avagoyamug

Active Member

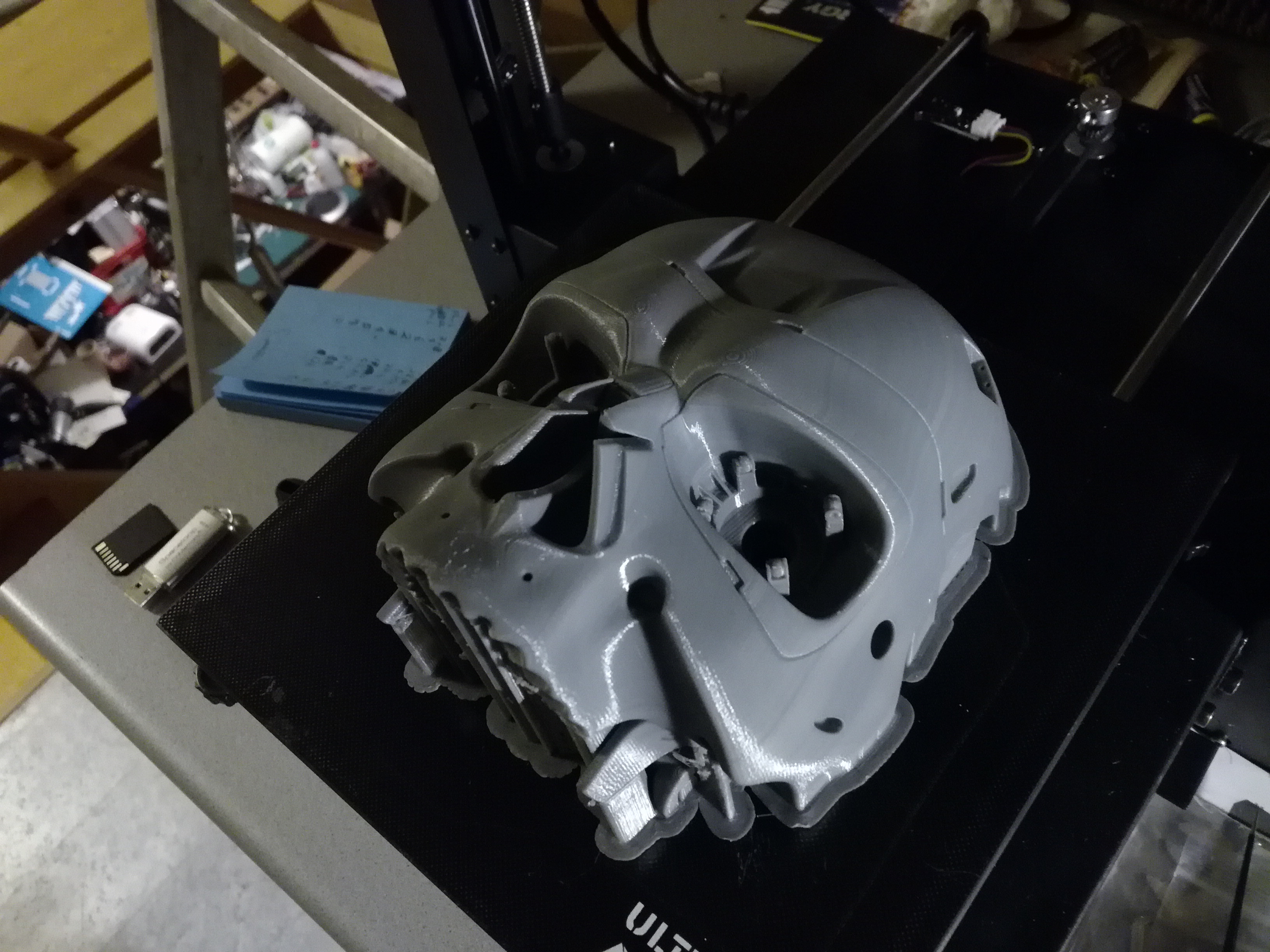

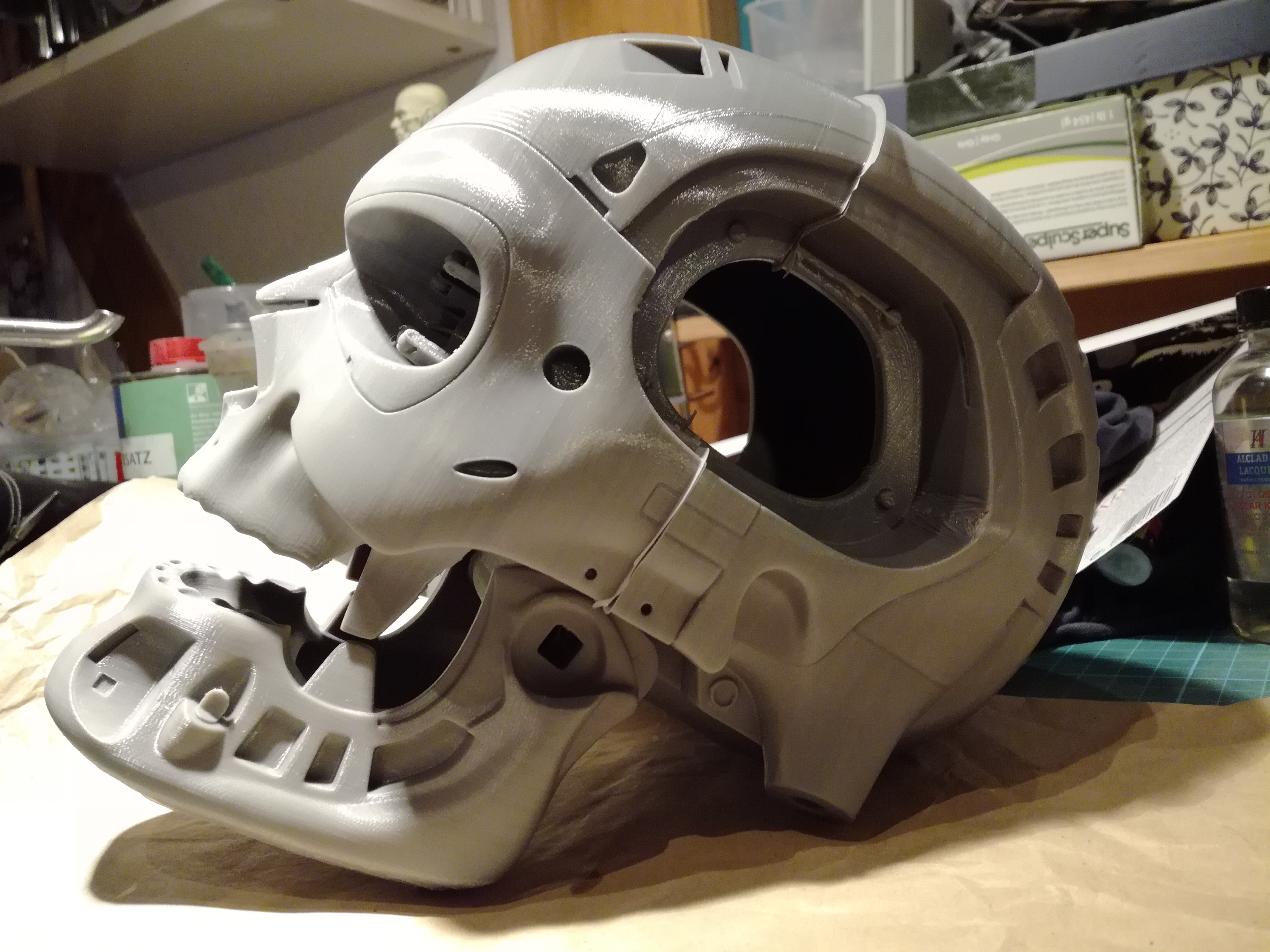

Awesome! So you already finished the 1/1 endoskull?

Could you post some closeups of the skull? ...I'd be very curious on how the panelines and finer details come out..

Which layersize do you print this on? I'm planing on using a very fine resolution (like 0.1), but the skull alone will propably print hundreds of hours on this resolution...

Could you post some closeups of the skull? ...I'd be very curious on how the panelines and finer details come out..

Which layersize do you print this on? I'm planing on using a very fine resolution (like 0.1), but the skull alone will propably print hundreds of hours on this resolution...