You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

joberg

Legendary Member

Unless it`s an all female crewyour model bud, any colour would look good on this model, well apart from pink

skiffy

Sr Member

Haha! I don't have any pink paint.

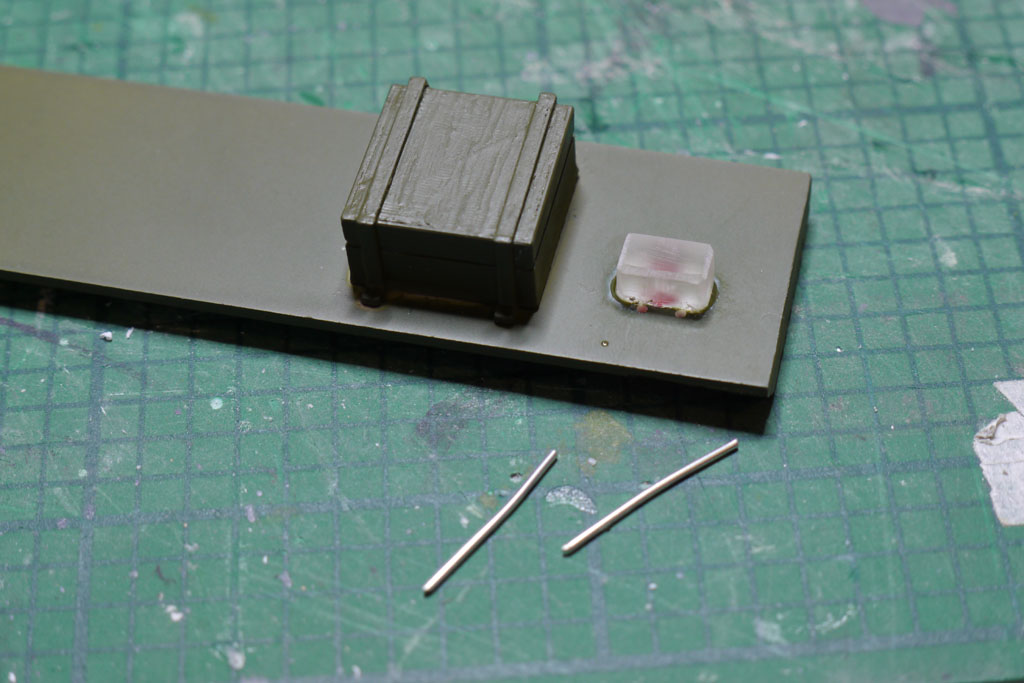

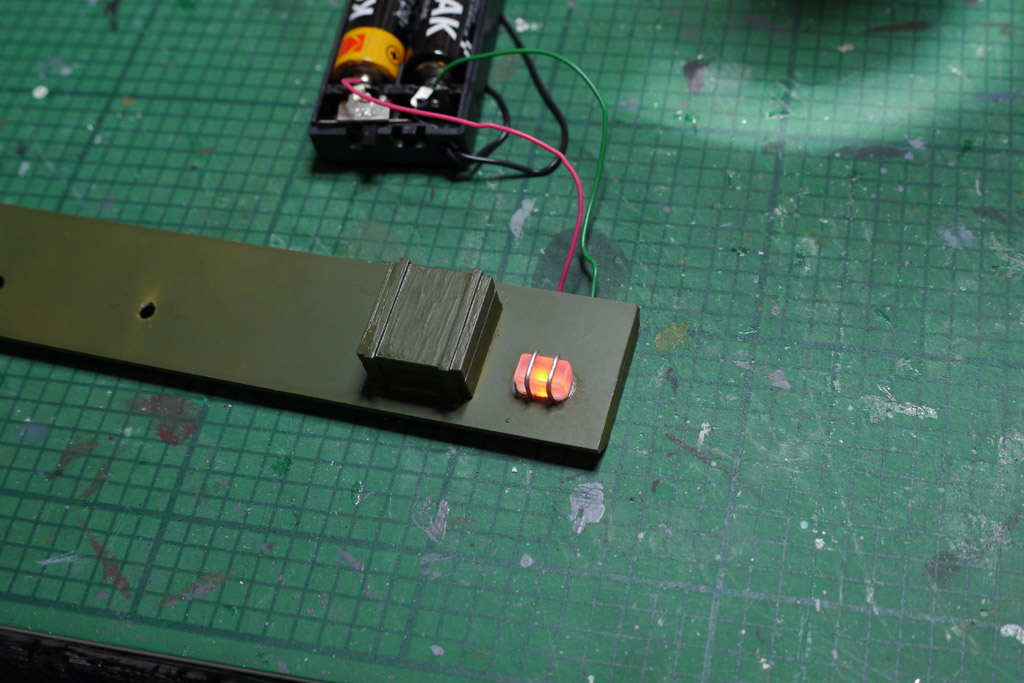

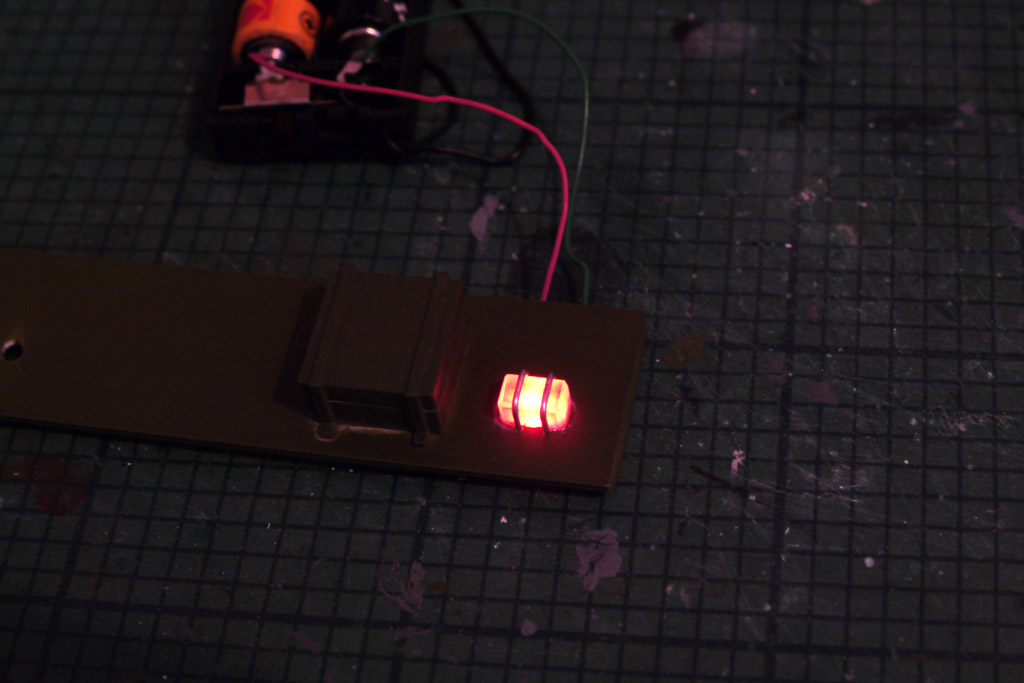

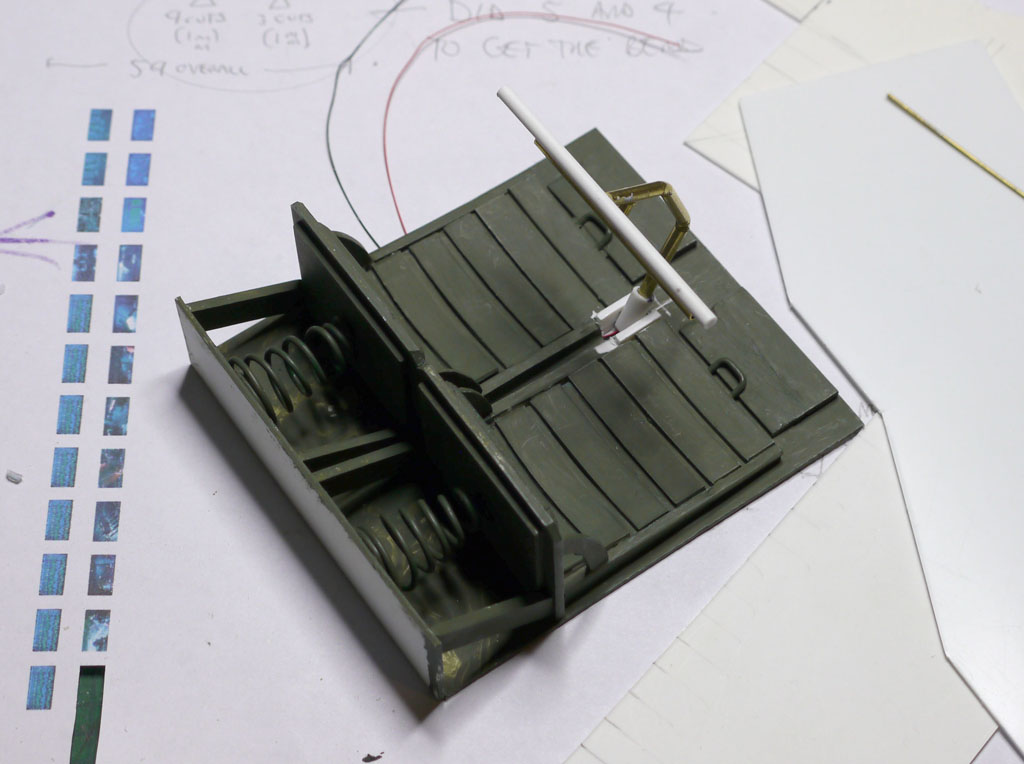

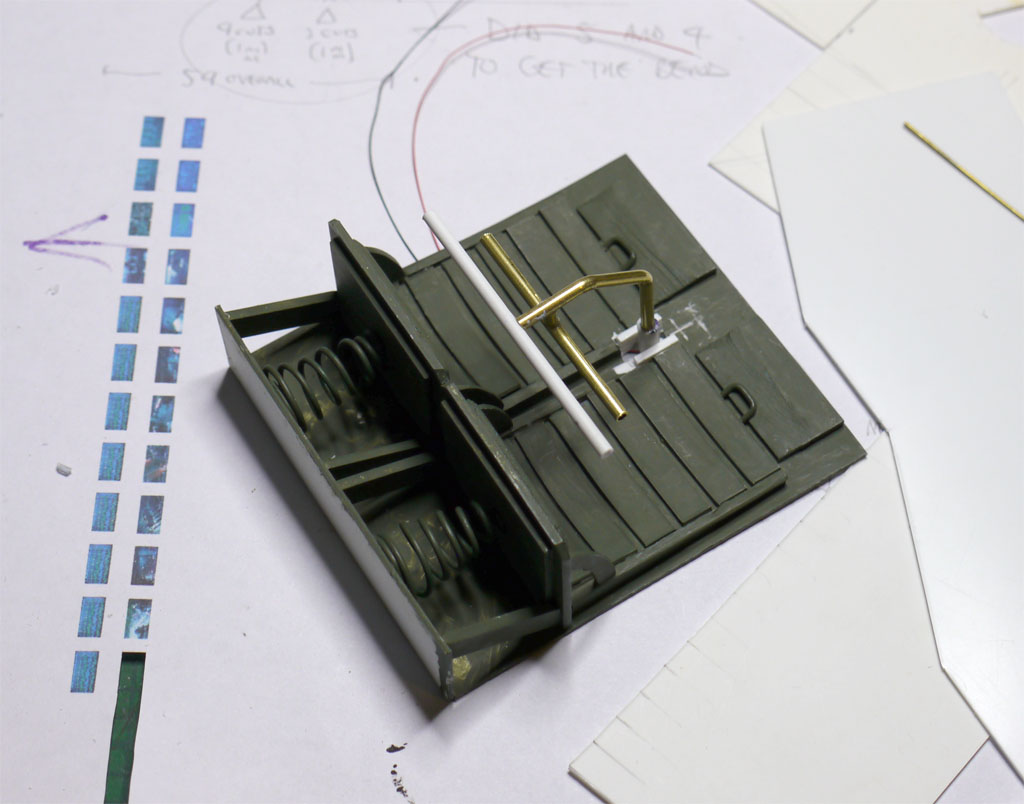

I've been wondering how to tackle the rear lights and I was planning to 3d print them and had made up a print file ready to go. My resin printer is busy at the moment and I had time to work today so I though - what the heck - I'll make them up from some clear stock.

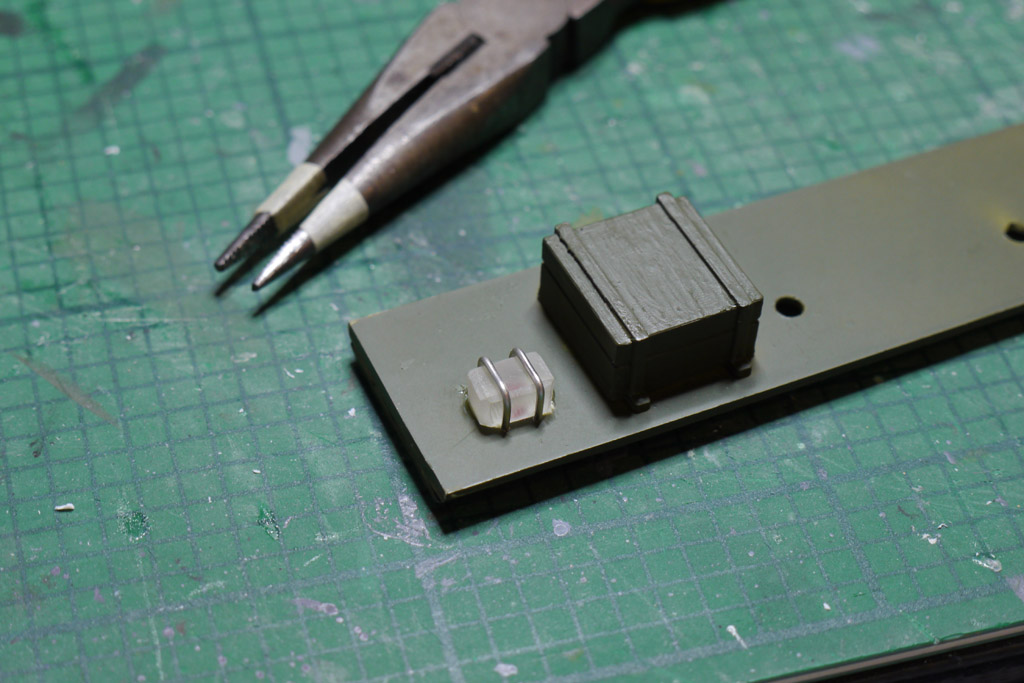

I've shaped the lens, left it cloudy and popped a red LED behind it. I'm making the wire protectors (brush guard type things) from 1mm solder.

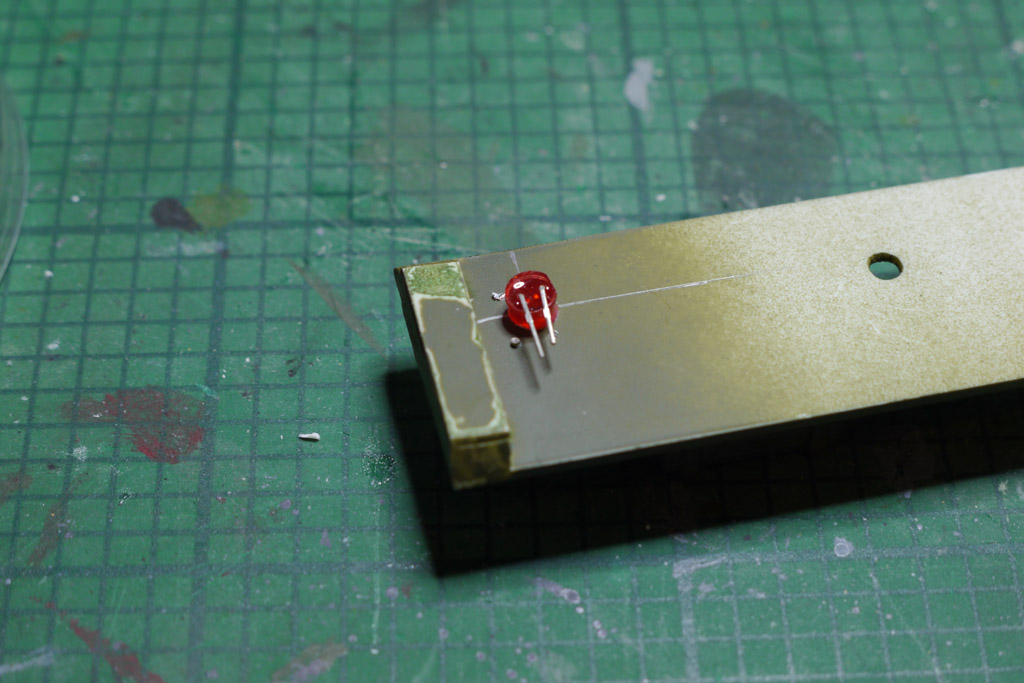

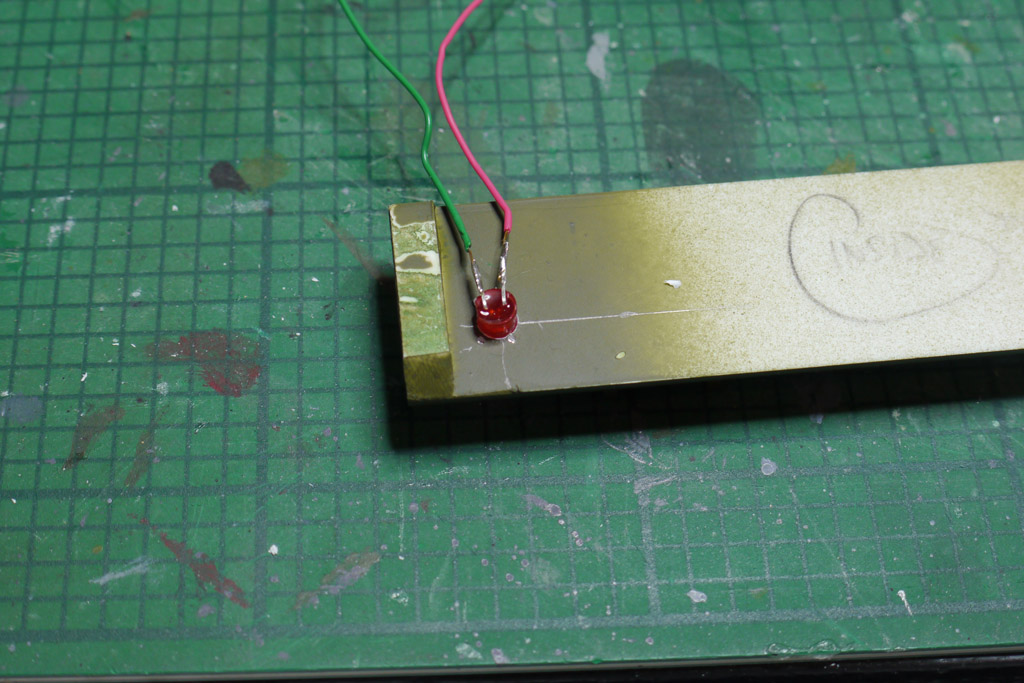

Here's one complete.

On the back-side I'll be light blocking the rest of the LED.

I'm getting better at soldering but still not great.

It doesn't look that great when floodlit for the camera. It looks better in real life.

..and with the light off.

I've been wondering how to tackle the rear lights and I was planning to 3d print them and had made up a print file ready to go. My resin printer is busy at the moment and I had time to work today so I though - what the heck - I'll make them up from some clear stock.

I've shaped the lens, left it cloudy and popped a red LED behind it. I'm making the wire protectors (brush guard type things) from 1mm solder.

Here's one complete.

On the back-side I'll be light blocking the rest of the LED.

I'm getting better at soldering but still not great.

It doesn't look that great when floodlit for the camera. It looks better in real life.

..and with the light off.

skiffy

Sr Member

Yes Joberg! I'm gaining in confidence as I go.

I did a little bit on the DSGR missiles today.

I printed out some missile tips in resin (you can see unused ones still on the base block). They just got a little dab of glue since they fit quite snug.

I cut Q-tips in half as holders while I paint the missiles. I'll be working on the bays and covers too but have to build the hinges first. More on that later.

I did a little bit on the DSGR missiles today.

I printed out some missile tips in resin (you can see unused ones still on the base block). They just got a little dab of glue since they fit quite snug.

I cut Q-tips in half as holders while I paint the missiles. I'll be working on the bays and covers too but have to build the hinges first. More on that later.

skiffy

Sr Member

I've painted and fitted the DSGR launchers. They pivot up and down really well.

Here they are in deployed mode. I won't be attaching the covers until the roof is painted and finished.

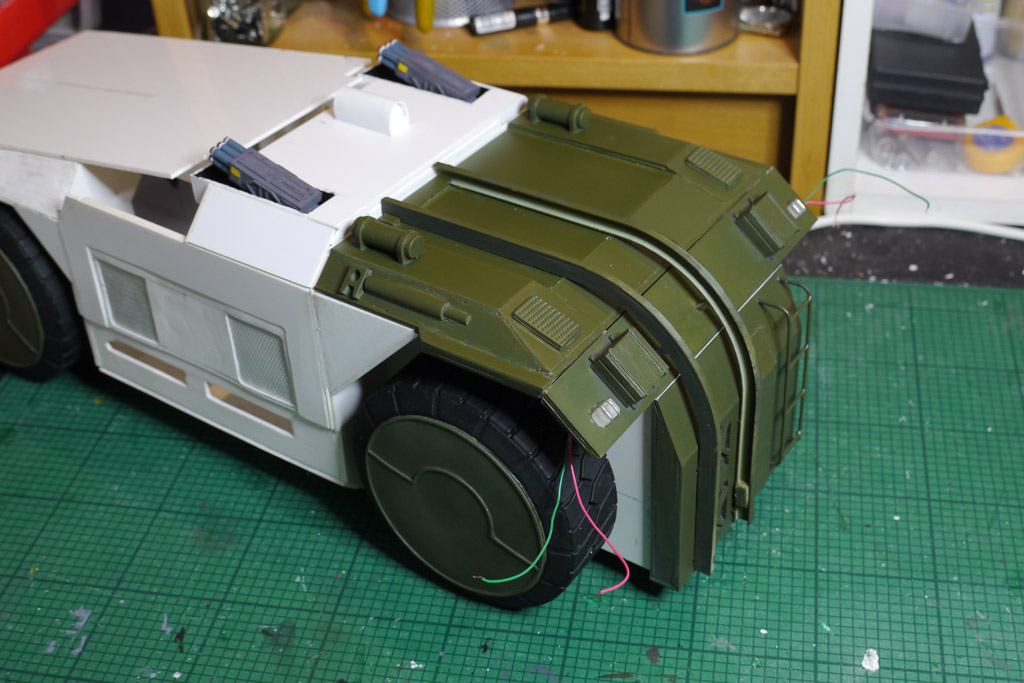

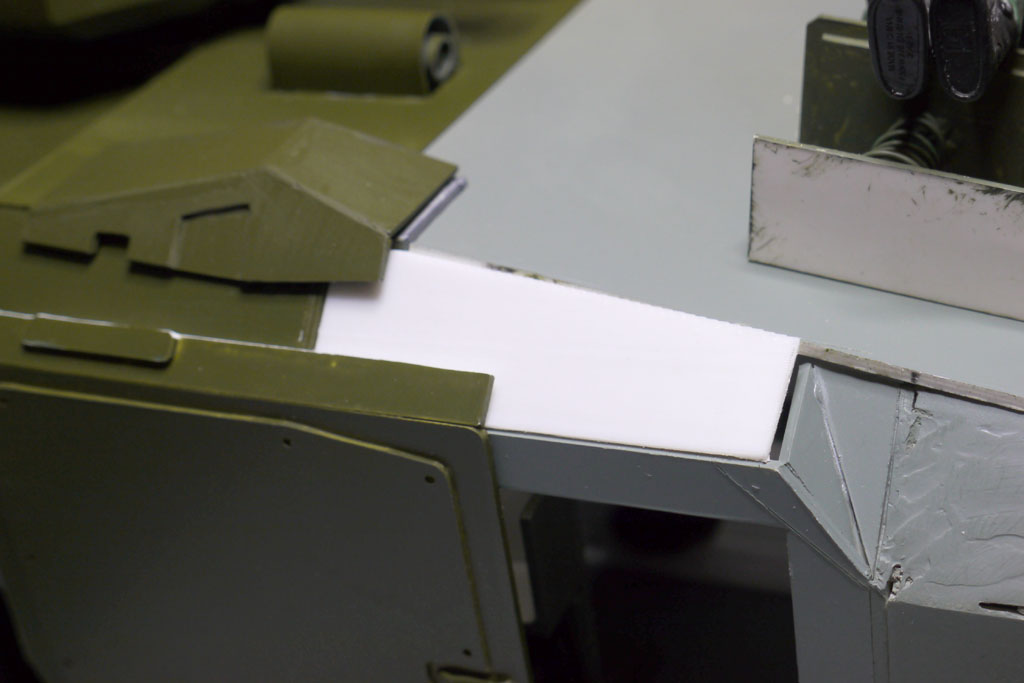

I've also started to assemble and permanently fix the rear exterior section. I'm stealing the genius opening method used in the Hiya Toys 1:18 scale APC.

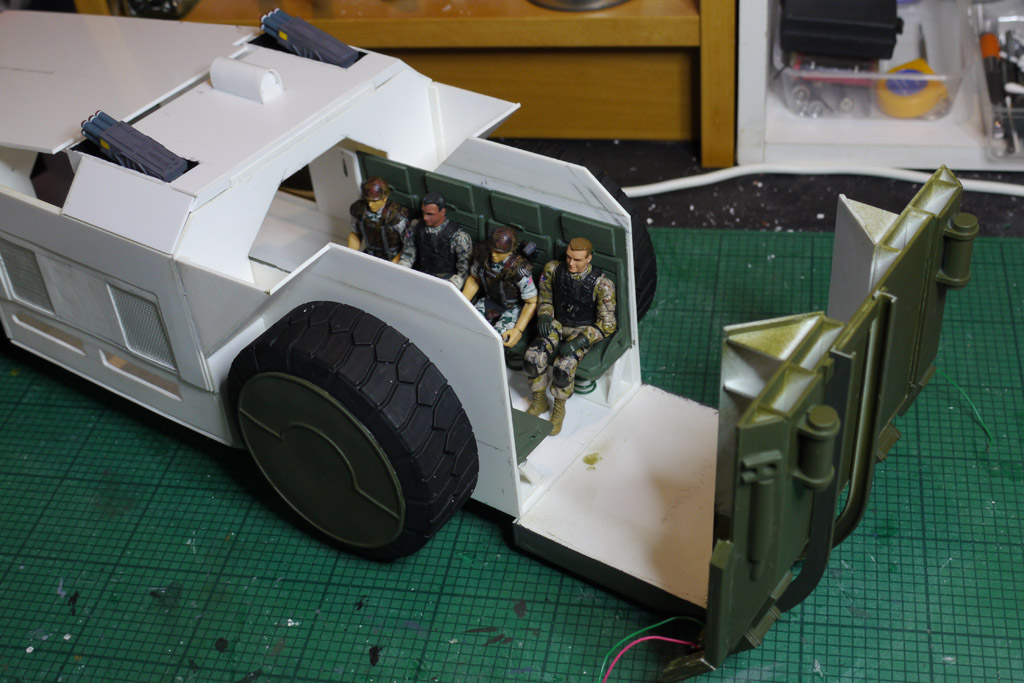

Here it is glued up and mocked up closed and opened. I'll be working out how the hinges will function next.

This last shot illustrates something I've been keen to preserve from the start. My APC can comfortably fit 4 marines on each side of the rear compartment. I don't think the Hiya Toys one can do that - based on images I've seen.

Still LOTS to do so I'd better get back at it.

Here they are in deployed mode. I won't be attaching the covers until the roof is painted and finished.

I've also started to assemble and permanently fix the rear exterior section. I'm stealing the genius opening method used in the Hiya Toys 1:18 scale APC.

Here it is glued up and mocked up closed and opened. I'll be working out how the hinges will function next.

This last shot illustrates something I've been keen to preserve from the start. My APC can comfortably fit 4 marines on each side of the rear compartment. I don't think the Hiya Toys one can do that - based on images I've seen.

Still LOTS to do so I'd better get back at it.

skiffy

Sr Member

Thanks Joburg - that's a straight steal from the Hiya Toys APC.Love the way that rear is opening and closing!! It sure is cozy inside but it's looking great

skiffy

Sr Member

That's right Saavik256 - the production team removed tons of lead cladding from the original airport tug. Coincidentally, there's a good chance that my late father helped build that tug. It was built locally and he was a sheet metal fabricator.I remember reading that, since the original vehicle was an airport tug, they had to remove an insane amount of weights from it and it was still stupidly heavy afterwards.

Chuffy 70

Active Member

Nice hinge job skiffy, makes for good access and those Chupa missiles have come up a treat...

Good job too on the rear lights, they look splendid...having to plan lighting for a 1/18 scale Razor Crest, so I'm watching with renewed interest on your electrics and fear of the soldering iron!!!

Good job too on the rear lights, they look splendid...having to plan lighting for a 1/18 scale Razor Crest, so I'm watching with renewed interest on your electrics and fear of the soldering iron!!!

skiffy

Sr Member

Thanks Chuffy 70, I'm hoping the wiring will be pretty simple (it'll all run on 3v) so we'll see!

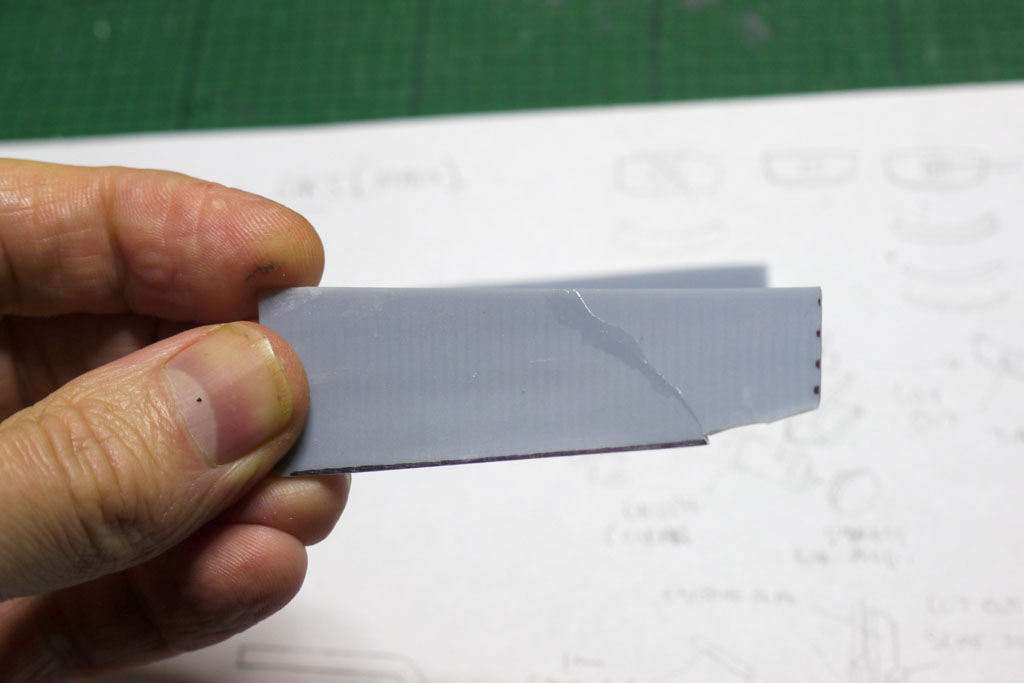

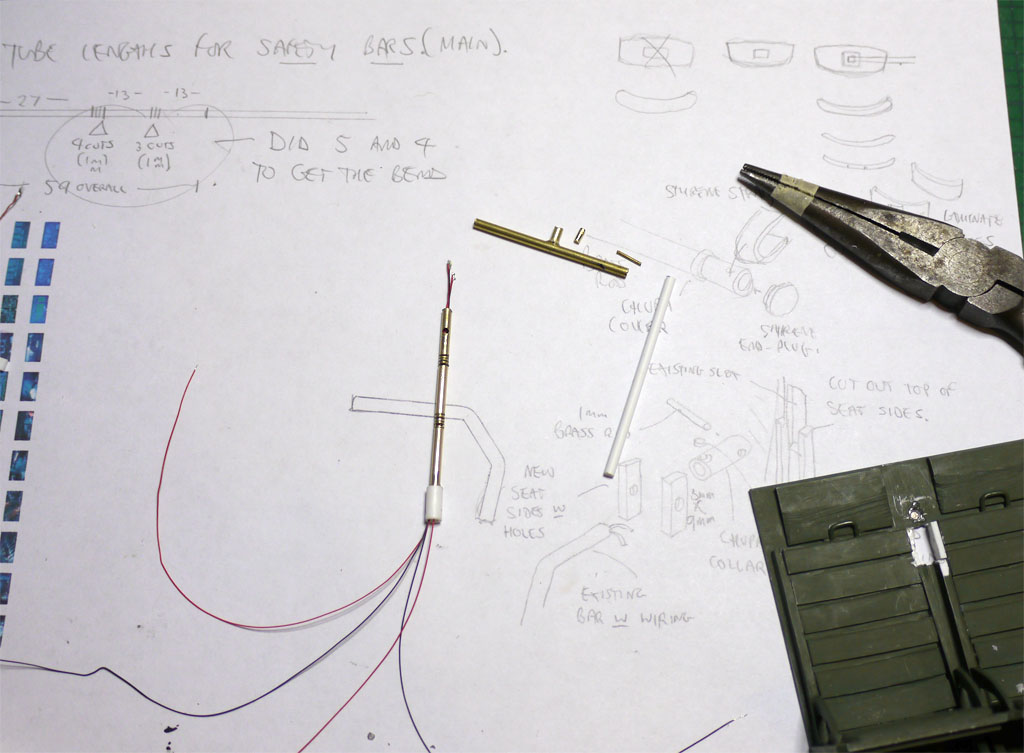

Work is busy but I got a little time over a couple of days. The hull has had a coat of primer and I've adapted the rear seating to allow for the hinge.

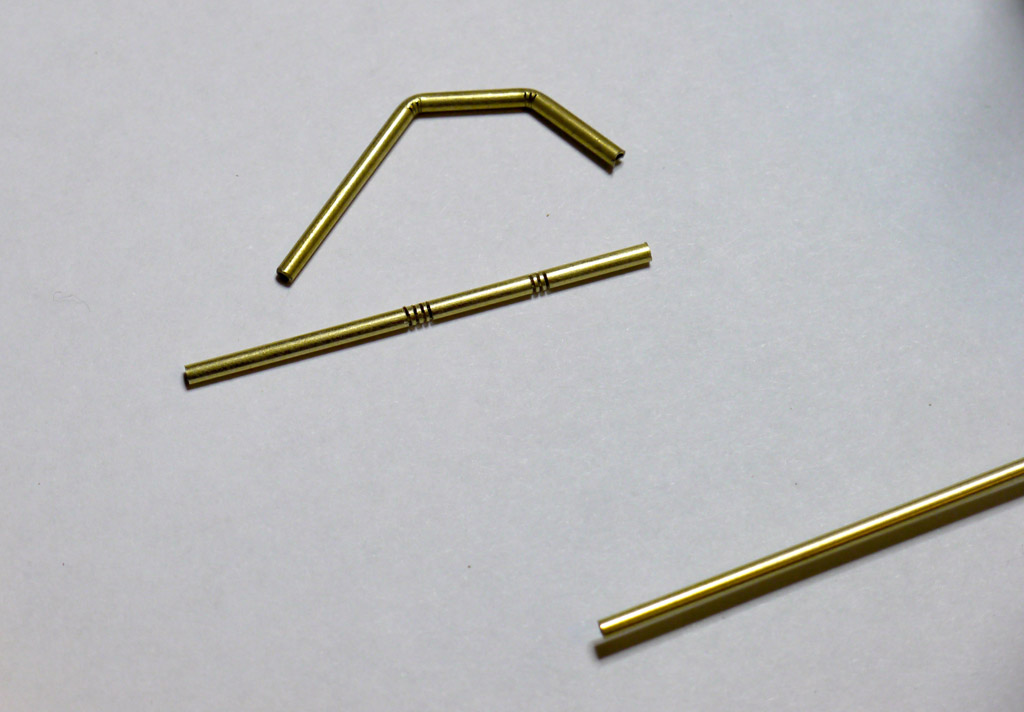

I'm cutting brass tube to bend up and create the main spar of the swing-down seat restraints. I have a test one to measure from and I'm cutting the rest adding slots to help stop kinks in the two bends.

It's tedious work but I'm getting there.

Meanwhile, I've saved images of the TOC screens (from screenshots of the movie) and tried printing them out on specially made water-slide decal paper. Unfortunately the results were very poor.

Once we're back in University I can laser-print on thin acetate instead - which will work a lot better.

Work is busy but I got a little time over a couple of days. The hull has had a coat of primer and I've adapted the rear seating to allow for the hinge.

I'm cutting brass tube to bend up and create the main spar of the swing-down seat restraints. I have a test one to measure from and I'm cutting the rest adding slots to help stop kinks in the two bends.

It's tedious work but I'm getting there.

Meanwhile, I've saved images of the TOC screens (from screenshots of the movie) and tried printing them out on specially made water-slide decal paper. Unfortunately the results were very poor.

Once we're back in University I can laser-print on thin acetate instead - which will work a lot better.

Last edited:

skiffy

Sr Member

Thanks. It's very handy! I can't think of a better way to do it at this scale.Ooohh...love that little trick to bend tubes

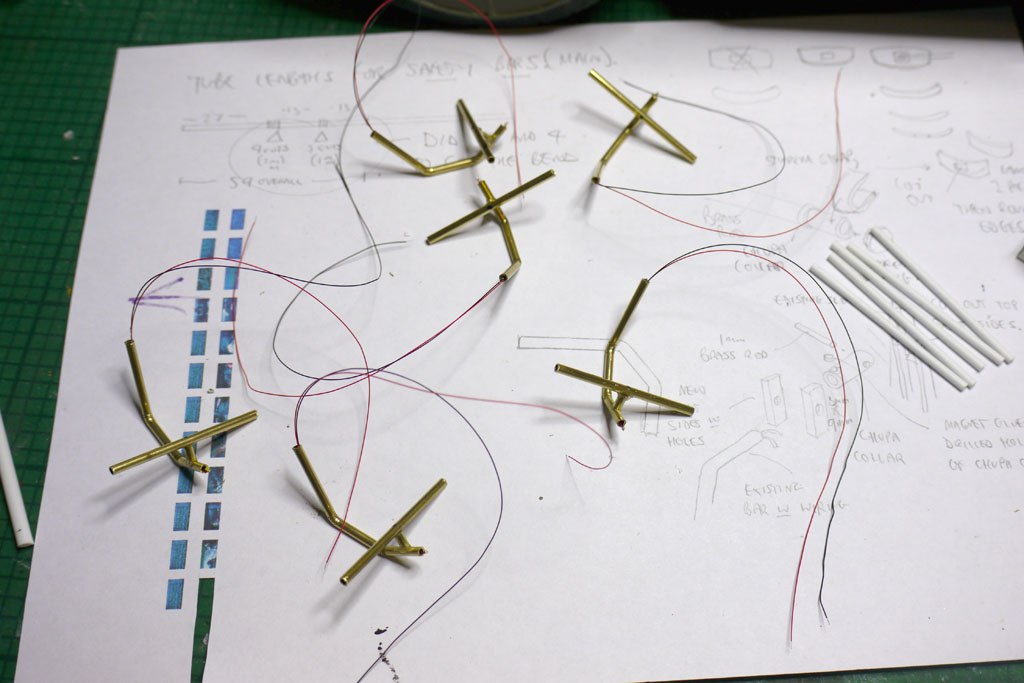

I've done a little more on the seat restraints.

I've bent up all 6 main bars and the short supports that link them to the padded bits.

The smaller bits are the short central spar ringed in red.

I've had to file 18 tiny fish-mouths to make sure these all join up correctly and my eyes aren't what they once were!

skiffy

Sr Member

It's the Easter break for me at University so I get a small respite from teaching remotely, which started as a novelty but is actually horrible. I'd far rather be in a class offering practical help and advice.

Anyway - on with the build!

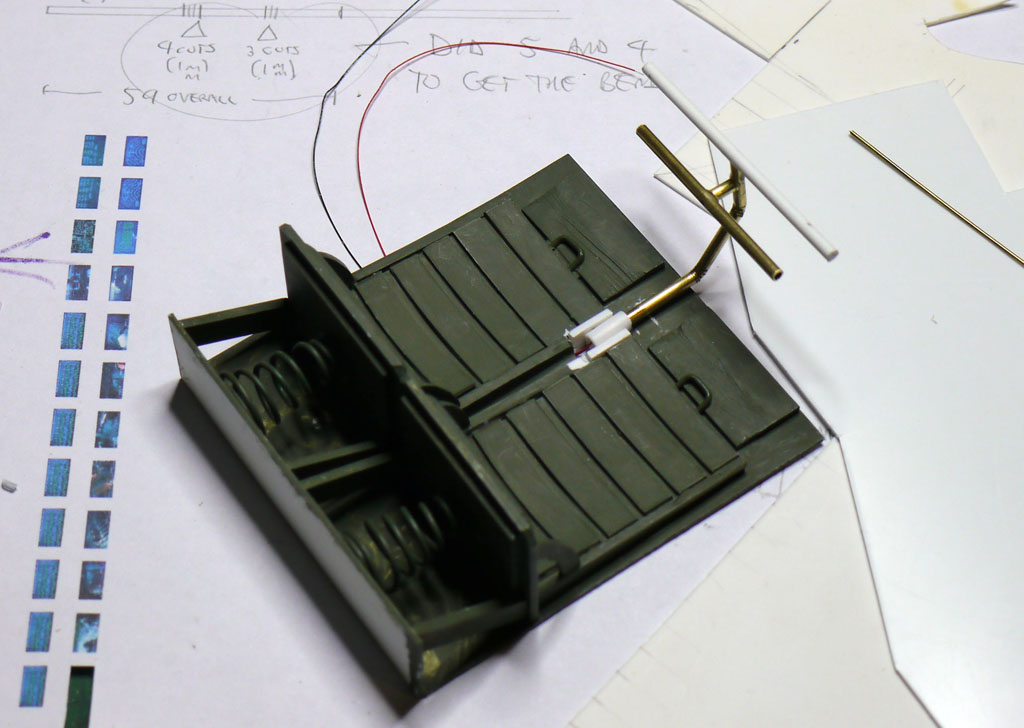

Here are the seat restraints having just had their micro LED lights fitted.

I couldn't really get a close enough shot but you can just see the LED poking out of the end of this one.

I finally figured out a way to mount the bars and let them rise and fall without protruding out of the back of the chair.

After I took these shots I added a tiny (2mm x 1mm) magnet at the top of the bar near the hinge and one embedded in the wall above it (you can see where I've marked a cross in pencil) so that the bars will stay in the 'up' position without falling.

Anyway - on with the build!

Here are the seat restraints having just had their micro LED lights fitted.

I couldn't really get a close enough shot but you can just see the LED poking out of the end of this one.

I finally figured out a way to mount the bars and let them rise and fall without protruding out of the back of the chair.

After I took these shots I added a tiny (2mm x 1mm) magnet at the top of the bar near the hinge and one embedded in the wall above it (you can see where I've marked a cross in pencil) so that the bars will stay in the 'up' position without falling.

skiffy

Sr Member

I promised myself that I'd show the bad as well as the good. Not everything goes to plan or works perfectly first time, so here's an update with a couple of things that haven't quite worked.

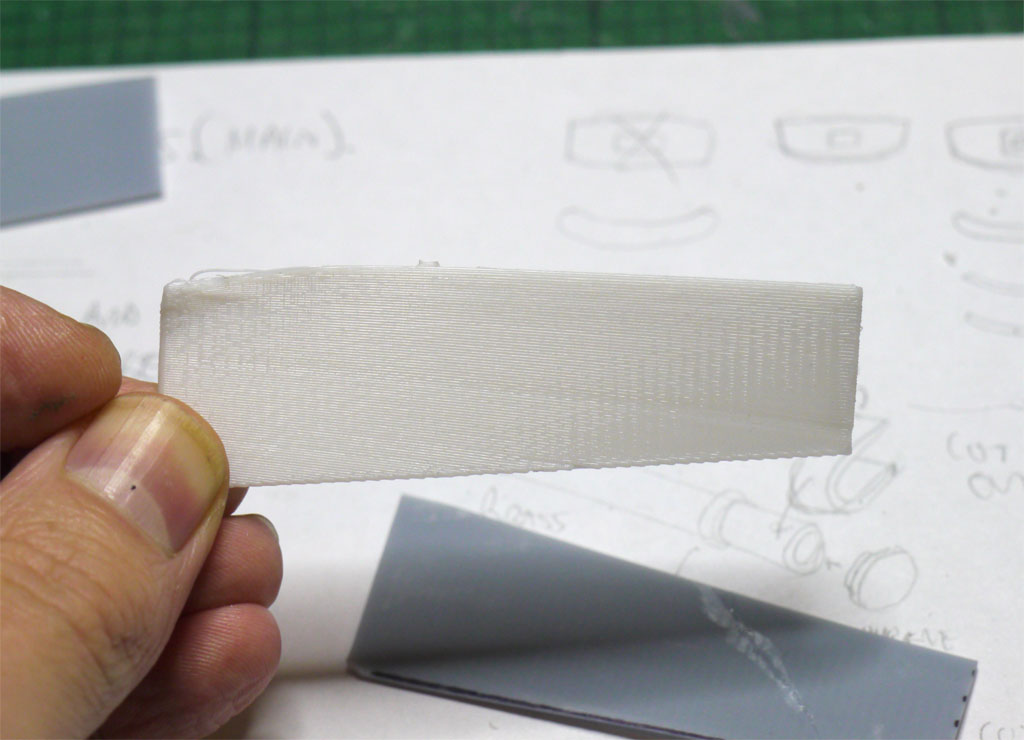

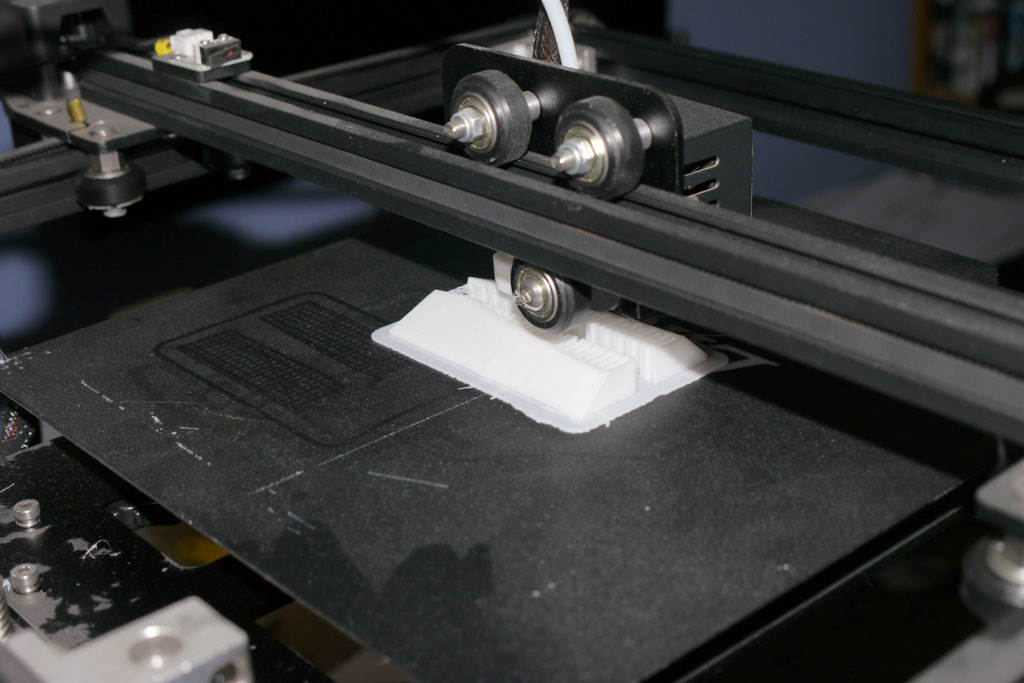

I've been working on this gap in the roofline which is a complex form with a twist - not a flat plate. It's on both sides and I don't want to build it up with formers as I did with the one further forward.

I measured up the profile and made a copy for either side in resin.

Unfortunately the resin is far too brittle to use for this and one snapped (and was glued) as you can see.

So, I printed some out in PLA filament instead. The one on this side is almost there - but the profile is a little off.

Plus - the one for the other side had some printing errors and isn't fit to use.

I'm printing up a second set with an adjusted profile - hopefully these will fit better.

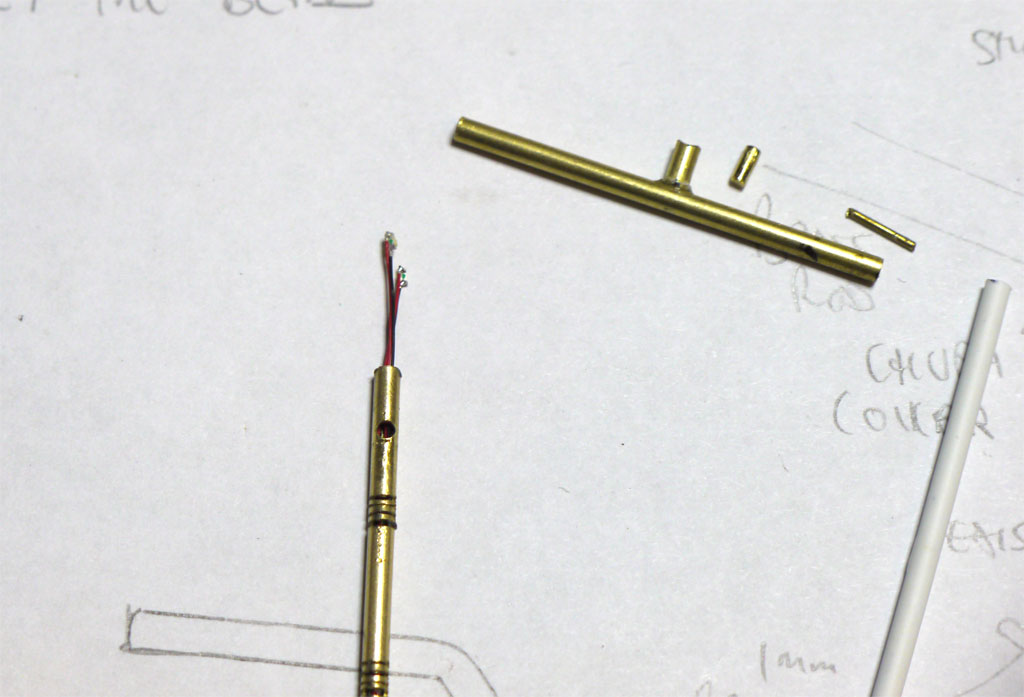

As well as that, I tested the lighting in the seat restraint bars and found that despite my earlier testing (where I got lucky) these micro LEDs have a definite front and back - meaning that one side of the bar will be lit far better than the other. The only real solution is to put two in there, back to back.

That's a problem, because I've glued all of the single ones in place. I'm working to produce one finished one to make sure it'll work, then do the rest. I have to straighten out every restraint, drill out the LED and wiring (destroying the glued-in LED in the process) and threading two in there.

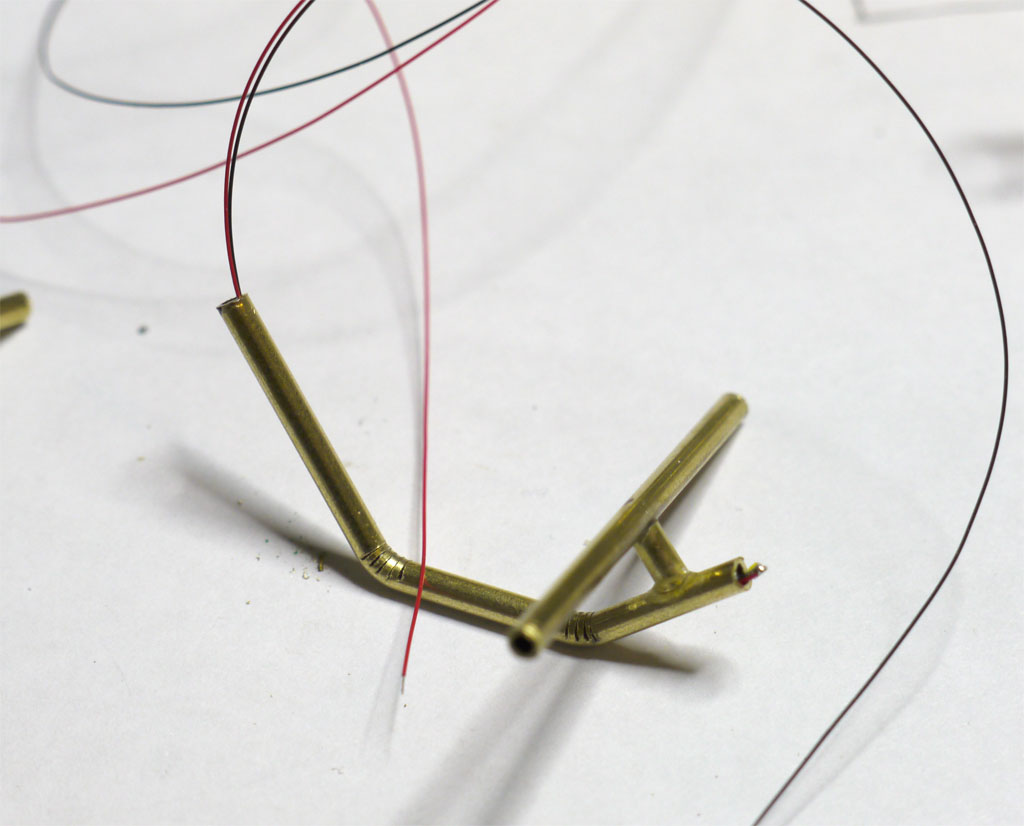

In this shot you can see that there are two LED lamps in there. I'm also strengthening the T bars with a rod inside, and a hole drilled in the main bar. I can't braze these joints - they're too close together so I have to glue them.

Here I'm making swivelling clamps that I'll attach the curved pad to. Hopefully this part will go to plan.

I've been working on this gap in the roofline which is a complex form with a twist - not a flat plate. It's on both sides and I don't want to build it up with formers as I did with the one further forward.

I measured up the profile and made a copy for either side in resin.

Unfortunately the resin is far too brittle to use for this and one snapped (and was glued) as you can see.

So, I printed some out in PLA filament instead. The one on this side is almost there - but the profile is a little off.

Plus - the one for the other side had some printing errors and isn't fit to use.

I'm printing up a second set with an adjusted profile - hopefully these will fit better.

As well as that, I tested the lighting in the seat restraint bars and found that despite my earlier testing (where I got lucky) these micro LEDs have a definite front and back - meaning that one side of the bar will be lit far better than the other. The only real solution is to put two in there, back to back.

That's a problem, because I've glued all of the single ones in place. I'm working to produce one finished one to make sure it'll work, then do the rest. I have to straighten out every restraint, drill out the LED and wiring (destroying the glued-in LED in the process) and threading two in there.

In this shot you can see that there are two LED lamps in there. I'm also strengthening the T bars with a rod inside, and a hole drilled in the main bar. I can't braze these joints - they're too close together so I have to glue them.

Here I'm making swivelling clamps that I'll attach the curved pad to. Hopefully this part will go to plan.

Similar threads

- Replies

- 19

- Views

- 1,288

- Replies

- 24

- Views

- 1,937

- Replies

- 10

- Views

- 743