfect sense for someone that was doing this manually and just eyeballing it. Thankfully, the high resolution reference images include several aligned closeups of the emitter section with the saber rotated between images, so we have good views of each of the emitter posts/cutouts. This allowed me to really, really nail everything on the emitter shroud. Some more details can be seen in this image of the prototype saber:

8. Black Emitter Section - I believe this portion of the original saber was clearly cast resin, in fact, based on the reference images its clear it was even slightly warped/out of round. Since accurately replicating that would be too challenging for very little noticeable difference, several of the imperfections were incorporated into the machined delrin replica. For example, the spacing and depths of the grooves vary ever so slightly (seen in the model screenshot above with the red lines).

9. Emitter Bezel & Fender Washer - It is very clear from both the reference images of the original hero prop and Anakin Starkiller's resin stunt saber that at some point the saber was damaged or assembled incorrectly, because the emitter bezel is angled and off axis with the rest of the saber. This is something that Dan was adamant about replicating accurately. As such there are two interchangeable aluminum cores that can be used to assemble the saber. The first ensures that the bezel and washer are correctly angled and off center, just like in the reference images this results in slight gaps between the tops of one or two of the emitter posts and the bottom of the emitter bezel. The second emitter core allows for the bezel and washer to be assembled on to the saber centered and level. This swapable configuration is a really cool detail that I'm really glad we were able to incorporate into this replica.

There are dozens of additional details that I have not outlined in this post. This is really just a summary of how we got to where we are. Hopefully it is totally apparent that Dan and I are obsessed with this saber and made no compromises when it comes to accurately replicating this prop.

Last edited:

GreyGuard38

Active Member

An incredible amount of time, research, thought and dedication in this project!

I share your obsession and truly appreciate your time and dedication to get this as accurate as possibleSince we are transitioning to production, and this thread is getting a little long with over 400 posts I wanted to post a summary of the various features of this replica.

Overview and Philosophy

From the very beginning this replica was intended to be a 100% accurate replica of the original hero prop. That means a completely static replica where no detail was too small to replicate. All of the idiosyncrasies of the original prop are present and virtually nothing is symmetrical or evenly spaced. The original hero prop includes various tell-tale signs about the specific manufacturing processes and even machine setups that were used. As such, this replica aims to recreate those to the maximum extent practical.

Approach

The 3D CAD model for this replica was iterated using high resolution non-publicly available reference images of the original hero prop. Dimensions were scaled using known parts. Then, using Solidworks Parametric CAD and Rhino 7 3D design software each reference image was painstakingly replicated using virtual cameras within the 3D design space. This is an incredibly time consuming process that takes into account exact orientation, distance from camera, and even the focal length of lens that was originally used to take each reference image. This allowed the model to be precisely overlayed on the reference images to iterate and verify geometry and positioning of all features. Additionally, Anakin Starkiller's original production made resin stunt saber was used for relative sizing of features and to validate general qualitative aspects of the model.

Details

View attachment 1658652

1. Pommel & Cubes – Each of the various angles and organic curves of the original pommel are accurately represented on this replica. As evidenced by careful inspection of the hero reference images and damage present on the original hero prop, the pommel cubes are 6 individual pieces. This leaves slight gaps under the edges of the cubes recessed within the groove of the pommel. The backside of each cube features a very small chamfered edge where it comes into contact with the pommel, just like the original prop. Additionally, the cubes are very slightly unevenly spaced. This replica features setscrews and pins to ensure proper alignment of the pommel cubes to each other and the assembled pommel to the rest of the saber.

View attachment 1658654

2. Grip Shroud – This is one of the trickiest parts of the saber to replicate. Previous replicas have come very close but there are several small details that have never been nailed. The main cutout has various compound radii and terminates at an odd angle rather than a perfectly perpendicular to the saber’s axis. Additionally, just like the original prop, the inner diameter of the grip shroud is slightly oversized leaving a noticeable gap between the inner diameter of the aluminum shroud and the outer diameter of black grip section. The angled face of the “shoulder” that transitions to the neck features an accurate interrupted cut where the lathe tool was very touched off and then slightly backed off again before the angled cut was continued. This results in essentially a slight groove in the middle of the angle and two separate very slightly offset angled faces.

View attachment 1658655

3. Grip Section - As previously mentioned, the grip section OD is undersized leaving a gap between it and the grip shroud. The exact spacing, and size of each groove in the grip section was recreated down to the 1/10th of a millimeter to accurately replicate this section that is a key contributor to the overall look of this saber.

4. Core & Neck - At the core of this saber is one solid aluminum piece that is visible through the grooves in the grip section and as the neck of the saber. This part is critical to the accurate clocking of the pommel, covertech knob, and emitter section. This part is the main driver of the heft and overall solid feel/construction of this replica.

5. Red Button / Port Plug (The Part Formerly Known as Blanking Cap) - I was very fortunate, thanks to my experience in the aerospace industry, to be able to find a parts distributor that had several original blanking caps in stock. Let me tell you, since these are real aerospace parts with certifications and pedigree, these were not cheap or easy to obtain. With the original parts in hand Anakin Starkiller and myself were able to completely accurately replicate the original part. I was able to reference the various aerospace standards that govern parts such as these, and we were even able to source the standard knurling wheel that was used. Below is a picture of one of my original blanking caps meshed with the correct knurling wheel.

View attachment 1658657

6. Brass Knob & Purple Hemi - Again turning to aerospace, it is my belief that these parts were originally a modified Parker Hose Barb/Plug (or similar part) and a standard aerospace aluminum rivet (the purple coating is intentionally used on these to indicate the specific material). I was even able to source several thousand of the correct original purple rivets. I am very pleased to say that each replica saber will include a modified authentic Parker Hose Barb with a real purple aerospace rivet. All original parts, no replicas here!

View attachment 1658686

7. Emitter Shroud - This is one of the more nuanced parts of this saber and easily the area I spent the most time replicating (by an order of magnitude). The geometry and spacing of the three cutouts in this section are another area that has never been accurately replicated and something I became completely obsessed with. I have over 50 separate model files of this part, with each file including countless iterations. Believe me when I say there is not a single feature within the emitter cutouts that is A) symmetric/consistent within that one cutout, or B) consistent with the equivalent features in the other cutouts. Every curve, radius, angle, etc. Even the spacing of the three cutouts is inconsistent. Before I even started this thread I was pulling my hair out for months trying to figure out how they got the angled faces indicated below by the blue arrows:

View attachment 1658691

Thankfully, I took a step back and applied a little bit of Occam's Razor. It turns out the angled nature of these faces (present on all three emitter cutouts) is a natural result of the specific milling setup and approach that was used. In fact, once I realized this, I realized it is incredibly simple to replicate and does not require any complex 4+ axis machines. From the perspective of the machinist these features are essentially machined in 2 dimensions (since the mill tool can be kept at a consistent Z height and only moved on X & Y). I truly believe that the original prop was machined with your standard three axis knee mill, no fancy CNC machines or anything like that. So what was the big breakthrough I had? Well I always thought about these features as cutouts in the emitter shroud. To put it another way I was focused on the material that was removed, instead I needed to think about the material that remained. The machinist wasn't trying to machine cutouts, he was trying to machine three emitter "posts":

View attachment 1658697

The red circles and lines show the mill tool and its path to machine one side of one emitter "post". See how simple the geometry looks from this perspective? It really was that simple. The asymmetric corner radii on each side of the emitter post are simply the result of the angle of the cut on each side of the emitter post and the point at which the angle starts being different. This makes perfect sense for someone that was doing this manually and just eyeballing it. Thankfully, the high resolution reference images include several aligned closeups of the emitter section with the saber rotated between images, so we have good views of each of the emitter posts/cutouts. This allowed me to really, really nail everything on the emitter shroud. Some more details can be seen in this image of the prototype saber:

View attachment 1658698

8. Black Emitter Section - I believe this portion of the original saber was clearly cast resin, in fact, based on the reference images its clear it was even slightly warped/out of round. Since accurately replicating that would be too challenging for very little noticeable difference, several of the imperfections were incorporated into the machined delrin replica. For example, the spacing and depths of the grooves vary ever so slightly (seen in the model screenshot above with the red lines).

9. Emitter Bezel & Fender Washer - It is very clear from both the reference images of the original hero prop and Anakin Starkiller's resin stunt saber that at some point the saber was damaged or assembled incorrectly, because the emitter bezel is angled and off axis with the rest of the saber. This is something that Dan was adamant about replicating accurately. As such there are two interchangeable aluminum cores that can be used to assemble the saber. The first ensures that the bezel and washer are correctly angled and off center, just like in the reference images this results in slight gaps between the tops of one or two of the emitter posts and the bottom of the emitter bezel. The second emitter core allows for the bezel and washer to be assembled on to the saber centered and level. This swapable configuration is a really cool detail that I'm really glad we were able to incorporate into this replica.

There are dozens of additional details that I have not outlined in this post. This is really just a summary of how we got to where we are. Hopefully it is totally apparent that Dan and I are obsessed with this saber and made no compromises when it comes to accurately replicating this prop.

Sa1yan5pirit

Active Member

Wow... All I can say is thank you for your work and dedication guys  .

.

Been wanting something like this since 99.

Looking forward to a Qui-Gon and Maul (in the far future). *fingers crossed*

Been wanting something like this since 99.

Looking forward to a Qui-Gon and Maul (in the far future). *fingers crossed*

Anakin Starkiller did the Maul a couple of years ago:Wow... All I can say is thank you for your work and dedication guys.

Been wanting something like this since 99.

Looking forward to a Qui-Gon and Maul (in the far future). *fingers crossed*

Malice Double Bladed Laser Sword Kit | Stars' End

Most of the time, when you see a prop on screen in a Sci-fi or Fantasy film, even though you're meant to think its tritanium or durasteel, what you're actually looking at is a cast resin piece. And although some prop replicators might choose to idealize their collection, fashioning an...

www.atstarsend.com

www.atstarsend.com

Last edited:

Sa1yan5pirit

Active Member

Thanks I ordered this now. Hopefully I can get all the remaining parts for assembly here in europe. I might have to order the rod via amazon us.Anakin Starkiller did the Maul a couple of years ago:

Malice Double Bladed Laser Sword Kit | Stars' End

Most of the time, when you see a prop on screen in a Sci-fi or Fantasy film, even though you're meant to think its tritanium or durasteel, what you're actually looking at is a cast resin piece. And although some prop replicators might choose to idealize their collection, fashioning an...www.atstarsend.com

Similar threads

- Replies

- 43

- Views

- 3,616

- Replies

- 2

- Views

- 873

- Replies

- 11

- Views

- 2,423

- Replies

- 2

- Views

- 1,650

- Replies

- 3

- Views

- 305