JNordgren42

Sr Member

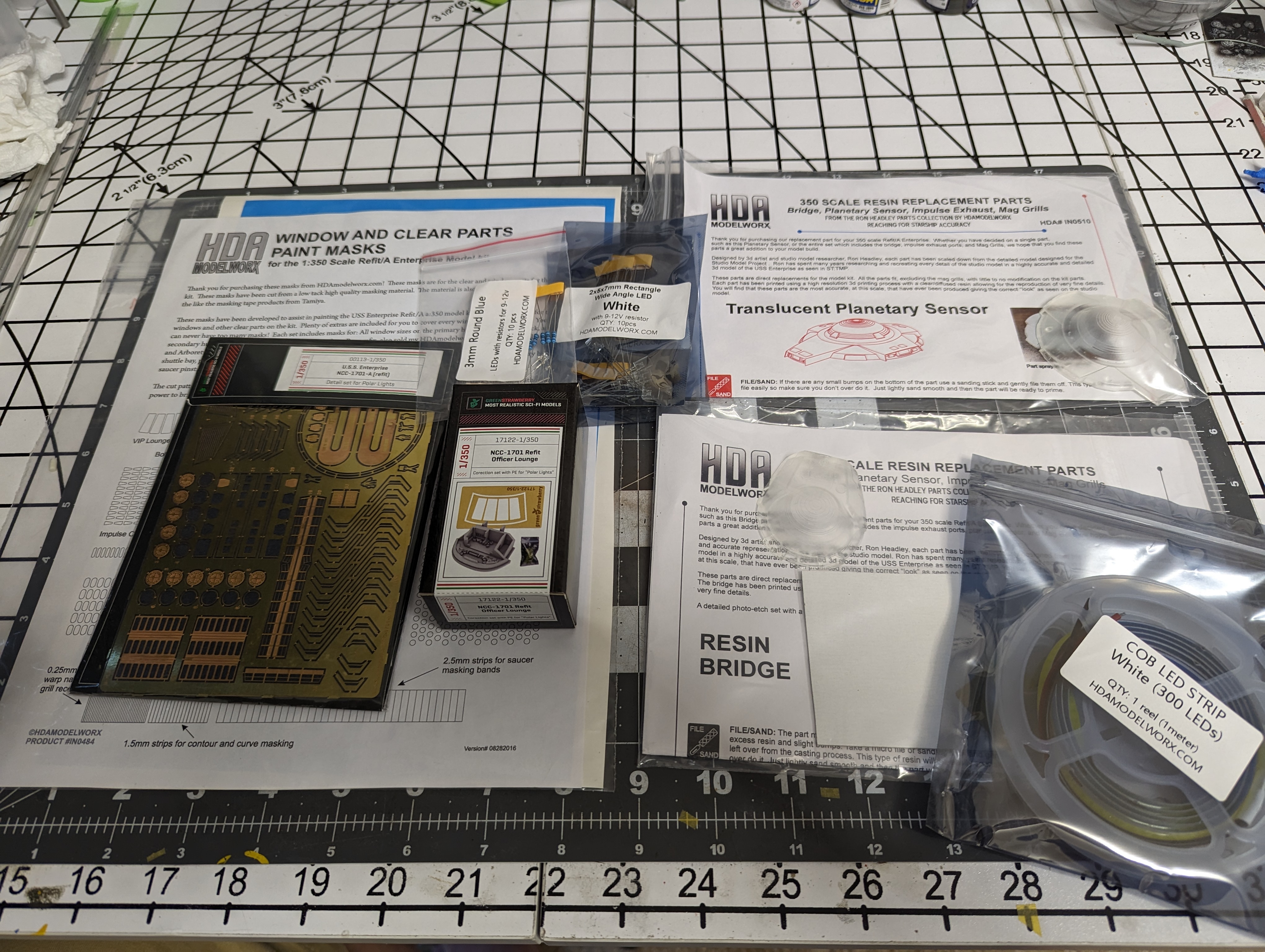

My HDA Modelworx order arrived with a bunch of goodies!

HDA replacement bridge

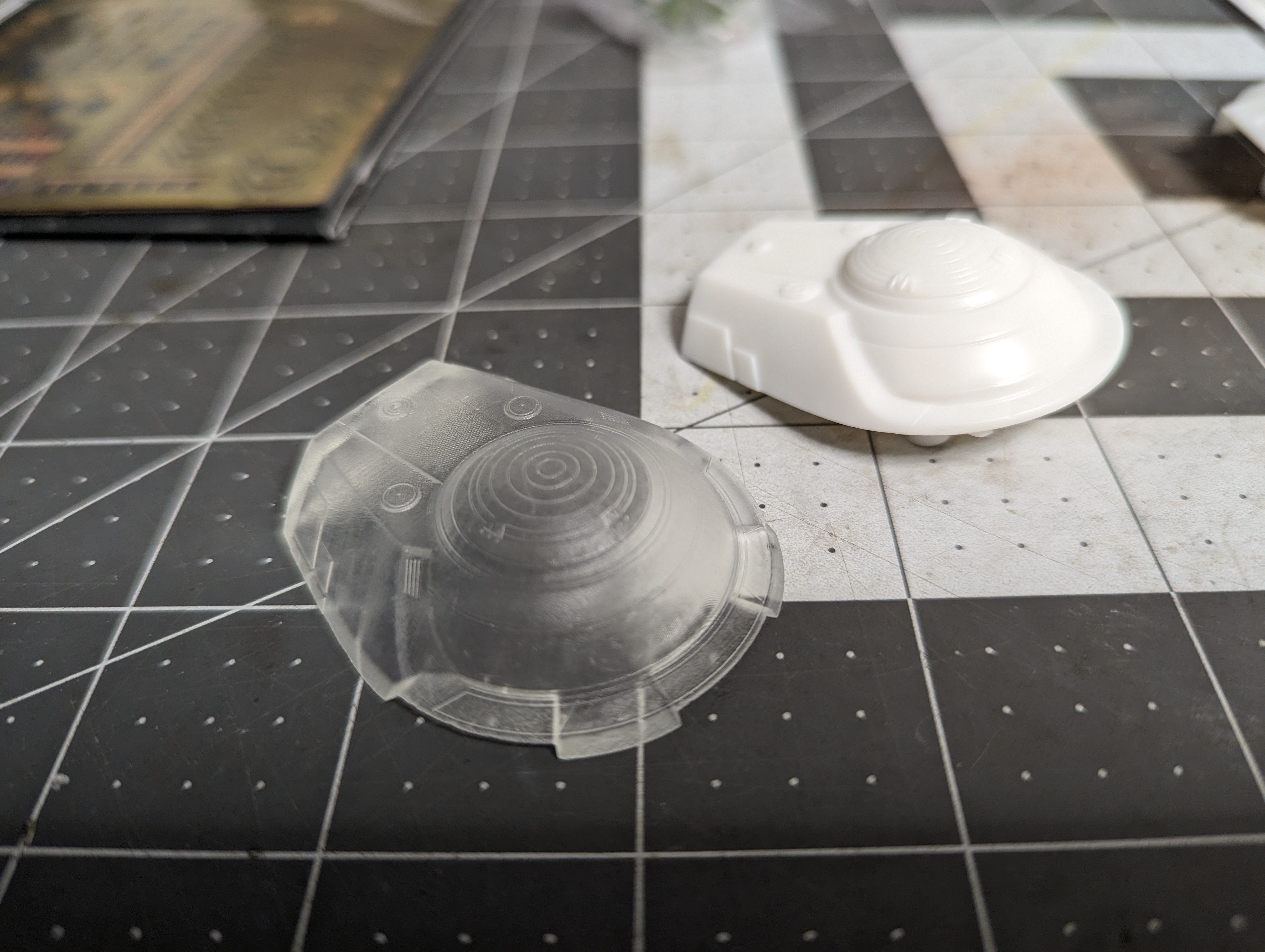

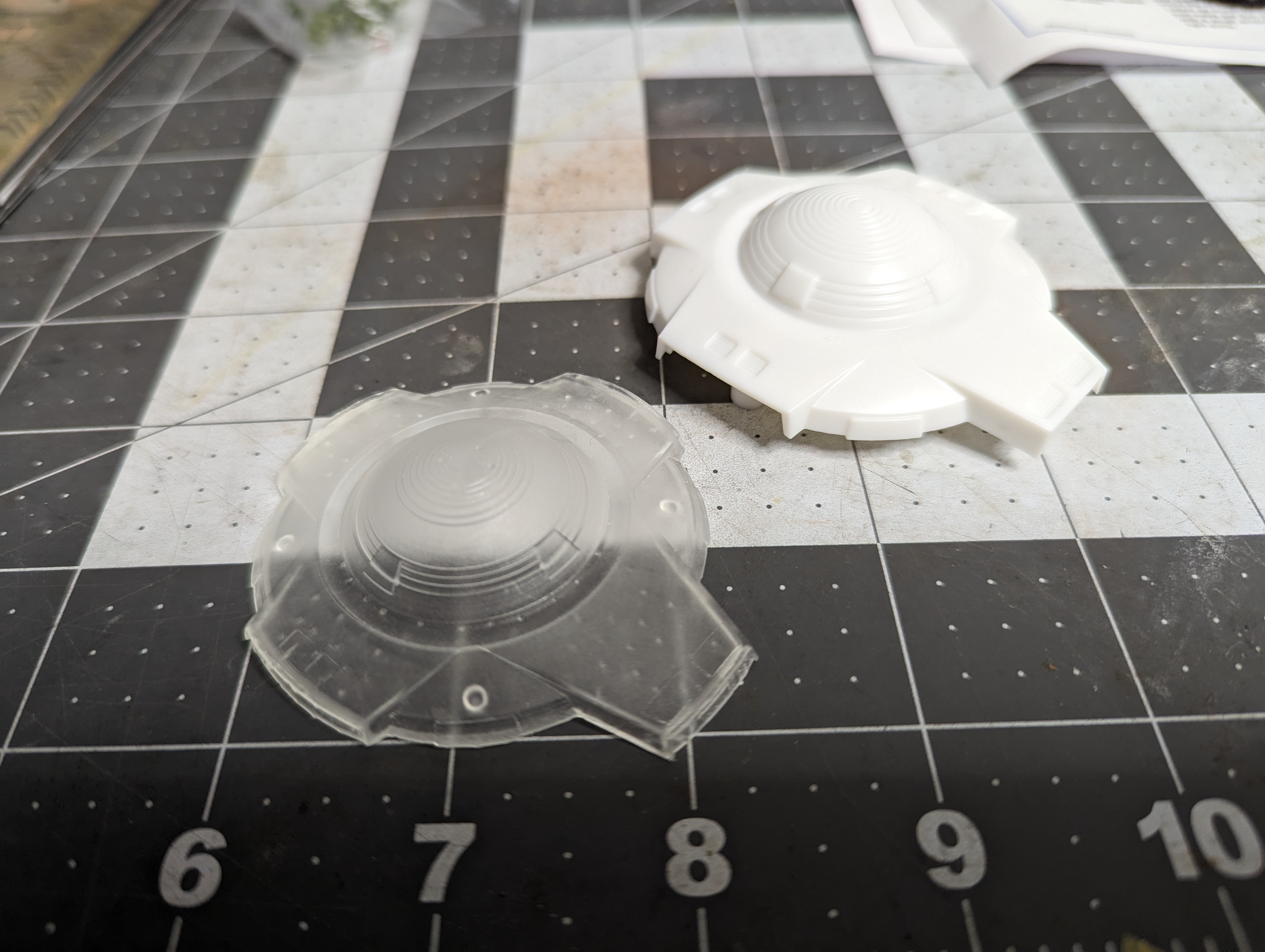

HDA planetary sensor array

HDA window masks

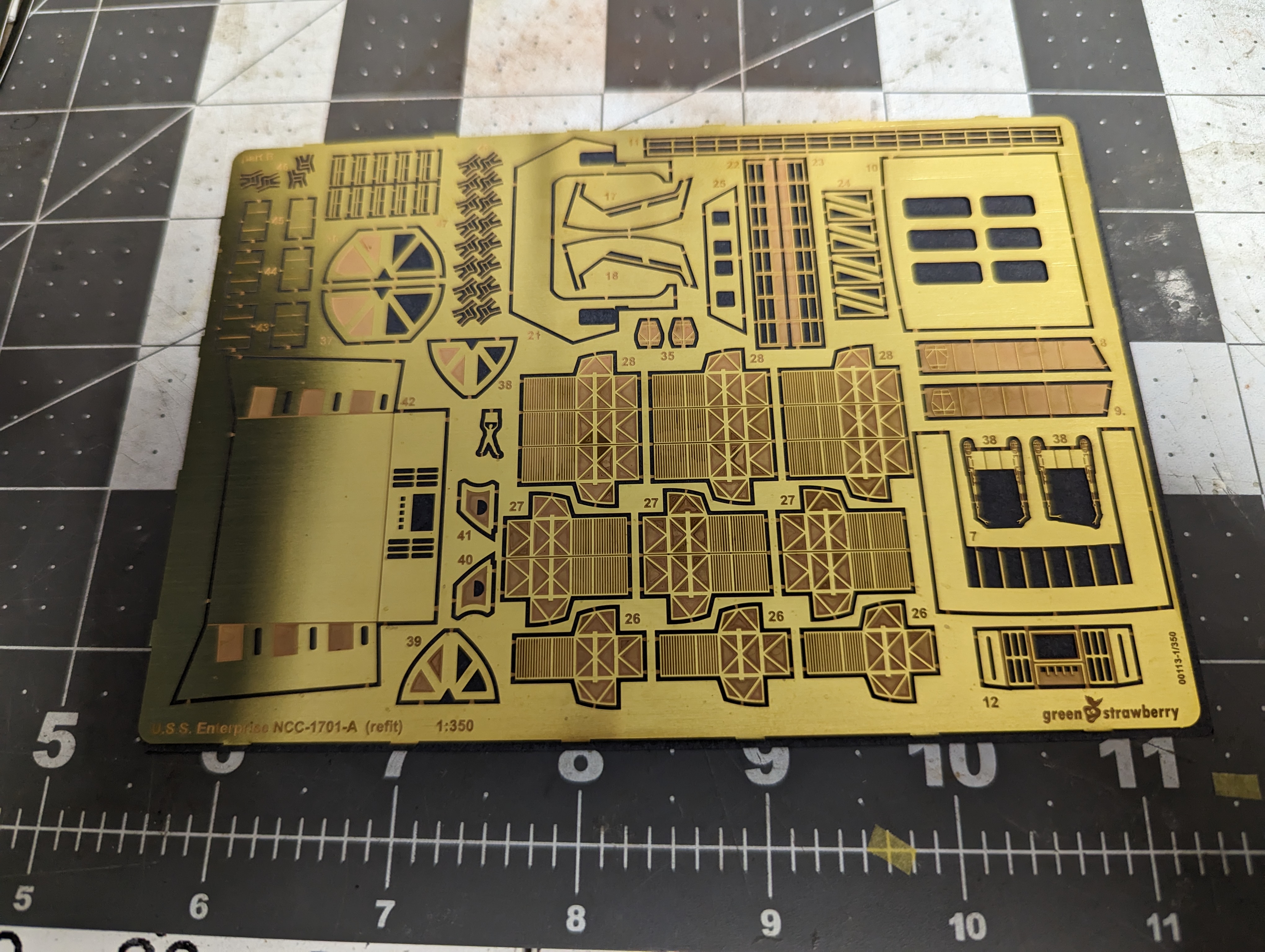

Greenstrawberry PE set (they were out of the Paragrafix set)

Greenstrawberry officers lounge

COB led strip (warp grilles)

3mm blue LEDs (warp deflection crystals)

2x5mm rectangular LEDs (bridge & planetary array spotlights)

Arduino board and DotStar LEDs arrive tomorrow.

HDA replacement bridge

HDA planetary sensor array

HDA window masks

Greenstrawberry PE set (they were out of the Paragrafix set)

Greenstrawberry officers lounge

COB led strip (warp grilles)

3mm blue LEDs (warp deflection crystals)

2x5mm rectangular LEDs (bridge & planetary array spotlights)

Arduino board and DotStar LEDs arrive tomorrow.