You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BTTF 2 Docs binoculars build

- Thread starter Coinprop

- Start date

-

- Tags

- binoculars bttf bttf2 docbrown

OncleCharlie

Active Member

I’m finishing up the run I’m doing on the Mondoshawan bust, and it will be done within a few weeks.

I don’t like having to many projects at the same time, so I can’t commit to anything until I’m done with the busts.

The binoculars will be done in a run, and I will start a interest thread soon, and if there is any interest I will make it in to a run.

And since all the parts are already done and I have a master and molds, so when started it will not take long.

I don’t like having to many projects at the same time, so I can’t commit to anything until I’m done with the busts.

The binoculars will be done in a run, and I will start a interest thread soon, and if there is any interest I will make it in to a run.

And since all the parts are already done and I have a master and molds, so when started it will not take long.

MAKE BELIEVE

Master Member

Good. Do keep us updated

I made an interest thread, if some of you guys are still interested in this.

www.therpf.com

www.therpf.com

Limited Run - BTTF II Docs binoculars

Hey I made a build thread a while back when I made Doc’s future binoculars for my own collection. And many asked if I’d do a run, and since there was some interest then, I thought that I would check to see if there is interest now. I haven’t decided if it will be a kit or a finished...

I thought that I would do a quick “how I did it” when building the binocs.

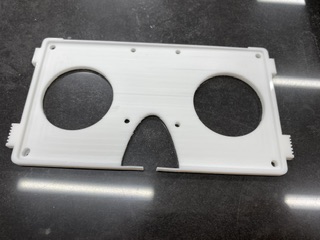

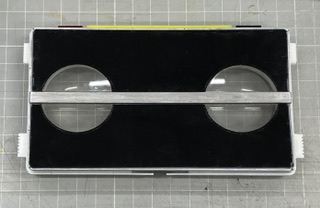

This is the kit.

Start by taking all the flat parts except for the lenses and lay them flat on a sanding paper and lightly sand them until they are flat to the surface.

I always have a flat stone in the shop that I can lay a sandpaper on, that way I get a very flat surface. But a desktop is also good.

Hold the piece as flat as possible and move it in circular motions, or a figure 8!

And also check that they fit to each other, if they don’t just take a file or sand paper until they do.

The material is very easy to sand, so do it in baby steps so you don’t overdo it!

Also sand the white base part the same way.

Make sure it fits the stand.

Step 2

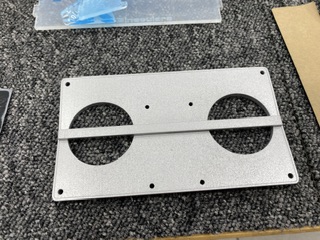

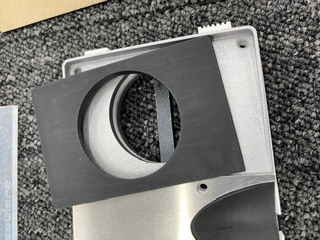

When all the parts fit nicely together it’s time for the aluminum part.

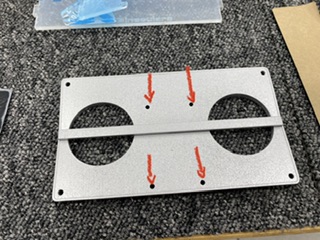

Place it between the pieces as in the image below, use the “base part” as a base to hold all the parts together. Sand the sides of the aluminum plate until it fits freely but snug.

Turn everything around and use the holes in the base part to mark the aluminum plate with a sharpie.

And now punch the markings and drill holes that are 4mm (or just slightly smaller than the screw heads.

This is the kit.

Start by taking all the flat parts except for the lenses and lay them flat on a sanding paper and lightly sand them until they are flat to the surface.

I always have a flat stone in the shop that I can lay a sandpaper on, that way I get a very flat surface. But a desktop is also good.

Hold the piece as flat as possible and move it in circular motions, or a figure 8!

And also check that they fit to each other, if they don’t just take a file or sand paper until they do.

The material is very easy to sand, so do it in baby steps so you don’t overdo it!

Also sand the white base part the same way.

Make sure it fits the stand.

Step 2

When all the parts fit nicely together it’s time for the aluminum part.

Place it between the pieces as in the image below, use the “base part” as a base to hold all the parts together. Sand the sides of the aluminum plate until it fits freely but snug.

Turn everything around and use the holes in the base part to mark the aluminum plate with a sharpie.

And now punch the markings and drill holes that are 4mm (or just slightly smaller than the screw heads.

Last edited:

Step 3

Take the parts that is going to be silver/Metall and check them if they needs any filling, then prime them lightly.

When dried paint with silver if your choosing.

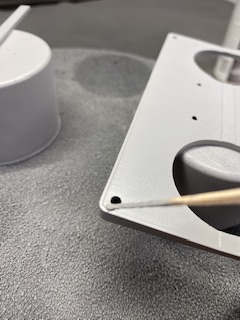

Small tip!

If there is a micro “hole” that is visible when priming, spray a little primer on a lid or something, then take a toothpick or something else and dip it in the primer paint, then apply it to the hole and it will suck itself in there and fill out the micro hole.

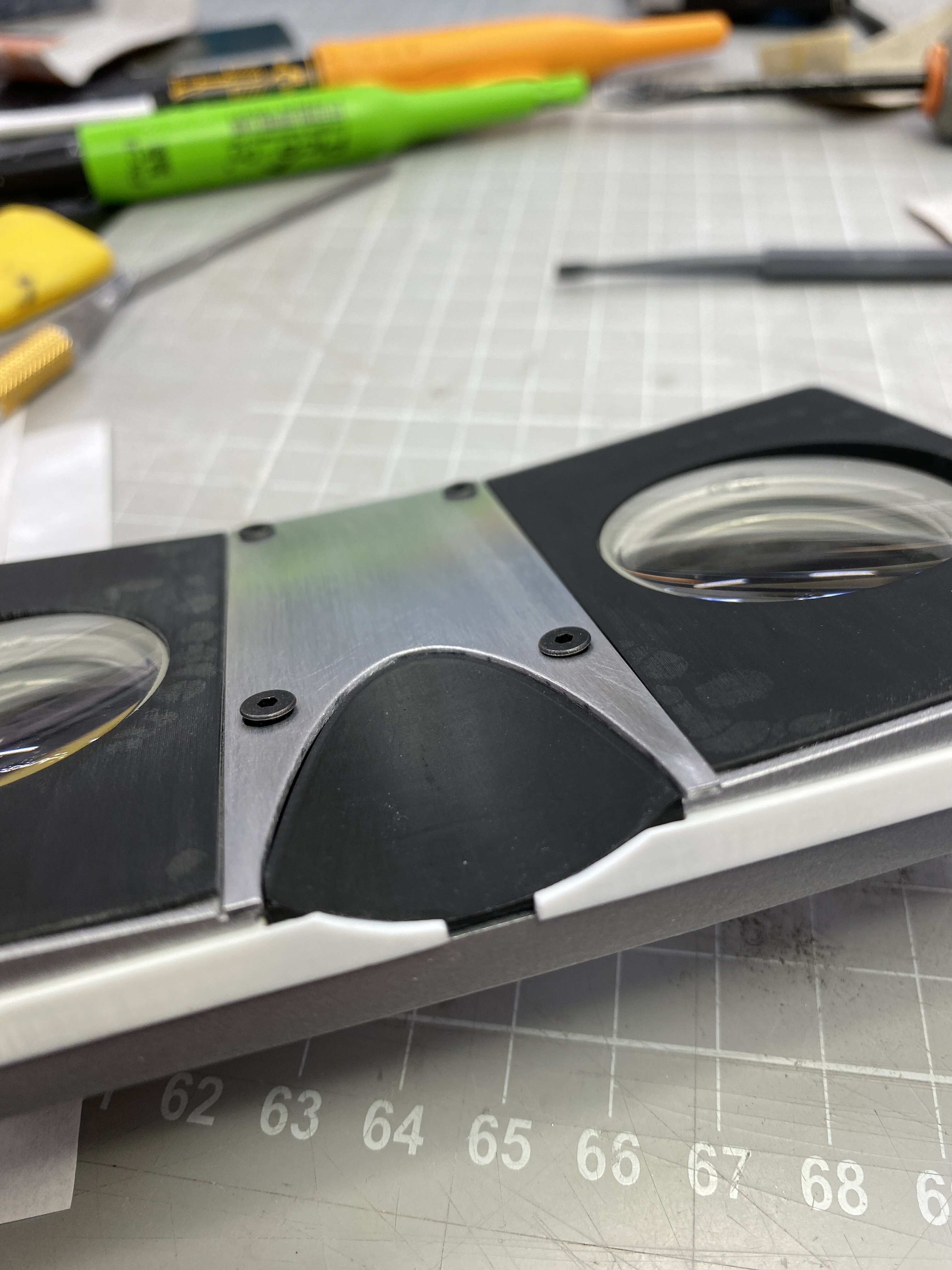

When this is done glue these pieces together as in the picture.

Now it’s time for the lenses, please check everything that it all fits together. And the lenses should have its highest point at the lowest edge of the black part in the picture.

Glue the lenses with loctite fast glue (or any other fast glue) and please be careful not to get too much glue that spills out on the lens. Use a toothpick or something to apply the glue as this gives you more control, and it’s very tight between the lenses and the base part.

Now glue the black parts that fits over the lense (as in the picture).

And now is a good time to use a black marker to paint this section black.

When fitting the “black nose piece” to the base frame, just scratch the surface on the base piece with an exacto knife until you can get the nosepiece i side.

Then use the aluminum plate as a guide to carve away the rest of the material, until the nosepiece fits.

Take the parts that is going to be silver/Metall and check them if they needs any filling, then prime them lightly.

When dried paint with silver if your choosing.

Small tip!

If there is a micro “hole” that is visible when priming, spray a little primer on a lid or something, then take a toothpick or something else and dip it in the primer paint, then apply it to the hole and it will suck itself in there and fill out the micro hole.

When this is done glue these pieces together as in the picture.

Now it’s time for the lenses, please check everything that it all fits together. And the lenses should have its highest point at the lowest edge of the black part in the picture.

Glue the lenses with loctite fast glue (or any other fast glue) and please be careful not to get too much glue that spills out on the lens. Use a toothpick or something to apply the glue as this gives you more control, and it’s very tight between the lenses and the base part.

Now glue the black parts that fits over the lense (as in the picture).

And now is a good time to use a black marker to paint this section black.

When fitting the “black nose piece” to the base frame, just scratch the surface on the base piece with an exacto knife until you can get the nosepiece i side.

Then use the aluminum plate as a guide to carve away the rest of the material, until the nosepiece fits.

Attachments

Last edited:

Step 4

Spray paint the front plate on one side, but first take off the protective film on one side and leave it be on the other side.

Repeat until there is a good solid layer of the transparent paint.

I use a spray paint that is a black translucent paint, used to paint car lamps or break light covers.

Here are the 2 versions. The first is a screen accurate paint job and the second is the prop seen on “screen used”.

Spray paint the front plate on one side, but first take off the protective film on one side and leave it be on the other side.

Repeat until there is a good solid layer of the transparent paint.

I use a spray paint that is a black translucent paint, used to paint car lamps or break light covers.

Here are the 2 versions. The first is a screen accurate paint job and the second is the prop seen on “screen used”.

Last edited:

Step 5

Before screwing in the screws, check that the holes line up, there is one of the holes that need a little tweaking, the way I did it was with a drill to make the hole a little larger, and it don’t matter if these holes are larger. (in the white base piece)

After the screws are in place, all the parts should be tight and secure together.

When you are happy, just apply a small drop of glue to the screws so the stay in place and keep the peace’s like a sandwich. (Image just for reference on the location for the glue)

Step 6

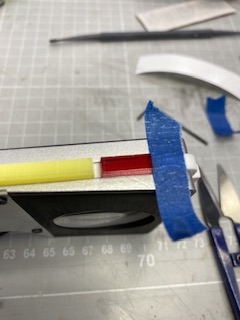

Put the double sided tape as in the picture.

Go ahead and please the “tinted” front plates as in the picture.

Note that it’s the painted side down!

Press firmly for a few seconds to secure it, repeat for both pieces. And make sure that it is flush with the flat rod in the middle.

Step 7

Glue the black “nose” piece in place. And trim down the white base part as in the picture. This can be done with a dremel, file or sandpaper, use the black nose part as guide. The finishing touches can be done with a sharp exacto knife.

Before screwing in the screws, check that the holes line up, there is one of the holes that need a little tweaking, the way I did it was with a drill to make the hole a little larger, and it don’t matter if these holes are larger. (in the white base piece)

After the screws are in place, all the parts should be tight and secure together.

When you are happy, just apply a small drop of glue to the screws so the stay in place and keep the peace’s like a sandwich. (Image just for reference on the location for the glue)

Step 6

Put the double sided tape as in the picture.

Go ahead and please the “tinted” front plates as in the picture.

Note that it’s the painted side down!

Press firmly for a few seconds to secure it, repeat for both pieces. And make sure that it is flush with the flat rod in the middle.

Step 7

Glue the black “nose” piece in place. And trim down the white base part as in the picture. This can be done with a dremel, file or sandpaper, use the black nose part as guide. The finishing touches can be done with a sharp exacto knife.

Last edited:

Last step

Put the yellow button in the middle so it have equal space to the left and right. Mark on side with some masking tape like in the picture.

And glue the yellow button in place.

Then mark the green and red the same way, and glue in place.

And now it’s all done!

This is the way I do it, but this is just a quick guide to get an idea on how it can be done. There are no wrong ways, just go slow and take your time.

I think it’s a very fun build, and this is the finished prop replica.

Put the yellow button in the middle so it have equal space to the left and right. Mark on side with some masking tape like in the picture.

And glue the yellow button in place.

Then mark the green and red the same way, and glue in place.

And now it’s all done!

This is the way I do it, but this is just a quick guide to get an idea on how it can be done. There are no wrong ways, just go slow and take your time.

I think it’s a very fun build, and this is the finished prop replica.

Similar threads

- Replies

- 18

- Views

- 1,043