craig g

Sr Member

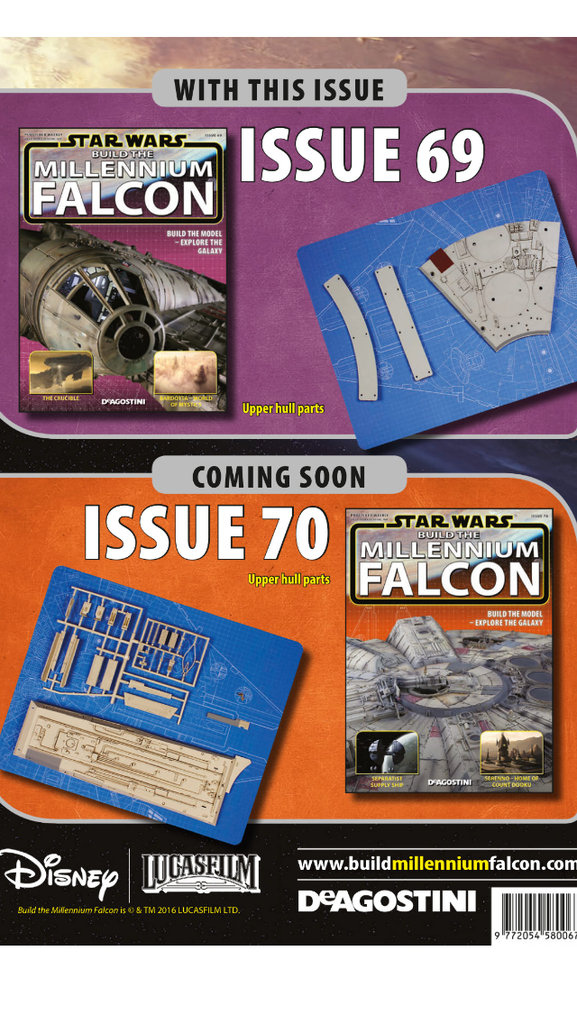

So I heard that in issue 70 we will start seeing one of the mandibles, or at least part of one. Does anyone have any photos? Even if someone has some photos of the rear deck it would be great!

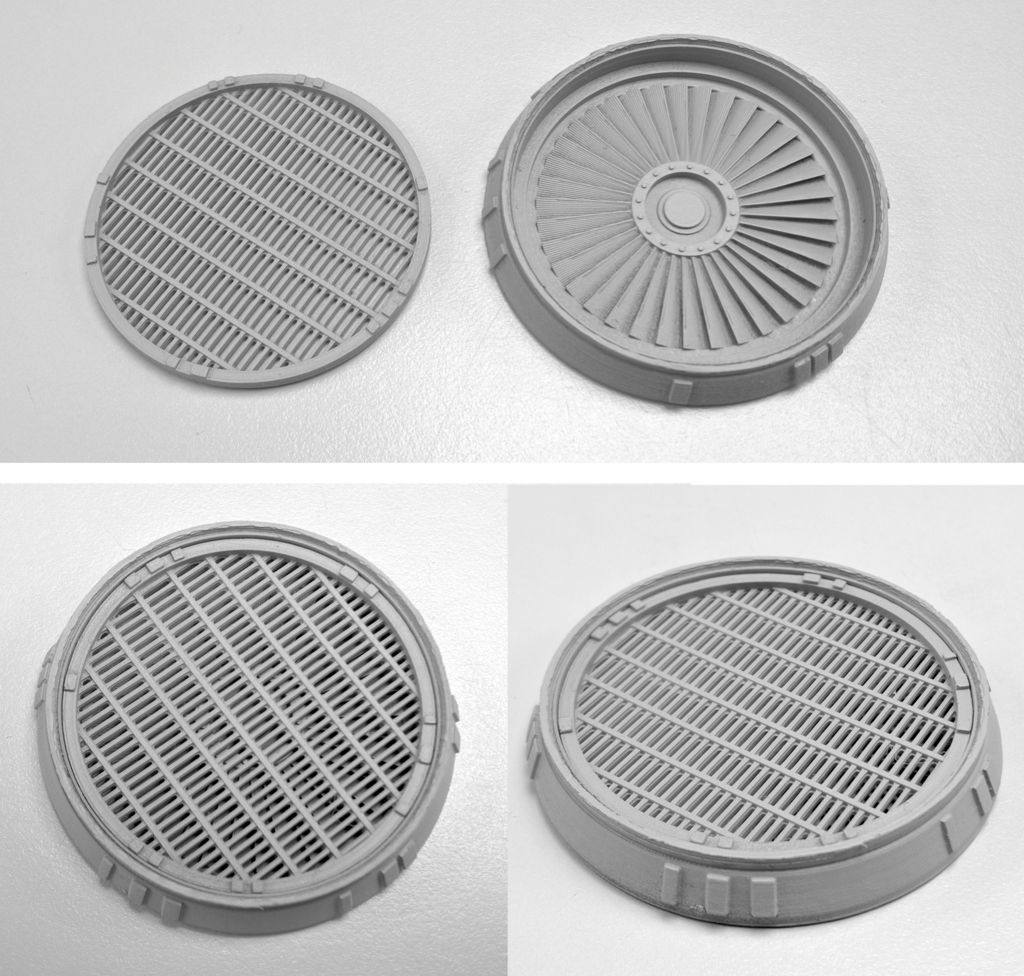

Good view of the engine deck about 20 seconds into this video https://youtu.be/i7MMsM-YwDA