sandbagger

Master Member

BOOYAAAAHHHH!! FRAK YEAH! Finally back to the Viper build!

My other major projects are all but done, so it's time to get stuck into it.

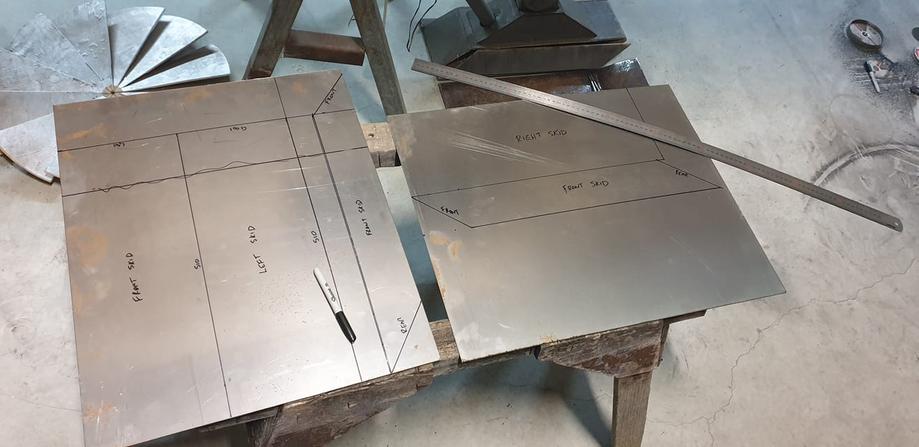

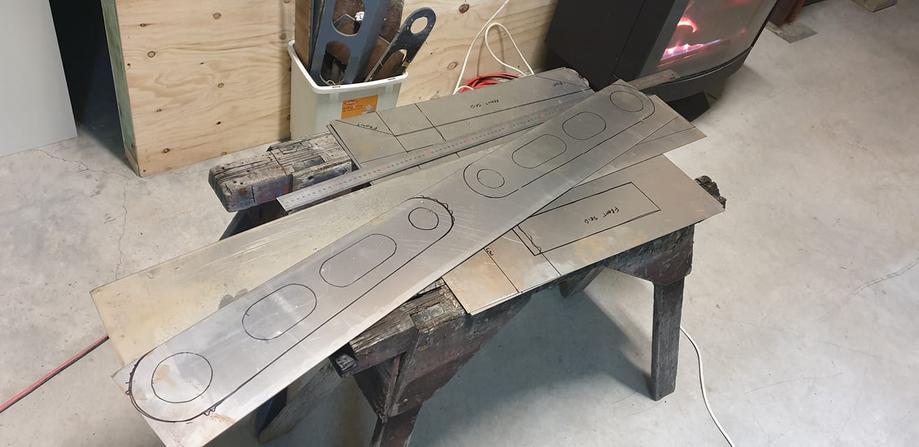

Last night I started by pulling all the plywood cladding off the landing gear and started to replace it with steel. I am also fitting concealed axle mounts in the skids, so I can put temporary wheels on each one, for moving the ship when needed.

As I go, I am repairing all the damaged polystyrene, caused by moving it around the property. I've already spent some time realigning modules that have shifted, so the fit is flush.

When I can, I will look at getting the canopy along to an aluminium welding service to get it solidified, positioning brackets removed, then get some polycarbonate windows fitted into it.

The turbines, front and rear need to be tuned and joined with through- driveshafts, then belted to a clutched, central drive motor. I've pulled out the front turbine fans to get a clear look through the nacelle and plan it out.

I repaired the wiring of some of the cockpit instruments last night. The sound system needs more work.

The wing frames need to be welded together, fitted then skinned, then fit the cannons.

Plans for an 8 metre low-rider trailer are in the works, with fold down sides and removable roof, for weatherproofing, security and transport to shows.

Lots to do.

Baz.

My other major projects are all but done, so it's time to get stuck into it.

Last night I started by pulling all the plywood cladding off the landing gear and started to replace it with steel. I am also fitting concealed axle mounts in the skids, so I can put temporary wheels on each one, for moving the ship when needed.

As I go, I am repairing all the damaged polystyrene, caused by moving it around the property. I've already spent some time realigning modules that have shifted, so the fit is flush.

When I can, I will look at getting the canopy along to an aluminium welding service to get it solidified, positioning brackets removed, then get some polycarbonate windows fitted into it.

The turbines, front and rear need to be tuned and joined with through- driveshafts, then belted to a clutched, central drive motor. I've pulled out the front turbine fans to get a clear look through the nacelle and plan it out.

I repaired the wiring of some of the cockpit instruments last night. The sound system needs more work.

The wing frames need to be welded together, fitted then skinned, then fit the cannons.

Plans for an 8 metre low-rider trailer are in the works, with fold down sides and removable roof, for weatherproofing, security and transport to shows.

Lots to do.

Baz.