You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bugstomper

New Member

I'm truly fascinated by your build.

I do own several different models of the APC (Halcyon, HCG, Hiyatoys...) and none of them really fulfills my idea of the APC.

With the many differences between filming model, Full-Size Prop and interior set, there have to be compromises when trying to combine them into one model.

I think you did a great job so far, taking some liberties in some spots, but staying as close as possible to the references in others.

One example of "Stupid on-Screen" is the blue-ish shine of rear lights seen in the film (you can even make out hints of blue bulbs in the prop photos too).

I fully agree with you - the should be red anyway.

I do own several different models of the APC (Halcyon, HCG, Hiyatoys...) and none of them really fulfills my idea of the APC.

With the many differences between filming model, Full-Size Prop and interior set, there have to be compromises when trying to combine them into one model.

I think you did a great job so far, taking some liberties in some spots, but staying as close as possible to the references in others.

One example of "Stupid on-Screen" is the blue-ish shine of rear lights seen in the film (you can even make out hints of blue bulbs in the prop photos too).

I fully agree with you - the should be red anyway.

skiffy

Sr Member

Thank you Bugstomper, it's a continual compromise and gets me scratching my head sometimes but it's fun.

I did a little more on the chest armour tonight.

I won't be adding that much else - mainly the buckles/straps and the little shoulder insert bits. There's not much point adding a ton of detail for 1:18 scale and I'm still unsure quite how it'll be integrated with the figures.

I did a little more on the chest armour tonight.

I won't be adding that much else - mainly the buckles/straps and the little shoulder insert bits. There's not much point adding a ton of detail for 1:18 scale and I'm still unsure quite how it'll be integrated with the figures.

skiffy

Sr Member

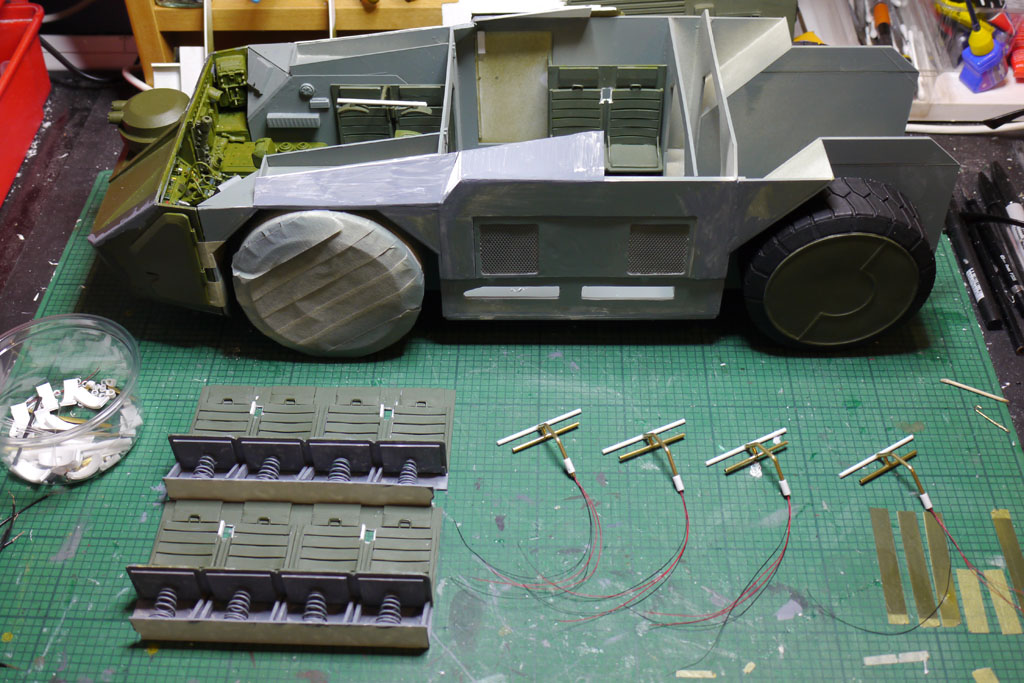

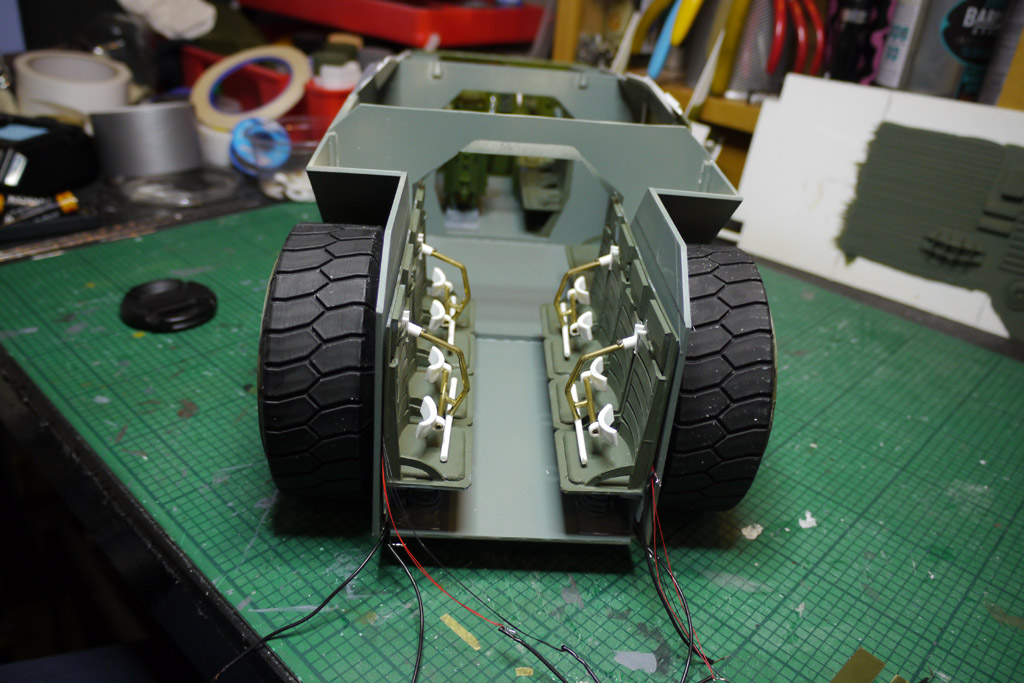

My new fibre optics and micro LED lights arrived so I could now crack on with fitting out the seat restraint lighting for the rear-bay seating area.

The tub at the left side contains all the components to build up the seat restraints. There's styrene sheet pads, brass tube, styrene brackets, brass hinge pins, fibre optic strand for the lighting - all sorts of stuff.

These long, hollow white styrene tubes have 2 back-to-back micro LEDs fitted in the middle and the wiring feeds through the brass tube and out the back. Dealing with that wiring (each wire is approx 0.2mm thick) is and will be a pain. I found that the only way to strip the insulation off it is to burn it off with a lighter. I'm not looking forward to soldering it - might need a microscope. LOL.

The tub at the left side contains all the components to build up the seat restraints. There's styrene sheet pads, brass tube, styrene brackets, brass hinge pins, fibre optic strand for the lighting - all sorts of stuff.

These long, hollow white styrene tubes have 2 back-to-back micro LEDs fitted in the middle and the wiring feeds through the brass tube and out the back. Dealing with that wiring (each wire is approx 0.2mm thick) is and will be a pain. I found that the only way to strip the insulation off it is to burn it off with a lighter. I'm not looking forward to soldering it - might need a microscope. LOL.

Awesome work, and a pleasure to watch this come together!

Have you come up with an explanation as to where the engine sits? Or what does it use for propulsion?

Have you come up with an explanation as to where the engine sits? Or what does it use for propulsion?

NostromoCrew - Thank you very much! Ah, yes, the engines. I reckon each wheel contains an electric radial engine powered by a fusion reactor somewhere.

Joberg - me too! Hopefully soon.

Right! Each wheel is powered by an integral built micro reactor. Needs refueling every 200 earth years.

Problem solved

skiffy

Sr Member

I'm back after a very busy week at college and I've devoted some time to this build - enough to warrant an update.

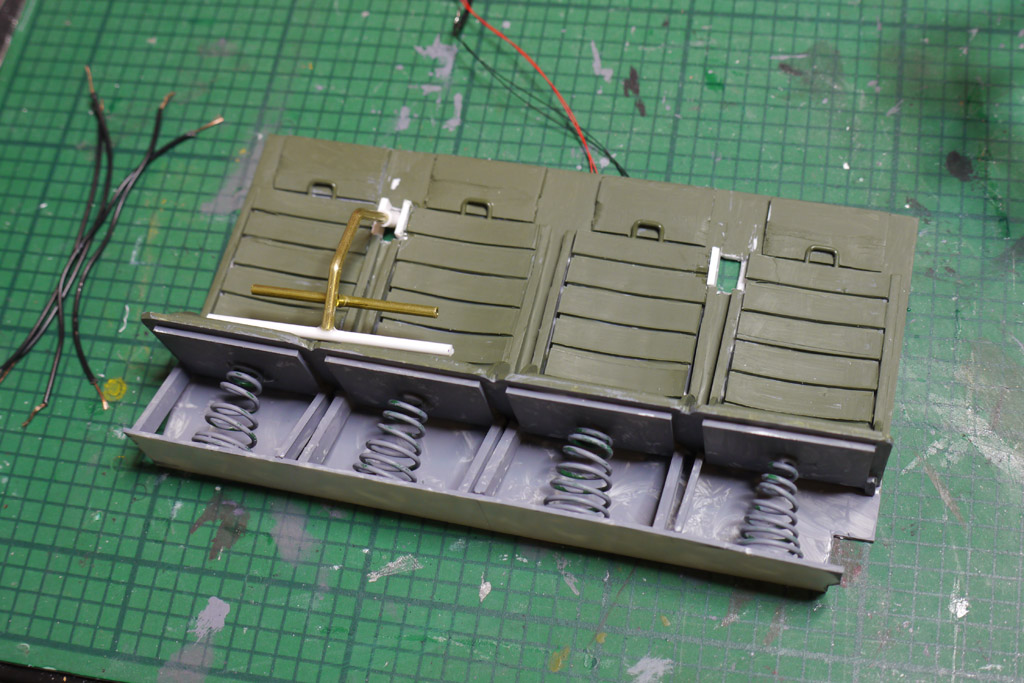

Here I'm building the hinges that let the seating restraints pivot up and down.

The tiny wires that lead from the LEDs need soldering onto more robust wiring that will connect them to the interior wiring loom later on.

These are the components for the torso pads.

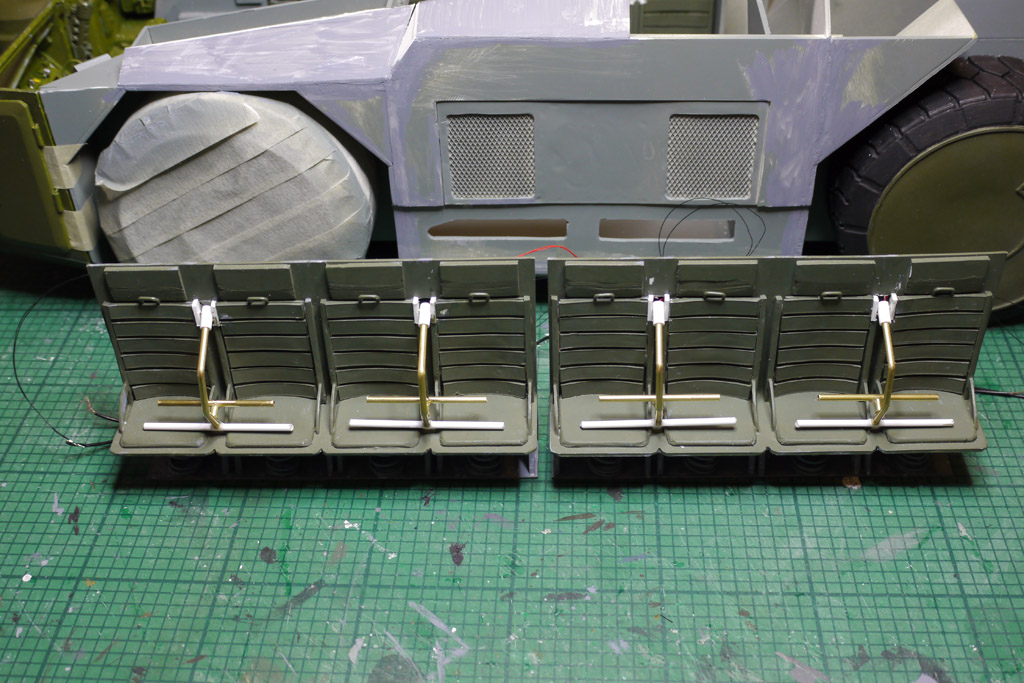

There's four all done! Next step is to add the torso pads.

Done, yay! I keep a grubby old pair of green plastic tweezers which are VERY handy for handling magnets - especially the ones I'll be adding here, which are 2mm x 1mm.

In this shot you can hopefully see two magnets glued to the base of the brass upright - right against the white hinge collar.

After matching magnets are embedded into the wall between the seats, they keep the restraints in the 'up' position.

..and here they are fully down.

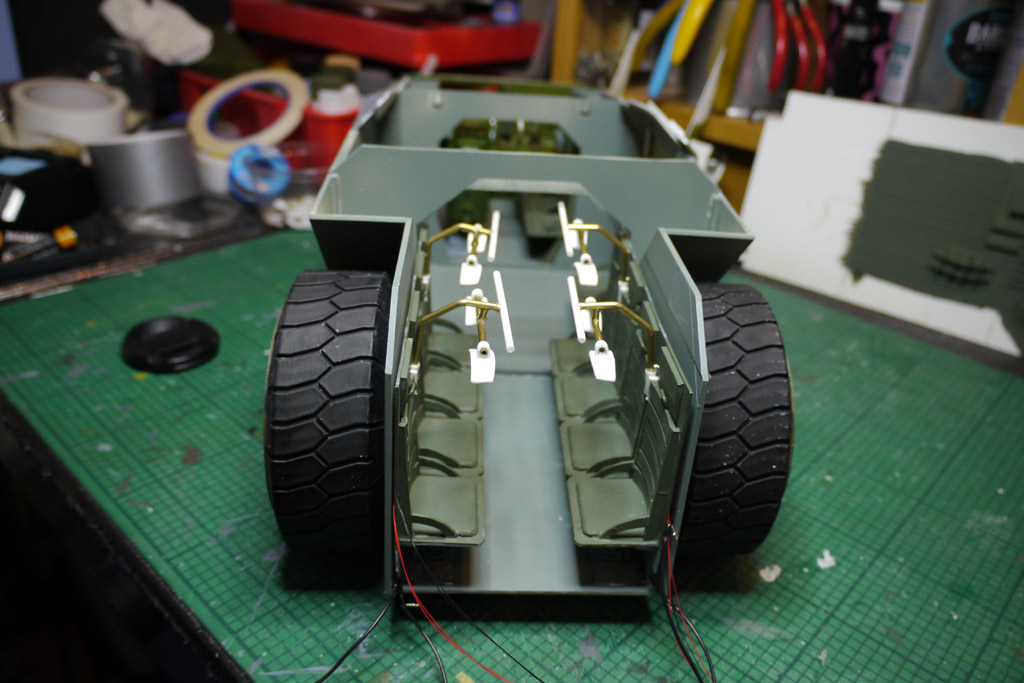

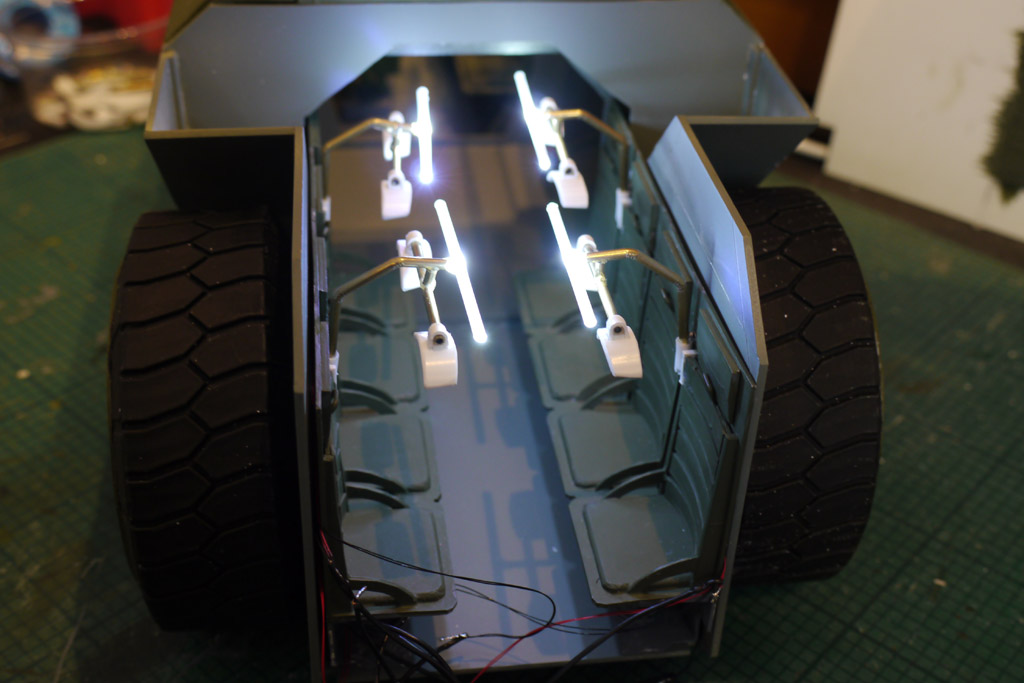

Of course I had to wire them up and see how it looked.

Not too shabby! On to painting next, then I'll add in some troops, put the roof on and we'll see how it all looks together.

Here I'm building the hinges that let the seating restraints pivot up and down.

The tiny wires that lead from the LEDs need soldering onto more robust wiring that will connect them to the interior wiring loom later on.

These are the components for the torso pads.

There's four all done! Next step is to add the torso pads.

Done, yay! I keep a grubby old pair of green plastic tweezers which are VERY handy for handling magnets - especially the ones I'll be adding here, which are 2mm x 1mm.

In this shot you can hopefully see two magnets glued to the base of the brass upright - right against the white hinge collar.

After matching magnets are embedded into the wall between the seats, they keep the restraints in the 'up' position.

..and here they are fully down.

Of course I had to wire them up and see how it looked.

Not too shabby! On to painting next, then I'll add in some troops, put the roof on and we'll see how it all looks together.

Lt Washburn

Sr Member

I appreciate that you're showing restraint(s).

skiffy

Sr Member

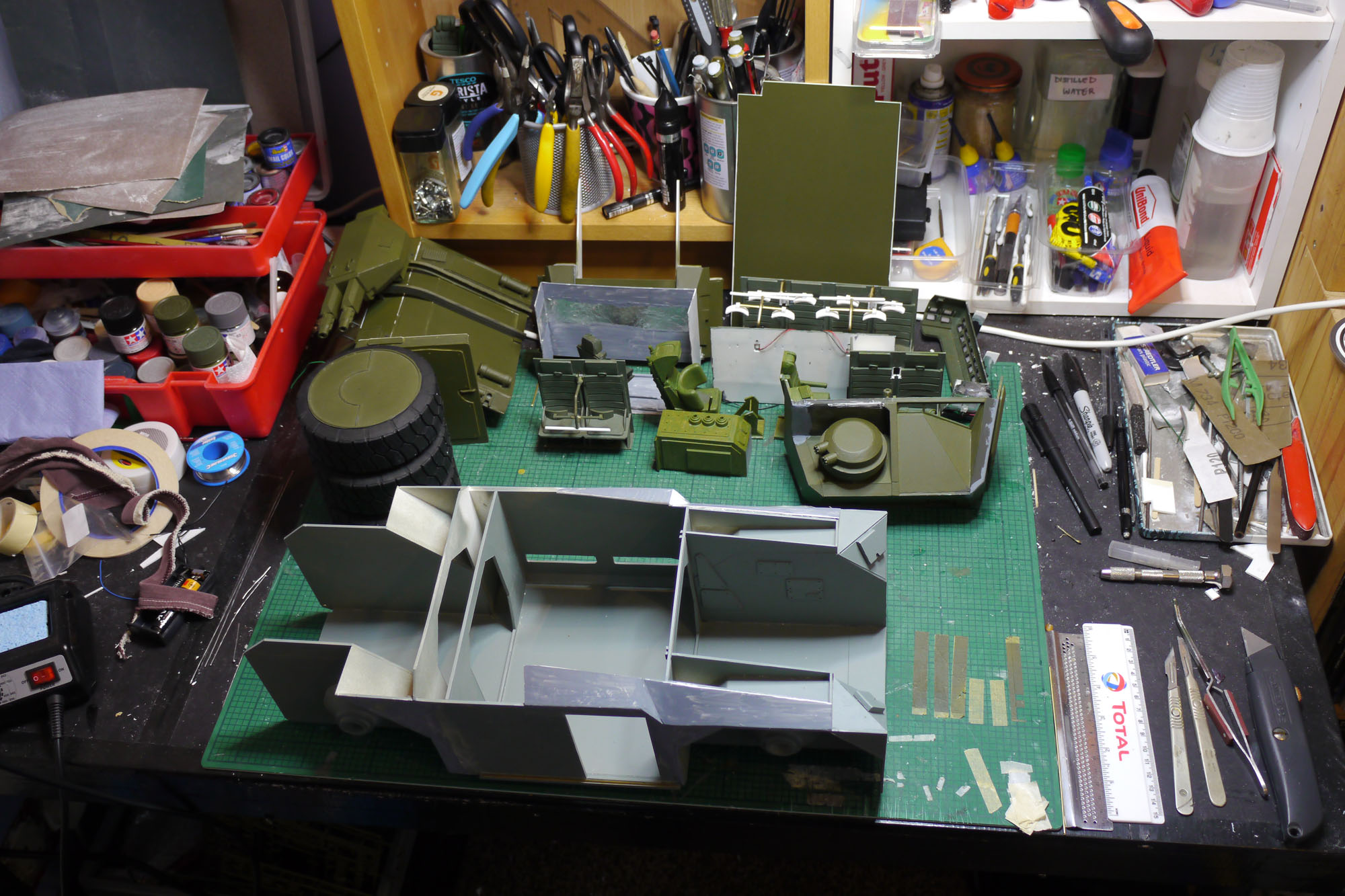

We're back. I’m just about done teaching for the year so I've finally got some time to come back to this build and I've started with a fairly stress-free task - spraying up the main chassis exterior with Tamiya Olive Drab TS-28 in the rattle can.

First up is of course to strip all the other parts off.

Then we're off to the shed to spray - luckily there's very little wind today.

Now it's back on the bench and getting everything put back.

That's looking good. I'm touching up some parts of the surface where I've filled gaps etc.

Next up is ordering micro slide switches for the battery packs (the existing ones are not reliable) and sorting out the wiring loom before I start dressing/painting the interior.

First up is of course to strip all the other parts off.

Then we're off to the shed to spray - luckily there's very little wind today.

Now it's back on the bench and getting everything put back.

That's looking good. I'm touching up some parts of the surface where I've filled gaps etc.

Next up is ordering micro slide switches for the battery packs (the existing ones are not reliable) and sorting out the wiring loom before I start dressing/painting the interior.

I've been wondering how this one was going  awesome project!

awesome project!

Tanolucas

Active Member

An incredible job in terms of quality and detail, you achieved everything to perfection. I have one half done, I started it before I had my 3d printer, I built it from a paper model, just change the paper for plastic sheets. I think I'll never finish it. Anyway, congratulations, it is a beautiful model that you made. I am waiting to see more progress.

markleighthomas

New Member

This is amazing! I'm going to build a 1/10 scale! Would you be kind enough to share your stl files?

skiffy

Sr Member

I will be doing at some point yes. I'll be collecting them together and cleaning them up. Of course there's a lot of scratch-building here too so the STLs are just a part of that.This is amazing! I'm going to build a 1/10 scale! Would you be kind enough to share your stl files?

A great place to start is with Graham Langridge's blueprints if you can get hold of them.

skiffy

Sr Member

Thank you Axlotl.

Yes, indeed Joberg. Hopefully not long now.

My daughter got married two weeks ago so I've been helping prep for that for a while. It was a fabulous wedding and the hard work setting it up paid off - it went without a hitch. Now I've got some time for hobbies again.

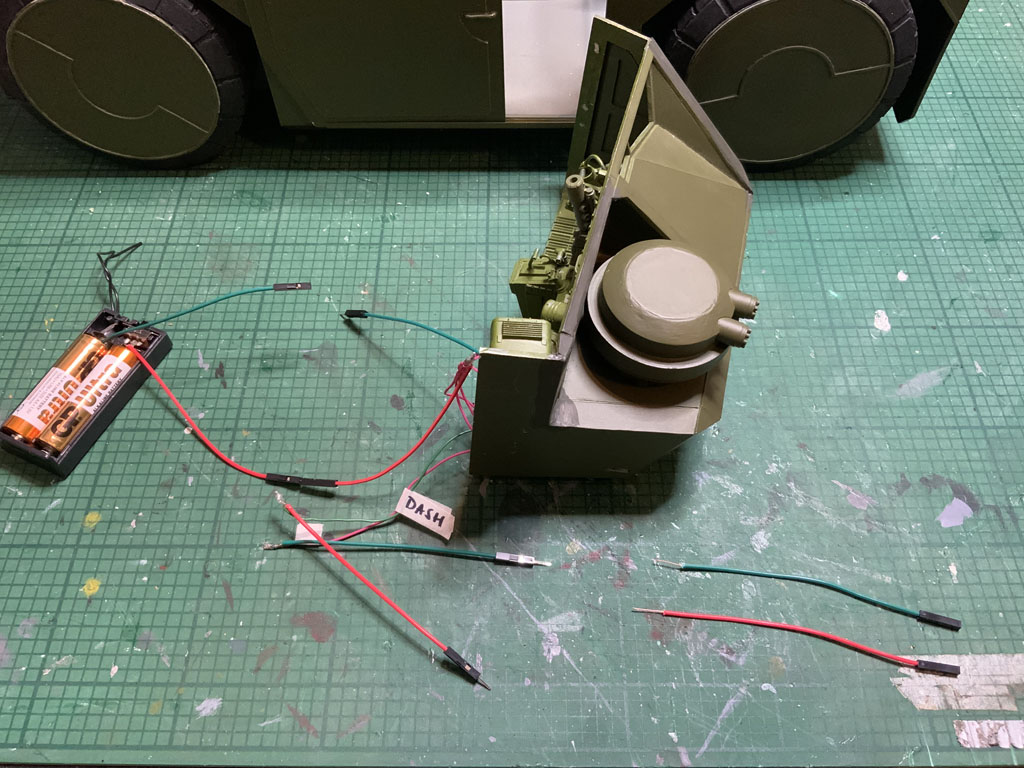

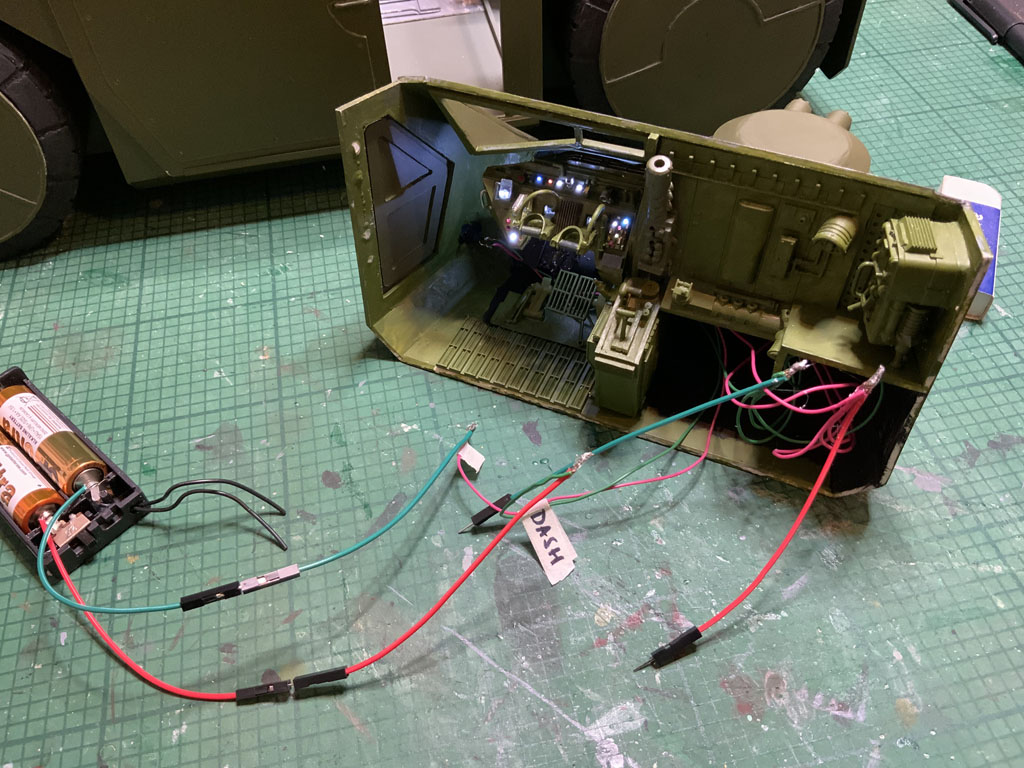

While figuring out how to wire all this stuff together I found these little connectors from an electronics kit. They're perfect for joining the lighting wiring between different sections of the build.

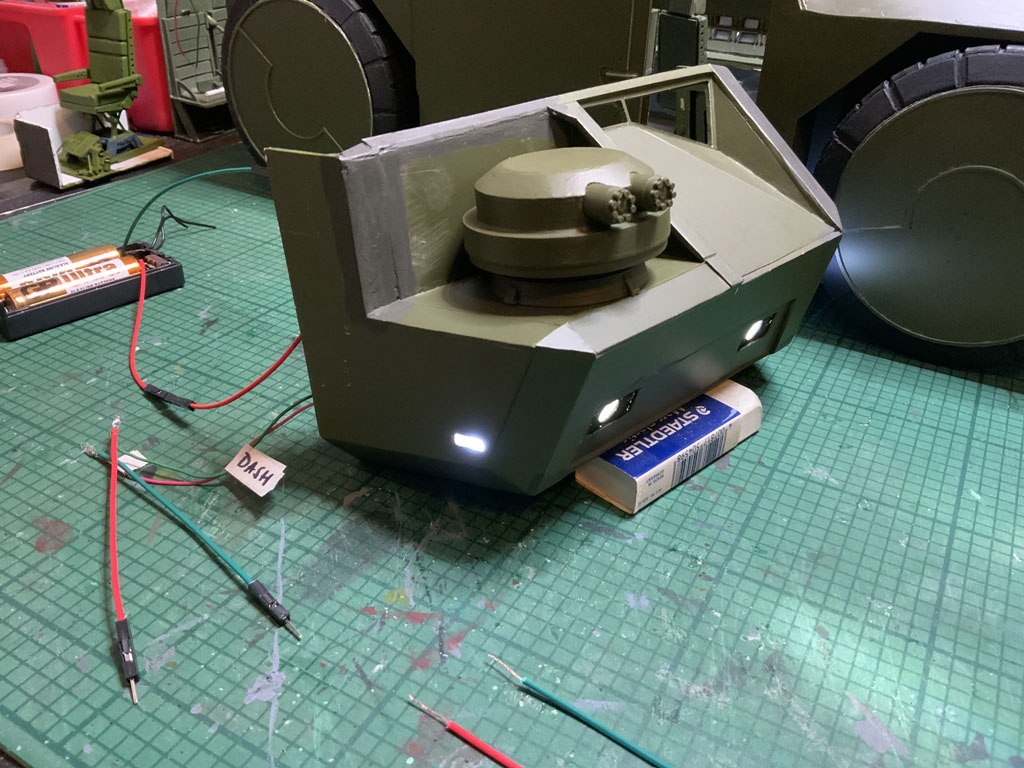

There will be two loops running throughout the APC, one for interior lighting, one for the exterior. I'll also have another switch somewhere for the main searchlight on top. I checked the exterior loop first.

..then the interior which is just the dashboard for now but will have an overhead red cabin light too.

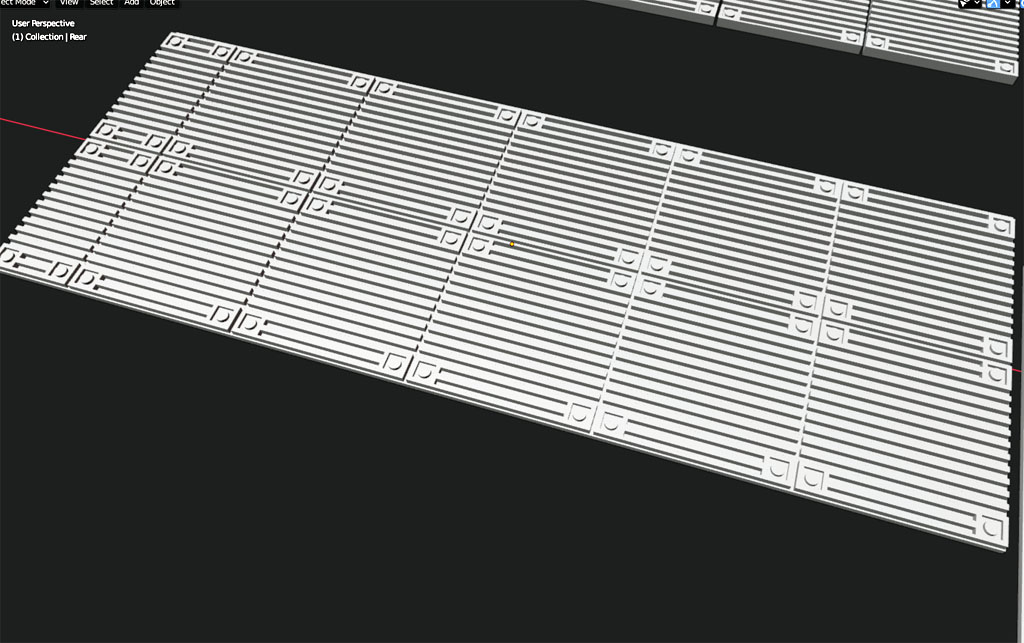

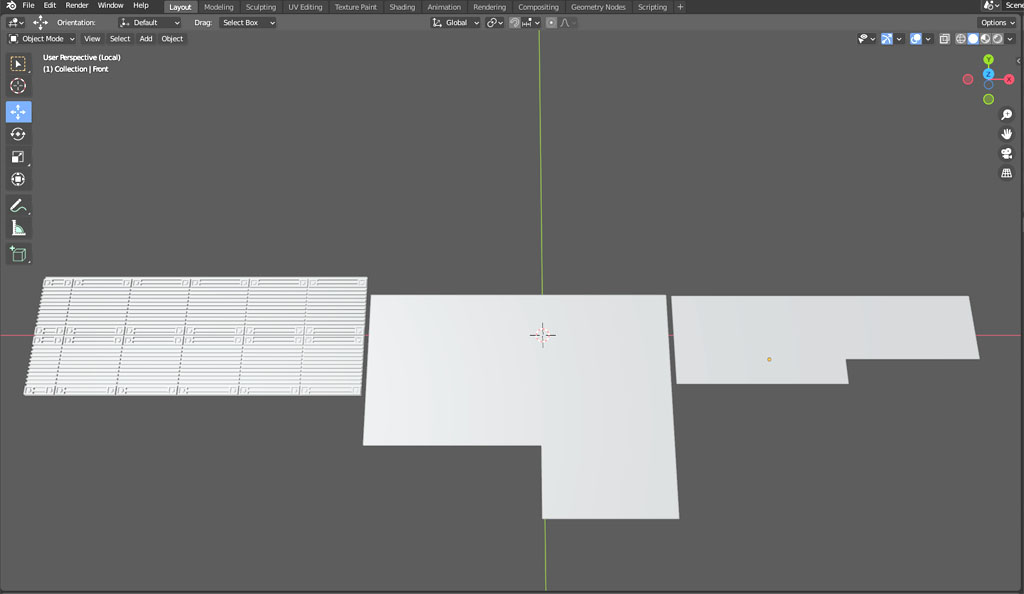

Another task I've been putting off is flooring panels. I recently got a 3d printer upgrade and have only just got the settings dialled in so I'll be printing these out.

I've measured the three floor panels and tested paper versions for fit.

I'll have a go at printing them out and update with progress.

Yes, indeed Joberg. Hopefully not long now.

My daughter got married two weeks ago so I've been helping prep for that for a while. It was a fabulous wedding and the hard work setting it up paid off - it went without a hitch. Now I've got some time for hobbies again.

While figuring out how to wire all this stuff together I found these little connectors from an electronics kit. They're perfect for joining the lighting wiring between different sections of the build.

There will be two loops running throughout the APC, one for interior lighting, one for the exterior. I'll also have another switch somewhere for the main searchlight on top. I checked the exterior loop first.

..then the interior which is just the dashboard for now but will have an overhead red cabin light too.

Another task I've been putting off is flooring panels. I recently got a 3d printer upgrade and have only just got the settings dialled in so I'll be printing these out.

I've measured the three floor panels and tested paper versions for fit.

I'll have a go at printing them out and update with progress.

skiffy

Sr Member

So, on to 3d printing. Here I've given the first print a coat of Olive Drab, a pin wash with black ink, then a light dry-brush with a sand/soil base.

Fits nice! The white section on the left is one of the paper templates.

I'm happy with the colour of this so I'll do the rest the same - maybe add some chipping wear later. I'll also finalise the paint and detail finish of a lot of the other interior fitments.

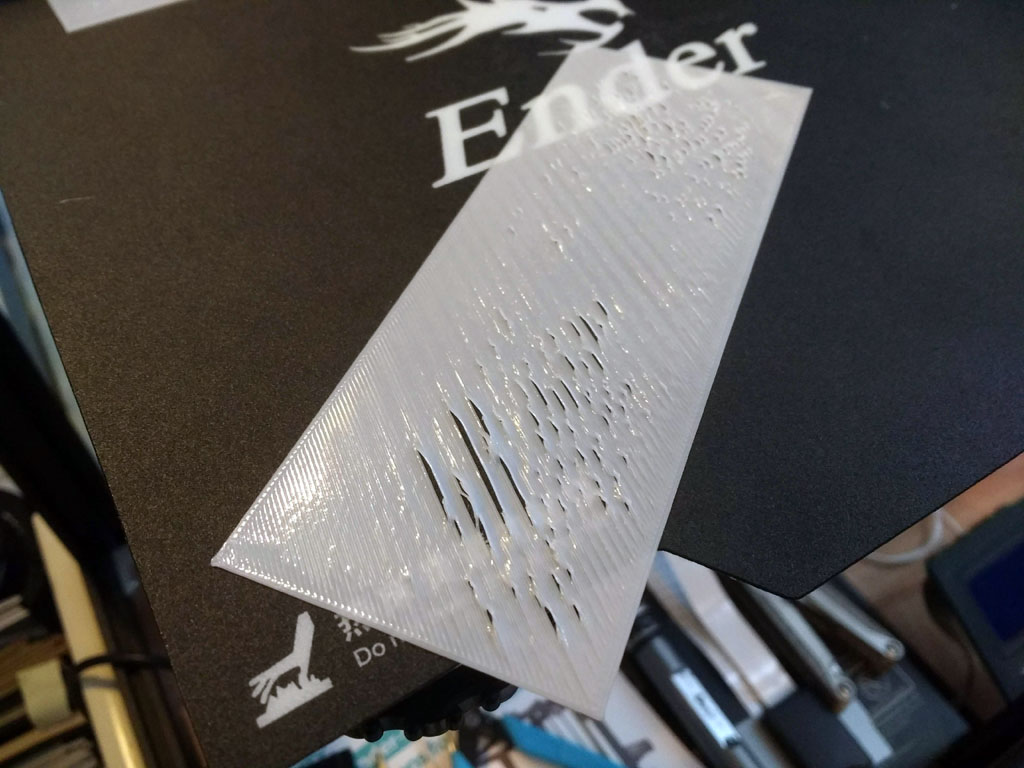

Of course not everything goes to plan and I promised, you'll get the whole journey - warts and all.

This first print wasn't going well. It's either the bed heating that's too low/high and/or damp filament (PLA). Anyway, I swapped to another filament reel and all was well for the second print.

Fits nice! The white section on the left is one of the paper templates.

I'm happy with the colour of this so I'll do the rest the same - maybe add some chipping wear later. I'll also finalise the paint and detail finish of a lot of the other interior fitments.

Of course not everything goes to plan and I promised, you'll get the whole journey - warts and all.

This first print wasn't going well. It's either the bed heating that's too low/high and/or damp filament (PLA). Anyway, I swapped to another filament reel and all was well for the second print.

Similar threads

- Replies

- 19

- Views

- 1,286

- Replies

- 24

- Views

- 1,936

- Replies

- 10

- Views

- 742