TazMan2000

Master Member

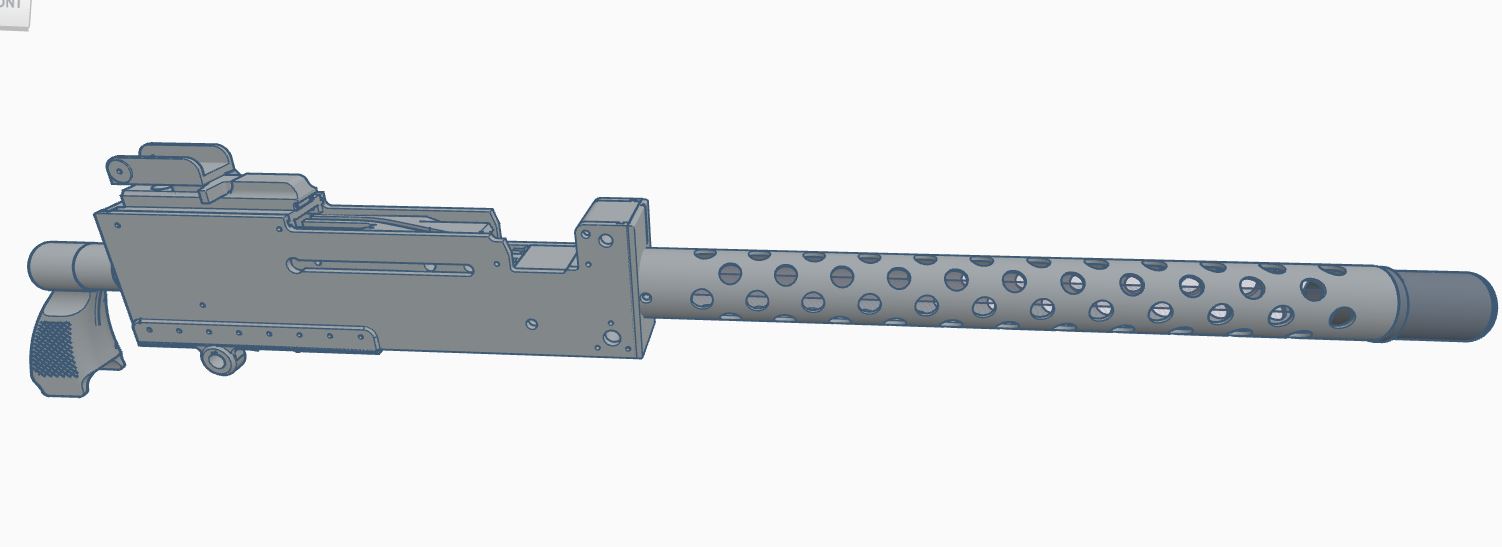

A member of Cults3D wanted a Browning M1919, so I decided to design the A4 version of that weapon. I managed to find some blueprints on this, so, I'm following them. I thought it would be easy with the blueprints, but not so much...probably because I'm doing some of the internal components and making these components movable.

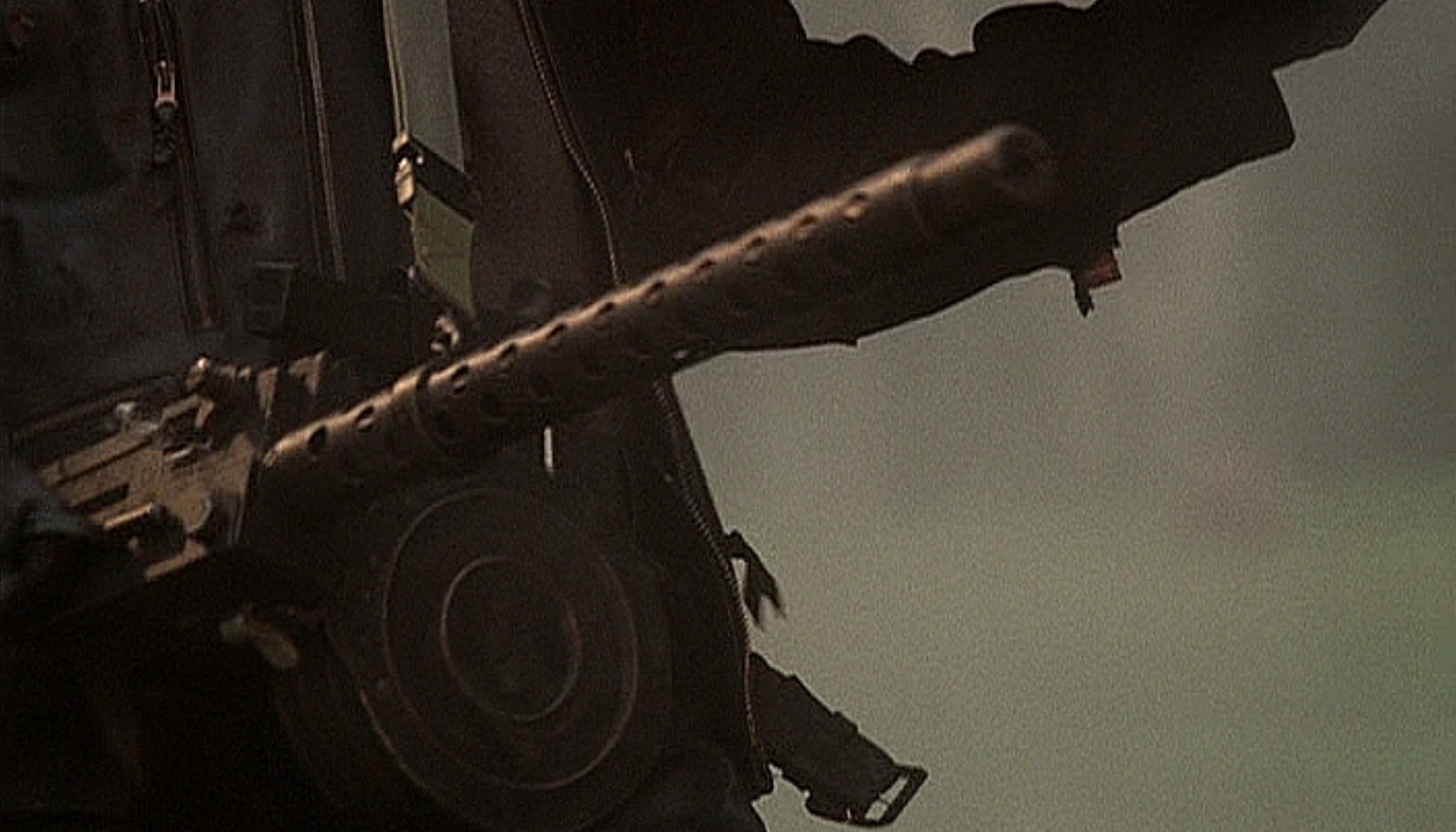

I'll probably design the ammo drum, that Arnie used in Terminator: Judgement Day, even though I don't believe it ever was designed in the real world.

TazMan2000

I'll probably design the ammo drum, that Arnie used in Terminator: Judgement Day, even though I don't believe it ever was designed in the real world.

TazMan2000