DANG! I didn't realize the scale! This is amazing!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2x Studio Scale Falcon Gun Turret- Scratchbuild

- Thread starter Bondo Fett

- Start date

So, I stated at the beginning that I planned to scratch-build all the detail elements so that I didn't have to spend more time researching than actually building. Also I assumed that some of the bits, when finally identifies, wouldn't exist at the larger scale I am working in. Well...

Trying to ID this thing:

On my 1:72 FineMolds Falcon I used a split landing wheel from an ME-109. It seemed yo do the trick.

Browsing through the sprues of some of my stockpile of cheap-o 1:72 tank kits I run across this:

Ding! So the ILM guys probably used the turret hatch frame from the old Monogram 1:32 Screamin Mimi Sherman kit.

Then searching the web for good pics of the actual turret hatch for my scratch-build I discover that there are 1:16 scale cast pot metal hatches for the radio control model crowd.

Crazy where this stuff will lead you.

Trying to ID this thing:

On my 1:72 FineMolds Falcon I used a split landing wheel from an ME-109. It seemed yo do the trick.

Browsing through the sprues of some of my stockpile of cheap-o 1:72 tank kits I run across this:

Ding! So the ILM guys probably used the turret hatch frame from the old Monogram 1:32 Screamin Mimi Sherman kit.

Then searching the web for good pics of the actual turret hatch for my scratch-build I discover that there are 1:16 scale cast pot metal hatches for the radio control model crowd.

Crazy where this stuff will lead you.

TazMan2000

Master Member

Cool project.

TazMan2000

TazMan2000

Slowly moving this build along. Thanks, all, for being patient...

Mounting of the hatch ring. Drove the hinge pins out of the hatches (and into the spares box they go...).

The ring has a deep collar inside and since I thought it would look more interesting with some depth I decided to cut away the styrene cladding with a hole-saw to give the ring a place to drop into, rather than grinding it flush with the hull plate. However, the collar was deeper than the .080" styrene. So I built up the thickness of the outer ring with lightweight filler (bondo- small b). I released the hull plate with a little paste wax and mashed my filled ring into its place.

After it sets (let it cool or it will crumble when you try to pry it apart) the waxed hull plate can be cleaned up with some alcohol.

Then a little clean-up and it looks like these parts where meant to be together.

Now I'm thinking some sort of 1" diameter tank wheel will go in the center to cover the hole and this detail will be licked.

Mounting of the hatch ring. Drove the hinge pins out of the hatches (and into the spares box they go...).

The ring has a deep collar inside and since I thought it would look more interesting with some depth I decided to cut away the styrene cladding with a hole-saw to give the ring a place to drop into, rather than grinding it flush with the hull plate. However, the collar was deeper than the .080" styrene. So I built up the thickness of the outer ring with lightweight filler (bondo- small b). I released the hull plate with a little paste wax and mashed my filled ring into its place.

After it sets (let it cool or it will crumble when you try to pry it apart) the waxed hull plate can be cleaned up with some alcohol.

Then a little clean-up and it looks like these parts where meant to be together.

Now I'm thinking some sort of 1" diameter tank wheel will go in the center to cover the hole and this detail will be licked.

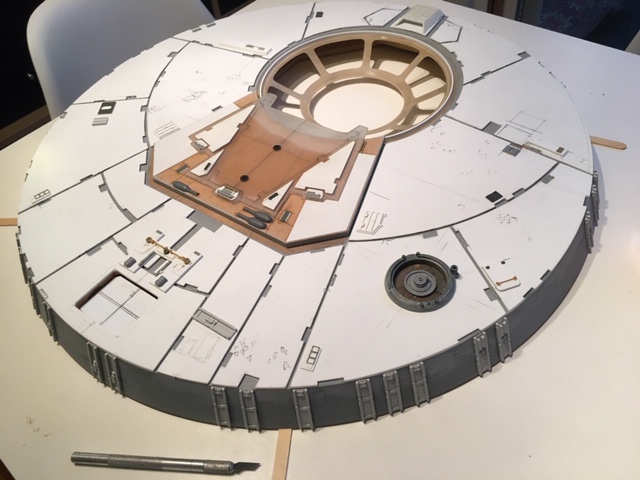

Hello again, recently got around to dusting off- literally- this old piece. I've had it hanging on my wall unpainted for too long. Someone asked me what kind of high-tech toilet seat it was. Point taken.

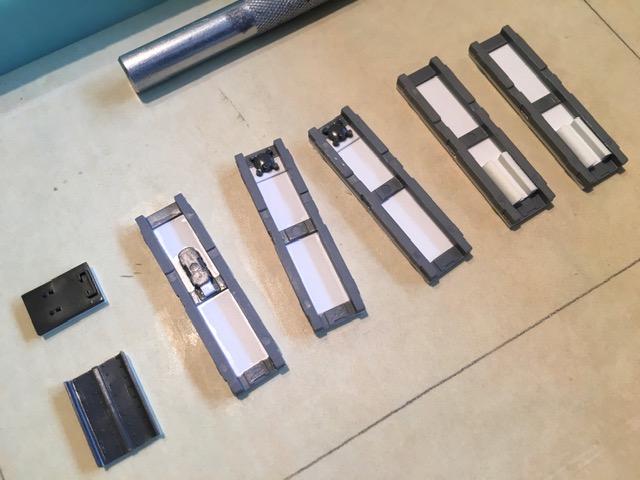

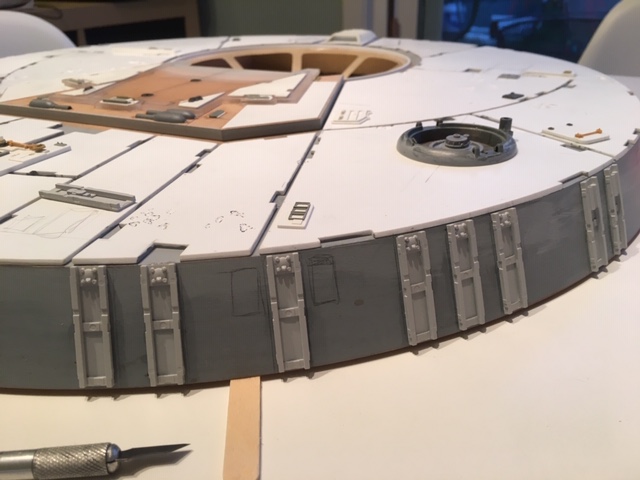

Focused on the slim, ladder-like details surrounding the rim of the turret. Had a little difficulty working out what the greebs were on the original, but I'm pretty sure they are mostly made of the racks for German mortars, unsure of the kit. So I scaled up and used bits from this kit:

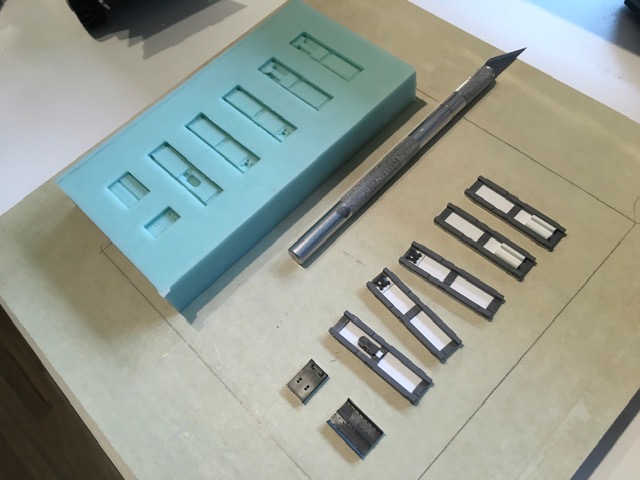

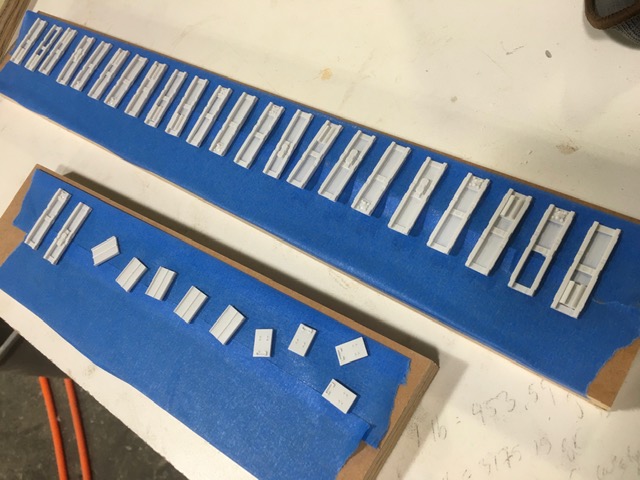

I need about twenty of the pieces, with tiny differences in detail, so I ran a mold and cast up a pile of resin parts. Its the first use of cast parts on this build, so far everything else has been oob or fabricated.

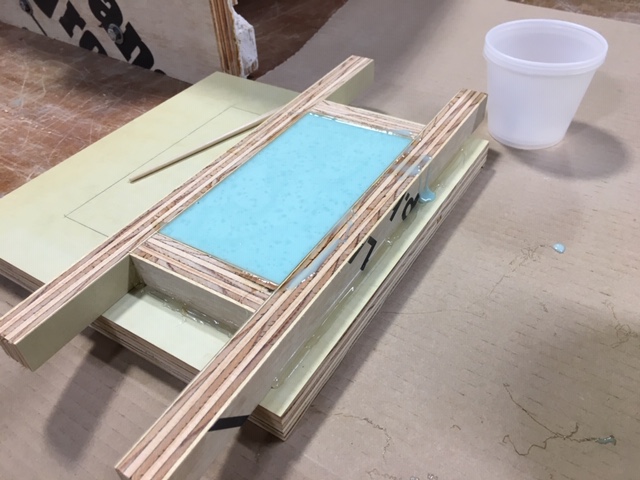

That's SmoothOn Rebound 40 brushable silicone. It can be poured, as well.

Five pours and I've got all I need.

BTW I've started pressure casting and I can't believe the improvement in the quality of the casts. I'm using a pressure pot modified from a paint rig. I'm never going back.

Focused on the slim, ladder-like details surrounding the rim of the turret. Had a little difficulty working out what the greebs were on the original, but I'm pretty sure they are mostly made of the racks for German mortars, unsure of the kit. So I scaled up and used bits from this kit:

I need about twenty of the pieces, with tiny differences in detail, so I ran a mold and cast up a pile of resin parts. Its the first use of cast parts on this build, so far everything else has been oob or fabricated.

That's SmoothOn Rebound 40 brushable silicone. It can be poured, as well.

Five pours and I've got all I need.

BTW I've started pressure casting and I can't believe the improvement in the quality of the casts. I'm using a pressure pot modified from a paint rig. I'm never going back.

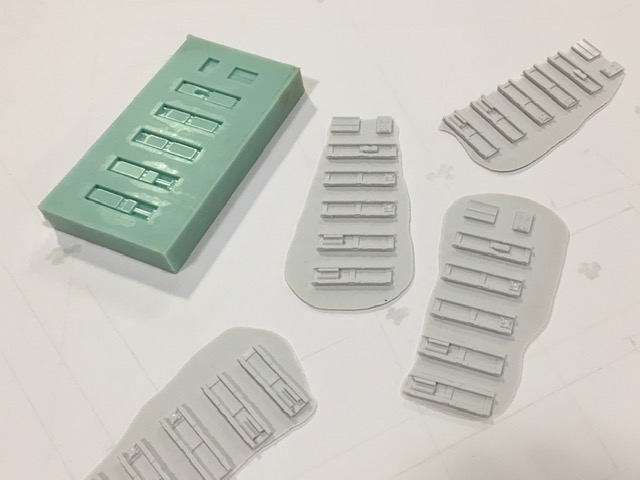

Resin casts trimmed and sanded. By the way- to clean up my resin casts I stick a piece of 120 grit sand paper to a flat board and move the casting around in different directions until the flashing drops off the back. Works pretty good but is time consuming. If anyone has a better technique I'd love to hear about it.

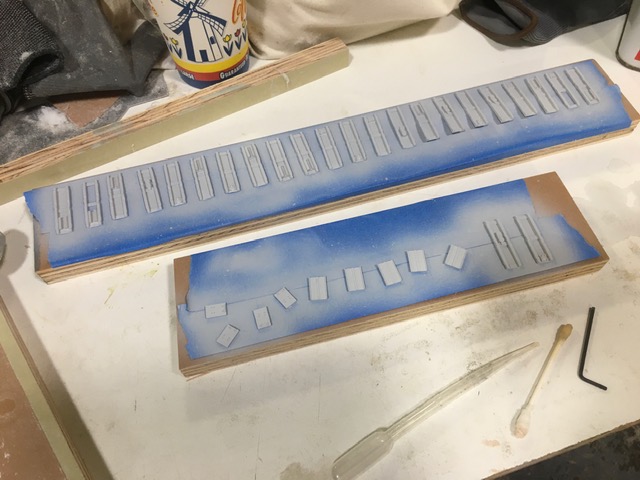

This is Mr Resin primer from Mr. Surfacer. I don't know if it is better than any other lacquer-based primer for urethane resin, but whatevs. The close-up shows the little embellishments I made to try to match the original filming model (5-footer). I've had to embellish because the donor kits don't always scale up with the same characteristics. I've managed to work in the Universal Greeblie finally.

Hoping to get these bits attached to the big piece and get some pics up this weekend.

This is Mr Resin primer from Mr. Surfacer. I don't know if it is better than any other lacquer-based primer for urethane resin, but whatevs. The close-up shows the little embellishments I made to try to match the original filming model (5-footer). I've had to embellish because the donor kits don't always scale up with the same characteristics. I've managed to work in the Universal Greeblie finally.

Hoping to get these bits attached to the big piece and get some pics up this weekend.

And here they are attached to the edge (rim?) of the turret. Finally gives it some definition and makes it look like a surface. I need to add the mortars next (one reason I used a kit instead of just fabricating the details- those mortars are all over the turret).

About the window port- I had a bunch of pictures of the construction, but because I allow my 7-year old to play with my tablet, I no longer have access to them or even know if they still exist. It is made of laminated epoxy/fiberglass with styrene details. I'll get some close-ups and a better description later.

About the window port- I had a bunch of pictures of the construction, but because I allow my 7-year old to play with my tablet, I no longer have access to them or even know if they still exist. It is made of laminated epoxy/fiberglass with styrene details. I'll get some close-ups and a better description later.

Your doing great job on this!

I have a casting technique you might find helpful to get flat backs on your parts.

Spray a piece of acrylic that's about the size of your mold with mold release, and then set it on top while the resin cures.

You'll want to place it on carefully not trap bubbles. I overfill the mold slightly, then set the acrylic on one corner while tilted at an angle. Lay the acrylic down like you are closing a (horizontal) door to push the bubbles and excess resin away. If the acrylic is clear, you'll be able to see if you trapped any bubbles. Set a light weight on it to keep it in place. Not too heavy! You don't want to compress the silicone.

After the resin cures, you just need to flex the acrylic a bit to pop your part off.

Perfectly flat back with no sanding!

I have a casting technique you might find helpful to get flat backs on your parts.

Spray a piece of acrylic that's about the size of your mold with mold release, and then set it on top while the resin cures.

You'll want to place it on carefully not trap bubbles. I overfill the mold slightly, then set the acrylic on one corner while tilted at an angle. Lay the acrylic down like you are closing a (horizontal) door to push the bubbles and excess resin away. If the acrylic is clear, you'll be able to see if you trapped any bubbles. Set a light weight on it to keep it in place. Not too heavy! You don't want to compress the silicone.

After the resin cures, you just need to flex the acrylic a bit to pop your part off.

Perfectly flat back with no sanding!

I love that idea! I just happen to have plenty of acrylic lying around, I might have to run some parts just to try it. Thanks, Duncanator!Your doing great job on this!

I have a casting technique you might find helpful to get flat backs on your parts.

Spray a piece of acrylic that's about the size of your mold with mold release, and then set it on top while the resin cures.

You'll want to place it on carefully not trap bubbles. I overfill the mold slightly, then set the acrylic on one corner while tilted at an angle. Lay the acrylic down like you are closing a (horizontal) door to push the bubbles and excess resin away. If the acrylic is clear, you'll be able to see if you trapped any bubbles. Set a light weight on it to keep it in place. Not too heavy! You don't want to compress the silicone.

After the resin cures, you just need to flex the acrylic a bit to pop your part off.

Perfectly flat back with no sanding!

newmagrathea

Sr Member

I don't know why you're doing this, and I don't care. I love it. Please tell me you're not going to stop once the turret is done. Please make an entire 2x Falcon.

Thanks! I don't know why and I don't care either! This whole thing got started with the idea of building a larger, close-up version of one of the Falcon's maintenance bays (or gear well? jockey box? greeblie hole?- what do we call these things?) I thought I could build it big enough so that I would fabricate all the details and then I wouldn't need to buy any rare kits. I imagined making just enough curved pie-slice of the hull to show the recessed bay, then decided it would end up too big, so I settled on building just the top turret. Come to think of it, maybe I will some day. Don't think my living room can fit a ten-foot Falcon, though.I don't know why you're doing this, and I don't care. I love it. Please tell me you're not going to stop once the turret is done. Please make an entire 2x Falcon.

Don't think my living room can fit a ten-foot Falcon, though.

Ah come on! You don't need a couch and coffee table in there. Where are your priorities!

That will require delicate negotiation. At least the turret hangs on the wall.

Here are a couple of shots of the window frame in it's current state. I think I mentioned before that I have lost all my pictures I took while making it so all I can give is a description.

I made a mold form as a negative out of MDF, bondo, and aluminum sheet stock. I made some perfunctory etched lines in the surface so I would know where to cut out the individual panes later. Primer, paste wax, then a few coats of PVA (polyvinyl alcohol) to seal and release it.

The frame itself is laminated epoxy/glass using West System resin and veil glass which is about the thinnest and and finest glass weave I had on hand. Two layers, IIRC, and the piece ended up about .060". I put a little calcium carbonate in the face coat which makes the resin both smoother and harder. In fact it is so hard I could hardly sand out the little flaws and artifacts from the finished piece. Cut out the window panes with my handy Dremel. This is the back of the frame. The weave and an overlap can be seen.

I had a devil of a time splicing a piece of styrene lumber together to make it long enough to wrap it around the outside of the frame. Fortunately I can hide the punky splice under the gun mount. Still need to add more styrene elements to the radial spokes, then it will be primer time.

I made a mold form as a negative out of MDF, bondo, and aluminum sheet stock. I made some perfunctory etched lines in the surface so I would know where to cut out the individual panes later. Primer, paste wax, then a few coats of PVA (polyvinyl alcohol) to seal and release it.

The frame itself is laminated epoxy/glass using West System resin and veil glass which is about the thinnest and and finest glass weave I had on hand. Two layers, IIRC, and the piece ended up about .060". I put a little calcium carbonate in the face coat which makes the resin both smoother and harder. In fact it is so hard I could hardly sand out the little flaws and artifacts from the finished piece. Cut out the window panes with my handy Dremel. This is the back of the frame. The weave and an overlap can be seen.

I had a devil of a time splicing a piece of styrene lumber together to make it long enough to wrap it around the outside of the frame. Fortunately I can hide the punky splice under the gun mount. Still need to add more styrene elements to the radial spokes, then it will be primer time.

Ha, ha! Thank you for the nudge, yes it lives still, but not much movement to show. I do have the muzzle of the quad barrels modeled up, I will have to look around for my pictures- or just take new ones.Bumperoo to see if that project is still on or finished

Similar threads

- Replies

- 23

- Views

- 1,267